Home / Welding technique

Back

Reading time: 3 min

0

690

The concept of “welding” refers not only to metal. It is also needed when working with materials such as polypropylene, polyethylenepropylene, polyethylene, that is, polymers.

This type of welding is called extrusion. Polymer parts are connected using a special filler material. The main thing is that their composition is the same. This will guarantee the quality of the seam.

The extrusion method comes in handy when you need to connect sheets of film, polypropylene and parts of any containers.

Less suitable for PVC products. And it is not suitable in the case of polyethylene and other plastic pipes under pressure. Its 80% strength in this case is catastrophically low.

- General information

- General rules

- Specifics

- Technology

- What types of extruders are there?

- Summary

General information

The extrusion method is specially designed to join thick-walled elements. Unlike the traditional one with a rod, where hot air is needed, here with a seam there is almost no pain.

Extrusion is fleeting, the welder’s participation is minimal, you don’t have to worry about observing the process regime, and it takes a long time to master the basics of “seammaking.”

Extrusion science is accessible even to a beginner. Craftsmen will be able to boast of a manual welding extruder by making it themselves.

Welding in manual and automatic modes is up to you. Among the extruders in the first case, Leister fusion 3c stands out. The advantages are a simple and rational body, it weighs modestly, and the performance is higher.

Yes, the rod is also safe in terms of “twisting”. A good range of accessories for welding can be found on the website of the Weldmax online store.

When welding, sometimes you need to walk through narrow places. Leister fusion 2 is suitable for just these purposes. It is easy to use, small in size, and resistant to mechanical stress. Fusion 2 will not upset the engine with cold starts.

It is impossible not to say a few words about the manual screw welding extruder from the line of the same company. None of the entire range of this manufacturer can compare with Leister weldplast s6 in terms of power. However, it is not very noisy, and you will be surprised at how many programs there are.

Design

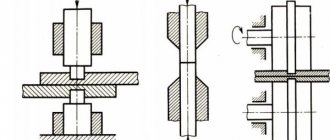

Any welding extruder is a dual device. One of its components is a powerful heater with a temperature switch, which is designed to melt plastic. The other is the actual extrusion device, equipped with a screw mechanism that supplies the melt through a nozzle-nozzle.

Depending on the type of feed (rod or granules), the extruder may contain a chopper (crusher). Solid material takes longer to heat to the desired state, and feeding it requires a more complex design than a traditional, inexpensive and easy-to-use auger. Thus, less complex and less expensive extruders are mostly designed to be fed with pellets.

In general, the design of a typical extruder contains, in addition to the above, the following components and elements:

- asynchronous electric motor;

- “clip” for food;

- extrusion chamber;

- melting chamber;

- heating element;

- nozzle attachment (good models have a set of several nozzles);

- straight and side handles;

- control unit with thermostat.

Depending on the type of power supply of the welding extruder, the supplied additive either immediately enters the melting chamber (loose granules), or enters the extrusion chamber, where it is preheated, crushed, and only then melted. The molten mass is fed through a nozzle to the welding seam, where it solidifies in a matter of seconds.

General rules

When extrusion welding, all parts must fit together. This refers to the chemical composition, fluidity and density. In the case when you have parts with different indicators, the additive composition is selected as something between the parts that need to be connected.

The edges of parts must be cleaned with care. It is common for most types of thermoplastics to oxidize in the atmosphere. It is better to start cleaning 15-20 minutes before the start of the process.

It is not allowed to leave random debris on surfaces. The quality of work will suffer.

Did you fail to connect the prepared surfaces during this time? This means that the cleaning will have to start all over again. And further. Using a solvent for this is a bad idea!

Extruder welding

1. Principle of extruder welding

1.1 Purpose

Extrusion welding – technological features of the process, equipment design. Extrusion welding is a technology that is used to join materials such as:

- Polypropylene;

- Polyethylene;

- Plastics.

- PVC

- PVDF

Extrusion welding is not used for installation of pressure pipelines. The reason is that the butt arrangement of the elements - pipes - does not provide a strength indicator higher than 80% of the strength of the product itself, in this case pipes made of thermoplastics.

1.2 Requirements

To achieve a high strength of butt welds when welding materials based on PVC and PVDF, 2 basic requirements must be met: 1. Only materials with identical characteristics and chemical composition must be joined. This means the following indicators: • Density; • MFR – melt fluidity indicator. The use of extrusion welding requires the use of filler material corresponding to the density and fluidity of the melt of the joining plastic surfaces. Attention! If the materials being joined have different melt flow rates, it is necessary to select an additive whose MFR is the average fluidity rate. 2. The surfaces to be joined must be thoroughly cleaned. Extrusion welding does not tolerate even small amounts of oxidized material on the surfaces of materials. Therefore, to ensure the strength of joints and seams, cleaning of polypropylene, polyethylene, plastics, and other materials should be carried out 20 minutes before welding. This requirement must be fulfilled as accurately as possible, which is due to the low fluidity and alteration of materials in the area where the seam is formed.

1.3 Extrusion welding - specification

Extrusion welding is focused on joining thick-walled components, parts, surfaces made of PVC, PVDF. Extrusion technology has the following advantages compared to the method of welding materials with hot air using filler material: • Reduces welding time; • Minimizes the influence of the human factor on the strength properties of seams; • Formation of a continuous joint - a seam along the joining surfaces.

1.4 Extrusion welding - technological organization of the process

Extrusion welding technology requires surface preparation before joining. This is done in three ways: • Creating a welding groove, a recess on the joining surfaces; • Formation of a bevel, an angled cut at the ends of the connected surfaces; • Laying materials overlapping. The welding process itself begins with heating the materials in order to bring them to a plastic state. For this purpose, a stream of heated air supplied by the nozzle of a welding extruder is used. Stationary industrial complexes heat materials before welding with radiation. Simultaneously with plasticization, the filler material is prepared. This is done by feeding the base into the extruder screw - PVC granules or rods, which are brought to a viscous-flowing state by heating. Stirring transforms the molten material into a uniform, homogeneous mass. The resulting material is fed with the help of a welding shoe to the place where the surfaces join to form a seam. The welding shoe creates the pressure necessary for this process. Stationary industrial complexes may have a different scheme for the compression effect on the filler material, using separate components and assemblies.

1.5. Features of the welding extruder

Extruders are equipped with air heaters to ensure plasticization of the materials being joined. This is necessary to supply filler material. A stream of hot air enters the welding site through a preheating nozzle, due to which the materials being joined are heated. The temperature of the air flow is regulated by a special controller. There are 2 options for installing an air supply system for heating:

- Built-in air supply units;

- The air supply is organized using external sources. This could be a compressor or a pneumatic network.

In screw-type extruders, the filler material is loaded into a specialized container, a chamber called an extrusion screw.

Its rotation is ensured by an electric motor; its functions are most often performed by a hand drill. The operation of the extruder implies longer operation of the electric screw drive, therefore reliable extruders are equipped with modified drives that have an increased service life. Plasticization of the filler material in the screw is ensured by electric heaters. They are placed on the outside of the auger chamber, their temperature conditions of the heaters are controlled and set through a special control device. Advanced modifications of extruders are equipped with this system. Simple models of devices heat the material in a screw chamber with air passing along the outer contour of the screw chamber. For this purpose, a special cavity is provided in the extruder design. It is then fed into the welding area to plasticize the materials being welded. Such a device for heating the filler material provides for linking the temperature of the air flow passing through the cavity of the screw chamber with the temperature of the air supplied to heat the materials before welding. The additive itself is fed into the welding zone through the welding shoe. Some models are equipped with a simplified system for moving filler material through the heat-affected area. Welding rod - the material enters the profile rollers, they forcefully transfer it into the opening of the heating section, which has a cylindrical shape. This is where electric heaters come into play and begin a thermal effect on the additive, turning it into a homogeneous, heated viscous mass. This scheme turns the rear part of the bar into a pusher for the front. Plunger extruders have low productivity. This feature is compensated by its compact dimensions, which allows you to work with the device in hard-to-reach places. The disadvantage of plunger extruders is the high demands on the diameter and shape of the filler material rod. It should be smooth, without errors. There is no possibility of loading granular material into plunger extruders. The plastic filler mass is supplied to the weld formation site through the welding shoe. This is a common technological feature of screw and plunger welding machines. The working surface of the shoe matches the shape of the mating surfaces. Its front part is equipped with a special nose, which does not allow the entry of filler material in front of the welding zone. The additive exerts pressure on the toe of the shoe, creating a translational movement of the apparatus in a given direction, where a seam is formed. The speed of movement in this case is determined by the performance indicator and the cross-sectional area of the seam. 1.6 Materials to be welded - temperature conditions, features

Most often, HDPE and PP are welded with an extruder. These are thermoplastics of the first group, their advantage is the large temperature range between reaching the state of plasticization and thermal destruction (destruction from exposure to temperatures) is 50–186 degrees C. Significant overheating of such materials does not have a critical effect on them. The second group of thermoplastics includes PVC; PVDF, on the contrary, are distinguished by a small temperature difference between plasticization and thermal destruction. This feature requires increased attention to the temperature regime; it must be observed as accurately as possible. This can only be achieved by debugging the heating system of the device. Welding PVC has one more feature - extruders designed to work with this material are equipped with a specially shaped screw. It ensures thorough mixing of the additive and control of the temperature effect on it. This avoids thermal destruction. The temperature instability of the second group of thermoplastics requires compliance with one more requirement when welding. The device cannot be left in standby mode for a long time; it must be turned off completely during long periods of time. Another disadvantage of PVC is increased chemical activity when heated, as well as abrasiveness. Because of this, specialized technological requirements are imposed on the screw chamber.

2. Shapes of extrusion welds

The basic shapes of extrusion joints are defined in the industry standard DVS 2207-4. The document also contains rules for welding:

- The seams are formed in one pass;

- It is advisable to make a double-sided seam, it provides high strength materials to thermoplastic products;

- Double-sided seam saves filler material.

- A double-sided seam has less impact on the performance of the base sheet or film during cooling.

The GOST 16310-80 standard contains fewer requirements for preparing the basis for welding and its implementation.

There is no description of welding shoes in the regulatory document. At the same time, GOST 16310-80 describes in detail the types and shapes of seams. 3. Shapes and features of welding shoes

The additive, ready for use, enters the seam formation zone through the welding shoe. It also performs the following functions:

- Applies pressure on the incoming material;

- Forms a seam;

- Smoothes the seam surface.

Accordingly, the size and shape of the welding shoe determines the shape and size of the seam.

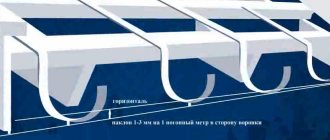

The material from which the shoe is made is group IV fluoroplastic or PTFE. It has high levels of heat resistance and anti-adhesion. The depth of the pressure creation zone must be at least 1/5 of the seam depth. The depth of the incision should be approximately 0.5 mm, extending forward. This allows the support not to deform the surface of the root layer. This is easy to do, since the material is in a heated state. The shoe nose prevents uncontrolled additive distribution. In turn, the pressure created by it propels the apparatus. The nose of the shoe should not come into contact with the sheets being welded, but its shape should follow their configuration. This requirement can be met by creating a gap between the toe of the shoe and the root layer of 1 to 3 mm. It itself should have a rounded front and back edge. This support prevents additive leakage. To do this, it is necessary to create a clamping force during welding. 4. Preparation for the welding process

Preparation for the welding process Sheets and film must be prepared immediately before starting the process. This is due to the rapid oxidation of the polymer surface. Also, the reason for this requirement is the possibility of contamination on the surface of the substrate: dust, moisture, which will significantly reduce the strength properties of the seam. It is necessary to prepare polymers for welding 20 minutes before the start of welding. If more than the specified time period has passed, you should re-prepare and start welding immediately. Attention! Removal of contamination from the surface of polymers is carried out mechanically, for example, using scrapers. Degreasing compounds are ineffective in preparation for extrusion welding.

4.1 V-stitch

A V-shaped seam requires pre-treatment of the ends and edges of the joining materials. This preparation is carried out using carpentry tools: • Rasp; • Planer; • Hacksaws; • Chisels. The bevel created at the edges should ensure that the seam opens in the range of 45–90 degrees. Thick polymer sheets require creating a bevel with a large angle; thin ones with a smaller one. The opening angle should ensure that the additive fills the entire space formed by the end cuts. The limited opening angle for thick-walled materials is determined by the total width of the seam and overlap zones on its surface. This figure should not exceed 30 mm. Ignoring this requirement will not allow creating the necessary force that will ensure that the additive does not protrude beyond the edges of the welding shoe. The root layer of the seam should contain millimeter-long unmown areas. Their absence will lead to overheating and melting of the material in the welding zone due to uneven movement of the welding machine. The consequence of this will also be a violation of the width of the gap between the sheets; it will become noticeably wider or narrower. The material is fixed before welding begins, thereby creating a uniform gap. Its optimal width should not be more than 2 mm. This will allow the additive to penetrate into the interior of the materials being welded, which guarantees high quality welding. Mechanical processing of the seam should be carried out no closer than 2 mm from the edges of the bevel. This is done provided that the overlap of the joint head in two directions is no more than 2 mm.

4.2 X-stitch

This type of seam is a double-sided version of the V-joint. This allows you to use the same requirements and rules in your work. The only difference is the inability to control the quality of welding of the root layer with an X-shaped seam. This feature changes the requirements for working with the base:

- Bevels are formed at the ends;

- Their opening angle is 30–60 degrees;

- The front side is processed mechanically at a distance of 2 mm from the edge of the bevel;

- The root layer is fixed without gap;

- It is first necessary to carry out the joining using a hot air gun using a special nozzle;

- A V-shaped seam of the front part is formed;

Now you need to turn the sheets over and repeat all the above steps on the other side.

4.3 Joint type HV

For this type of seam, the opening angle is determined by the thickness of the root layer and is 45–60 degrees. The vertical sheet has a more significant influence on this. Here it is necessary to leave a non-beveled area 1 mm wide at the end. The sheets must be fixed so that there is a gap of 2 mm between them. This will guarantee high-quality welding. Attention! The distance from the edge of the horizontal sheet to the beginning of the seam after welding must be at least 10 mm. The plane located on the left side is processed mechanically no closer than 3 mm from the edge of the bevel. Here it is necessary to provide a reserve. The algorithm of actions when forming a seam of the HV shape is similar to creating an X-shaped seam.

4.4 K-stitch

Corner internal connection requires preliminary fixation of sheets. This is done using a hot air gun. For temporary welding, a special nozzle or nozzle with filler material is suitable. The temporary fixation area is processed using a scraper:

- When using a welding attachment, this is done with the sharpened edge of a scraper;

- The use of filler material requires machining with a rounded scraper surface.

The root layer is now ready for extrusion welding. Seam with variable cross-section The seam configurations presented above are idealized, but often the operator is faced with the need to form a seam whose cross-section will change. An example of such work is welding a pipe into a pipe of a larger diameter. For the high-quality implementation of such a task, modernization of the shoe is required. This is a parallelepiped with rounded corners; it is in contact with the upper part of the root base, where the angle between the straight sheets is 90 degrees, and with the lower part, where the angle can reach 120–140 degrees.

Specifics

It is necessary to weld pipes and other configurations made of polyethylene using extrusion welding along the welding channels, the surfaces of the films that are overlapped, and the corners of the polypropylene sheet will also be a guide.

The working areas are preheated to t, at which the plasticization process should start. For this purpose, heated air is taken, which comes directly from the welding unit.

External sources such as thermal study, which is provided by a stationary extruder, will do.

Now the filler material that has been selected (you can also use a rod) is placed in a special chamber of the device in granular form, where it is heated.

When the mass reaches the stage of fluidity, then, using a screw, it is squeezed out using a welding shoe to where the intended seam is located. You can replace the screw, depending on what kind of extruder and disk you have.

Homemade device

The welding extruder is a complex mechanism for professional use. Its price starts from 30 thousand rubles for the simplest model, and can reach one hundred thousand or more for a powerful and high-performance one. Domestic developments are also presented on the market; they are 10-20% cheaper than imported ones, but are still quite expensive.

Therefore, if a one-time need arises to weld, for example, two water pipes (their usual material of manufacture is polypropylene), it is easier to use a home-made extruder. The simplest version of the design is a powerful construction hair dryer, equipped with a nozzle for a rod - either homemade, made of tin, or industrially made .

In this case, the bar will be fed manually. The power of the hair dryer is enough to melt it, but the quality of the seam, of course, will be lower than that of industrial models.

If possible, the hair dryer can be connected to a screw or plunger drive to supply power. In this case, if you install a receiving chamber, it will be possible to use granulated raw materials.

A commutator motor is recommended for the drive, since the operation of the extruder implies a constant change in torque. Engines of other types are less resistant to this operating mode.

Technology

At the start of the extrusion welding process, the surfaces to be joined must be in a viscous state. Therefore, the air flow, which has been heated to the required t, is directed through the nozzle to the welding site.

Heating is possible using a hot air gun built into the extruder. Hot air will also be provided by a compressor and a pneumatic network available in the organization. At the same time, t in a hot air gun and from other sources can be adjusted.

The essence of the method

To join polymers by extrusion welding, it is necessary to heat the polymers being welded and use special additives that are supplied to the welding site. An apparatus called an extruder is used as equipment for joining polymer products using extrusion welding. The small size of this instrument, however, allows the inclusion of a rather complex device.

The appearance is somewhat reminiscent of an electric drill, which is convenient to hold in one hand, equipped with a special nozzle and a heating device. An important part of the design is the welding shoe, which is pressed against the parts to be joined. Inside the extruder there is a screw, the shell of which is heated by electric heaters. The welding rod is fed through a hole in the screw body. Granules poured into a special hopper can also be used, depending on the design features.

The additive is heated from the screw body and turns into a homogeneous viscous mass, fed through a hole in the shoe to the welding site. On the other hand, it is necessary to heat up the parts themselves to be welded. This is carried out by a stream of hot air heated to the required temperature using electric heating.

Hot air is also supplied to the welding site through an opening in the shoe. The air is heated before the hot filler material is supplied. Extruders have the ability to regulate the temperature of both air and filler material. The shoe varies depending on the size and shape of the seam.

Extrusion welding can only be used on polymers called thermoplastics. Their peculiarity is that they can maintain a viscous-fluid state over a wide temperature range. In this case, the thermoplastics being connected must be made of the same material. To minimize heat loss during the process, the largest possible rod diameter should be used, as well as a high feed rate of filler material.

There are two types of extrusion welding. The non-contact method involves the use of a press or clamping device to apply pressure to the parts being welded. With the contact method, pressure is created by a flow of molten filler material.

What types of extruders are there?

They are represented by screw and screwless samples. In the first extruders, the melting process takes place in a chamber. It is fed externally by a screw.

In those that do not have one, extrusion is carried out using a part of the rod that has not yet melted, which means it remains quite hard. Screwless extruders have a second name – plunger extruders. They are characterized by lower productivity.

They exclude the use of granular additives. But they will penetrate into the most inaccessible places. The tip of the welding shoe is equipped with a special hole. It provides control over the flow of additive to the welding site.

The extrusion method is used when work is to be done with Group I thermoplastics, including polypropylene and low-pressure polyethylene. They have their own specifics.

Acceptable melting is separated from irreversible thermal destruction by 50 degrees. That is, you should not be afraid of damage to the material if it overheats by only 30 or 40 degrees.

It’s a completely different matter if you have group II thermoplastics such as PVC or PVDF. With them, you need to carefully monitor the temperature during the heating process.

When working with thermoplastics of this group, a specially shaped screw is needed. It ensures optimal mixing of the additive, preventing overheating of the material and guaranteeing high-quality extrusion welding.

Scheme of work

Since the surfaces to be joined must become viscous before welding, air heated to a certain temperature is released into the welding zone from a special nozzle. The temperature can be adjusted. Heating can be carried out by built-in heaters in the extruder (heat gun), or can come from external media (compressor or pneumatic network in the organization).

Samples of screws for welding extruder

Extruders come in screw and screwless types. Screw extruders are distinguished by the fact that the filler material is melted in the screw chamber and pushed out by the screw. In screwless extruders, the filler material is pushed out using the solid, not yet molten part of the rod. Such extruders are also called plunger extruders. Their productivity is less than that of screw ones; it is impossible to use granules with them as a filler material. But it can easily be used in hard-to-reach places. At the end of the welding shoe there is a special hole that controls the flow of filler material into the welding zone.

The extrusion type of welding is used more often for low-density polyethylene, polypropylene, and other group 1 thermoplastics. This group is distinctive in that the difference between the molten state and the state of thermal destruction is approximately fifty degrees. Thus, slight overheating of 30-40 degrees will not damage the material. Thermoplastics of the 2nd group are PVDF and PVC. The temperature difference between the above states is small, which requires strict adherence to the temperature regime in the heating zone. The screw for group 2 thermoplastics must have a special shape for more thorough mixing of the filler material without overheating.

Thus, the extrusion method of welding polypropylene products is the easiest for beginners and is used for joining thick-walled products. Beginners can make a manual welding extruder with their own hands. It is quite easy to choose a manual extruder for welding, since there are many devices on the market for this type of connection, one of the most popular is the leister fusion 2 welding extruder.