When arranging the external part of the sewer network of a private house, the installation of various wells is often required. They help monitor and repair the drainage system. In fact, a septic tank is also one of the types of well structures. But there are other designs, each with its own purpose. On a house plot with a difficult terrain and slope, you will definitely have to think about where and how to make a sewer drop well in order to dampen the power of the water flow.

Types of drop wells

There are designs:

- to increase the speed of water movement - “fast currents” (tray with a large slope);

- to slow down the flow: with a baffle-weir wall (water hits it, slows down and flows down) or steps inside the well.

There are models equipped with a water seal. Such differential sewer wells are used when it is necessary to increase the level of the pipeline. Water accumulates inside a special chamber, and only when it rises to the outlet does it continue to move through the network.

Container structure

The drainage and sewer systems perform various functions. In this case, sewerage can be stormwater, domestic and industrial. Despite all these differences, drop wells have the same structure. So, a typical container consists of the following elements:

- Support bottom.

- Working chambers that have a cylindrical shape.

- Neck.

- Cover with hatch.

The differential type well has a similar design and operating principle. The difference is that the working chamber is equipped with bumpers and gentle overflows, which are designed to dampen the flow of water.

Read more about the use of differential wells

Designs that involve changing the depth of the pipeline, according to SNiP 2.04.03-85, are used:

- to change the speed of movement of wastewater;

- in the last well before the reservoir, if the shore outlets are flooded;

- when it intersects with underground structures.

They can also be used to connect sewer networks located at different depths. If the difference is small (up to 0.5 m) and the pipe diameter is no more than 600 mm, it is permissible to use conventional tray structures.

Depending on the outer section of the pipes, the height of the difference can be from 2 to 4 m (inlets and outlets up to 600 and up to 200 mm, respectively). If it does not exceed 3 m, choose shaft-type wells with steps (the distance between them is from 1.5 to 2 m). For pipelines with a diameter of 600 mm or more, differences of more than 3 meters are preferably designed as weirs of a practical profile.

Purpose of the design

If there is a large difference in height between the starting and ending points of the sewer and drainage system, then a drop well is a mandatory intermediate element. The fact is that a large amount of water during movement creates a lot of pressure and load on the walls of the pipelines. As a result, this can lead to system destruction and failure.

The installation of a differential well is carried out in the following cases:

- If there is a need to forcibly reduce the speed of wastewater.

- The structure is installed when pipelines are laid over utility lines that were laid earlier.

- If the pipeline is laid under highways and other transport routes, the well used to transfer wastewater from a high pipe to a low one is an integral element of the sewer system.

In such cases, the rate of water flow naturally increases. To protect the system from the negative impact of such speed, it is necessary to install a differential well equipped with a water absorber.

Tip: If the pipeline has a diameter of 60 cm and a drop of 50 cm, then you can get by with a conventional inspection well.

Today, there are several types of differential wells, which have their own design and functional features. When choosing a container, you should pay attention to the characteristics of the soil, the topography of the site and the design of the pipeline.

Products of the POLIPLASTIC Group

The structures sold by the company are made of plastic. Its advantages include low weight (ensuring low transportation costs and ease of installation of the structure), corrosion resistance, tightness, and long service life (up to 100 years). One of the product samples - a differential sewer well - has the following dimensions:

- diameter – 1600 mm;

- shaft height – 5750 mm;

- diameter of exits (inputs) – 1200 mm.

Inside there is a flow damper, which is required to reduce the speed of the medium. It also serves as an observation deck. The well is equipped with a ladder for ease of maintenance. Entrances and exits are made of polymer corrugated pipe.

It is possible to produce custom models according to Album No. 5 of the document “Chambers and wells of rainwater drainage. Standard materials for design 902-09-46.88.” Production is carried out according to designs that indicate the required height differences.

The need to use standard solutions

Drawing up a project for a drainage system requires calculating a large number of containers. They perform similar tasks and work under the same conditions. It takes a long time to design each well separately. Due to the large volume of work, errors or miscalculations are possible. In addition, it is necessary to ensure compliance with the requirements of SNiP and SP, which complicates the calculations. If a complex project is being drawn up with atypical operating conditions or network configuration, the calculation time will be too long.

To speed up design work, eliminate errors and miscalculations, an album “difference sewer well, standard project” has been compiled. This is a section of Standard Design Solutions, a catalog of available structures made from different materials. It is a collection of tables that display the parameters of containers of different sizes. They are designed so that you can easily select a design with the required number and diameter of pipes. The use of TPR significantly speeds up the process of drawing up working documentation, since the task of calculating each well separately is removed. You can choose ready-made solutions that meet regulatory requirements.

Among experts, a “standard storm drainage design” is considered a useful guide. Rainfall systems are complex and highly dependent on the terrain or structure configuration. At the same time, it is extremely difficult to calculate the amount of waste in advance. The specifics of the work also differ from domestic sewerage. Drainage comes from outside, collects on the roof or territory, and ends up in open trays. There is a constant need to transfer water to lower levels and enter it into underground collectors from the ground surface. The availability of ready-made catalogs compiled on the basis of current standards significantly speeds up design. Sometimes it is necessary to change the parameters of finished structures if operating conditions or other factors require it. Usually, a standard sewer drop well is used as a basis; a new look is obtained by making amendments to the dimensions or equipment of the container. At the same time, it is necessary to limit changes so that they do not affect existing rules and regulations. Any violation will result in refusal to approve the project.

How to make a drop well yourself ↑

It is difficult to independently equip structures with multi-stage water traps and a channel. These are quite large and complex structures, the construction of which will require the development of design documentation. It is much easier to purchase a factory-made prefabricated plastic frame for installation or use reinforced concrete rings of standard designs.

Prefabricated sewerage element made of expensive plastic, but extremely easy to install

The technology for installing differential wells for sewerage includes:

- Digging a pit to a depth below the freezing point of the soil on the site.

- Pour and compact a gravel cushion of 20–30 cm.

- Installing a concrete slab at the bottom of the pit or pouring a monolithic slab foundation.

- Installation of a plastic product or laying reinforced concrete rings.

- Arrangement inside the bump stop.

- Connecting inputs and outputs with careful sealing of all joints.

- Closing the structure with a lid with an inspection hatch.

- Filling the hole with earth.

If, in addition to the main inlet, you also have to connect inlet pipes from the side, then they should be located above or flush with the main pipeline. The lateral flow of water should not interfere with the central one, and should not itself have any obstacles in its path. Its speed must be lower than the main watercourse, otherwise it is already turning into the main one, then the design of the well and fenders will need to be changed.

If the groundwater level is high, the concrete rings should be coated with bitumen waterproofing before backfilling. The structure must be reliably protected from corrosion.

Installation of storm wells

Now let’s move smoothly to one of the most important points of this article. However, we noted above about the installation work that is carried out to install different types of storm wells. But let's now talk about everything in order:

There are two types of storm wells:

- Linear option - its basis is a drainage pipeline, which is located at a depth of 50-70 cm. As a rule, an inspection well is connected to it. It is mainly used for repair work or emergency wastewater release. The minimum diameter of this type of well is 500 mm.

- Point version - a distinctive feature of this type of wells is point wells. They are located in places where there is the highest level of water accumulation. It is worth noting that they are located like vertical drainage pipes, the task of which is to direct not only surface, but also groundwater to places with high throughput (immersion depth reaches 3-4 m).

And based on the type of wells, the installation method is directly selected.

Installation of a linear well includes the following steps in its process:

- It is necessary to dig a pit, thereby expanding and deepening the trench for drainage;

- In equal proportions, sand is poured onto the bottom of the pit, and then crushed stone (about 10-15 cm);

- Then you need to lay a layer of waterproofing on the crushed stone;

- After which, first a concrete screed is laid on top, and then a polymer structure (the step with the concrete screed can be skipped);

- Pipes are connected to the inlets available at the well;

- It is necessary to first add crushed stone around the drainage pipe, and then fill the pit with a soil covering.

The point type of well and the installation work associated with it also have several stages:

- The work begins with drilling a shaft in a pre-selected area, the diameter of which is 200-300 mm;

- Then a so-called “stocking” made of geotextile is lowered there, having previously thrown a couple of large stones;

- Thus, the “stocking” is filled to the very end. But it is important to take into account that stones are added first, and then crushed stone (fractions 20-40 cm).

This method is one of the cheapest. If you are interested in more expensive installation, then it is necessary to strengthen the well body with casing pipe. Then, at the customer’s discretion, they are fastened to the drainage pipes either with a cross or a tee. This well, in addition to its functions, can also serve as a structure that relieves the load on the main drainage line.

Polymer wells

Plastic well Wells

made of modern plastics have given sewer network designers a completely different degree of freedom.

The development of technology has also had its say: modern mobile systems can service hundreds of meters of sewer pipelines without going underground.

Thanks to this, it became possible to significantly reduce the size of products.

Where previously it was necessary to use meter-long, at least 70-centimeter rings, now you can install a compact plastic device up to diameter 300 mm.

Polymer products are also distinguished by their low weight and the ability to accurately adjust the size to the needs of a specific highway.

Essence of the structure

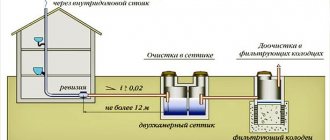

The sewerage (drainage, stormwater) system on a private plot, when properly organized, is a rather complex combination of various elements. In addition to the pipeline itself, it provides various types of wells that ensure the functionality, maintenance, and safety of the entire system. The main types of wells: inspection, rotary, differential, storage and filtration structures.

Thanks to their presence, opportunities are created for:

- visual monitoring of the sewerage system;

- arrangement of safe turns and branches;

- pipe cleaning;

- accumulation, filtration and disposal of wastewater and other activities necessary for operation.

A drop well is installed in cases where it is necessary to lay pipes in an area with a significant slope or when it is necessary to significantly change the depth of their location at intersections with communications or any obstacles.

With the help of these structures the following tasks are solved:

- alignment of the pipeline route in the presence of difficult terrain;

- compensation for changes in pipe depth;

- optimization of pipe placement in relation to the water level in the drainage reservoir.

The most important goal is to avoid excessive speed of fluid movement in the pipe, when a destructive hydraulic shock occurs when it bends.

A differential well is most often installed specifically to dampen hydraulic loads when running pipes on a slope with a significant angle. If such measures are not taken, then large loads appear at the junction of the inclined pipe with the horizontal section, which can destroy the metal, especially since solids can also move with the flow.

The need for such a design may also arise on flat areas, when the sewer route intersects with other highways (for example, a water supply or gas pipeline) or when difficult obstacles appear (for example, a rocky exit, a concrete slab, etc.).

In this case, the depth of the pipe changes quite sharply, which leads to problems similar to the circumstances already discussed.