- November 23, 2018

- Weapons and ammunition

- Natali Michaelis

“How to blue the barrels of a hunting rifle at home?” – one of the most frequently asked questions on thematic forums. As a rule, novice hunters who have just begun to comprehend the beauty of this fishery are interested in this. From a technologist's point of view, steel bluing is a complex process of applying a very thin coating to metal using various chemical reactions. You will find information on how to do this at home in our article.

Significance of the procedure

Most gun lovers are interested in this issue when they want to decorate the barrel of a gun more beautifully. However, this process has at least two more advantages: coating the metal with a thin film gives the barrel different shades, which increases its camouflage (especially in the sun), and the weapon will also be less susceptible to corrosion in the future. For a true hunter, both of these factors should be truly important. Therefore, it is worth approaching the bluing of hunting rifle barrels at home with great responsibility.

Features of the technology

You can often hear people say that bluing a gun can only be done in a factory setting; however, this statement is only half true. Yes, steel undergoes higher quality chemical treatment during the industrial process. This is explained by the high content of iron oxide in the substances used at the plant.

At home, achieving high-quality blackening of metal can be very difficult. According to some experts, oxidation of steel can only occur at the factory, however, this is not the only way in which a barrel can be blued. Most "home" technologies are divided into three main groups according to the fundamental principles that are necessary to carry out the process.

- oxidizing agent treatment;

- hot bluing of steel;

- cold blued steel.

Each of these processes has both its pros and cons. Features of the technology, as well as the step-by-step implementation of each process will be described in the following sections. However, first you need to familiarize yourself with the safety regulations, compliance with which is mandatory.

Means for bluing metals

Relatively simple methods of bluing, available for doing it yourself, include surface application of oil, saltpeter and the purchased composition “Clover”

Sapphire for bluing

Oil coating

This is one of the most popular home methods. The technology is divided into the following operations:

- The part is sanded and degreased with a solvent.

- Cover with oil.

- In a muffle furnace it is heated to 350-400 °C. It is permissible to use an oven.

- The cooled part takes on a black or brown tint.

- To saturate the color, the procedure is repeated.

The oil is applied with a brush or by dipping the product into a container of oil. Different types of oil are used, such as

- weapons;

- olive;

- flaxseed

Use of saltpeter

Home craftsmen achieve excellent results using saltpeter solution. You can purchase a ready-made solution, or you can make it yourself:

- water-1000 ml;

- sodium nitrate - 0.5 kg;

- caustic soda - 0.5 kg.

After boiling for an hour, a smooth surface of a deep blue-black color is obtained that does not require further processing.

Means "Clover"

The gel-like product can be purchased in 50 ml jars and is used for alloys with a chromium content of no more than 3 percent

Means "Clover"

It is designed to restore localized corrosion. To obtain a bright shade, the product will have to be applied several times. The product should first be sanded and wiped with a degreaser.

Apply clover with a brush and leave for two minutes. The white-yellow coating that appears is washed off with water and the part is wiped with a rag.

Preparatory procedures

Whatever method you choose for bluing a gun barrel, you must perform a number of preparatory procedures in a certain sequence, which will be described below.

- We carefully clean the surface of the barrel on which the steel will be blued using a cleaning rod.

- We polish the surface to perfect condition.

- We disinfect the surface (after this, all work is done exclusively with rubber gloves).

- We use special substances for bluing metal.

- We re-process the surface with a grinder.

After this, you can start bluing the metal, observing safety regulations.

Features of metal bluing

In industrial conditions, the blackening of the top layer of metal is removed by changing its structural composition.

In addition, a protective coating is applied in a special way, providing high-quality protection against corrosion.

Using industrial methods to combat rusty metal at home is not only impossible, but also economically unprofitable.

Video:

Independent hot or cold coating is performed by applying some special compounds to the metal surface, which not only remove its blackening, but also form a thin protective film.

The means for bluing can be purchased at any specialized store, and in a fairly wide assortment.

Thus, bluing in saltpeter allows you to achieve a fairly high-quality result; in addition, a special pencil for bluing allows you to effectively remove the blackening from the metal.

In some cases, you can use orthophosphoric or citric acid, and also prepare a solution for treating stainless steel in oil.

Regardless of which technology - phosphoric acid, citric acid or oil - is chosen to combat rusty metal, the entire process can be divided into several separate stages.

First of all, the metal surface is thoroughly polished and cleaned. After this, degreasing is carried out, for which a special solution is used.

Next, carefully apply the selected bluing agent. At the final stage, finishing of the metal surface is performed.

It should be noted that depending on the part, its technical characteristics, as well as the chosen method for bluing, certain nuances and subtleties may arise, but the general algorithm of actions always remains unchanged.

It should also be remembered that after degreasing the surface to be treated, it should not be touched, which means that all work is best done with rubber gloves.

IMPORTANT TO KNOW: How to make metal engraving with your own hands?

Safety precautions

It is not difficult to guess that bluing the barrels of a hunting rifle at home is a rather dangerous procedure, so compliance with safety measures must be unconditional. To begin with, it is worth noting that chemical solutions contain a large number of active substances, which must be stored in a place inaccessible to unauthorized people. Also, do not forget that the entire process must be carried out in special containers.

Blueing of hunting rifle barrels at home should be carried out in a well-ventilated room, since breathing chemicals and dust is quite harmful to the human body. To sand the surface, it is best to use fine-grained sand, sandpaper or pumice.

Solution and brush

In specialized stores you can purchase various types of chemical mixtures that are used to blue gun barrels. As a rule, most of them are applied with a regular brush to the metal surface. Among such products, the most popular are “Voron-3” (domestic version) and “Parisian oxide” (imported mixture).

The advantages of this method can be seen with the naked eye. The process is quite simple, and you don’t have to make the bluing liquid yourself. Security requirements are also minimal.

However, this method also has certain disadvantages. Firstly, using a brush it will be quite difficult to penetrate into all the “cracks” of the weapon, due to the complexity of its configuration. Also, to make the product smooth, you will have to resort to additional polishing. Well, the most unpleasant thing is that when barrels are blued using a cold method, even slight chemical damage will leave a strong mark, after which the treatment will have to be repeated.

Cold bluing at home

“Clover” does not require heat treatment of the part, so this method is considered cold bluing. Cold bluing can be carried out by other means.

- "Voron-3M". The drug forms a dense film of deep black color on the surface.

- "Paris Oxide" An imported selenium-based preparation is supplied in three containers: 1- for surface preparation, 2- the main composition and 3- a fixative that gives the coating additional protection.

Liquid for cold bluing is applied to the parts with a brush, and after painting it is washed off with warm soapy water. The method is popular for processing barrels and other parts of firearms that do not require boiling.

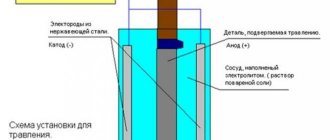

Immersion method

This method involves immersing metal parts of the weapon in a solution. The main advantage of this method of bluing a gun barrel at home is that the liquid will penetrate even the most inaccessible parts of the parts, which is why the coating layer becomes more uniform. Also, the liquid does not splash, unlike the first case, when it is applied with a brush.

You can prepare such a solution yourself or purchase it ready-made in a specialized store. For the first case, you will need to mix the following ingredients:

- FeCl3 (iron chloride) – 75 grams.

- HNO3 (nitric acid) – 20 grams.

- CuSO4 (copper sulfate) – 20 grams.

- C2H5OH (ethyl alcohol) – 30 grams.

Burnishing with rusty varnish

Such a knife is not suitable for bluing edged weapons, since the steel on most knives is poorly resistant to mechanical stress and wears out quickly. However, if you still want to bury your hunting dagger, then it is best to use rusty varnish - one of the most effective and low-cost methods. The essence of the method is to treat the surface with a corrosive medium - rusty varnish. By the way, this method is also suitable for bluing barrels.

The preparation of rusty varnish must be carried out outdoors or in a well-ventilated area. To avoid inhaling harmful gases during the process, use a special protective respirator. First, you need to place 12 grams of hydrochloric acid in a glass container, then add 20 grams of nitric acid. It is worth paying special attention to the fact that reagents should be measured by weight and not by volume, since they have different densities. Even one extra gram can lead to impaired reactions. Then 30 grams of rust (iron scale) and 5 grams of iron filings are added to the dishes.

After this, you need to wait some time for the reaction to pass. As soon as the process occurs, you need to add 50 grams of medical alcohol (ethyl alcohol C2H5OH) and 50 grams of distilled water to the solution.

The trunks are immersed in the solution for 12 hours, after which they must be treated to remove salts and scale that have precipitated. After this, the parts are re-immersed in the solution and kept in it until the metal turns black. After this, the metal is washed with cold water, and the red marks left by the solution are brushed off. As a result of such procedures, you can get a fairly good result of barrel bluing at home.

As in the case of using a brush, after the procedure the part is washed well under cold water using detergents. If you decide to bury a knife in this way, then the time the blade is kept in the solution should be controlled by you personally, since the steel on knives is different from gun steel. Prolonged exposure to rusty varnish can negatively affect the quality of bladed weapons.

Using rusty varnish

Many people use a method for bluing metal that is called “blueing with rusty metal.” With it you can achieve a flat and smooth surface at minimal financial cost.

Its essence lies in placing the workpiece in a corrosive chemical environment.

As a result of this bluing, red and black iron oxides appear on the metal surface.

Video:

To remove the red deposits, use a brush with stiff metal bristles, leaving the black oxide behind. It should be noted that this processing method is quite lengthy, but effective.

In any case, first the metal is mechanically processed and degreased, and only after that the product is placed in a special solution.

The liquid for bluing with rusty varnish is prepared in special porcelain containers, and it is necessary to use products to protect the skin.

The solution in this case is prepared on the basis of hydrochloric acid.

It must be poured in a small amount into the prepared container and mixed with iron rust, metal filings and nitric acid.

Next, the solution is thoroughly mixed until the chemical reaction completes, which is accompanied by the release of gas.

After this, water and ordinary vodka must be added to the mixture in equal quantities.

The solution must sit for a certain time, after which it must be drained to remove scale and precipitated salts.

Next, you need to place the metal being processed into the mixture for a certain time and wait until it turns black, after which it is washed abundantly under water.

Hot bluing

Are you interested in how to bury a gun at home? Many craftsmen prefer to use the hot method, considering it the only correct one. The arguments are quite simple. For a product that has been blued using a hot method, the protective coating lasts much longer, and the absence of harmful fumes during the procedure is an additional advantage.

This method is also commonly called oil bluing, since the technology involves the use of this substance. This method is quite simple. First, the part is heated to a high temperature, after which it is immersed in oil. Gun oil, olive linseed oil, or even machine oil can serve as a quenching liquid - this is not so important. The part is kept in the container for about 10 seconds, after which it must be removed, otherwise the metal will become covered with various stains.

The next step is to “boil” the oil on the surface. For this purpose, you can use a blowtorch or a stationary gas stove. An important point in blueing steel is determining the moment the part is “ready”. Experienced gunsmiths say that you need to stop heating the liquid the moment the gun barrel turns black. Oil is one of the oldest and most effective means for bluing the barrels of hunting weapons. Reviews about this method on thematic forums indicate its effectiveness.

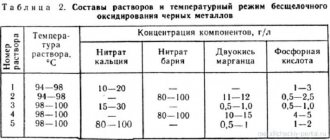

Chemical oxidation treatment

Most often, metal surface treatment is carried out using chemical oxidation.

This method is quite effective and, if the technology is followed, allows you to achieve a high quality final result.

This method of bluing metal is based on the ability of the metal to oxidize.

Video:

At the preliminary stage, it is necessary to mechanically treat the surface of the workpiece, as well as completely degrease it.

After this, the appropriate solution should be properly prepared.

For these purposes, you should take a container of a certain size, which must be made of porcelain.

Next, one hundred milliliters of ordinary tap water is poured into it, after which a small amount of sodium nitrate and about one hundred grams of technical soda are added.

After this, the solution should be thoroughly mixed and ensure that all components are dissolved in it.

The resulting mixture should be heated to a temperature of about one hundred and forty degrees Celsius, and the workpiece should be immersed in it for about thirty minutes.

After the specified time has elapsed, the part is removed from the solution and thoroughly washed with distilled water.

Next, you should dry it thoroughly and generously lubricate it with machine oil using a soft brush, achieving a uniform layer.

IMPORTANT TO KNOW: Methods and types of mechanical processing of metals

The metal surface treated in this way will acquire a pronounced black tint with a blue tint.

If the bluing was done correctly and in accordance with the technology, the metal will become smooth and does not require subsequent polishing.

In the video posted in the section, you can see how a metal surface is treated at home using a chemical solution.

Oxidizing agent treatment

For a person who understands chemical processes, the question of bluing barrels should disappear by itself. The first thing that should come to mind is the need to treat the trunks with a special oxidizer. The only disadvantage of this method is that the mixture must be heated to the melting point, however, it is not always possible to do this at home. Most often, the processing is carried out using various nitrates, which is why the second name of the process came from - bluing of trunks in saltpeter. Although the choice of oxidizing agents is not limited to it, saltpeter is most often used at home - safely and effectively.

Methodology

Immersion time in the chemical composition does not exceed 30 minutes. During this half hour, you must carefully monitor the immersed parts and remove them as soon as they are completely blackened. This technique allows you to blue barrels at home, obtaining a hard metal coating that will not violate its integrity.

The metal oxidation method is considered quite effective, but very expensive and difficult for beginners. The process will require a certain skill and good knowledge of chemistry from the gunsmith. It should also be noted that bluing of stainless steel must be carried out with other reagents.

Video

If you are interested in the process of “home” barrel bluing, we recommend that you familiarize yourself with the following video. It will help you more clearly understand all the stages of cold bluing.

In conclusion, it is worth noting once again that bluing barrels at home is a rather hazardous process for health, so it must be carried out only with unconditional adherence to safety precautions. When using various reagents, be sure to use protective gloves, and carry out all work in a well-ventilated area.

Methods for bluing metals at home and requirements for their implementation

Popular methods of bluing metal at home are:

- Boiling in self-prepared or purchased chemical compositions.

- Coating the steel with special oil and subsequent heat treatment.

- Coating the surface with the prepared composition at room temperature.

Burnishing steel at home

Chemical bluing of iron also involves preparatory operations of etching and cleaning, as well as grinding and polishing.

When carrying out blueing of steel, it is important to select a container for the solution so that it completely covers the object being treated.

What is bluing?

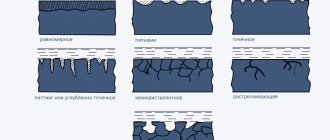

Burnishing is the application of a thin film of oxides to the previously prepared surface of steel or cast iron parts, protecting against corrosion and giving the metal a bluish-black color. The thickness of the film ranges from 1 to 10 microns; the thicker it is, the deeper and darker the color of the coating. The classic method of bluing, used for several hundred years, is to apply drying oil or linseed oil to the surface of heated metal. The result is a fine-crystalline coating that has protective anti-corrosion properties and a pleasant blue-black color. It is customary to judge the heating temperature by color, although this method is not very accurate. The blue color, most suitable for bluing, appears when steel is heated to 300-320°.

The coating obtained in the traditional way was not distinguished by proper strength, durability, and did not provide complete protection against rust. Over time, other, more effective methods of bluing metal were developed. Most of them were created specifically for weapons, since the specific service of weapon metal did not allow other finishing methods. One of the reasons for the need to use other coating methods was the task of abandoning the heating of weapon barrels, which had a negative impact on the condition of the metal, its physical and chemical properties.

What can be achieved by bluing

As a result of chemical or thermal treatment, a layer of iron oxide with a thickness of 1 to 10 microns appears on the surface of a steel part. The thickness of the layer is determined by the selected processing technology.

Blueing of metal allows you to achieve two main goals:

- Increasing the corrosion resistance of the product. Treated parts do not rust.

- Improved appearance. It is especially important for those parts that, due to operating conditions, cannot be painted.

Temperature conditions for bluing

The treatment does not affect other properties of the steel.

Blueing of steel is possible not only in production conditions, but also at home. There are many methods and compositions, almost all of them involve the use of chemically active substances that can cause serious harm to health. To successfully and safely use these substances at home, you must follow the following safety rules:

- Use a protective mask and gloves.

- Ensure ventilation of the room in which work is carried out.

- Use stainless steel utensils.

- Do not exceed the recommended processing temperature.

What is it used for?

Initially, the procedure was carried out solely for the purpose of protection against rust, since there were no other types of coating, and the operating conditions of the weapon greatly contributed to the development of corrosion processes. Currently, in addition to its protective functions, bluing is considered as a decorative coating that gives weapons a traditional look. It is noteworthy that the appearance of a weapon is considered by a large number of owners to be one of the most important components of its performance, while protection against corrosion is not considered a problem at all. However, all currently used types and methods of bluing provide a sufficient degree of protection of the metal surface from moisture. It is also necessary to understand that any bluing agent does not create a coating layer, but only promotes the formation of a reaction as a result of which this layer appears on the surface of the metal.

Types of bluing

There are the following types of metal bluing:

- alkaline . The steel surface heated to 135-150° is covered with a thin layer of alkaline solutions, causing an oxidation reaction and the creation of a protective film;

- acidic _ Produced by electrochemical or chemical methods using acid solutions;

- thermal _ Refers to traditional methods of bluing, although there are more modern technologies with the formation of protective films in vapors of ammonia-alcohol compounds or in molten salts.

There are a huge variety of methods for applying protection, from complex multi-step processes to simpler and faster procedures. All of them are characterized by a limited period of validity and do not provide absolute protection from moisture. The barrels of hunting rifles must be blued from time to time, and the condition of the weapon must be constantly monitored. Coating cannot be considered as a final solution to the problem; it is only a way to somewhat reduce the consequences of contact with water and slow down the rate of rust formation.

What methods are available to perform at home?

Complex technological operations are not possible at home, but simpler procedures are quite possible. There are several basic bluing methods:

All three methods can be done at home, for which you need to acquire all the necessary materials and equipment, as well as study and understand in detail the physical and chemical essence of the processes. It is not recommended to get down to business without understanding the meaning of the operations being performed. Any method consists of the same steps:

- Cleaning, removal of old coating and rust.

- Grinding, removal of cavities, small scratches, dents.

- Degreasing. The surface layer of fat is removed, for which various chemical reagents are used. After completing this stage, work with metal only with rubber gloves.

- Actually bluing.

- Finishing the metal surface.

The most important point (apart from the coating itself) is degreasing. After this you can start bluing. Let's consider the possible options.

Cold bluing

The principle of cold bluing is simple - a special liquid is applied to a previously prepared surface. There are ready-made formulations:

The first two products are sold in stores. With the third, the matter is more complicated - in its finished form it is stored for a long time, but it is practically never on sale, there are only advertisements for the sale of old stocks. Making rusty varnish is a complex and dangerous procedure, since you have to mix 50 ml of hydrochloric and 54 ml of nitric acids, 30 g of steel or cast iron filings, and 20-30 g of scale.

All this is dissolved in 1 liter of distilled water, not immediately, but gradually:

- A third of nitric acid and a third of chips with scale are carefully poured into hydrochloric acid. The reaction will begin, you must wait for it to subside.

- Repeat the procedure and wait for the end of the reaction again.

- Pour out the remaining chips and scale, pour out the last third of the nitric acid. Seal and leave for a day. Then add a liter of distilled water to the resulting brown solution, after which the rusty varnish is ready. You can use it for a long time, it becomes harmless and does not require special precautions.

Other bluing methods

Very often, a special pencil for bluing is used for metal processing.

Before using a pencil for bluing, the metal surface is treated mechanically and then thoroughly degreased.

Such bluing of steel, if all technological requirements are met, is quite effective and allows you to obtain a smooth and even surface. It is also very common to get rid of corrosion with varnish.

As in all other cases, before treating the surface with varnish, it is treated by mechanical action.

Next, the metal is degreased, on the surface of which there should be no traces of dirt and grease. Varnish treatment is quite effective and does not require serious financial costs.

When working with varnish or pencil, it is necessary to use special protective equipment so that the product used does not come into contact with the skin.

Video:

You can also perform the treatment by painting the metal surface with a solution called “Clover”.

This method of painting with Clover is quite effective with minor corrosion of the metal surface.

IMPORTANT TO KNOW: Secrets of copper plating at home

In this case, it is necessary to paint the treated surface with Clover as thoroughly as possible, several times.

The composition Clover is sold in special small tubes. The price of Clover also varies from place to place.

Clover has a gel consistency. The main advantage of using Clover is its ease of use.

Simply sand the part, then degrease it with gasoline, and then apply Clover. After a few minutes, when the gel is absorbed, rinse off the residue with water.

It is best to burnish heavily damaged metal with a solution of saltpeter.

To prepare a solution of nitrate, only stainless steel utensils should be used, and the skin must be protected from contact with the mixture.

As a result of bluing with saltpeter, the metal surface acquires a pleasant reddish tint, which is complemented by a slightly bluish tint.

Video:

A solution of nitrate for bluing is prepared from one liter of water and a small amount of sodium nitrate, as well as caustic soda.

This mixture has a rather pungent, pungent odor, and therefore it is better to use a respirator when working with it.