Technical parameters of aluminum sheet AMG3M

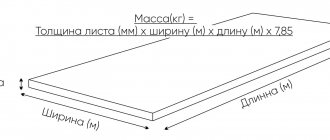

The technical performance of aluminum sheet made from AMG3M alloy is influenced by the processing of the rolled product and the grade of the alloy used. Depending on these parameters, the following metric characteristics are established, which are expressed in millimeters (mm):

- The length range is 2,000 – 7,000 mm;

- Widths range from 600 to 2,000 mm. Step - 200 mm. These indicators are established by state standards. Aluminum sheets with a length of 900 mm are an exception to the accepted standards.

- Thickness ranges from 0.3 to 10.5 mm. This value is enshrined in the regulatory document - GOST 21631-75. Additionally, in this document you can find information about permissible errors in production.

Pros and cons of products made from AMG3M alloy

Products from the AMG3M brand combine metals such as aluminum and magnesium. This unique combination made it possible to obtain a material that has such properties as - deformation under pressure; anti-corrosion resistance; increased plasticity; high weldability.

The ratio of magnesium to the total composition of the alloy must have clear values, since deviations from these parameters lead to the production of a material whose characteristics differ significantly. Increasing the content of the magnesium component in the alloy to 4% reduces its elastic properties and increases strength. Significant excess, in turn, can make the alloy very brittle.

Differences between AMG3M and other brands

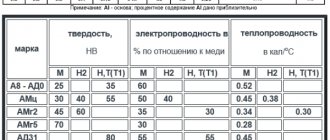

Below are the main differences between alloys of various grades - AMts and AMG3M:

- AMts brand material has increased plastic properties, as well as thermal and electrical conductivity characteristics. Plasticity and corrosion resistance are minimal.

- The AMG3M alloy has improved strength and is highly resistant to corrosion. Plasticity, thermal and electrical conductivity properties are reduced. The ductility and fluidity indicators are comparable to the characteristics of the AMG5M alloy.

In terms of its physicochemical parameters, the AMG3M alloy is close to the AMG2 alloy. But since the content of the magnesium component in the AMG3M alloy is higher and amounts to 3%, this has a significant impact on its strength indicators. The AMG3M alloy is used for the manufacture of aluminum sheets, which are classified as non-ferrous rolled products and have a thickness in the range of 0.5 - 10 mm.

The Resurs company offers you AMG3M aluminum sheets of standard thickness. Additionally, it is possible to order the production of aluminum sheets with non-standard characteristics.

Main characteristics and features of steel 03Х17Н14М3

According to GOST steel 03Х17Н14М3

is classified as a high-alloy chromium-nickel steel of the austenitic group, and therefore there are a lot of requests for “03Х17Н14М3 to buy”.

The main property of this metal is its high degree of resistance to external adverse factors. Steel 03Х17Н14М3

does not have a ferritic structure, which means it is resistant to pitting corrosion even in chlorine-containing environments. This steel is also characterized by excellent resistance to intergranular and knife corrosion.

Resistance to corrosion in the atmosphere for 03Х17Н14М3

exceeds that of ordinary quality carbon steel without coating by 4500 times, galvanized steel by 500 times, aluminum by 50 times, brass by 25 times.

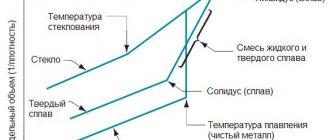

Steel tolerates temperature conditions (maximum and minimum) well and does not lose its properties due to temperature changes. The operating temperature of steel reaches +600°C with a long service life.

Steel 03Х17Н14М3

It is characterized by high manufacturability, it can be easily deformed and welded using any methods.

Thanks to its unique characteristics, 03Х17Н14М3 is suitable for the production of wire for meshes with a micron diameter. What is important is that both mesh and wire made of this steel are characterized by the highest resistance to such highly aggressive environments as boiling phosphoric, sulfuric, and 10% acetic acids. Also 03Х17Н14М3

does not lose its properties in citric and nitric acids, in sulfuric acid environments, and in sea water. Mesh and wire made of 03Х17Н14М3 do not corrode at sub-zero temperatures, in a steam environment saturated with aggressive substances.

Explanation and description of the AMG3M brand

What does the abbreviation AMG3M stand for?

“A” characterizes the metal from which the alloy is made. In this case it is aluminum.

“Mg” - indicates the presence of magnesium in the alloy;

“3” - shows the percentage of magnesium. In this case, the alloy contains 3% magnesium. The purity of the metal increases with decreasing percentage of magnesium;

“M” - indicates the softness and annealing of the material. Heat treatment may not be applied to sheets that are made in compliance with all rules, regulations and GOSTs. If there is no letter M at the end of the alloy designation after the percentage, this indicates that the alloy has not been subjected to thermal changes or treatment.

The alloy from which AMG3M aluminum sheets are produced mostly contains only aluminum and magnesium components. However, it may also contain additional impurities. They determine the properties of the alloy. Regulatory documents contain the following information about the composition of the AMG3M alloy:

- The content of aluminum as the base metal is 97.2%;

- Magnesium content ranges from 2.8% to 3%. Magnesium has the greatest influence on the physical and mechanical properties of the alloy. GOST 4784-97 sets the optimal magnesium content in the alloy at 3%. It is this indicator that provides the AMG3M alloy with strength and weldability;

- Iron content is no more than 0.5%;

- Manganese content ranges from 0.1 to 0.5%;

- The silicon content cannot exceed 0.4%;

- The copper and titanium content is 0.15% each.

The AMG3M alloy can also be found under another marking - 5254N11.

Characteristics of 3M titanium alloy

| Description | Designation |

| Alloy grade: titanium | 3M |

| Alloy classification: | Titanium wrought alloy |

| Industrial Application: | production of long products, special equipment parts, production of ingots, semi-finished products |

Percentage composition according to GOST 19207–91

| N | Zr | Al | Ti | C | Fe | O | Si | Impurities |

| ≤ 0.04 | ≤ 0.3 | 3.5 — 5 | 93.89 — 96.2 | ≤ 0.1 | ≤ 0.25 | ≤ 0.15 | ≤ 0.12 | only 0.3 |

Note : the base is titanium. First of all, this alloy is very strong, paramagnetic, and can be welded quite easily; like other titanium alloys, it has exceptional corrosion resistance, which plays an important role in technical industries. Alloying increases the corrosion resistance and strength characteristics of titanium by 2–3 times.

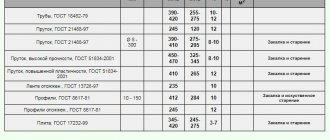

Mechanical characteristics (temperature 20°C)

| Assortment | Size | KCU | y | Heat treatment. | d5 | sT | sв |

| Wire, GOST 27265–87 | Delivery status | 13 | 580−735 | ||||

| — | mm | kJ/m2 | % | — | % | MPa | MPa |

sв — Short-term strength limit

d5 — Elongation at break

Physical characteristics of titanium 3M

| MPa | Degree | W/(m degrees) | 1/Degree | J/(kg degrees) | Ohm m | g/cm3 |

| 100 | 8.2 | 540 | ||||

| 1.12 | 20 | 18.85 | 4,5 | |||

| E 10- 5 | T | l | a 10 6 | C | R 10 9 | r |

Designations: mechanical characteristics:

| Description | Designation |

| Tensile strength (short-term), [MPa] | sв |

| Impact strength, [kJ/m2] | KCU |

| Yield strength at residual deformation (proportionality limit), [MPa] | sT |

| Brinell hardness, [MPa] | HB |

| Relative narrowing, [%] | y |

Properties of AMG3M alloy

— Increased anti-corrosion resistance. This property ensures the use of aluminum sheet products in unfavorable environmental conditions. At the same time, aluminum sheets made from AMG3m alloy do not require additional processing;

— Ease of mechanical action, regardless of the condition - drilling, cutting, pressure or press, welding, etc.;

— High strength and hardness, but at the same time excellent ductility. If necessary, the AMG3M alloy can be subjected to hardening or annealing. This will further increase the strength of the material;

— Low weight allows you to easily and quickly transport and install aluminum sheets made of AMG3M alloy;

— The operating temperature of aluminum products ranges from +20 to + 2,000 degrees.

Weldability

| not limited | — welding is carried out without further heat treatment and without heating |

| weldable with restrictions | — welding is possible when heated to a temperature of 100−120°C and further heat treatment |

| difficult to weld | — in order to obtain high-quality welded joints, additional operations are necessary: during the welding process - heating to a temperature of 200−300°C, heat treatment at the end of welding - annealing |

Production of aluminum alloy sheets of the AMG3M brand

Aluminum sheet is characterized by a solid cross-section, with a flat rectangular shape. It is made by two rolling methods: cold, hot. The length of the product according to established standards is in the range of 0.5 - 10 mm. If necessary, it is possible to produce products of non-standard sizes. This issue is discussed individually.

- There are several classifications of aluminum sheets made from AMG3M alloy.

- release form:

- general purpose or standard. They are most often used in industry;

corrugated aluminum sheet. The main difference between this form of aluminum sheet production is the application of a special pattern or groove. Using the convex parts of the riffle, various patterns are obtained, which also have their own classification:

1) the lentil pattern is made using one riffle that changes the angle;

2) the checkerboard arrangement of the riffles makes it possible to obtain a pattern called a duet;

3) five riffles are located perpendicular to the other 5 riffles. As a result of this arrangement, it is possible to achieve a pattern called a quintet.

- aluminum perforated rolled products;

- rolled aluminum corrugated.

Thanks to corrugation, rolled aluminum acquires an attractive appearance. Corrugation also increases the sheet's slip resistance, increasing its anti-slip ability. To manufacture aluminum alloy sheets of the AMG3M brand, we are guided by certain standards that establish the dimensions of the sheet and corrugations. GOST 21631-76 contains information on the length of the sides of corrugated aluminum sheets. The numerical value is in the range of 1.2 by 3.0 or 1.5 by 3.0 m. The thickness does not take into account protrusions and is 1.2 - 4 mm.

Standards

| Name | Code | Standards |

| Ribbons | B54 | GOST 1018-77, GOST 20707-80, GOST 1173-2006, GOST R 50248-92, OST 4.021.077-92 |

| Rods | B55 | GOST 1535-2006, OST 4.021.019-92 |

| Pipes made of non-ferrous metals and alloys | B64 | GOST 2624-77, GOST 11383-75, GOST 20900-75, GOST 617-2006, OST 4.021.122-92 |

| Sheets and strips | B53 | GOST 495-92, OST 4.021.049-92 |

| Non-ferrous metals, including rare ones, and their alloys | B51 | GOST 859-2001, OST 4.021.009-92 |

Areas of application of rolled aluminum made from AMG3M alloy

Due to the unique properties of aluminum sheet, it is used in various areas of human life. Below are the areas of use of the product depending on certain properties.

— As mentioned above, aluminum sheet is made from AMG3M alloy using two rolling methods: hot and cold. This production method allows us to obtain a product that has high welding properties. This allows the use of aluminum sheets to create structures that will be operated under minimal loads.

— Anti-corrosion resistance. This characteristic of aluminum sheet is obtained due to the unique properties of the AMG3M brand alloy used. For this, the products have found wide application in the chemical industry.

— Electrical conductivity, anti-corrosion resistance, and durability allow the use of aluminum sheets in the electrical cable industry. It is also popular in construction and in the nuclear industry.

— Low weight and ductility under the influence of mechanical processing methods have made it possible to use aluminum sheets in the installation of ventilation and air conditioning systems.

A wide range of applications suggests that aluminum sheets made from AMG3M alloy are high-quality and versatile products on the modern market and help solve a wide range of issues.

Heat treatment of AMG3M alloy makes it possible to increase a number of material characteristics. Due to this, aluminum sheets are used to create units that operate under high pressure. Such equipment includes a hydraulic pump, pipelines, various designs for the transport sector, and many others. etc. Thermally treated material serves as lining for freight vehicles.

The Resurs company occupies one of the leading positions in the sales of rolled metal products on the Russian market. We cooperate with leading manufacturers of aluminum alloy sheets of the AMG3M brand, thanks to which we offer products of the highest quality, which are produced in compliance with all regulations and standards specific to this type of product. The high quality of the alloy ensures excellent performance properties of the product at competitive prices.

Another undeniable advantage of working with the Resurs company is the comfortable location of warehouse and office premises. This will allow you to quickly and conveniently place an order and organize the collection of goods. We also deliver goods ourselves.

Buy at a good price

Rolled titanium grade 3 M that is sold meets the most stringent requirements. The popularity of products made from this alloy is due to the high quality of the products, their real cost and great variety. Our company's products are manufactured under absolute control at all technological stages, which provides a 100% quality guarantee. has all the capabilities to produce high-quality custom-made products of non-standard options and sizes. Technological capabilities make it possible to ensure the prompt production of an individual order in the event that the required type of product is not available in a standard version.

Production

The production of aluminum sheets from AMG3M alloy takes into account all the standards and regulations that are prescribed in GOST 21631-76. The delivery of this type of rolled metal product is accompanied by all necessary quality documents and certificates of conformity, which confirm the quality of the product and guarantee compliance with the declared characteristics.

GOST 21631-76 includes the following information.

— Rolling method: hot, cold. Cold rolling is used in cases where the thickness of the aluminum sheet should be no more than 6 mm;

— Information about plating.

Plating is the procedure of applying an additional protective coating to the surface of a sheet. Plating is divided into two types:

— normal cladding is used to provide additional anti-corrosion protection for aluminum sheets. It is mainly used for products that have increased strength. When the thickness of the aluminum sheet is more than 1.9 mm, cladding is performed using aluminum. In this case, strict requirements for the thickness of the cladding layer must be observed. Its value should be 2% of the thickness of the aluminum sheet. If the thickness is less than 1.9 mm, then the following requirement must be met during cladding: the thickness of the cladding layer is more than 4% of the total thickness of the aluminum sheet. After plating, additional markings in the form of the letter “A” are applied to the aluminum sheets;

— technological cladding is used more for aesthetic purposes. It gives rolled aluminum a pleasant appearance and further reduces the difficulties during rolling. It is applied in a layer that has a thickness of 1.5 of the total thickness. To mark technological cladding, the letter designation “B” is used.

In cases where cladding is not required, technical aluminum is used in the production of aluminum sheets, which is characterized by high density and increased anti-corrosion properties.

The cost of aluminum sheets made from AMG3M alloy is directly dependent on certain parameters:

- weight;

- size;

- order volume;

- additional characteristics.

The Resurs website offers you prices for standard products that have known characteristics. In case of manufacturing products according to individual parameters, you must consult with our specialist. He will tell you in detail about all the features and help you calculate the price of the product.

Physical characteristics of 3M titanium alloy

| Description | Designation |

| Temperature at which these characteristics were obtained, in °C | 20°C |

| Coefficient of linear thermal expansion αx106 at 100 °C [1/ °С] | 8,2 |

| Density [g/cm3] | 4,5 |

| Modulus of elasticity of the 1st kind E [MPa]x10-5 | 1,12 |

| Elongation at break d5 in % | 13 |

| Short-term strength limit sв [MPa] | 580−735 |

| Electrical resistivity, Ohmxmm2/m | 1,6 |

Delivery and service services

The Resurs company supplies rolled metal throughout the Russian Federation. You can choose any delivery method convenient for you:

- pickup;

- delivery by our own forces. We cooperate with transport companies that deliver goods to you. Calculation of delivery costs is individual in each case. Managers of the Resurs company will calculate the cost of delivery and take care of organizational issues.

All necessary information is posted on the website of the Resource organization. If you have any questions or cannot find an answer to a question you are interested in, you can call the numbers listed on our website and 8, or send a request in writing by email. We will try to consider your application as soon as possible and provide a prompt response.

The Resurs company is a direct supplier of rolled metal from large manufacturing companies. We offer you a product that meets all the necessary requirements and has an excellent price-quality ratio.

Additionally, we offer metalworking services:

- cutting;

- flexible;

- cutting, etc.