Work on stamping and pressing of various workpieces requires the use of special punches. This product is used for marking device components during metal processing or in the stamping process. In order to make high-quality stamping or marking of a device assembly, direct pressure must be applied to it. It is for this purpose that the punch was developed, which can be of very different designs.

Experts identify the following types of such devices:

- cutting;

- punching;

- piercing;

- perforated

How dies and punches work

During pressing, a durable tamping punch exerts strong pressure on a special press washer, which in turn transfers pressure to the workpiece. As a result, the desired workpiece is squeezed out through the matrix. The punch is capable of operating under enormous thermal and power loads, so it is made from wear-resistant metal. The device is very durable and is not damaged by temperature changes.

In other words, a die is considered a device that, using pressure, can produce a workpiece of the required shape and size. When stamping various parts, it is the most important tool. When polyurethane is used together with it, a high-quality matrix is made from it, which will be the response unit of the stamp.

When assembling any type of stamp, the design of this device always completely coincides with the cutting edge of the matrix. In other words, such a product is a closing unit that is capable of creating the upper part of the workpiece. A set of punches is a small press that can efficiently mark or stamp various components. Using this device, it is possible to produce blanks of any size or apply high-quality markings, which can be mirrored or regular.

Punch sets are used in metalworking plants that press iron blanks or produce sheet metal parts. In the construction industry, using this device, you can make aerated concrete blocks that have various voids.

What materials are matrices most often made of?

Aluminum and soft metals

Aluminum is used to create matrices in Moscow due to its softness and durability. At the same time, this material is the most expensive among analogues, and its processing takes a lot of time. It is best to make matrices from metal intended for the production of large batches of products.

MDF

The matrix is created using CNC milling machines. First, a 3D design is made on a computer, and then the milling machine starts working. Using the machine greatly increases the accuracy of the work, and also reduces costs and time for it. The required height of the finished matrix is achieved by gluing MDF boards, and the top layer is additionally impregnated with a special compound. However, such matrices are short-lived and rarely withstand more than 10 shoots.

Model plates

As with MDF, the matrix is made using CNC machines. The general procedure is very similar to the process with MDF. The main difference is that model slabs are much stronger and can last up to several tens of times longer. The downside is that the cost is quite high, but still lower than that of metal options.

The main purpose of the matrix

In order to make a workpiece of the required shape, a matrix is used, which can be made from:

- polyurethane;

- rubber;

- various metals.

To make an iron part, the matrix must be made of specialized strong steel, which has high wear resistance. Such a structure should be equipped with polished walls and not have a lid.

Experts distinguish the following types of matrices:

- simple;

- complex;

- universal.

The most complex design solutions are used quite rarely, so they are produced to individual order. An example of simple matrices is molds for the production of various blocks and small bricks.

How to make a die for forging

Today it is not difficult to purchase ready-made stamps with various shapes, including standard sheets, crow's feet, peaks, clamps and others.

However, how can you make forging dies with your own hands, what do you need for this and what materials should you use?

Material

The matrix material must have high qualities, because the finished stamp will constantly be in contact with heated workpieces, and, moreover, will constantly experience shock and compressive loads.

To make such a template, you can take steel from a car axle shaft, as shown in the video presented:

You can also make a matrix on the surface of the striker of one of the working hammers.

Or any other piece of steel with excellent properties to resist deformation and strong heating will do.

What you need

To make a matrix, you will need the appropriate tool: grinder, chisels, hammers and others.

There are types of stamps that are made on a milling machine. For example, like in this video:

The previous video perfectly shows how to make the simplest type of matrix - a crow's foot, using only a grinder, a file and a welding machine.

Manufacturing process

The complexity of manufacturing matrices depends on the pattern applied to its surface. Elementary embossing such as crow's feet or clamps is much easier to make than, for example, figured peaks or sheets. Complex designs will have to be applied with chisels and chisels.

- To make a simple crow's foot stamp, a blank is prepared. Its surface is leveled.

- On the working side you need to make markings in the form of diverging lines. Initially, the central axis is knocked off, and only then two or three branches from it.

- I use a grinder and a cutting wheel to make cuts along the lines, deepening them along the edges.

- Using an angle grinder, you need to form triangular projections along the slots.

- After which the entire relief is finished with a file.

- If a double-sided crimp is made, you need to make a mirror image from the same piece of material with protrusions that exactly match the depressions on the first matrix.

- The crimp is connected in the form of tongs.

- The striking side can be further strengthened with a striker welded on top.

- For convenient use of double-sided crimping, you can additionally make a stopper from a pipe or other similar material.

- Additionally, the steel must be hardened to increase its strength properties.

If everything is done correctly, then such a homemade matrix will serve for a very long time.

An even simpler stamp for the production of crow's feet can be a bar of steel with longitudinal grooves cut and brought to the desired shape. On this form you can very simply make a one-sided design by hand forging.

What can you add to the material in this article? Share your experience in making dies for forging metal, as well as techniques for using them in forging work. Join the discussion in the comments section of this article.

Materials for the manufacture of punches and dies

The main task of a set of punches is to force the part through the matrix. This work is done under enormous pressure. When using hot pressing, the workpieces are exposed to high temperatures. Because of this, different types of materials are used to produce punches and dies. Devices for cold pressing are made from specialized high-strength steel, which has a high degree of hardening.

The materials for the manufacture of these parts meet the following characteristics:

- high degree of wear resistance;

- great strength;

- corrosion resistance.

Alloy steel is not suitable for high temperature applications. Metal can become brittle under the influence of temperature differences. Any punch has the highest degree of hardness over its entire height. In the hot method of manufacturing dies for steel stamping, the upper part of the product is made of specialized metals that are not subject to deformation at high temperatures and have a high degree of wear resistance. This technology can provide the greatest durability of the device. Sometimes modern types of various polymers are used. For example, it could be polyurethane, which has good elasticity and great strength.

Manufacturing process

The matrix manufacturing process must be calculated very accurately. The quality of the future part depends on this. All work is carried out according to drawings. Each stage must be done professionally.

- First, the shape of the workpiece is obtained on a press or using high temperature.

- The shape is then processed by specialists on a lathe.

- The next stage is finishing and heat treatment.

- The last stage is chrome plating of the working surface.

Making a matrix is a complex process. The work performed by specialists on equipment plays an important role. The accuracy of the product depends on their qualifications. Grinding machines are used for this. Hardening during the manufacturing process is of great importance in the manufacture of matrices. This gives the workpiece ductility and strength.

The easiest forms to manufacture are those that represent bodies of rotation. The work is performed on CNC milling machines, which makes it possible to make precise dimensions and improve quality.

It is important to choose the right material for making the part. The cost and quality of the product depends on this. Soft metals, copper, bronze are not suitable for making matrices. Our company’s specialists will help you understand all the nuances of making a custom matrix.

Main characteristics of the product

Absolutely any type of stamps has a certain warranty period. The main components of this device are the matrix and the punch, which wear out quite quickly. These units must be changed regularly because they can last about 5 years without replacement. The equipment of vibration presses and stamping devices has a different design. This is done so that it is possible to carry out various technical operations.

For this reason, extensive grinding is performed when producing cylindrical dies. Craftsmen do rough processing of the device, and then clean grinding. The device is sharpened and polished at the last stage of its manufacture.

To make shaped punches, a technological impression is used. The device is hardened in a hot oven for 10 minutes. Next, the final sanding begins. To obtain a product of complex shape, a large amount of specialized equipment is used. It is almost impossible to do without the use of milling and planing machines.

Similar equipment is needed for matrix production. When the molds for the press are made of very high quality, and the punch is equipped with an accurate cut line, the stamp will have a high degree of wear resistance and a long service life. Experts believe that making stamps with your own hands is very difficult. To do this, you need to have a lot of knowledge in the field of metal processing.

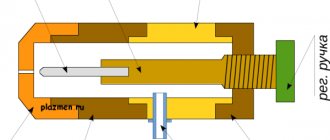

Features of matrix production

The steel blanks used for the dies are additionally hardened using a fiber laser. This approach makes it possible to increase the hardness of the working surface up to 60 HRC. Hardened structural steel is highly resistant to high temperatures that occur when processing metal workpieces on sheet bending equipment.

The PLASMET company produces and sells dies for sheet bending machines. The catalog contains standard equipment of various types (A, T, L, W, etc.), it is possible to manufacture it to order, taking into account the client’s requirements. In the production of equipment we use only high-quality steel alloys - C45, C50, 1.2312, etc. Guaranteed quality, long service life without deformation and destruction of the tool, favorable prices for equipment - these are some of the advantages of PLASMET products. To clarify the information you are interested in, request a current catalog, or fill out an application for the production of a non-standard tool, use the form on the website or call the phone number provided.

Concept and characteristics

The matrix is an integral element of any stamp and press, which is a bounding box of a given shape.

According to versatility, they are distinguished:

- simple matrices that can be used for the manufacture of only one type of product (the production of most building blocks and bricks);

- complex (combined) products for the manufacture of two or more product names.

Depending on the scope of application, matrices can be:

- Molding. This type is used to imprint a certain structure on a working surface (making molds for pouring concrete and paving slabs).

- Punching and punching. They are used to create holes of various shapes, and for greater accuracy they are often made detachable.

- Bending. Such products are needed for the manufacture of molds from thin sheet metal.

The matrix operates integrally from the punch - the closing element that forms the product from above and performs the function of a press, stamp or marker.