Choosing a filter for a welder's mask

The work of a welder involves health risks.

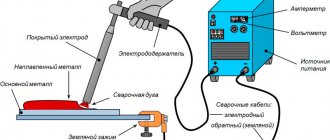

When a welding arc occurs, the worker’s skin and eyes are exposed to infrared and ultraviolet radiation, heat, and may also be damaged by specks of molten metal. A protective helmet protects the worker’s face from mechanical impact, and light filters on the welding mask reduce the effect of radiation on the eyes to zero. Manufacturers produce different welding glasses, whose classification is determined by many factors, for example, the equipment used for work. One thing is certain: the choice of a light filter for a welding helmet directly depends on the degree of darkness of the glass.

Types of glass

There are three main types of glasses for welding helmets on the welding equipment market:

- With constant or constant darkness.

- With variable dimming (they are called chameleons).

- Magnifying glasses with diopters.

Glass with constant darkness

The darkening of permanent filters is created by adding copper and nickel metals to the product. Most often they are used in gas and electric arc welding machines. If the current changes frequently during work, the welder needs to quickly select the right filter. This is inconvenient because it takes time and wastes the master’s energy. In addition, nothing is visible through such a filter until welding begins. These are the disadvantages of such glass. But they are distinguished by their durability and affordable price.

Variable dimming filters

Chameleon light filters for welding helmets are much more convenient and functional. Representing a liquid crystal screen, they are able to reduce the transmission of light due to the fact that the particles alternate the sequence of their arrangement. In addition to several LCD screens, the glass kit includes an infrared and ultraviolet protection screen and a polymer designed to protect against metal drops.

During welding, the chameleon mask allows you to see the surrounding space, which greatly simplifies the work process. Unlike permanently darkened glass, chameleons are more expensive because they are a complex device.

Magnifying glasses

In fact, diopter lenses are additional equipment. They serve to enlarge the image and are installed between darkening filters. Convenient for craftsmen with low vision or when working with sheets of thin metal.

Marking of filters

The filter markings indicate the following characteristics:

- Degree of darkness.

- Optical glass type.

- Light scattering indicator.

- Uniformity of shading.

- Angular dependence.

Darkness level

The main parameter by which glass is selected for certain jobs. Modern filters may use Russian or foreign markings, depending on the manufacturer. Domestic designations range from C1 to C13, but most often glasses with markers from C4 to C8 are used for welding masks.

| Glass class | Error indicator |

| 1 | 0.1 DIN |

| 2 | 0.2 DIN |

| 3 | 0.3 DIN |

European samples are marked from 7 to 16 DIN, although it is more likely to use filters with a rating from 8 to 14 DIN. The degree of shading is better for glasses with a larger number in the marking.

Filter dimming range

The parameter is selected depending on the type of welding. Any Chameleon protective mask is suitable for MMA. Even for professional use, a range of 9-13 DIN is sufficient. To work with semi-automatic or argon-arc TIG machines, the ideal filter is one that will work in the dimming range of 5-9 DIN.

For convenience, it is better to choose a model with manual adjustment in order to adjust the operation of the light filter to the current welding process.

Of all the possible options, combined solutions are considered the best - masks with two dimming ranges:

- 4-8 DIN – suitable for welding work in TIG welding mode and manual arc welding in poor lighting conditions.

- 8-13 DIN - used in good lighting at high currents.

To set up a light filter for a welding helmet, use the table:

| Welding process / Current, A | 5 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 |

| MMA | 8 | 8 | 8 | 9 | 9 | 10 | 10 | 10 | 11 | 11 | 11 |

| MIG-MAG | 8 | 8 | 8 | 9 | 9 | 10 | 10 | 10 | 11 | 11 | 11 |

| TIG | 5 | 8 | 9 | 9 | 10 | 10 | 11 | 11 | 11 | 11 | 12 |

| PLASMA CUTTING | 9 | 9 | 9 | 9 | 9 | 9 | 10 | 11 | 11 | 12 | 12 |

Usually you can find out about the degree of darkening only in the equipment passport. For ease of selection, FUBAG welding helmets are marked accordingly in the name. This helps to quickly identify the model with the desired parameter.

The FUBAG product range includes all possible options. For example, OPTIMA 9-13 with adjustable shade level in the range of 9-13 DIN is suitable for MMA and MIG-MAG welding. If you are also planning argon arc welding, the Ultima 5-13 Visor will be an excellent choice.

Conformity table between Russian and foreign markings of light filters

| Russian classification | Foreign classification |

| C4 | 9 DIN |

| C4 – C5 | 10 DIN |

| C5 | 11 DIN |

| C6 – C7 | 12 DIN |

| C8 | 13 DIN |

Optical glass type

After the darkness marker on the glass, 4 numbers are indicated separated by a slash. The first number refers to the classification of the filter according to its optical characteristics. It indicates how clearly objects are visible: 1 – no distortion, 2 – average distortion, 3 – periodic distortion of visibility.

The degree of curvature depends on the materials used to make the product.

Light scattering index

Depends on the quality of the liquid crystals that are used for automatic dimming. The faster they react to changes in current during welding and change their position, the clearer the image will be. Just like with an optical characteristic, clarity has 3 degrees, the first of which indicates the clearest image possible, the second - a slight blur, and the third - the periodic occurrence of blurred areas.

Shading Uniformity

Because classic filters contain mixtures of metals, the bonding may be uneven during their manufacture. This will result in less darkness in some areas and more in others. The numerical designation of this classification indicates the maximum error rate.

Angular dependence

The welding flash hits the filter at a certain angle. This parameter specifies the degree of darkness depending on the reflection angle. The higher the number, the weaker the protection is. This parameter has three designations from 1 to 3.

Additional markings

You should be aware that some manufacturers indicate additional parameters in the labeling of light filters.

G – designation for gas welding: 1 – low power; 2 – average; 3 – high.

D – work at blast furnaces.

P – industrial production at rolling mills.

B – for work in open spaces.

U – increased strength.

How are glasses for welding helmets classified?

The production of welding helmet glasses, as mentioned in the above information, is carried out under strict controls. The classification of their quality is determined by four different parameters, the markings of which are placed on the front of the body of any welding helmet.

The marking includes four different numbers written through a fraction symbol. Each position can take values in the range from 1 to 3. One is the best parameter, three is the worst. If the quality of a certain characteristic is worse than the third indicator, such glass is considered to be of poor quality and is not put on free sale.

The order of the numbers is always specific, since each value denotes a specific characteristic.

- The first position indicates the optical class of the product. This parameter determines the quality of the “picture” obtained through the glass of the welding helmet. The value of this parameter is determined by the quality of the film that is used in the glass creation process, as well as the quality of the raw materials for production.

- The second position indicates the degree of light scattering. This value is determined by the purity of the liquid crystals, thanks to which the function of automatically adjusting the degree of darkness becomes feasible. The purity of the crystals affects the haze of the image obtained through the glass. Therefore, one indicates that the image is as clear as possible, three indicates that it is fuzzy.

- The third position indicates the homogeneity of the welding glass. In simple terms, this parameter determines the evenness of the shading over the entire area of the glass. The fact is that the arrangement of crystals in the structure of the mask may be uneven, therefore, the level of darkness at a certain point of the glass may be greater than at another.

- The last number indicates the angular dependence of the welding glass. It indicates the angle at which the bright light from the arc of the welding machine hits the light sensors. That is, simply put, the parameter talks about the speed of the sensors’ response to light, depending on the angle at which they hit them.

Marking of welding glasses

As you can understand, a product with the maximum level of quality should have four units in its marking. In addition to the main characteristics, the model names may contain various additional abbreviations indicating a specific parameter:

- U – the body of the product has increased strength due to the use of mineral substances in the production process of welding glass;

- G1 – the main purpose of the mask is to use it in the gas welding process;

- G2 - the main purpose of the mask is to use it exclusively for medium-power gas welding;

- G3 - similar to the previous parameters, except that welding work takes place at the maximum possible power;

- D1 – glass can be used near furnaces, in forges and near rolling machines;

- D2 – glass is used exclusively near furnaces;

- D3 – glass is used near blast furnaces and glass furnaces;

- P1 – the mask is used when working near forges, heating furnaces, as well as near rolling machines;

- P2 – glass can withstand prolonged exposure to high temperatures up to 1200 degrees Celsius;

- P3 - similar to the previous parameter, with the exception of an increased limit of 1500 degrees Celsius;

- B1 – welding helmet is used in open areas during the construction process;

- B2 - welding helmet is used in open areas during the process of electric or gas welding.

In order to greatly simplify the repair of welding helmets, most manufacturers produce them with the same overall dimensions of the groove for glass. This allows you to simply replace the glass if it fails. Most often, chameleon type glass has the following dimensions: 110x90x9 (length, width and thickness, respectively).

Selecting a filter

Before purchasing protective equipment for welding, you need to determine exactly what the choice of a light filter depends on. The characteristics listed above can help you purchase a good, high-quality product that will protect the technician’s eyesight and face, as well as make his work easier.

When choosing welding glass, you need to pay attention to the following issues:

- Filter sizes. It is important to select a product that fits the size of the welder’s shield or mask, otherwise there is a risk of encountering problems before work begins.

- Filter type: permanent or automatic dimming. It may depend on the goals pursued by the master, for example, to use equipment for the same work. In this case, it is enough to purchase glass with a permanent darkening of one reading. If frequent welding and changes in current strength are expected, it is better to opt for automatic chameleon masks. They allow you to adjust the degree and speed of darkness, and through them you can clearly see the surrounding space.

- Dimming response speed. An important parameter that allows you to maintain eye health. If the speed is not satisfactory for some reason, it is most likely due to a malfunction of the mask or its improper use. You should read the instructions or replace the filter with a working one.

- The presence or absence of additional protection. Additional protection on the filters is provided by a polymer film that improves visual characteristics and protects the mask from impacts of small solid particles.

Selecting automatic filters

Protective welding glasses have been produced for decades. Generations of welders have used these and were happy with them, welding the hulls of spaceships and nuclear submarines. Modern glasses are more advanced and much more convenient to use.

However, professionals choose masks with automatic light filters. The possibilities of this equipment are great, the advantages are undeniable.

The automatic light filter is securely fixed on the mask. Fastening is done simply with a screwdriver and 2 screws. The energy source is solar or conventional batteries, which are always commercially available. Models with two types of batteries built into one mask are popular. The presence of 3 regulators greatly simplifies control.

On the outside of the mask or at the top left of the filter itself there is a dimming intensity control. The second regulator can set the required sensitivity - the value of the intensity of the rays from which the dimming will begin.

For working outside on a sunny day, you can choose one indicator, for night welding - another. The third knob allows you to set the time after which the darkening will begin.

The combination of all the capabilities of the automatic light filter provides convenient conditions for safe work.

To successfully select a model, you need to evaluate all potential loads and possible types of work; Check the welder's vision level.

Safety glasses should be comfortable. Incorrectly chosen parameters of darkness and dioptres can provoke a gradual deterioration of vision; lead to a violation of welding technology, in the worst case – cause damage to the retina and cornea of the eyes.

Possible malfunctions and ways to eliminate them

An automatic light filter for a welding helmet is a complex invention, and sometimes malfunctions may occur in its operation. Some can be fixed with professional repairs, while others can be fixed on your own.

| Malfunction | How to fix |

| Dimming occurs unevenly | Correct the distance between the glass and the eyes |

| Flickering, poor dimming | Clean the filter or replace it with a new one |

| Response is delayed | Move work to a room where the temperature is above -5 ° |

| Blur | Clean the filter, adjust the lighting, adjust the settings correctly |

Having knowledge about choosing a good and high-quality light filter, you can safely go to the store and buy a product that meets your needs.

Types of glass

A light filter for a welding helmet protects human eyes from thermal, infrared, ultraviolet radiation and splashes of molten metal.

When welding, cheap filters with a fixed degree of darkness (colored glass), expensive automatic filters for a welding mask (popularly called a chameleon) and polymer materials are used.

Tinted glass. To reduce light transmittance, impurities of non-ferrous metals (copper and nickel) are added to the material. Its light transmittance depends on the content of impurities in glass.

There are Russian and international markings for the degree of darkness. The domestic classification is marked from C4 to C8, which corresponds to the European 9-13 DIN. The table (below) will help you understand the correspondence of markings.

Glass Chameleon. Automatic windows use a liquid crystal screen. Liquid crystals change the construction sequence when the light voltage changes, thereby achieving different darkening. Modern filters have from 1 to 3 layers of LCD glass.

Polymer materials. They have high ductility and darkening ability.

Welding masks use combined materials, polymer film for protection against mechanical damage, and glass. Which, if necessary, are easily replaced.

Video:

Differences in glass darkness

The domestic industry supplies the market with light filters for welding marked C4-C8, corresponding to the European classification 9-13 DIN. Light-tinted glass C4 and C8 have no external differences. But C4 has less protection.

When choosing (purchasing), you can check the filter for counterfeit using a fluorescent lamp. Through glass C4 the filament of the light bulb will be clearly visible, but through glass C8 it will be difficult to see. If there are no differences, then it is better to refuse the purchase.

Pros advise having 2-3 filters with different protection for a welder’s mask. Then during welding work you can choose the best option.

The table (below) will help you select the degree of darkening of welding filters depending on the welding current and type of welding.

The table shows the recommended values. Depending on the weld, you can choose a shade that is one number less or more.

Sometimes, glass for electric welding marked E.1-E.5 comes on sale.

Chameleon light filter for welding helmet

Automatic liquid crystal filters have advantages over their fixed counterparts. Extensive settings adjust the dimming to any brightness and arc diameter.

Chameleon has several layers of crystals located in layers of polymer protection, a power supply and control unit, and arc detection sensors.

An automatic light filter is not a complicated device:

- the device is attached to the mask with two screws;

- Powered by a solar panel and replaceable batteries;

- has 3 control devices:

- Shade control 5-13 DIN and 9-13 DIN. The location is external (on the left side of the mask) or internal (on the filter itself).

- sensitivity (moment of automatic dimming) is adjusted depending on the time of day (day, night).

- dimming time adjustment (long, medium and short).

Video:

Malfunctions of automatic light filters and solutions

- Uneven dimming. Adjust the distance between the glass and your eyes.

- The filter flickers or dims poorly. The protective glass is dirty or damaged (clean, replace). At low current, set the switch to the “Long” position (slow).

- Low sensitivity. It's getting colder outside, the thermometer is less than -5°.

- Bad visibility. Dirty protection glass. Bad light. Incorrect dimming level setting.

Video:

For your home, you shouldn’t buy a welder’s mask with an automatic light filter from a well-known brand. It’s stupid to pay 15-40 thousand rubles for a model that you will have to use a couple of times a year.

It’s better to buy a Chinese model (good), prices start at 3 thousand rubles. Well-known manufacturers are TECMEN (Tekmen) and Resanta.

Filter switching speed

When choosing a welder's mask, you need to take into account one more parameter - the speed of switching the light filter. The higher it is, the less chance of catching “bunnies” during a flash of fire from a welding arc. If you frequently use welding, it is better to take care of your eye health and focus on this parameter.

Automatic filter lightening speed

The switching speed should not be confused with the brightening speed. Unlike the first, clarification should not occur immediately after the arc fades, but with some delay. It is worth making sure that the welder’s mask has the ability to adjust the delay in filter brightening.

Setting the filter sensitivity

Sensitivity allows you to adjust the response of the mask to the surrounding conditions. Adjustment is present on most modern filters, but, like other parameters, it cannot be ignored. By adjusting this parameter, you can eliminate the possibility of accidental activation of the filter in bright sunlight and at the same time improve work in a room with a clear lack of light.

It’s worth adopting – the adjustment can be smooth or stepwise. Choose a smooth setting, otherwise you will quickly get tired due to sudden changes (darkening/lightening).

Chameleon welding mask sensors

Most often, welding helmet models are equipped with 2 or 4 sensors. In most cases, 2 is enough to ensure normal functionality of the equipment. However, 4 sensors benefit if you have to work in conditions where fences, objects or structures can block the glow of the arc.

Filter power supply

When choosing a welding mask, you should not lose sight of less obvious details than a light filter. Its power system can operate from solar panels or built-in lithium batteries. It is preferable that both types are present in the mask. Thus, replaceable batteries will protect you in difficult situations, preventing unpleasant “surprises”.

Grinding function

One of the useful, but not required functions. Thanks to the ability to set the sensitivity to a minimum and turn off the sensors, you can use a mask for protection while cleaning seams with an angle grinder.

A few words about the ergonomics of a welding helmet

We've sorted out the parameters and functions. Now let's pay a little attention to the design itself. Be sure to evaluate the weight of the mask, comfortable fit and reliability of the latches. The weight of the masks varies from 0.5 to 2 kg. The larger it is, the more difficult it is to work under long loads. Adjustable coverage and a headband with an insert made of soft material will help ensure comfort. Many novice welders and professionals will be attracted by the increased size of the screen (viewing window). The larger the visibility area, the better the contact with the work area and the easier the welding process is controlled.

For frequent adjustments, models with external adjustment are suitable.

Useful care tips

Choose the optimal parameters “for yourself”, including functions and ergonomic features. Don't forget that manufacturers often offer chameleon welding helmets in different colors. Well, to ensure that the mask lasts as long as possible, follow the care recommendations below:

- Take care of the light filter - it is damaged by mechanical impact. To wipe it, use a clean soft cloth. Always choose water as your liquid. Never wipe the filter with alcohol-containing products or solvents. This will damage the special film that covers the filter, which will lead to partial malfunction or complete failure.

- When buying a mask, immediately pay attention to the additional protective glass. They are consumables for welding masks. If there is a large amount of work, there should be plenty of them.

- Use chameleon welder mask filters carefully in low temperatures. Due to the design features, they can operate with a delay, which will make welding not just difficult, but even impossible.

Types of filters by purpose

Different types of welding differ in the type and intensity of radiation. In addition to the main worker, an assistant is often involved in the process, who is also in close proximity to the arc and burning gas. Depending on the type of work performed, glass for a welder’s mask is divided into types:

- electric welding and electric gas welding, E1 – E5,

- gas welding and gas cutting, G1 – G3,

- for auxiliary workers, B1 - B3.

For the chameleon mask, the filters are designated C3 – C8. They are used for different types of welding.

Protective glasses can be inserted with masks, goggles and visors . Goggles can only be used when welding with gas; they do not protect the face from burns. You have to hold the shield with one hand, which limits the ability to work intensively.

Additional designations

Particularly punctual manufacturers sometimes indicate additional information in addition to the basic information on welding glasses. This marking contains letters and numbers:

- U is the first letter of the word “hardened”. If there is such a letter on the welding glasses, then they will withstand the mechanical impact of solid particles flying with an energy of up to 0.6 J;

- G-1 designates glass for both welders and his assistants when performing electric welding in open spaces;

- G-2 is written on products for gas welders when working at medium power;

- G-3 informs about the purpose of glass for welders performing powerful welding;

- The letter D denotes glass for blast furnace workers. But this is a separate topic.

- P denotes products for rolling mill workers;

- B - 1 says that the glasses are intended for auxiliary work not related to welding, which is performed in bright sun;

- B-2 says that welding glasses are used for auxiliary work in all types of welding, performed both on the street and in the workshop.

Taking into account all the information provided, and having received additional advice from a representative of the manufacturer or supplier, you can wisely select the necessary protective glasses.

Why use filters

It is enough to look at a burning incandescent light bulb for a few seconds, and its shape will be reflected on the retina. When a person looks away, he still sees this spiral everywhere for a long time. Hot molten metal glows and emits more eye-irritating rays than an incandescent light bulb. As a result, the cornea and lens are damaged. They suffer severe burns, which over time can lead to blindness.

Using a welding filter allows you to preserve your vision and see the most necessary elements of welding.

Based on the darkening intensity, light filters are divided into several types. For masks, the classification and designation according to GOST R 12.4.238-2007 SSBT is used, in the domestic marking C4 - C8 for electric arc welding. The international designation is written DIN 7 - 12.

Types of light filters for electric welding

The first protective means for the organs of vision were dark glasses that did not transmit light. With the development of technology, convenient light filters have appeared that can change the degree of darkness depending on the radiation.

Each type has its own characteristics with positive qualities and disadvantages.

With constant

Nickel or copper is added to glass during its manufacture. They significantly reduce the amount of ultraviolet and infrared rays, reflecting them like a mirror .

You can choose the right glass based on the work to be done, markings and shading coefficient. In addition, you need to know exactly the fit size on the mask. Because glass has different sizes.

Important! The inconvenience of use is that the glass filter has to be constantly rearranged when changing the size and power of the arc, for example, welding a seam in several levels with electrodes of different diameters.

With replaceable

Polymer films can be inserted into light filters, and they change their darkening depending on the brightness of the light falling on the surface . According to this principle, glasses for everyday use, nicknamed Chameleon, are created. The disadvantage of polymer filters is their response time. When welding begins, the first rays may enter the eyes.

Such filters are additionally equipped with a polarizing protective layer that cuts off UV and IR radiation.

Polymer filters with replaceable shading are convenient for use in gas welding and cutting, where the metal gradually melts.

Diopter lenses

Diopter lenses are installed on masks, but are not independent filters. They are used as a magnifying glass when working with small parts . If a welder has poor eyesight, he should choose glass with the appropriate diopters to constantly use, since wearing ordinary glasses under a mask is problematic.

For the chameleon mask

The light filter for the chameleon mask is an electronic mechanism powered by a power supply . The main filter element is liquid crystal film. When light hits it, the crystals change their polarization and do not allow certain rays to pass through. The activity of liquid crystals depends on the strength of the current supplied to the film.

The quality of the light filter in a chameleon mask can depend on many factors. The liquid crystal base is sensitive:

- to temperature changes,

- long-term non-use,

- vibrations,

- dynamic loads,

- cleanliness of the outer glass.

The choice of mask depends on the type of work performed. Transparency adjustment is made within a certain range. The degree of protection is determined by the number of films in the filter, which can be from 1 to 3 pieces.

The filter is charged from a replaceable lithium battery or a built-in solar panel located on the front side of the mask above the glass.

The main advantage of the “chameleon” filter is that you don’t need to remove the mask to see the welding site and remove the slag. It becomes transparent in the absence of bright radiation.

Welding helmets “chameleon”: operating principle and main parameters

Welding helmets “chameleon”: operating principle and main parameters

Recently, “chameleon” type welding helmets with an automatic light filter have become especially popular among professionals and amateurs. They not only provide the necessary protection for the face and neck from drops of molten metal and reliably protect the eyes from harmful ultraviolet and infrared radiation, but also make the welding process as comfortable as possible. If it is possible to adjust the basic parameters, such a mask is suitable for most welding technologies, and also allows you to perform related work, for example, grinding seams. How does a “chameleon” welding helmet work and what characteristics should you pay special attention to when choosing?

Design and principle of operation of the “chameleon” welding helmet

The main feature of “chameleon” masks is the presence of an automatic light filter, which, when the welding arc is ignited, almost instantly goes into a dark state, and after it fades, it becomes transparent again. It is a rather complex electro-optical device with a multilayer structure, each component of which performs a specific function.

External protective glass protects the remaining layers from mechanical damage, polarizing films protect against glare, special UV and IR filters block radiation harmful to the eyes, liquid crystal cells change the degree of dimming, and photocells react to changes in illumination. The operation of the light filter is controlled by a miniature electronic unit, powered by a built-in battery, which in turn is charged by solar panels.

Even if the battery is completely dead, the power is turned off manually or there is a malfunction, the chameleon filter protects your eyes well thanks to its built-in filters. So even if it suddenly does not work, the welder does not risk getting a corneal burn. At the same time, you shouldn’t constantly use a mask in this state - you might end up catching “bunnies.” In addition, it will simply be uncomfortable to work.

In normal operation, darkening when the arc is ignited is provided by liquid crystals, which, when voltage is applied, are arranged in a certain order, blocking light. The signal for power supply is a sensor based on photocells, triggered by a bright flash, located in the front part of the filter. Modern masks use multiple liquid crystal layers to provide the required degree of darkness regardless of the angle at which the light hits the filter.

Basic parameters of a chameleon-type welding helmet

When choosing a welding helmet for certain types or conditions of welding, you should pay special attention to a number of basic characteristics, which are described in detail below. However, first of all, you need to make sure that the data provided by the manufacturer is reliable. This can only be guaranteed if the manufacturer has a TR CU 019/2011 certificate “On the safety of personal protective equipment.” Naturally, it is better to buy a mask not at the market, but at official retail outlets, even if it is a little more expensive there. But in this case there is much less chance of purchasing a fake.

Optical class of the light filter ( optical class, light scattering, homogeneity, angular dependence of the degree of darkening ). In fact, these are four different indicators, but most often they are considered as a set and are designated simply as “optical class of the filter,” which does not interfere with the desire to determine the quality of the mask according to individual criteria. The optical class in accordance with the EN379 standard must be indicated on the surface of the mask filter in the format x/x/x/x (optical class/light scattering/homogeneity/angular dependence of the degree of darkness) or x/x/x (optical class/light scattering/homogeneity ), where x can take values 1, 2 or 3. The lower the number, the higher the class of the individual indicator and the optical properties of the filter as a whole. Accordingly, on the best masks the designation looks like 1/1/1/1 or 1/1/1.

Optical class (as a separate indicator) characterizes the quality of glass manufacturing and filter assembly. The higher it is, the less optical distortion of the object observed through the viewing window of the mask. Light scattering is responsible for the ability of liquid crystal cells to transmit light through themselves without deflection. The higher the light scattering, the higher the transparency of the filter. Homogeneity determines the uniformity of darkening of the filter in different areas. For the first class the difference should not exceed ±0.1 DIN. The angular dependence of the degree of darkening, in turn, characterizes the change in the degree of darkening depending on the angle of the viewing window to the working surface. While working in masks, all parameters of which correspond to class 1, the eyes get tired significantly less than when using protective equipment with individual indicators of class 2 or 3, since they do not have to compensate for the shortcomings of the optics.

Speed of operation (switching on) of the light filter/dimming time . This parameter indicates the reaction speed of the filter. In fact, this is the time period during which it goes from a transparent state to a darkened state after ignition of the arc. The minimum acceptable darkening time is 1-2 milliseconds (0.001-0.002 s). However, even modern amateur “chameleons” switch in 0.1 milliseconds (0.0001 s or 100 μs), and professional ones even faster - in 0.05 ms (0.00005 s or 50 μs). Darkening time is of particular importance when performing spot welding, which involves frequent arc ignition for short periods of time.

Speed of operation (turning off) of the light filter / time to turn off the dimming . The opposite parameter to the previous one, indicating the time of transition from a darkened state to a transparent one. Usually in “chameleons” it is adjusted in the range of 0.2-0.8 s, allowing you to adapt to a specific type of work. Such a long period compared to the darkening time is explained by the fact that after the arc dies out, the highly heated metal continues to glow quite brightly for some time.

Darkening degree. This indicator determines the degree of eye protection from harmful radiation. Indicated for both the transparent state of the filter (usually 4 DIN) and the dark state (11-13 DIN). In many professional chameleon masks, the shade level is adjustable from 9 to 13, and sometimes from 5 to 13 DIN. This allows you to adjust the “transparency” as desired for different welding technologies and conditions, making the mask universal.

Trigger sensitivity. Determines the response of sensors to radiation of varying intensities. If the sensitivity is too high, darkening may occur from sun glare, and if the sensitivity is low, switching does not occur even with gas welding or arc welding at low currents. Most chameleon masks provide smooth sensitivity adjustment.

When choosing a “chameleon” type welding helmet, along with the above main parameters and their adjustment ranges, you should pay attention to such characteristics as weight, size of the viewing window, body material, number of sensors, ability to replace batteries and light filter, etc. It should also be taken into account that product parameters may vary depending on operating temperature conditions.

How to choose

Light filters for welding masks can be selected by marking . It has 4 digits. Each of them characterizes a certain indicator.

- Optical class number. Determines the clarity of the image through the filter.

- Level of light scattering. As the value of the number increases, the image received by the eyes deteriorates, the picture becomes cloudy. Best seen with marking value 1.

- The level of darkness and the uniformity of its distribution over all glass surfaces.

- Angular dependence of darkening, its degree when rotated by 15⁰.

Welding glass markings indicate how well the arc will be visible and the degree of eye protection while welding, including turning your head slightly.

Electric welder of the 6th category in the metal structures workshop of the LZSK plant V. P. Magriyanov: “When electric arc welding, light filters are selected according to the degree of darkening, depending on the diameter of the electrode that will be used. For example, C4 is suitable for an electrode with a diameter of 4 mm or less. A stronger arc will blind your eyes. If, on the contrary, we take glass with a higher degree of protection, then through it it will not be possible to see the elements of the weld pool.”

Glass for a welding helmet - what you need to know, how to choose?

Welder safety is the first thing you should take care of when starting work. Most of the protection is provided by glass, through which the master looks at the work area. There should be no damage, scratches or even cracks on it. If the viewing window is defective, it should be replaced as soon as possible.

In most cases, protective glasses for welding helmets have the same properties and dimensions. The only exceptions are complex models of shields, which require special glass to be installed.

Malfunctions of automatic light filters and solutions

The main malfunctions of glass for a chameleon welding helmet are the violation of its transparency and protection:

- Dimming doesn't work

- greatly obscures the arc;

- The degree of darkness is not adjustable.

Masks with lithium batteries need to be replaced. Models with a built-in power supply should be exposed to the sun. Above the glass are solar panels that are charged by light. They shrink if the mask has not been used for a long time and bright light has not hit it.

The second cause of problems is the oxidation of contacts. If the warranty period has expired, you should disassemble the protective device and check the contacts, clean them, coat them with a special lubricant or varnish that allows current to pass through.

When working in the cold, you need to know that the automatic mode for changing transparency on the Chameleon slows down when cooling. At temperatures below – 10⁰ it stops working completely.

It is convenient to carry out welding wearing a chameleon mask. But it has disadvantages. There is no point in buying an expensive protective attribute for amateurs who occasionally craft. It is also not suitable for work in the field, especially in the cold. Liquid crystal filters allow specialists working in production to cook with high productivity.

Choosing a welding mask

Welding is a rather risky profession, but you can’t live without it; even in the 21st century, manual labor is invaluable and cannot always be automated. Working with welding is not the easiest, and if you add certain risks to this, then not everyone dares to weld on their own. The requirements for organizing a workplace are not casually regulated and are quite high. The most vulnerable organs when working with welding are the organs of vision and breathing. Bright light, sparks, high temperatures, toxic fumes - this is what protection is needed at all stages of welding work. Welding masks provide partial and sometimes complete protection. Your health will depend on how responsibly you approach the choice of protection. Agree, it is better to spend money once on purchasing high-quality protection than to pay bills for treatment for many years.

This is important to know: the effect of welding on the organs of vision and breathing

Under no circumstances should you work with welding without a protective mask, even if the entire work takes seconds. Welders are frequent clients of ophthalmologists, not only because they neglected the main rule, but also because they selected masks with insufficient protection from the effects of electric arc radiation. Arc welding is considered the most dangerous type of electric welding; the glow is the most intense, therefore, the degree of darkness of the protective mask should be high.

Damage during welding work can be caused not only by the intensity of radiation; most often, the harmful effects on the organs of vision and breathing are complex. They can be divided into 4 groups:

– Thermal. Damage is caused by high temperatures when working with electric welding with metal; injuries from hot fumes, hot metal or sparks are possible. It is recommended to choose protective masks made from materials that are resistant to high temperatures, with optimal body thickness, with fastenings, and without a tight fit to the skin.

- Chemical. As you know, most of the organs of vision and breathing are covered by mucous tissues, which are most sensitive to fumes, smoke, and chemical changes in the composition of the air. Of course, in this case, a lot depends on what material you have to work with. A welding helmet cannot provide complete protection from chemical burns, but if you know that you will be working with metals containing nickel, chromium, etc., then when choosing, give preference to masks with the ability to filter air, completely closed like a helmet.

- Light ones. Not only the welder, but also third-party observers can get a light burn by just looking at the light radiation. Such a burn occurs from the radiation of ultraviolet and infrared waves, i.e. precisely those that we cannot see. Even a regular shield will do to protect against light radiation, but it is much more important to choose the right filter.

– Mechanical. Damage caused by sparks, fragments, etc. coming into contact with the eyes, skin, etc. Not only do metal shavings fly at speed, they are also hot, so contact with the eye, skin or hair can be costly to your health. The best option is to choose a welding helmet that protects the entire head, not just the face.

Types of protective filters

Light filters are a specific material that can filter out invisible and visible light spectra that are most harmful to vision.

Several types of light filters are used in welding helmets:

– Tinted glass. Used in classic old-style welding helmets. Impurities of non-ferrous metals, such as copper or nickel, are added to glass to reduce light transmittance. A higher content of impurities in glass provides lower light transmittance, and vice versa. Glass tinting is marked according to both Russian (C4 - C8) and European (9 - 13 DIN) classifications. Upon external inspection, it is difficult to find differences in glass, however, C8 (DIN 13) has the greatest light protection. To check the quality of the glass, it is enough to look through them at the incandescent lamp; through C4 the filament of the lamp will be clearly visible, through C8 the filament is almost impossible to see. If the result does not differ during inspection, this indicates poor quality of the product.

– Polymer filters. Not so long ago, materials appeared on the market with parameters superior to glass. Polymers are strong and lightweight, have ductility and the same shading properties as glass. Often combined with other materials to achieve better protective qualities. Widely used in combination with safety and tinting glasses.

- Chameleon. The most suitable filter providing complete protection. The automatically darkening filter adapts to any type of welding and different powers. The liquid crystal screen works on the principle of polarization of liquid metals. Between the polarizing films are liquid crystals; under the influence of voltage, the crystals are aligned in such a way as to block polarized light. In addition, chameleon filters provide constant protection from ultraviolet and infrared spectra; even in a faulty state, protection is provided from the most harmful radiation.

Welding helmets with chameleon filters have gained popularity among users for their versatility and reliability. Such masks do not require recharging or third-party power; they are equipped with built-in lithium batteries and solar panels. They are equipped with photosensitive sensors for better adaptability to changes in radiation; illumination of the arc zone is possible. The filter in its initial state is transparent, which allows you to perform intermediate stages of work in the mask, or use it in other areas.

When choosing an automatic light filter, you should pay attention to the adjustment options. The sensitivity of the filter allows you to configure the filter to turn on/off depending on the brightness of the arc. A useful feature when working on sunny days, when the filter can turn on in response to the sun.

The opening delay time is another important adjustment, necessary to prevent premature opening at the end of welding, since after the arc is turned off, the metal is still burning.

Weight and dimensions of the welding helmet

A parameter that should not be overlooked is the weight of the welding helmet. Working with hot metal and welding is not easy, but if you add to this a heavy helmet with limited air access, then it all turns into torture. The mask should not be heavy; in addition, it is advisable to choose a model with the ability to adjust the headband, seat depth and angle of the mask. The presence of additional softening pads will also not be superfluous.

How to choose high-quality welding protective glass?

It is worth saying that depending on the specific type or method of welding, you need to use a welding helmet of a certain category. On the modern welding equipment market there are a large number of different models from different manufacturers.

Welding glass sizes

The first thing you need to pay attention to is the size of the glass for the mask. Since it simply may not fit the dimensions of the groove on your equipment. Next, you need to decide on the type of welding glass, namely the presence of an automatic dimming adjustment function.

Darkening of welding glasses

Permanently darkened glass is sold at a significantly lower price compared to chameleon models. However, their use in the welding process is associated with certain difficulties. Of course, if you rarely use a mask, then there is no point in spending money on a multifunctional model. However, professionals in their field, choosing between classic glass and chameleon, give their preference to the second option.

Since the process of automatically adjusting the level of darkness depending on the intensity of the bright light of the arc of welding equipment occurs only after it is turned on. Therefore, great attention must be paid to the response speed of photosensitive sensors. An insufficient value of this parameter puts the organs of vision at risk. “Flagship” models of chameleon-type glass react to bright light within a few thousandths of a second. More budget versions operate after hundredths of a second.

Great attention should also be paid to the maximum limit of the degree of darkness, as well as the entire range of these values. The larger it is, the greater the level of versatility the product has. The ideal option is equipment that can change its dimming level in the range of values from 9 to 13 DIN.

You should also pay attention to such characteristics as smooth adjustment, the ability to manually adjust the technical parameters of the product, the presence of additional protective properties, etc.