The design of a gasoline blowtorch and its instructions must be studied very carefully, since this type of device is a fire hazard. Often during repairs or installation of any structure it is necessary to heat the surfaces for better assembly.

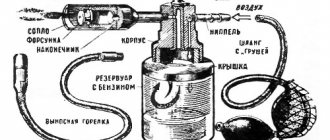

Blowtorch device.

The use of various portable gas burners or electric hair dryers is not widely used in the household. These industrial devices are difficult to use, so a blowtorch is used to quickly heat them up. But numerous questions about operation often come to specialists. This is due, first of all, to the fact that people are a little lazy to read the instructions to the end. The descriptions and instructions are quite boring and complicated. Therefore, it is necessary to describe the operation of the lamp in a simpler way.

Blowtorch - what is it?

Lighting the blowtorch.

The lamp is a heating device. It is filled with some substance that turns into a gaseous state during combustion. The emerging jet from the nozzle begins to draw in oxygen, resulting in a fire.

A blowtorch consists of two main parts: a reservoir and a burner. The installed burner is often called an ejector to carry out the movement of air and decaying products formed during the combustion process. The principle of operation is the traction created by its design. The product is poured into the tank as fuel, and then closed with a tight lid equipped with a seal. The same burner is attached to the top, which consists of some parts, with the help of which the whole process takes place. The operation of a blowtorch begins with manual action on the pump, which leads to the achievement of excess pressure. Under its influence, the available fuel begins to exit and enters the injector. During the passage through the tube, which is washed by the flame, the fuel begins to heat up and evaporate. This increases combustion efficiency.

Design and principle of operation

The main thing in any blowtorch is that it converts the latent chemical energy of various fuels into thermal energy. For the combustion reaction, predominantly liquid fuel is used - solid substances cannot be used, and there are still few gas models. In terms of design, blowtorches of 2021 differ little from their prototypes, which appeared back in the 1880s. It is advisable to use such technology in a wide variety of industries. It is also in demand in the domestic sphere.

It is worth noting that today blowtorches have competitors - gas burners and electric hair dryers. But gas can easily explode, and electricity is not available everywhere. Therefore, a convenient device that you can take with you and use even in the field will remain relevant for a long time. The lamp is designed quite simply. The fuel for its operation is accumulated in a special tank.

There is a special rod that prevents fluid from flowing through the pump when it should not flow. The fuel moves towards the burner under pressure. In a special compartment it is mixed with air and therefore flammable. Initially, liquid fuel is sprayed, but as the temperature rises, it completely transforms into gaseous form. The device also includes:

- jet for more efficient dosing;

- a shield that prevents wind from affecting the combustion process;

- radiator channels of the mixing device;

- neck (absent in simplified models);

- the calyx, where the initial heating occurs;

- the handle by which the device is held;

- ejector;

- a needle valve that provides dosage of fuel consumption;

- evaporator;

- nozzle;

- nozzle cleaning tool.

What do you use to fill a blowtorch?

Soldering iron tip temperature controller circuits.

A blowtorch can be refilled with alcohol, kerosene or gasoline. Gasoline blowtorches are widely used in everyday life. This combustion medium is much easier to find, and this type of fuel is economical.

As for the type of gasoline, there is still a lot of debate and speculation. Each specialist prefers his own type, which is divided into low-octane and high-octane. For short-term work, you can use special gasoline for a blowtorch. They are sold in any hardware stores. If you have to work with the lamp for a long time during repairs, then this brand of gasoline will entail significant financial costs. Therefore, ordinary people and frequent users of a gasoline lamp use plain gasoline for their cars. The main thing is to purchase high-quality and purified gasoline without any impurities. Because the slightest sediment in the liquid can lead to clogging of the tube and nozzle in the burner, and then the entire device will be out of working order.

To prevent such problems, use low octane gasoline. It contains virtually no impurities and is more suitable for working with a blowtorch. At the same time, the octane number is not so important; it does not in any way affect the ignition and temperature of the resulting flame.

Use of a gasoline blowtorch

Reworking the soldering iron tip.

A couple of decades ago, a blowtorch was used everywhere when it was necessary to heat a surface or metal. It was often used in production, because there was no replacement for it. Now, with modern technologies, alternative options have appeared, so the blowtorch has begun to be slightly replaced. But it is not always convenient to use modern technology. There are times when it is necessary to heat the material where there is no electricity, so you cannot use, for example, a pre-prepared electric hair dryer.

If it is not possible to use a burner in the cold in winter, then a blowtorch comes to the rescue. Almost every man on the farm still has a blowtorch from Soviet times, which is periodically used in the following cases:

- There is often a need to use a soldering iron, and this device is excellent for heating the soldering iron itself and the solder;

- if it is necessary to weld metals with heating temperatures up to 1000 degrees;

- melt metal at a heating temperature of up to 900 degrees;

- when it is necessary to remove old varnish from metal objects;

- for heating and thawing frozen water in pipes and sewers;

- in cold weather, car engines are warmed up using a blowtorch;

- sometimes you need to disassemble threaded connections that have rusted from age; a blowtorch is perfect for this job;

- When breeding livestock, this device is used to resin the skins of slaughtered animals.

Application [ edit | edit code ]

The blowtorch is used for:

- heating parts and melting solder during soldering,

- welding of some materials at temperatures up to 1000–1100 °C,

- soldering iron heating,

- heating varnish and paint coatings to remove them,

- warming frozen water pipes,

- tarring pork carcasses (burning out bristles),

- disinfection and disinsection of premises,

- cooking in camp conditions (with certain devices - in particular, a specially curved pipe),

- dismantling rusted connections of steel and cast iron pipes.

Gasoline blowtorch: technical characteristics

Tinning the soldering iron tip.

This useful tool for everyday life is produced in Russia by several manufacturers. They all have different dimensions and fuel consumption. Having analyzed the characteristics, we can highlight the following general parameters:

- the capacity of the tank is one of the main components of the overall presentation of the lamp, varies from 0.5 l to 2 l;

- despite the capacity, there is a set indicator for the maximum filling of the tank from 0.4 l to 1.5 l;

- almost all blowtorches have a maximum pressure during operation not exceeding 0.3 MPa;

- fuel consumption is also calculated, which does not exceed 1.2 l/h;

- the diameter of the tank depends on its capacity: the minimum parameter is 100 mm, the maximum is 145 mm;

- the weight of a gasoline blowtorch without fuel is from 1 kg to 2 kg;

- manufacturer's warranty – 1 year;

- The service life of any blowtorch is 5 years.

How to choose soldering equipment

When choosing a lamp, you should take into account four main criteria:

1. Design features of the device. A blowtorch, in addition to the main components (fuel tank, burner), can also have a hose, the length of which reaches up to 1.5 meters.

Such an “addition” will be an integral advantage of the equipment when carrying out suspended work.

2. Type of cylinder. There are blowtorches with a pierced cylinder without a valve and lamps with an attached valve. The first ones are used one-time without the possibility of adjusting the level of fire received at the exit. This is a blowtorch, the price of which is much lower (in the range of 300-650 rubles) than that of a lamp with a valve (the price can reach several thousand). This is the only advantage of the type under consideration. Equipment with an attached valve is much more practical, more economical, but, as you already understood, also more expensive.

3. Type of fuel used. It is worth considering here that lamps running on gasoline or kerosene will produce a flame whose temperature exceeds 1100 °C. There is also a gas blowtorch. The weight of such a lamp is insignificant, which makes it easy to operate it while carrying out work in weight.

4. Volume of the fuel tank. Considered an important technical characteristic. The operating time of the device depends on this indicator. If the work is designed for 60 minutes and a gasoline or kerosene lamp is used, its fuel tank must have a volume of 1 liter or more. If you are using a gas blowtorch, a volume of 0.1 liters will be sufficient. It is also worth noting that a gas lamp is cheaper to maintain, but in some technical characteristics it may still be inferior to its competitors.

An analysis of demand in the construction materials market shows that gasoline blowtorches are still in greatest demand.

Blowtorch: instructions

Having understood all the features and types of blowtorches and opted for a gasoline blowtorch, we get to work.

Before starting work, it is worth stipulating one important rule in operation - work with this tool should only take place outdoors. If there is an urgent need, then short-term operation of the device indoors is allowed, but with good ventilation.

The following instructions follow:

There are three types of blowtorches: kerosene, gasoline, and alcohol.

- Before starting work, it is necessary to fill the tank with a substance in the form of low-octane gasoline in a volume that will not exceed ¾ of the entire tank. The empty part is necessary to obtain the pressure required for operation.

- Excessive pressure is obtained only after manual pumping in the amount of 6-10 pieces. They must be carried out with gentle movements.

- Next, fuel is poured into the burner bath. It can be used in the same way that was poured into the tank - the same gasoline. Ideally, of course, use ethyl alcohol, which will not leave soot when burned. The filled fuel is ignited to achieve initial heating of the evaporator. Here the condition is met: at the moment of igniting the fuel in the bath, the lamp is installed so that it is not exposed to drafts and wind.

- After the fuel in the bath has stopped burning, it is necessary to open the shut-off needle. Next they look at the condition: if there are jets of steam produced by heating, light the torch. If you observe liquid after warming up, it should be repeated. Accurate determination of when to open the locking needle comes with experience. After several uses, you will definitely open the needle, and re-warming will not be required, which will significantly reduce the time.

- The fuel supply can be increased over time if necessary. Here they are guided by heating the evaporator. To further speed up the fuel heating process, the tool can be placed next to a metal object with the nozzle to the surface at a distance of 2-3 cm.

- When starting work and further, adjust the size of the torch yourself. This is done with a locking needle. If the torch goes out, is uneven, or has other operational defects, you should stop working and thoroughly clean the nozzle with a special needle designed for cleaning.

- Completion of work is carried out by extinguishing the lamp. This is done by closing the needle. Once the lamp has cooled, you can open the tank to release the pressure.

But working with this device is not so simple. Here you should take precautions that are often neglected.

Precautionary measures

Installation of a preheater blowtorch.

Not all users of a gasoline blowtorch are careful when using them. But it could simply explode. The thing is that the lamp is rightfully considered a fire hazardous device. Its tank, which contains a flammable liquid, is located too close to the burning torch.

Therefore, when working with a blowtorch, you must observe the following rules that prohibit:

- continue to use the device if you detect a leak of fuel or vapors generated during combustion;

- deviate from the rules and use prohibited fuel: any blowtorch requires the use of only established and permitted fuel;

- use a blowtorch for a long time, because the tank heats up to 50 degrees - the maximum norm established by the manufacturer;

- operate the device if there is a malfunction of the safety valve;

- open or refill the lamp while the torch is burning, here you should close the shut-off needle and wait for the blowtorch to cool completely; it is the opening of a hot lamp that leads to an explosion, which has dire consequences;

- operate indoors or without proper ventilation.

These simple safety rules will help you achieve efficient operation when using a blowtorch.

Safety precautions [ edit | edit code ]

In addition to the obvious fire hazard, a blowtorch is a potentially explosive device, since the tank contains a mixture of fuel vapor and air under high pressure, and the tank heats up during operation. Therefore, when using a blowtorch, strict adherence to safety rules is required, namely:

- do not allow the tank to heat up to a temperature above 50 °C;

- do not open the tank lid and do not refill while the lamp is running or has not yet cooled down;

- do not create excess pressure in the lamp, do not use gasoline in a lamp intended for the use of kerosene;

- monitor the tightness of the pump valves and connections;

- During transportation and storage, make sure that there is no excess pressure and no fuel residues in the tank.

The most common cause of a blowtorch explosion is the opening of the hot torch reservoir lid. In this case, gasoline vapors come into contact with a burner heated to 500-600 °C and ignite, causing an explosion of the steam-air mixture in and around the tank. You also need to take into account that the old lamps used kerosene; when filling with gasoline and subsequent use, the tank burst under pressure. Burns in this case are almost inevitable, since they usually occur when trying to “pump up”

Reviews about working with a blowtorch

On the Internet and other sources you can find numerous reviews about the convenient operation of this device.

But there are also those people who, after purchasing a lamp, begin to complain about the inconsistencies specified in the instructions.

You can often see two complaints that occupy the first positions among all negative reviews. These include:

- Inconsistency with the service life specified by the manufacturer. For many users, within a couple of months after starting to work with the device, the tube and nozzle become clogged. With a detailed consideration of the issue and the intervention of specialists, an explanation for such complaints is found. It turns out that not everyone read the instructions for using this device. And of course, most do not follow the rules for selecting fuel for a lamp. That is, when using motor gasoline, users do not pay attention to the composition and quality of the fuel. But the use of high-octane gasoline can lead to similar problems.

- Metal whose heating temperature does not exceed 1000 degrees does not heat up. There are two options for incorrect operation. Firstly, the user simply cannot withstand the required amount of time for heating. Secondly, without understanding the characteristics of the heated metal, it tries to heat an object with a heating temperature of more than 1000 degrees.

According to experts, anyone who does not have initial skills can use a blowtorch.