Aluminum alloy D16 is high-strength duralumin of the A1–Cu–Mg system with alloyed manganese additives. In terms of hardness and mechanical strength, it is not inferior to steel, but, unlike it, it has a 3 times lighter specific gravity. In this regard, it is actively used in all areas of industry, especially in aircraft manufacturing, in the manufacture of power structural elements.

However, D16 duralumin has one main drawback - low corrosion resistance and requires special anti-corrosion protection products. In most cases, the alloy is clad or anodized, which significantly increases its corrosion resistance.

Decoding of the D16T brand

Decoding the brand allows you to determine its main performance qualities and chemical composition. Brand D16T belongs to the class of duralumin, which is characterized by a high concentration of alloying elements.

Today, D16T is deciphered using GOST. Unlike other alloys, these alloys are marked according to their own system. Duralumin D16T is deciphered as follows:

- D – designation of materials of the duralumin group. It differs significantly from ordinary aluminum, which is due to the inclusion of various alloying elements in the composition. The concentration of other chemical elements allows you to change many performance qualities.

- 16 – alloy number. In essence, this figure does not indicate any qualities, but it is used to designate an alloy with certain qualities.

- T is a symbol that denotes hardening and natural aging. Heat treatment associated with hardening involves exposure to high temperatures, due to which the surface layer is reconstructed.

D16T aluminum is very common in areas where critical mechanisms and devices are produced that will be subject to serious environmental impact.

Download GOST 4784-97

Heat treatment of alloy D16T

To improve the working properties, D16T is subjected to heat treatment, which takes place in several stages.

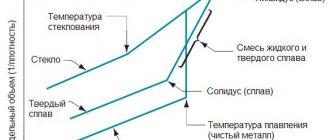

At the first stage, hardening is performed at a temperature of 495 – 505 ºC. It is undesirable to use higher temperatures, as a phenomenon such as burnout occurs. It leads to a sharp drop in some parameters of D16T.

At the second stage, duralumin is quenched in water, and its temperature plays an important role. The optimal hardening temperature is 250-350 ºC. It is upon reaching these temperatures that the alloy gains maximum resistance to intercrystalline corrosion.

At the third stage, the alloy is subjected to aging. To do this, it is aged for several days (usually 4 - 5 days) at a temperature of 18 - 20 ºC.

Upon completion of the above operations, the D16T alloy receives a hardness of 125 - 130 HB. This is the highest figure among the entire duralumin family.

Chemical composition

The chemical composition of each material has its own specific characteristics, which determine the physical and mechanical qualities.

The considered aluminum alloy D16T belongs to the Al-Cu-Mg group with manganese alloying. The chemical composition of the D16T alloy is characterized as follows:

- Most of the alloy is aluminum, the concentration of which reaches 94.7%.

- The rest of the mass comes from magnesium, copper and other various impurities.

- The inclusion of manganese in the composition significantly increases the corrosion resistance of the D16T alloy and increases some mechanical properties.

- The composition includes a small proportion of titanium and iron. The concentration of iron has a negative effect on the D16T alloy. This is due to the fact that such a chemical element does not dissolve in aluminum and creates inhomogeneous plates. The concentration of iron is maintained within strict limits, since a non-uniform structure can lead to serious problems.

Chemical composition of alloy D16T

Duralumin is produced with careful control of the concentration of all elements. An increase in the amount of iron in the composition leads to the fact that the metal becomes less homogeneous, due to which the quality decreases and other performance qualities deteriorate. Titanium and manganese must also be maintained within a certain concentration range, since too high and low levels can lead to changes in basic physical and mechanical properties.

Designations

| Name | Meaning |

| Designation GOST Cyrillic | D16 |

| Designation GOST Latin | D16 |

| Translit | D16 |

| By chemical elements | D16 |

| Name | Meaning |

| Designation GOST Cyrillic | 1160 |

| Designation GOST Latin | 1160 |

| Translit | 1160 |

| By chemical elements | 1160 |

Material properties

Alloy D16T, the characteristics of which can be called very attractive, has a huge number of advantages in comparison with other alloys.

The features of duralumin determine that this alloy is in many ways superior to conventional aluminum and other materials. The physical and mechanical properties are as follows:

- High structural stability. Due to this, manufactured products can last a long time and withstand significant environmental impacts.

- The density of the material determines its low specific gravity, the level of which is 2800 kg/m3. Due to this, the resulting products become light. That is why D16T has become widespread in the aircraft industry and in the manufacture of elements that are used in the manufacture of equipment for the space industry. In order for the device to be able to overcome the earth's gravity with less energy consumption, the created structure must have low weight. Studies indicate that D16T is 3 times lighter than steel.

- Increased resistance to microscopic deformation during operation. This is due to the fact that the elastic modulus has a fairly high value.

- The high tensile strength of D16T is achieved due to the inclusion of a huge amount of alloying elements, for example, titanium. At the same time, the hardness of the D16T alloy is 42 MPa.

Mechanical properties of alloy D16T at a certain temperature

Mechanical and physical properties of alloy D16T

In addition, the melting point of D16T duralumin is quite high. Due to this, it is possible to use the alloy to create various devices that can be operated under high air resistance. Too high a resistance causes the metal to heat up and become softer and more ductile. The high melting point made it possible to use duralumin in the manufacture of aircraft, since ordinary aluminum heats up and becomes soft and less durable.

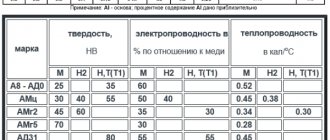

Grades of aluminum and aluminum alloys

For convenience, we will omit the word “grade” in the names of aluminum alloys, for example, “AD33 aluminum alloy” and not “AD33 grade aluminum alloy”. In my opinion, when naming alloys, the word “grade” seems completely unnecessary – the word “alloy” is completely sufficient.

To distinguish between different versions of pure aluminum, the term “aluminum grade” is used, for example, aluminum grade AD00. This is useful in this case because grades of aluminum are not by definition aluminum alloys.

In the standards of the CIS countries, three types of designations for grades of aluminum and aluminum alloys are used: traditional unsystematic alphanumeric and system digital, as well as international digital and chemical ones for existing international analogues. For example, for alloy D1 these are: D1, 1110, AlCu4MgSi and 2021.

Application area

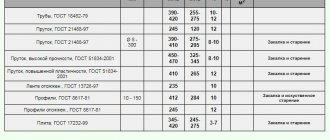

The wide range of applications of D16T is associated with its basic performance qualities. It is worth considering that difficulties arising during the production process significantly increase the cost of this alloy. Despite the spread of aluminum, duralumin is used only when required. Alloy D16T is available in the following types:

- Sheets.

- Corners.

- Rods.

- Plates.

Wheel spacers made of D16T alloy

Gas pipe cover made of D16T

It is worth considering that the alloy is extremely rarely supplied to the production site in its pure form. To improve basic performance qualities, chemical-thermal treatment is often carried out. Blanks are used to produce the following products:

- Sheathing elements.

- Frames.

- Tractions.

- Spars.

Release form:

- In its purest form. As previously noted, blanks in this form are rare.

- In a hardened or naturally aged state.

- After artificial aging.

- Clad.

- Burnt out.

Rivets made from the material in question have become very widespread. This is due to the fact that rivets made of D16T are characterized by a high shear resistance.

Heat treatment can significantly increase basic performance qualities. According to established standards, this kind of improvement makes it possible to increase the resistance of the metal to high temperatures. For example, fasteners can withstand temperatures from 120 to 230 degrees Celsius. The alloy is also used in the mechanical engineering sector to create a body.

Description

Alloy D16 is used : for the manufacture of power elements of aircraft structures, car bodies, pipes operating at temperatures up to +230 ° C; hot-pressed drill pipes of variable cross-section; profiles with a cross-sectional area of up to 200 cm2 and a circumscribed circle diameter of up to 350 mm, intended for use in the aviation industry and special branches of mechanical engineering; round drawn and rolled pipes for pipelines of transmission shafts and control rods of aircraft; pressed panels of constant cross-section with longitudinal fins for the aircraft industry, manufactured by unrolling pressed finned tubes into a plane with a web width of up to 2100 mm; pressed large-sized pipes.

Note

According to ISO 209−1, alloy grade D16 has the designations AlCuMg1 and 2024, alloy D16ch - 2124.

Moderately strong aluminum alloys

Aluminum alloys Al-Mg (5xxx series)

Not thermally hardenable.

Magnesium in an amount of up to 6% provides solid solution strengthening of the alloy and high efficiency of strain hardening. Therefore, alloys of the 5xxx series have fairly high strength properties. These alloys widely have good corrosion resistance, especially resistance to corrosion in seawater and marine atmosphere, and are therefore widely used in shipbuilding, mainly in the form of sheets. These alloys are used to make stamped car body and chassis parts due to their good combination of strength and formability.

Aluminum alloys Al-Mg-Si (6xxx series)

These alloys are sometimes (only here) called “avial”.

The strengthening phase is the Mg2Si compound.

Aluminum alloy AD31 is a complete analogue of the “American” alloy 6063 and, partially, the “European” alloy 6060. The ratio of the average silicon and magnesium content in it is close to the stoichiometric ratio of 1:1.73 for the Mg2Si compound.

- AD31 (6060/6063) is the most popular industrial aluminum alloy. Widely used for the manufacture of aluminum profiles for building enclosing structures (windows, doors, facades) and other, usually non-load-bearing structures.

- Aluminum alloy AD33 is an analogue of alloy 6061. It has a higher content of magnesium and silicon than AD31 (silicon in excess), as well as copper additives. More durable than AD31. Used in load-bearing building structures.

- Aluminum alloy AD35 is an analogue of alloy 6082. Compared to alloy AD33, there is almost the same amount of magnesium as in alloy AD33, and one and a half times more silicon and additionally up to 1% manganese. Therefore, the AD35 alloy is even more durable than AD33. Used in load-bearing building structures.