To obtain parts with a shaped surface configuration (end, external or internal) on metal-cutting lathes, a special cutting tool is installed in the tool holder - a shaped cutter. It ensures the accuracy of obtaining geometric dimensions, compliance of the resulting shape with the technical requirements of the design document and high labor productivity, which is important in the production of parts in mass and large-scale production. Surfaces are considered shaped if they are created by a curved type generatrix, a combination of rectilinear and curved generatrices, including those located at different angles. Feature of the tool: the profile corresponds to the profile of the future part. Such products are made for a specific part, so the cost of the cutting tool is high.

Classification

Shaped-type cutting tools are designed for processing the surfaces of workpieces made of soft, medium-hard and hard steels, soft and hard cast iron, brass, bronze, copper, aluminum and other non-ferrous metals and alloys. The work is performed on turret and lathe machines, including semi-automatic and automatic types.

Products are classified according to the following criteria:

- manufacturing material (carbide and high-speed cutting);

- manufacturing method (solid and composite);

- structures (round, prismatic and rod);

- type of surface being processed (external and internal);

- installation relative to the workpiece (tangential and radial);

- the shape of the forming shaped surfaces (ring, screw and flat);

- the location of the axis of the fastening hole relative to the workpiece (parallel and inclined);

- the location of the front surface (with a zero angle of inclination of the cutting edge and with a certain angle of inclination);

- method of fastening (mount-on, tail-mounted).

The cutting tool is made of alloy and high-speed steel. It depends on the grade of steel whether it will be made from a single piece of metal or a composite one. In the first case, it is advisable to make it of a solid structure, in the second - from several grades of steel. A composite type product is a holder made of ordinary steel, to which a cutting part made of special tool steel is glued, welded or attached. This method reduces the cost of manufacturing compared to a tool made entirely of expensive high-alloy steel.

Round shaped cutters

The round shaped cutter is a common cutting tool and is not difficult to make. It is used for processing the external and internal surfaces of workpieces made of different materials. A characteristic feature is that they can be re-sharpened, which can be done repeatedly. The tool is a rotating body with an angular groove to create the front surface and a hole for chip removal.

Prismatic shaped cutters

Tools of this type are designed for processing workpiece surfaces. With their help, you can obtain both external and internal surfaces of the required configuration. Prismatic shaped cutters are a product in the shape of a prism, the front surface of which is flat, and the back has a shaped shape. Such a cutting tool is installed in the tool holder using a connection called a dovetail. The tool is sharpened repeatedly along the front working surface. When turning, they provide high surface quality in terms of surface finish and roughness.

Shaped rod cutters

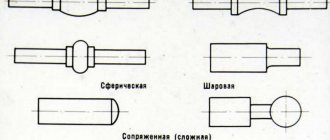

A rod shaped cutter differs from a conventional turning cutter in that it has a cutting edge that matches the shape of the future part. They are manufactured in several types: fillet, groove, radius and with a more complex profile - disk or prismatic design.

Radial

A radial cutting tool has a round or prismatic shape, with the first type used for processing both external and internal surfaces of the workpiece; Prismatic products are processed exclusively on external surfaces. It is installed in relation to the workpiece in the tool holder so as to ensure transverse feed - the axis of the workpiece in this case intersects at several or at one point with the cutting edge of the product.

Tangential

The tangential cutter is used for processing workpieces that poorly resist deflection and when making shallow profiles.

The cutting tool is installed in the tool holder so that it is tangent to the internal profile of the workpiece. This allows you to consistently introduce the cutting edges of the tool into work. The tool can be applied to the workpiece in several directions:

- longitudinal;

- transverse;

- at an angle to the axis.

Cutters with a positive rake angle improve the cutting process. They, together with products that also have an angle of inclination of the cutting edge, are used for the manufacture of particularly precise parts.

Various options and their purpose

The variety of cutting tools for wood when rotating on a lathe is very large. Experienced craftsmen create cutters of the shape they consider convenient for the implementation of individual tasks. Therefore, one personal cutter is not similar to another. However, there are standards for factory tools, some of which are basic, others highly specialized.

Reyer

This is one of the basic incisors. It can be recognized by its characteristic shape - the working part of the rail is not flat, but curved, forming a groove. Sharpening is done from the inside of the curve. They work with a rake, bringing it to the workpiece with the groove up.

Thanks to the shape of the blade, this cutter selects wood in a semicircle. Its longitudinally curved shape makes it very durable, making it well suited for rough turning of workpieces. With the help of a reyer you can also make smooth transitions and grooves with a semicircular profile.

Expert opinion Dmitry Konstantinovich Levin

The width of the rib ranges from 4 to 30 mm, and the sharpening angle is about 30 degrees.

Meysel

If a reyer is a relatively simple tool, which is intended primarily for rough, rough work, then a meisel is already much more difficult to use. It is unlikely that you will be able to master it in a couple of days of practice. This cutter is used already when the outlines of the wooden product are formed. However, for an experienced turner, the use of a meisel gives an even, smooth surface of wood of a given geometry.

The Meisel is a bit like a regular flat hammer chisel, but its blade is angled. Accordingly, the master must have at his disposal at least two meisels - left- and right-handed - in order to process mirrored areas.

Sharpening the meisel can be done either by beveling one side until it comes out flat, or by equally removing the metal layer from both sides. In this case, the width of the blade can reach up to 40 mm, and the bevel angle ranges from 60 to 75 degrees. When sharpening a cutting edge on both sides, the angle should be 20 – 25° on each side.

Shaped

After the main processing of the part in the headstocks has been completed, it is the turn of the figured cut. For this purpose, shaped cutters are used. They can have different shapes for turning grooves, grooves, and select grooves of complex shapes.

Klukarza.

The most common “styles” are:

- Klukarza. The shape of the cutter is similar to the reyer, but has a bend in the working part near the blade. Thanks to this shape, the cranberry can be used for small and complex work; it can reach places where tools with a straight working part cannot reach.

- Comb. It makes parallel grooves and grooves. With the proper level of skill, a thread is cut using a comb.

- Hook. Allows you to make an internal recess with a protruding edge, as well as various curved grooves.

- Crescent or dovetail. Used for turning round and faceted beads.

The process of turning a workpiece on a lathe significantly depends on the sharpening angle of the tool. Small angles (20 – 30°) are intended for fine work

They remove wood well, but if moved carelessly they can damage the workpiece or break themselves. Large angles (60 – 75°) are designed for rough work in hard rocks

They can remove less in one pass, but they are not afraid of knots and pressure created by the turner.

Features of product geometry

The geometry of a shaped cutter depends on its design, which in turn depends on the size and profile of the part. The main ones are cutting angles, sharpening, the main front and back, and also for some products additional angles are introduced into the design. The parameters can be very different. Proper design of the tool shape and the correct selection of the grade of steel/steels for its manufacture will help to obtain a high-quality part from a workpiece. The calculation of the profile of a future product is carried out by specialists in 2 ways: analytical and graphical, each of which requires certain skills and the ability to use specific reference books and literature. Work experience is also important.

General rules and safety precautions

Principles of safe work on a wood lathe:

- You should work in special clothing, which must be put on before turning on the machine;

- there should be no unnecessary objects or tools on the machine;

- be sure to check the workpiece for knots and cracks;

- check the serviceability of the cutting tool and its sharpness;

- wear safety glasses;

- when working, apply the cutter to the part only when the shaft reaches full rotation speed;

- do not tilt your head close to the machine;

- take measurements of the part only after stopping rotation;

- You must not leave the machine while it is working.

After work, it is recommended to remove chips with a special brush.

When working on a wood lathe, you need a whole set of different cutters. Each of them performs its own function and is designed for a specific job. Such cutters can be purchased in stores or made independently.

Tips for choosing a shaped cutter

As stated earlier, the tool is made for a specific part. Manufacturing work begins with design. The design stages are as follows:

- determined by the type of tool, the profile of which directly depends on the drawing data of the part;

- determined with the main and connecting dimensions, as well as with the angles of the cutting part and the installation of the cutter;

- perform a calculation of profile dimensions, the so-called correction calculation;

- are determined with tolerances.

Based on this, the material and manufacturing method are selected, and a drawing of the future product is made. In addition, they are determined with a holder for mounting on a specific model of machine. If necessary, it is also made. In most cases, a template is initially made, and a counter-template is used to control the dimensions during operation of the product.

Conclusion: a product is manufactured according to a known profile of a part that will be sharpened using a tool. The profile is determined in the plane of the front face and in the one that is perpendicular to the rear surface.

Geometric parameters and tool dimensions

- Geometry of the body or holder: L – length of the body, B and H – dimensions of the cross-sectional sides.

- Shape of the working cutting plate: l – length of the working part of the cutter, b – height of the plate body, S – thickness.

- Location of the cutting element in the body. The socket for the plate can occupy the entire width of the case or one of the corners. In the latter case, the width of the socket is indicated by the letter n. The plate can be placed in the socket at a certain angle to the body.

The blade for cutting the workpiece also has its own parameters, expressed in angles.

- “Gamma” displays the front sharpening angle - this is the main element of the cutting edge.

- “Alpha” is the rear main sharpening angle.

- “Alpha” with index 1 is the rear corner for auxiliary purposes.

- "Lambda" is the angle at which the cutting edge is inclined.

- “Phi” is the main purpose angle located in plan.

- “Phi” with index 1 is an auxiliary angle located in plan.

Selecting cutting mode

Cutting modes are selected depending on the following factors:

- brands of processed material;

- brand of material from which the cutting tool is made;

- length of the workpiece and its diameter;

- method of installing the tool on the machine;

- profile configurations and depths.

Approximate cutting modes with shaped cutters on metal-cutting machines, depending on the diameter of the workpiece and the width of the cutter, are shown in the table.

| Workpiece diameter, mm | Cutter width, mm | Feed speed, mm/rev. |

| 20 | 8 | 0,03 ÷ 0,09 |

| 10 | 0,03 ÷ 0,07 | |

| 15 | 0,02 ÷ 0,05 | |

| 25 | 8 | 0,04 ÷ 0,09 |

| 10 | 0,03 ÷ 0,085 | |

| 15 | 0,035 ÷ 0,75 | |

| 20 | 0,03 ÷ 0,06 | |

| 40 | 8 | 0,04 ÷ 0,09 |

| 10 | 0,04 ÷ 0,085 | |

| 15 | 0,04 ÷ 0,08 | |

| 20 | 0,04 ÷ 0,08 | |

| 30 | 0,035 ÷ 0,07 | |

| 40 | 0,03 ÷ 0,06 | |

| 60 | 8 | 0,04 ÷ 0,09 |

| 10 | 0,04 ÷ 0,085 | |

| 15 | 0,04 ÷ 0,08 | |

| 20 | 0,04 ÷ 0,08 | |

| 30 | 0,035 ÷ 0,07 | |

| 40 | 0,03 ÷ 0,06 | |

| 50 | 0,025 ÷ 0,055 |

In the video you can watch the process of turning a ball with a shaped cutting tool:

We ask you to share your experience of turning workpieces with a shaped cutter in the comments to the text, and for those who designed - the nuances of making a drawing of the cutter itself, holder, template and counter-template.

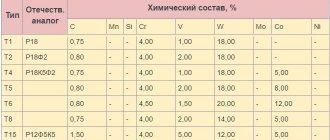

Labeling and manufacturers

The description of groove turning tools will be incomplete without mentioning the markings, which determine the composition of the material of their cutting part. For example, the T5K10 cutter is made of a hard alloy of the titanium-tungsten group, which contains 5% titanium carbide and 10% cobalt. The markings of products made from other materials are deciphered in a similar way.

The most famous manufacturers of grooving turning tools are:

- Dnepropetrovsk industrial tools plant (Ukraine);

- (Ukraine);

- Zenitech company (Switzerland);

- Proma company (Czech Republic);

- Itertool company (China).