Despite the variety of technologies and the emergence of new building materials, asphalt chips continue to be in demand both among construction companies and private households. If anyone still has little idea of how to lay asphalt chips with their own hands without a roller, I am ready to educate everyone about the intricacies of the process. I propose to take a close look at the characteristics and areas of application of the material, as well as get acquainted with the laying technology as applied to summer cottages and garden plots.

Source vesta-teplij-pol.ru

Share

Asphalt crumbs: preparation and composition

Asphalt granulate is a recyclable material obtained by recycling old road surfaces. There are two production technologies:

- Worn road surfaces are cut off from the surface during road reconstruction using cold milling (layer-by-layer cutting of the road surface). The result is the so-called crumb from under the cutter.

- The second method: after dismantling, the material is crushed mechanically in a crushing and screening plant (crumb chips). The resulting mixture is scattered into fractions (large, medium, fine). This increases the homogeneity and further stability of the material.

Source ytimg.com

Share

The technological value of the material is determined by the presence of bitumen in it. It envelops the granules of the granular material, which improves the final characteristics of the granulate. The composition may include additions, for example, rubber or cement concrete crumbs.

The resulting asphalt crumb is a mixture of crushed stone, sand, gravel and bitumen; the proportions in each specific case depend on the composition of the original road surface. On average, the mixture contains:

- Sand: up to 50-60%.

- Crushed stone: from 25 to 45%.

- Bitumen: 3-7%. The small amount of bitumen is explained by the fact that during the operation of the road it is lost (during the warm period it melts and is squeezed out of the road surface).

- Sometimes concrete is present in the mixture as an additional binder.

Source samstroy.com

Share

Laying the covering

Now you can lay the asphalt chips. The bitumen included in the composition acts as the main binding element. The coating can be made double. After laying and compacting the first layer, bitumen is applied, and then a second layer of crumbs. The optimal thickness of the total layer of asphalt pavement is 20 cm. At the same time, it is worth considering that the path should rise slightly above the ground (3 - 4 cm of elevation is enough). In general, the process is quite expensive in both time and money. But once you have made the tracks, you can forget about it for many years. High-quality small asphalt chips can be ordered here.

Applying a layer of crumbs simply on the ground significantly reduces the cost of the entire process, but at the same time the service life is very noticeably reduced. This coating will crack very quickly.

| Road construction is considered an important but labor-intensive industry. To lay road belts, squares and sidewalks, it is necessary to use suitable building materials. Asphalt chips make asphalt paving cheaper landscaping is simplified thanks to the use of recycled building materials. |

Asphalt crumbs

also called asphalt concrete granulate, which is obtained by processing dismantled asphalt layers. The asphalt concrete residues removed by the cutter are processed at a crushing and screening plant. In addition to small particles coated with bitumen, a small percentage of impurities is allowed in the final product. Impurities enter the granulate during the grinding process of recycled materials.

Specifications

Before you lay asphalt chips on your site, it is important to ensure that you purchase the appropriate mixture. Although the product is obtained in a very simple way right at the repair site, its characteristics, and, therefore, the properties and quality of the future coating, can differ significantly. On average, the crumb size is 3-5 mm, but the following parameters vary widely:

- Weight. The weight of one cubic meter of crumb varies from one and a half to two tons. This is related to the percentage of cement content; the heaviest are small fractions of asphalt concrete.

- Bitumen concentration. It is important to know that the bitumen component in a mixture produced locally is always higher than in a mixture obtained after processing elsewhere.

- Application time . A mixture with a high content of binding components is recommended for use in the warm season. Raw materials with low bitumen content are not suitable for the production of a solid coating; it is used only to eliminate local defects. Or improved by adding bitumen.

Source yandex.net

Share

- Price. Granulate from a mill costs 20-25% more than a similar mixture from a crusher. The cost is affected by the size of the fraction, the presence (or absence) of additives, and the cost of delivery to the customer’s area of residence.

Types of asphalt crumbs

When crushing and milling asphalt, material of various dimensions is obtained.

When milling, fine-grained material is obtained. By adding bitumen, the astringent properties are improved. Delivery to the construction site is carried out immediately after production, in a heated, softened state. High temperature of the mixture promotes better setting.

Crushed crumbs are larger in size. It has worse water resistance and grip. A positive quality of the crushed mixture is its low price. Adhesion, water resistance and damage resistance can be increased by adding bitumen emulsion to the mixture.

Advantages and disadvantages

Asphalt granulate is a recyclable material and at the same time a resource, valuable for its practicality and low cost. By using this material, you reduce the burden on natural resources, and in addition you can count on the following benefits:

- High quality coverage. The bitumen holds the mixture particles together without additional processing, resulting in a coating that is strong enough for a home driveway.

- The technology for laying asphalt chips is simple; the mixture is softer and lighter compared to crushed stone. To arrange a small area (up to 100 square meters), the efforts of a couple of people and ordinary available tools (wheelbarrows, shovels, rakes for leveling) will be enough.

- Constructing a deck from recycled materials will save you time and money.

Source pinimg.com

Share

- Trouble-free operation. When installed correctly, the fabric is resistant to weather changes and can withstand daily use.

- Laying a path or platform can be done in any weather, regardless of temperature and humidity.

- The product has the following disadvantages that you should be aware of:

- Over time, due to climatic reasons, the coating changes color.

- The characteristics of the mixture are difficult to determine. Different types of asphalt pavement can be recycled, with different inclusions of sand and concrete fractions. For this reason, quality is often inconsistent, especially with material from the crusher.

- The mixture may contain substances hazardous to health remaining on the road surface from the time it was used (for example, residues of spilled oil, acid).

Source pikabu.ru

Share

Pros and cons of using asphalt chips

First, let's mention the environmental aspect of using asphalt chips. Many people, among those who will beautify their summer cottage and have children and animals in the family, are interested in whether asphalt crumbs are harmful. Despite the fact that it contains bitumen - a product of oil refining, which accordingly causes more harm to the environment than good, the use of crumbs on the farm is more environmentally friendly than in the case of asphalt of the same volumes.

According to the documentation, asphalt crumbs have a hazard class of 4, on a par with household waste such as old clothes and shoes.

Next, it’s worth talking about the advantages that caused such widespread use:

- Wide range of applications, covering most areas of human economic activity;

- Affordable price, which makes asphalt crumbs stand out against the background of crushed stone or gravel and, due to similar properties, has recommended the crumbs as a suitable replacement for them;

- Long service life when used in suitable conditions: secondary roads and short paths and sports complexes;

- Easy to install. To do this, it is not necessary to prepare the surface in advance, and rolling asphalt chips does not necessarily require the participation of special equipment; in order to save money, it can be done with the help of passing cars;

- High resistance to adverse weather conditions.

Disadvantages of asphalt chips, like any other material, exist:

- More harmful impact on the environment compared to crushed stone or sand;

- The need for periodic renewal of the canvas.

However, all the shortcomings are completely offset by its numerous positive qualities.

Area of use

Before compacting asphalt chips on your site, I advise you to choose the right places to lay them. Due to its low aesthetics and low environmental friendliness, the material is used to a limited extent in landscape design. However, it is quite suitable for arranging the space around a private house, and is used in the following cases:

- For arranging pedestrian paths with low loads.

- For the arrangement of car parks and technological sites.

- Instead of flooring in a non-residential basement.

- For arranging a sports ground.

- For arranging technical buildings, for example, a barn or garage.

Source ypcdn.com

Share

Why is it profitable for us?

Managers on our company’s website will help you find an alternative to road surfaces. Free consultation will lead the customer to the final decision. Why spend more money when laying asphalt chips in your dacha

will save time and money.

If there are pieces of old asphalt concrete left on the site, our team will mill and recycle them. The presence of secondary raw materials will further reduce the total cost of asphalt concrete granulate at the dacha.

We offer clients a package of services, which includes asphalt crumbling, delivery and installation

included in the total estimate.

You just need to first calculate the total area of asphalted roads

and sites. Our specialist will deal with this issue free of charge. The client will receive hard coating in a short time at low prices!

To call a measurer for free, contact us!

Once removed, worn-out road surfaces turn into recyclable materials. The crushed material is used in asphalt production, construction and landscape design. Its use reduces the burden on natural resources.

Calculation of the required quantity

To calculate the quantity, you need to know the area of the future coating and the thickness of the backfill layer. But here it is necessary to take into account that the material will be compacted, and its shrinkage will be different, depending on how the compaction will be carried out.

It is believed that in its finished form (for example, in finishing a path) the layer of asphalt chips is 10 cm. At the same time, the roller is capable of compacting the material by 10 cm. That is, it is initially necessary to pour a layer of the mixture 20 cm or 0.2 m thick.

The required purchase volume is calculated by multiplying the area with a given coefficient. For example, to get coverage on an area of 100 square meters, multiply 100 by 0.2 and get 20 cubic meters of mixture.

If the site is compacted not with a roller, but with a vibrating plate (or roller tool), the compaction will be less dense and less material will be required. Before laying asphalt chips with your own hands, the required amount is calculated with a coefficient of 0.15; for the site considered, 15 cubic meters will be required.

Source tvernews.ru

Share

KAMAZ holds 6-12 cubic meters, but, depending on the fraction, a cubic meter of granulate weighs from 1500 to 1900 kg. In order to arrange a yard and, in addition, fill up road potholes behind the gate, one car with a carrying capacity of 6 tons is enough. It is more profitable to order material from April to September, during the period of minimum prices, and from local suppliers, in order to reduce delivery costs.

Laying technology

For owners interested in how to properly lay asphalt chips near their home, I offer a proven procedure consisting of the following steps:

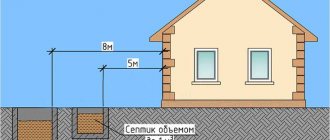

- The territory is marked taking into account the location of communications and vegetation.

- A layer of soil 20-30 cm thick is removed along the intended contour, geotextiles are laid on the bottom, and borders are placed along the edges.

- Asphalt crumbs are distributed around the perimeter and leveled with a rake.

Source samstroy.com

Share

- The surface is compacted until completely hardened. Narrow paths and small areas are compacted with a roller tool (hand roller). If the backfill area is large, it is convenient to rent a roller, which is often available from material suppliers.

- If desired, the surface can be additionally filled with molten bitumen, for which you will need a tin barrel, as well as protection in the form of tarpaulin mittens.

- An alternative method: compacted asphalt chips are melted with a gas torch and then rolled again.

- The surface will be ready for use in at least 24 hours.

Source pinimg.com

Share

Briefly about the main thing

Laying asphalt chips will help tidy up your garden area if saving money and time is important to you. The inexpensive material consists of recycled road surfaces and bitumen. Due to its ability to form a dense and durable coating, it is considered a practical alternative to crushed stone and sand.

The most important advantage of the material is its ease of installation; you can get a flat area or path using simple tools, without the help of professionals. The calculation of the required quantity is carried out taking into account the compaction method; In order for the fabric to be of high quality, geotextiles are placed in the base, and the surface is additionally filled with bitumen.

Question

Write in the comments what do you think, should a cushion of sand and crushed stone be made at the base of the asphalt chips?

Specification of building materials and their installation

Laying of asphalt concrete crumbs is done on a turnkey basis. This material is not used for high-traffic highways. It is relevant for:

- Site leveling;

- Preparing the road surface for subsequent asphalt paving;

- Pothole repair;

- Arrangement of temporary travel routes;

- Construction of roads of secondary importance;

- Laying road surfaces in areas with difficult climatic conditions.

A road made of asphalt chips cannot be absolutely smooth and resistant to heavy vehicles. For places with low traffic or for arranging the local area, a coverage of 100 mm is sufficient. The construction of temporary sites requires a thickness of 150 mm. 200 mm of asphalt chips are laid on local roads in order to save money. The cost of such material is from 640 rubles per 1 square meter. Such a road surface is several times cheaper than traditional asphalt paving.

The process of laying asphalt chips is quite simple. The building material is delivered to the site, dumped from a dump truck, leveled manually or using special equipment, and compacted with a roller. Due to the fact that it consists of elements of rubber trim and recycled asphalt, the material fits tightly. It will last up to 5 years. But provided that this is not a federal highway or a highway where heavy-tonnage transport paves the way. But for passenger vehicles this coating is safer. Due to the absence of a crushed stone base, it cannot fly off and damage the suspension or body of the vehicle. A non-specialist will not be able to visually distinguish crumbs from traditional asphalt.