Purpose

The name of this device has Greek roots and comes from the word rotten. In simple terms, these are special underground chambers that consist of one or several compartments through which various organic liquids and waste enter. Concrete septic tanks do not function as independent structures; they are used together with special post-treatment. Post-treatment is carried out underground. It follows from this that it cannot be said that this structure cannot cope with the tasks of treating wastewater and waste.

At dachas, concrete septic tanks are used to collect and treat organic waste and wastewater. The resulting sediment, after purification, is mineralized and can be used as fertilizer for plants and trees that grow in the country.

Preparing the trench and pit

The trench for the pipe leading to the installation from the outlet from the facility is made with a slope of 2% (20 mm per 1 linear meter). A leveling bedding is made at the bottom of the trench.

The pit for installation is 500 mm wider than the container on each side.

The length of the pit is determined by the total length of the system, taking into account an increase of 500 mm on each side of the treatment plant.

The maximum depth of a septic tank should not exceed 3 meters from the ground surface. (Dig a pit whose overall dimensions should be 500-600 mm larger than the dimensions of the septic tank around the entire perimeter. The height of the pit is determined depending on the depth to which this structure needs to be buried).

Preparing the trench and pit

Concrete septic tank design features

The main difference between a concrete septic tank and some other options is its integrity - in the sense that everything that is necessary for its operation is located in close proximity to each other. This is a monoblock product placed in one large hole - this is both an advantage and a disadvantage. The advantage is that you do not need to dig several holes, as is done in the case of making a septic tank from concrete rings, but the disadvantage is that you will have to dig a very large hole - at least 3 by 2 meters in size and 2 meters in depth. In principle, this is not important

More importantly, to produce it you will need formwork, which means at least additional costs and labor for its production

Like any other septic tank, a concrete product of this type is divided by partitions into two or three parts - three is better, since three-stage water purification is better, and such septic tanks last much longer.

- First pit. It receives wastewater coming out of the house. Here, heavy human waste is separated from the total mass of wastewater - it settles to the bottom, and more or less purified liquid is poured into the next pit.

- Second pit. So to speak, post-treatment - at its bottom there remains everything that did not have time to settle at the bottom of the first pit. Almost only liquid gets into the third compartment of the concrete septic tank for the dacha, which is what needed to be achieved.

- Third pit. This is a pit for water disposal - without impurities, the liquid is simply absorbed into the soil through the bottom and holes in the walls, without clogging the pores in the soil. This is precisely the whole point of such treatment plants. Due to the absence of impurities, the soil’s ability to absorb water does not disappear for a very long time.

You can see how a septic tank made of monolithic concrete works in this video.

As a rule, septic tanks, unlike ordinary drainage pits, serve faithfully for at least fifty years. And if, in addition to everything else, you also use biological products, whose task is to decompose solid waste, and even more. In principle, this nuance concerns not only the operating principle and design of a concrete septic tank - it is typical for any treatment facilities of this type. We will continue to build such a durable drainage pit.

Volume of the future septic tank

The service life of the tank depends on the correctly calculated volume. If there are several chambers, only the volume of the first is calculated. The remaining volumes of the chambers are taken depending on the displacement of the receiving compartment. Daily water consumption is taken as a basis. In this case, this number is increased three times. The next chamber should be half the size of the first. It receives water purified from heavy organic substances.

The number of rings is calculated by dividing the volume of the entire container by the volume of the ring itself. It is worth considering that there are several sizes of concrete rings for septic tanks on the building materials market. After counting the number of rings, it is easy to determine the volume of concrete mixture required.

The larger the volume of the septic tank, the less often it requires cleaning the wells Source prostroyer.ru

How to make a device with your own hands

In addition to the above tips, there are many more recommendations that are especially important to consider during construction, since only this will help to carry out the installation correctly, efficiently and without violating the technology. When installing rings, you must follow safety regulations

When installing rings, you must follow safety regulations

Namely:

Pouring is carried out using concrete grades such as B15 and higher. For mixing, you need to follow the proportions per 1 m3: crushed stone - 1200 kg, sand - 600 kg, cement - 400 kg, water - 200 l, superplasticizer C3 - 5 l. Before concreting the bottom, a sand cushion is laid at the very bottom of the pit. The sand is laid in a layer of 20 cm. Next, you need to make reinforcement, for which a special mesh is used. The mesh is taken for the manufacture of which reinforcement with rods with a diameter of 10 mm was used. The optimal cell size is 20x20 cm. The concrete is laid at least 3 cm above the surface of the reinforcement, and the subsequent arrangement of the walls can only begin after 2 weeks, so that the base hardens as firmly as possible. The walls should be no more than 20 cm thick, and the thickness of the partition between the chambers should be 15 cm. When setting up a rectangular septic tank, it is worth considering that high pressure will be exerted on it, so you need to increase the stability with the degree of soil resistance. To do this, reinforcement is carried out not only on the bottom, but also on the walls. In order to compact the concrete during laying, it is necessary to use an in-depth manual vibrator, since the usual method of bayoneting will not give the desired result in the form of compaction of the maximum level. The formwork should be assembled from edged boards, which will be cheaper and more convenient. The filling of the walls must be completed in one go, but if this is not possible, then before starting to pour the next layer, the first one must be coated with Penerat. This allows the adhesion between the layers to be at the highest level and eliminates the formation of gaps at the junction. Once the walls are poured, you need to wait at least 14 days, after which the formwork is removed. The structure is inspected for integrity, and if no defects are found, then the work continues, and if there are any, it is necessary to grout with cement mortar and apply a layer of waterproofing using a special mastic. Next, it remains to make the roof of the septic tank, for which formwork is assembled from boards

It is important to remember that concrete has considerable weight, and therefore the spans between the boards are supplemented with supports. This must be done every 1.5 m. The ceiling is reinforced in the same way as other parts of the tank, but here reinforcement with a rod thickness of 12 mm is used

The minimum amount of concrete on top is 3 cm. Before filling the container that will be used for sewage drains, you need to wait 3 weeks, remove the supports and cover with a layer of polyethylene while the concrete dries.

The work requires a considerable investment of effort and time, but in the end you can get a high-quality concrete septic tank. If you need to equip it in a private house, and do it yourself, then the concrete and reinforced concrete option is what you need. Such designs are thoughtful, comfortable, and most importantly - durable, stable and strong.

Installation of reinforced concrete slab

The bottom of the pit is covered with a sand cushion 150 mm thick and sprinkled with water.

In the pit, formwork is installed along its perimeter and to its entire depth, at the bottom of which a concrete slab reinforced with reinforcement is poured. The thickness of the slab is calculated based on the overall dimensions of the storage structure and the specific gravity of concrete

for reference

:

1 cubic meter of concrete weighs 2500 kg, usually 200-250 mm.

If a storage structure is installed in areas where vehicles move, a load slab is additionally poured, which serves to evenly distribute the loads. The thickness of the slab is 200 mm, the overall dimensions are 1000 mm larger than the dimensions of the septic tank. You can install a standard reinforced concrete slab (for small septic tanks) at the bottom of the pit, the overall dimensions of which should exceed the dimensions of the septic tank by 30-40 cm around the perimeter.

Image 2. Installation of reinforced concrete slab

Types of concrete septic tanks

Designs for storing wastewater differ in the number of chambers. When choosing, take into account the dimensions of the containers into which sewage flows.

The intensity of operation of drainage systems should be taken into account. Thanks to this, it becomes possible to correctly calculate the volume of the chambers

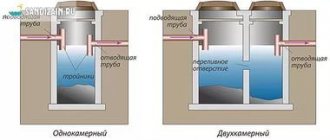

Single chamber

This design option is called a drain pit. This is the simplest septic tank, it is characterized by its small size. The main function is to store sewage. The drainage pit is cleaned regularly. The design is simple: there is a hatch on top for servicing the system, and in the side wall there is a hole for connecting a pipe through which the drains enter the pit.

In most cases, this option is used if 2 people live on the property. It is enough to build a small-sized concrete septic tank with your own hands: 1.5 m is the width of the wall, 2 m is the depth.

Double chamber

Between the two tanks there is a pipe through which purified waste flows. The first of the chambers is used as a settling tank, where solid fractions are separated naturally (they settle to the bottom). Sewage with a smaller amount of contaminants enters the second container through the pipe. Such wastewater is allowed to be discharged into the soil.

The first chamber is larger than the second in volume. In addition, the overflow at the outlet of the structure should be located lower than at the inlet. Thanks to this, the possibility of treated wastewater getting back into the first chamber is eliminated. Such designs provide the possibility of notifying that the container is overfilled, for which a critical liquid level alarm is used, and at the same time a float switch.

Three-chamber

These are more complex septic tanks. They are equipped with a forced aeration system. As a result, the process of cleaning and disposal of waste is accelerated. It is difficult to equip a septic tank of this type on your own, because the volume of installation work increases and the costs of equipment increase. Main nodes:

- compressor;

- aerator;

- submersible pump for pumping out treated wastewater.

Two- and three-chamber septic tanks are equipped with a ventilation system, as well as inspection hatches. In the first chamber, cleaning is carried out with the participation of anaerobic microorganisms, in the second - through aeration and aerobic microbes. The pump is located in the third compartment.

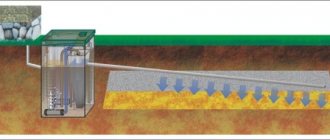

How to build an autonomous sewage system without odor

Inside a two- or three-chamber septic tank there live two types of bacteria for the disposal of organic matter:

- Anaerobic - found in the first compartment in layers of solid sediment. Oxygen is not required for their life.

- Aerobic - located in the second compartment, where clarified water with light organic impurities is drained. For their normal existence, oxygen is required, pumped by an aerator, and artificial algae (long-pile brushes, synthetic net), where the bacteria settle their colonies. They are suspended in the second chamber below the level of the overflow pipe.

The more bacteria there are, the more intensely they eat organic waste, which decomposes into activated sludge, water and carbon dioxide. The less undecomposed organic matter, the less odor inside and outside.

In aeration units, the element is preinstalled by default. In the case of homemade systems, such an airlift (airlift) can be made yourself.

Do-it-yourself tubular aerator for a septic tank

The design can only be called homemade in part, because you will need to buy an air compressor. Aeration is done in two ways:

- The compressor is installed directly on the septic tank. A casing or canopy is provided for it to protect it from precipitation. Then an “L”-shaped structure is made from a ⌀50 mm plastic sewer pipe and a corner. The horizontal end of the “L”-shaped part is connected to the compressor. The end of the vertical part of the pipe is plugged with a plastic plug, many ⌀2 mm holes are drilled on the sides to allow air bubbles to escape, and lowered into the second chamber of the septic tank (should not touch the bottom, the optimal distance to the bottom is 30 cm).

- The equipment is installed in the house. A PVC pipe ⌀5 cm is connected to it. It is laid parallel to the communications in the first well, and then through the overflow hole into the second well. The tube should be sealed at the end and have small drilled holes on the sides.

The bacteria will begin their work when both wells are filled. It will take about 2 weeks for them to develop. All this time, an unpleasant odor will be felt near the septic tank, which will disappear after it reaches operating mode.

Do-it-yourself biofilter for a septic tank

This is a compact chamber filled with inert material, populated by aerobic and anaerobic bacteria. This results in mechanical and biological treatment. It is appropriate to make such a filter in cases where, for some reason, it is not possible to equip a filtration field or drainage well.

Advantages:

- The quality of treatment is improved, and wastewater can be discharged into a ditch;

- Saving space on the site, since there is no need to construct an aeration field.

Flaws:

- the biofilter silts up quickly, the filler needs to be changed frequently;

- it is necessary to periodically add biological products (they are sold in dry or liquid form).

Filters are installed by default in factory bioseptic tanks, but in the case of homemade autonomous sewers, you will have to make it yourself. Moreover, there is no need to lay it down at the construction stage. A chamber with a biofilter can be added to the treatment plant at any time after preliminary cleaning of the septic tank. To build you need:

- Dig a pit to the size of the chamber in the immediate vicinity;

- build a frame of bricks, reinforced concrete or plastic;

- Connect the chamber with the biofilter to the septic tank;

- Fill the tank with expanded clay or other inert material. Additionally, plastic brushes or corrugations are used, on which colonies of bacteria settle;

- Fill the pit with soil from the outside, and place a hatch on top.

Separate biofilters are available for sale, ready for installation. However, they cost tens of thousands of rubles.

Construction technology

In order for the structure to be durable and of high quality, before starting construction, it is necessary to carefully prepare. First, you should familiarize yourself with the list of requirements that the sanitary and epidemiological station imposes on such installations:

- the installation should be no closer than 6 meters to the house;

- be sure to install rubber tanks;

- the pipe through which waste flows must be below the freezing level of the ground;

- the pipe must have a slope for every 2 cm of each meter of pipe.

- the total amount of organic waste and wastewater for 1 day;

- the volume of the installation must be at least 3 times the total amount of incoming wastewater;

- if the water consumption per day is no more than 1 cubic meter, then a single-chamber installation is sufficient.

To install a septic tank, a certain list of materials and tools is required:

- cement mortar for concreting;

- sewerage pipes;

- bitumen;

- tee;

- ventilation pipes;

- crushed stone;

- slate;

- hacksaw for cutting pipes;

- shovel;

- Master OK;

- ladder;

- container for mixing the solution.

To use a concrete septic tank, it is important to follow the construction technology. First you need to dig a pit

To install the structure, it is necessary to equip a special pit. The dimensions of the pit must meet the required data. In such a situation, they dig one hole. Afterwards it is divided in two. Each part will be a specific component in the treatment of organic waste

It is during this process that it is worth taking into account the level of freezing of the ground. To prevent the soil from falling off, you need to use plastic film.

In addition to the pit, it is necessary to dig trenches of a certain size for laying pipes. Drain pipes must be placed at an angle.

The next step is to strengthen the walls of the pit. To save resources, you can do this using sliding formwork.

It is performed for half of the pit, and then, after filling and drying, it is transported to another compartment of the pit. The panels are made of wood, mounted and fastened to each other using timber. They are fixed in the ground about 5-10 centimeters. They make holes to install pipes that are laid from housing. Installation takes place over a length of about 35 centimeters. Before you start filling the hole with mortar, the formwork must be strengthened with reinforcing bars. This is necessary so that the future installation will be more durable. Metal rods for fittings can be replaced with pipes made of different materials or wooden beams.

Next, you need to fill with concrete. Pouring can begin after the pit has been reinforced with reinforcement. To start mixing the solution, you need the following components - plasticizer, cement, water, sand. It is worth waiting a few weeks for the concrete mixture to dry and harden. If cracks appear on the surface, you can cover them with concrete mixture.

Now you can begin installing the partition. This partition is made from existing building materials - stone, brick. A pipe is installed between the compartments. With its help, waste from one compartment will be transferred to another. The first compartment deals with the sedimentation of solid components of wastewater. In the second compartment, organic waste is filtered and discharged into the soil. In order for the drainage pit to work better, it is advisable to install a tee in the overflow.

We must not forget about covering the installation. In order to provide strong support for the ceiling, it is necessary to install metal channels inside.

On top of them is a wooden shield. The shield should have small sides; they mark the limit of the hatch's clearance above the ceiling. Slate is placed on top of the shield. Only after this, pipes for ventilation are installed. How the final work is performed. The quality of the completed septic tank can be determined in a couple of weeks.

Choosing a location for installing a septic tank

When choosing a location for installation, you must be guided by the following recommendations:

- If possible, the installation should be located below the house along the natural slope of the area;

- Provide the possibility of access to the installation of a sewage disposal truck for pumping out sludge. Maximum distance 4-5 m (The length of the standard hose of a sewage disposal machine is 8 m, taking into account lowering);

- Locate the installation as close to home as possible. The optimal distance is 3-5 meters. It should be borne in mind that increasing the length of the route before installation makes cleaning more difficult in the event of a blockage. A route longer than 25 meters must be completed with an intermediate well;

- The route from the house to the installation must be straight. If it is impossible to organize a straight route, rotary wells are installed at the bends.

What is required for construction

It is quite possible to build a monolithic septic tank made of concrete or concrete blocks with your own hands, but you need to take into account the nuances.

Installing a septic tank made of concrete rings will require several people

You will need it yourself:

- Make a volume calculation;

- Prepare the pit;

- Do all the dirty work.

As for the capacity of the container, this is a purely individual parameter, and when choosing it you need to be guided by the volume of water that will be used

You especially need to pay attention to where exactly this object will be located on the site. The main thing is that the level of the septic tank is not higher than the house

Tips for use

- Do not throw garbage and solid household waste into drain pipes;

- Do not drain hot water, which will kill germs in the drain hole;

- Timely cleaning will extend the life of the septic tank;

- Do not repair the sewer system yourself.

The operation of a concrete septic tank involves not only draining the waste, but also cleaning the pipes, maintaining a sufficient number of microorganisms in the septic tank compartments and timely cleaning the pit from solids.

You need to try to use less chemicals in order to prevent corrosion of the monolith of the walls and bottom. In order to save water consumption, purified water can be used to water the garden.

How to make a monolithic septic tank with your own hands

To work you will need:

- sand;

- gravel;

- cement;

- plasticizer;

- molten bitumen;

- metal reinforcement elements: sheets, corners;

- polyethylene film;

- pipes;

- brick;

- boards, bars;

- fastening elements for wooden metal products;

- reinforcing wire and rods;

- Sander.

How to calculate volume?

First you need to decide on the dimensions of each chamber. You need to know the depth and width of the walls. The calculation principle is the same for rectangular and square septic tanks. It is necessary to multiply 3 values: the depth and width of 2 walls. According to this scheme, each camera is calculated.

How to choose the right place?

In this case, the location of surrounding objects is taken into account:

- the distance between the septic tank and a residential building should not be less than 5 m;

- if there is a well or borehole on the site, then the drainage pit is built much further (20 m between objects);

- leave 4 m to the border of the site;

- the septic tank is built at a distance of 5 m from the side of the road;

- to green spaces - 3 m;

- to a flowing reservoir - 5 m, and to a reservoir with standing water - 30 m;

- if there is a gas main nearby, you need to retreat 5 m.

Installation of a concrete septic tank

Instructions for performing installation work:

- Prepare the pit. Its walls must be smooth. During the digging process, a building level is used.

- Cover the pit with plastic film over all surfaces.

- The internal perimeter is being reinforced.

- The formwork is being installed.

- Holes are made in the wooden structure for connecting communications.

- Mix the solution using Portland cement, gravel, sand and plasticizer.

- After 28 days, work continues.

- The frame is mounted using metal corners, which are secured to the concrete with anchors.

- The frame is sheathed with flat slate and sealed with bitumen.

- Then the formwork is installed to fill the floor with concrete. Provide a hole for the ventilation pipe.

Manhole covers can be metal or wood. In both cases, a frame of corners is first installed. The hatch is installed using hinges. In order for the septic tank structure to serve for a long time, concrete is poured in 1 day. This eliminates the possibility of delamination. Separately, a pit is dug for a filter well. The installation principle is the same as for a drainage pit, but the bottom is not concreted. Instead, a sand and gravel cushion is installed.

Comfortable housing is the desire of every person, but not everyone can buy a ready-made house with everything they need. But this does not mean that everything you want cannot be done on your own; this requires very little money and patience. Any construction begins, first of all, with sewerage planning. With the presence of a sewer system in the country, it will not be difficult to connect all the necessary plumbing. The best choice would be to install a concrete septic tank yourself. In this article we will try to analyze all the nuances and subtleties of a concrete septic tank from.

Which septic tank is suitable for a country toilet?

It must be placed at a distance of 12 m from the house and 25 m from the source of water supply, in accordance with the current SNiP and SanPiN.

For an outdoor toilet it is not necessary to use a multi-chamber septic tank. A storage tank similar to a cesspool made of plastic or concrete with subsequent pumping by a sewer truck is quite sufficient. This option is more economical for a summer residence, especially for seasonal living. Containers can be plastic or made of monolithic concrete.

There are 3 types of location:

- Under the toilet. First the system is constructed and then the toilet is built.

- Part of the treatment plant protrudes outside the bathroom, where an exhaust hood and a hatch for pumping out sewage are installed.

- The septic tank is located at a distance from the restroom.

Types and schemes

Such structures can be of different types - completely monolithic or prefabricated, from separate rings. Both options have both advantages and disadvantages. Despite the fact that if the installation is properly organized, it is not difficult to complete the work, many specialists and consumers still prefer monolithic structures.

It is not difficult to install concrete septic tanks yourself, however, it is important not to forget about the presence of a wastewater treatment system in them. Everything that gets inside the chambers is sent for cleaning. When the cleaning is completed, the wastewater will go either into a special tank or to fertilize plants

All this must be taken into account when designing the future site.

Monolithic concrete septic tank, in turn, also comes in different types:

- single-chamber installations;

- two-chamber structures;

- three-chamber concrete structure.

A large number of compartments in a septic tank are not used, as this is not rational. All septic tanks have their own nuances and features.

In a single-chamber septic tank, heavy suspensions that enter the chamber fall down. They decompose into organic waste due to the influence of anaerobic microbes. Airborne gas vapors and individual chemical elements form a special separating crust on the surface. This crust clogs the pipes through which everything flows. Therefore, during installation it is necessary to place tees there.

Due to the fact that the decay of wastewater occurs together with the release of gas fumes, it is imperative that the septic tank made of concrete rings be ventilated. The filling level is controlled using a special float indicator:

- The single-chamber installation is easy to install and quite simple to use. However, you need to remember that its cleaning system often gets clogged, especially the pipes.

- A monolithic concrete septic tank of a two-chamber type does not have such a disadvantage; its drainage design can work much longer without additional cleaning. Ventilation is also installed there. The bottom of the second compartment can be filled with crushed stone, this will help protect the filters from clogging with solid parts of organic waste.

- A three-chamber septic tank requires a more complex device. In the first compartment, wastewater treatment is carried out. Waste of organic origin breaks down under the influence of anaerobic microbes, and the harder parts sink down. Biological purification occurs already in the second compartment. Thanks to the air pressure created by the compressor, the waste is mixed with special bacteria and, with the help of this maneuver, the organic matter disintegrates faster. The third compartment is necessary for more thorough additional purification of the remaining wastewater. The resulting liquid ultimately ends up in underground treatment.

How to determine the depth of the groundwater level

Before installing the septic tank, it is necessary to accurately measure the height of the groundwater in order to avoid errors during installation and during further operation. There are several ways to do this.

The easiest way is to communicate with your closest neighbors; most likely, one of them has already determined the water level and will be able to share the results. If your neighbors do not have such data, you can contact an organization engaged in engineering surveys. Geological examination will be carried out by experienced specialists, the owner of the site will receive a detailed official report. Based on the report, it will be possible to select the most suitable location for installation and draw up a plan for future construction work. The services of specialists are quite expensive, so this method is not suitable for everyone. Many owners of country houses prefer to determine the depth of groundwater themselves.

There are 4 ways to independently measure groundwater level. Each of them allows you to accurately determine the depth of the aquifer.

- Drilling rig. For this method, you will need a garden drill and a rod at least 2 m long. Markings are made on the rod along the length with an interval of 10 cm. Next, you need to drill a hole to the entire depth of the drill and wait a day for moisture to accumulate. Sometimes water appears immediately after drilling, but these are rather isolated cases. The next day, the height of the water is measured using a rod. To ensure accurate measurements, you can make a series of wells throughout the site and measure the level for several days in a row. To design the tank, take the smallest value from the results obtained.

- By vegetation. You can determine the groundwater level of a site by the wild plants growing on it. Below is a table of indicator plants, by the presence of which one can judge the proximity of an aquifer. In addition to these plants, high humidity can be judged by the rich growth of sorrel and the rapid development of currant bushes.

- Along the nearest bodies of water. If there are dug wells nearby, the necessary information can be obtained by looking into them and determining at what distance from the surface the water mirror is located in them. It is better to do this after heavy rainfall to get an accurate idea of the possible rise in groundwater. The presence of wetlands in the area indicates that groundwater is located close to the surface.

- According to signs. There are some folk signs, based on which we can draw a conclusion about the desired parameter in a summer cottage. Morning dew and evening fog are sure signs of a shallow aquifer. Another sign of high humidity can be the abundance of midges, mosquitoes and the absence of rodents in the local area.

Advantages

A concrete septic tank has a huge list of advantages. A person who uses the advantages of concrete septic tanks does not need to constantly clean out sewage pits. It is enough to perform such an operation once every couple of years. Concrete septic tanks do not require electricity; they operate completely autonomously.

For such a structure, there is no need to purchase and install special pumps or drainage systems. The construction of such a concrete structure is so simple that even a person with minimal construction experience can install it. It is possible to install reinforced concrete rings of any diameter and volume, everything depends only on the desires and needs of the consumer.

This concrete installation has a much longer service life than its plastic or steel counterparts. A concrete septic tank filters waste much better than other similar systems. The costs associated with the purchase of material and installation of the system are absolutely negligible.

Installation of a pipeline from the facility (building) to the neck of the septic tank

The supply pipeline is assembled from PVC-U pipes for external use. If the supply pipeline is shallow (up to 1 m), the pipes must be insulated before assembly.

Image 5. Installation of a pipeline to remove wastewater from the building to a septic tank

The top and side surfaces of the tank are covered with insulation (if the supply sewer pipe enters the septic tank less than 1 m from the ground surface).

Advantages and disadvantages of a concrete septic tank

When choosing an option for similar structures that differ in material (plastic, metal), take into account the positive and negative qualities. A concrete monolithic septic tank has the following advantages:

- relatively low price, and the option made of concrete rings is considered more affordable, but it is not monolithic and requires work to ensure the tightness of the structure;

- such products do not provide for the possibility of connecting to electrical equipment (automatic filtration systems, pumping stations, compressor), which allows them to be used in any conditions;

- you can build a septic tank with your own hands: when constructing a monolithic chamber, a concrete solution is prepared; you will not need to use special equipment to carry out the work;

- long-term operation;

- resistance to the negative effects of external factors: mechanical stress, chemicals;

- due to the absence of seams, the possibility of sewage penetrating into the ground is eliminated;

- a monolithic concrete septic tank is characterized by significant weight; it is much heavier than concrete and metal structures, which allows you to skip the stage of strengthening in the soil; for comparison, plastic analogues are characterized by much lighter weight and, when the soil heaves, tend to rise above the soil surface.

There are few disadvantages to such designs. Thus, they note the complexity of the work. A monolithic concrete septic tank is built with your own hands over a long period, since it uses the technology of pouring cement mortar, which requires the need to dry the walls and floor of the pit for 1 month.

Scheme of a two-chamber version

In this system, water undergoes preliminary settling before being discharged or pumped. According to sanitary standards, such water can be discharged into the ground. The advantages of this system lie in its compactness. With the same volume, two free-standing containers made of reinforced concrete rings take up more space than a monolithic concrete structure.

The diagram shows the proportions of the septic system. The optimal size of the receiving chamber should exceed the volume of the second settling tank in a ratio of 1:3 (+)

This septic tank has an internal concrete partition, which allows the water to settle in two stages. In addition, it can be equipped with a sensor that signals overflow.

The second overflow at the opposite end of the container is located slightly lower than the first, which eliminates the return of wastewater to the receiving compartment and ensures spontaneous overflow of the settled liquid into the next chamber.

A two-chamber drain pit needs to be pumped out once a year, a single-chamber pit - every 3-6 months, i.e. 2-3 times more often. A two-chamber will require more construction costs, but in the long run, exceeding the budget will quickly pay off

How to build a two-chamber septic tank using concrete rings is written here. We recommend that you familiarize yourself with this material.

Possible problems and their solutions

1. The septic tank gets clogged too quickly.

This is due to disruption of the microorganisms inside. It is necessary to pump out excess sludge from the first tank, leaving 15% sludge, and fill it with clean water, adding a bioactivator. If there is excess fat or lathering, you need to remove it using a special product. Microbes also die from low temperatures (you need to additionally insulate) or water that is too contaminated with detergents (you need to add a bioactivator and limit the aggressiveness of the drain).

2. An overflow has occurred. If the volume of the tank is incorrectly calculated, this is due either to blockages and growths in the pipes, or to siltation of the soil. They need to be cleaned both through inspection and with the help of drugs against growths. Blockages are common in pipes with L- and T-shaped joints, as well as a low slope.

3. Damaged walls of the product with cracks or shifts of 1 cm or more in size are plugged with glass-basalt reinforcement. Then they are filled with a waterproofing quick-setting mixture (special mixture or cement-sand mortar with liquid glass). 7 days after hardening, the damaged area is re-coated with waterproofing.