What is a file and what is it for?

A tool designed to remove a layer of metal from a workpiece is called a file. It is a metal strip on which a so-called notch is applied. It consists of cutting teeth made according to certain rules described in GOST 1465-80.

To control it, use a handle mounted on a specially formed shank. Several grades of steel are used for manufacturing. As a rule, this is steel containing 1.1 - 1.25% carbon. The steel grade can be ШХ15 or У10А, the latter steel is classified as unalloyed improved.

One of the main requirements for it is high hardness. That is why after heat treatment it is not tempered. In working condition, the surface has a hardness of 54-58 HRC.

The handle with which the control is performed can be wooden, plastic, or metal.

Set of files with wooden handles

They are produced in different shapes, lengths and with different parameters of cutting teeth.

It should be noted that the abundance of this product allows you to perform many types of work, in particular, it can be used to remove various types of contaminants, grind workpiece planes, remove flash and sprues. Using these products of special shapes, it is possible to sharpen saw chains and process gears.

It should be noted that it can be found in almost any home, garage and of course in production.

Features of choice and rules of care

When purchasing files, in addition to technical characteristics and dimensions, you should pay attention to the quality of the tool. He must have:

- uniform color of the working surface;

- clearly defined notch;

- a comfortable, ergonomically shaped handle that is securely fixed and does not slip.

To extend the service life of files, you must follow the rules of operation and storage. Firstly, it is undesirable to use a new tool to work with parts and workpieces covered with a thick layer of rust. Before starting treatment, it should be removed using a grinder or metal brushes. In addition, you must:

- Choose the right type and density of notches, taking into account the hardness of the materials and the characteristics of the parts being processed.

- Protect the tool from impacts and moisture, sanding dust, oils and aggressive substances.

- Clean up chips in a timely manner.

- The new tool should be used first for processing soft metals, which will ensure the removal of burrs without compromising cutting properties.

Classification of files by section shape

The parts processed with it can have different shapes. These can be sheets, profiles, etc. That is why, for productive work, manufacturers produce products of different shapes and geometric sizes. One of the classification options is by section shape. Manufacturers market products of the following types:

- flat;

- square;

- round;

- triangular;

- special;

- oval and some others.

Triangular file

Square metal file

Round file

In addition to the fact that products are distinguished by cross-sectional shape, they have different lengths and shapes. The minimum length is 50, maximum 500 mm. By the way, only the part on which the working teeth are applied is measured.

There is some relationship between the length of the working part and the size of the teeth. The longer the tool, the larger the size of the cutting tooth. Large is used when there is a need to remove a large amount of metal. But, after processing the material with a tool with large teeth, the surface turns out to be rough and scratched, and there is no need to talk about the accuracy of the processing. In cases where it is necessary to obtain a higher quality surface, products with fine teeth, for example velvet, are used.

Round velvet file

That is, processing is carried out in at least two stages using different types of files. At the first stage, rough processing is performed, and the finishing of the surface of the part is carried out by bringing the workpiece to the required parameters.

Types of files for metal

A file is a special cutting tool widely used in various industries. Externally, it is a steel bar of large or medium length with a wooden, plastic or rubberized handle attached to the base. It is necessary to provide the worker with comfort when working with the tool and reduce the risk of occupational injuries.

The body of the file is made of a special grade of steel, which allows the tool to interact with metal objects. The tail part of the steel beam is covered with a special pattern called excision. The nature and type of work performed will depend on the shape and size of the notch.

Processing of metal parts occurs through gradual grinding of layers with a tool until the product is given the required shape. The main thing is that the metal cutting part is selected for its intended purpose.

File shapes

The geometric shape of a metal file determines its scope of application in the production and processing of products:

- flat or flat pointed: processing flat metal parts, as well as smooth surfaces;

- square: necessary for cutting and forming technical holes of various polygonal shapes;

- triangular triangular: using such a metal cutting tool, you can polish, process and clean gaps, grooves and other manufacturing holes;

- semicircular: excellent for various types of processing of curved concave surfaces;

- round: used for sharpening and processing round or oval concave surfaces with a small radius of curvature;

- rhombic: processing of metal parts with teeth;

- hacksaw: a tool for sharpening narrow gaps, holes and other small parts.

In practice, round, triangular and flat files are most often used, since some of them can perform the functions of other tool shapes.

Types of files

The type of metal processing tool is determined based on its intended purpose:

- General purpose metal cutters. They are commonly used in plumbing. The tail part is made in the form of two jagged notches, which are superimposed on each other: their length can vary from 1 to 4.5 cm and can be combined with teeth of all sizes.

- Metal cutters for special purposes. They are necessary in the industrial sector, since their main task is to eliminate deviations and adjust small parts, grooves and surfaces of different radii of curvature. This type of tool has many varieties, which are selected based on the nature of the work performed: double-ended, flat, one-time and others.

- Needle files. This group of metal files includes the largest number of types. The ends of steel beams come in all possible geometric shapes, and the beam itself, as a rule, is not very long. Flat, round, hacksaw and all other types of needle files are characterized by the presence of a class 5 notch. Needles are used for processing small metal parts that coarser and more massive metalwork tools cannot handle.

- Rasps. Rasps differ from all other types of files by the particularly long part of the steel bar and large teeth on the tail. There are 3 main types of such tools: metal shoe cutters, hoof cutters and general purpose rasp files. The shape of the instrument is predominantly round and semicircular with an end of varying degrees of sharpness.

Types of notches and their geometry

In order to perform quality work as a metal carver, it is necessary to determine the required type of notch.

The structure and size of the teeth are also of great importance when choosing a tool. Steel teeth can be applied to the tail of a steel bar in different ways:

- milling;

- cutting;

- stretching;

- flow;

- cutting.

The most widely used in the field of processing metal products are metal cutters, the teeth of which are made by cutting them on special automated machines. Moreover, the notches themselves can be either double or single.

A notch with one end is designed to remove excess metal, which is equal in size to its teeth. That is why this type of tool is suitable for sharpening more pliable materials: wood, plastic and softer types of metal.

Double consists of two notches, one of which is the main one, and the second is auxiliary. The notches are located at a special angle relative to each other, which allows sharpening of hard materials (metals and their alloys).

The tooth geometry of files will depend on the number of notches on the body of the steel bar.

The fewer notches there are on the body of the steel bar, the larger the teeth will be.

File Features

Handmade products of this type can be divided into the following categories:

- Locksmith - we can say that this is a multi-purpose tool. It can be found in almost any enterprise, workshop, or household.

- Needle files are small-sized products designed for processing small parts. They are widely used by engravers, jewelers, and pattern makers. In addition, needle files are indispensable when processing in hard-to-reach places.

- Sharpeners - they are used for sharpening saw chains, hacksaws, etc.

- Rasps are products with the largest teeth and are used to work with non-metallic materials, that is, in cases where the usual one is not suitable for solving the assigned production or household tasks.

Bench square file

As already noted, working teeth are applied to the working surface. It can be single or double. For processing soft materials, a tool with an arc cut is used.

Point teeth are made on the surface of the rasp.

Types of notches on the surface of the tool

Based on the nature of the notches, it is customary to speak of a single or double design.

Single execution is more common with rough instruments. Here the tooth has a long cutting edge. Its length corresponds to the width of the file. To make it easier to penetrate into the thickness of the metal being processed, the notch is made inclined at an angle of 25⁰. The result is cutting with some displacement. It makes it easier to penetrate deeper into the part. The effort is slightly reduced.

The double design of the notches is made at an angle to each other. The second cut is made at an angle of 45⁰. Now the cutting teeth are limited in length. Where the lines intersect, places where chips break are formed. Consequently, such files require less physical effort during operation (no need to waste effort on twisting long shavings).

Types of notches

There is a classification option based on the type of notch applied. A little has already been said about single and double execution.

Meanwhile, there are two types of double notching. The first is called crossover. This is, in fact, a combination of a single and a second, small (auxiliary) one, it is performed at an angle to the base one. At the intersection points of the grooves, the resulting chips are broken. This type is most often used in the production of bench files.

The second version of the double notch is called Oberg. Auxiliary grooves are less frequent. In fact, this option can be called intermediate between single and double notches in terms of the quality of part processing.

Numbering of notches

The application is determined by taking into account the type, size and configuration of the applied teeth. To obtain a working surface, various technologies are used:

- roll;

- milling;

- slicing and many others.

Many manufacturers, in order to increase labor productivity, use specialized equipment that allows them not only to speed up the production of these products and expand the number of their types, but also to maintain their quality at the appropriate level.

The size of the tooth directly depends on the size and type of notch applied per unit length, usually 1 cm. That is, the fewer grooves per centimeter of length, the larger the size of the cutting tooth. In practice, files with cuts from 0 to 5 are used.

Notch No. 2

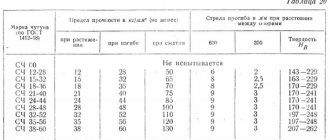

The largest types include teeth with No. 0 and No. 1. They are used when it is necessary to remove a layer of metal from 0.05 to 0.1 mm in one pass. Such a tool has the following disadvantage - low accuracy, it ranges from 0.1 to 0.2 mm.

Files with tooth sizes No. 2 and No. 3 are used in cases where it is necessary to remove a layer of metal from 0.02 to 0.06 mm. The accuracy of such a tool is from 0.02 to 0.05 mm.

For surface finishing, a product is used that allows you to remove a layer of metal from 0.01 to 0.005 mm. An instrument of this type is sometimes called a velvet instrument.

Geometric parameters of the notch

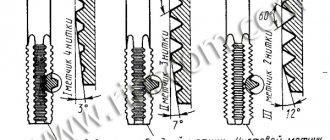

In accordance with the requirements of GOST 1465-80, set out in clause 2.1. On the surface of the tool, the notch is applied at an angle of 65 degrees relative to the axis.

In addition, it is also specified what technology it should be used to carry out. For example, round files can be made either by knurling or threading. All other types must be made using a notch.

Types of files and their purpose

Types of files by class and shape determine the main scope of application.

Class 1 includes tools with a notch numbered from 0 to 1.

This is a rough file; its main task is rough surface finishing.

The second class includes tools with abrasives No. 2 and 3.

This is a less coarse file, it is called a personal file, and is used primarily for finishing, because... it leaves a smoother surface.

Tools of classes 3,4,5 and 6 have a notch of 4 and 5 numbers.

They are better known as “velvet” or jewelry files and are used for finishing.

Types of files by shape

Classification by form subdivides the scope of application in more detail.

1. Flat, blunt-nosed files are considered universal tools because... They are designed for working on metal and wood.

They can easily handle flat and convex surfaces. They have a single notch on one of the side faces.

2. Flat pointed blades are used for processing external or internal flat surfaces; they are also used for sawing slots and grooves.

3. Square products have a sharp nose; they are used for sawing square and rectangular holes and narrowed surfaces.

4. The triangular shape is available in two versions - for layer-by-layer cutting of materials, processing internal corners of various shapes, triangular holes for filing small grooves and wedge-shaped grooves.

This type is also used for sharpening wood saws, which is why they are also called hacksaws.

5. Round shape - this type, like the triangular one, has two different subtypes.

For processing round grooves, holes, layer-by-layer sawing and for sharpening wood saws and saw chains.

6. The semicircular type classifies the tool as a universal one, as it combines the advantages of flat and round files.

Ideally performs processing of spherical and flat surfaces, has a pointed nose.

7. The rhombic shape makes it possible to effectively process materials with complex surface configurations, including working with gears, sprockets, wheels, and disks.

Files intended for specialized operations are called special purpose tools, these include diamond coatings and other cutting surfaces of higher hardness intended for non-ferrous alloys, metal, tiles or ceramics and other materials.

Types and sizes of notches

The nature of the notch determines the main types of files.

The profile and size of a file's teeth depend on the machine used to apply the cutting surface.

Typically used for production:

— saw-cutting machines with chisels; — milling machines; — grinding machines with special wheels; — gear cutting and broaching machines.

Regardless of the production method, all teeth have specified parameters for the angle of location, sharpening and cutting.

The more notches per 1 cm of working area, the smaller the notch teeth.

The ratio of the height to the pitch of the main notch must be at least 0.5.

File material

According to Russian and international standards, files are made from carbon tool steel.

These include the most common brands:

- U 10,12, 13; — At 10, 12, 13 A; — ShKh15 UA; — 13X and their foreign analogues.

File appearance

Today, a large number of this tool of various shapes are used. It can be classified not only by the shape of the section, but also by the shape of the bar itself.

Use of files of various shapes

Indeed, the shape of the bar largely determines the scope of application. That is, flat, used for processing flat surfaces located inside or outside the part. Square ones are used to develop holes of various shapes. Triangular has found its application in the processing of grooves and other parts. In addition, it is used for sharpening saws and other tools.

Sharpening a saw chain with a file

Semicircular, which can have a rectangular or pointed shape, are designed to work with convex or concave surfaces.

Round, used for working with round or oval holes. Diamond-shaped files are used to process gears.

Such an abundance of this tool (shape, size, etc.) can lead to confusion. And many sincerely believe that you should keep as many files as possible in your home workshop. But this is nothing more than a misconception. In fact, most surface treatment work can be done using tools of the following shapes - straight, round and triangular.

Set of files

By the way, the service life depends on the material, heat treatment parameters and the size of the notch.

Using files

Different shapes need to be used for certain parts. The classic flat model is used when you need to sand smooth surfaces. Triangular machines process grooves and grooves. Work is performed at an angle. Square - holes of different shapes. The bumps are ground into semicircular shapes and the grooves are leveled.

Metal files are considered a universal tool that is used for processing parts of various shapes. The variety of shapes, sizes of devices, and tooth sizes allows you to expand their scope of application.

Teeth size

In addition to the tooth size, products of this class differ from each other in the cutting density.

For rough surface treatment, products with large notches are used. It is called No. 1; there are from 5 to 15 teeth per centimeter. Its use makes it possible to remove a fairly thick layer of material in one pass, especially from soft materials; I call files of this type wrangler files.

Files No. 2 have from 14 to 25 grooves per centimeter of surface. This is perhaps the most popular type of this instrument. In fact, this file is most often used in practice.

Double cut file

Indeed, it can be used to process almost any material. But there is one subtlety: when working with soft metals or wood, after a fairly short time the notch will be clogged with processing waste. This is why it is necessary to clean the work surface with a wire brush.

Products with notches from 26 to 80 grooves per 1 centimeter are used for final surface treatment. After proper processing, there are practically no traces left on the surface.

Types of files

Despite the apparent simplicity of the tool, there are many classifications of files and their types. According to the number division, files can be: • Brutal files – No. 0-1. Designed for removing rust. Thanks to the large teeth (up to 12 notches per 1 centimeter of the working surface), it is easy to scrape off rust with a bastard tool, leaving a smooth, cleaned surface. • Personal and semi-personal – No. 2-3. Needed to remove excess layers of the workpiece. They have 13-44 notches per cm of surface. Thanks to this, you can quickly remove excess thickness from metal, plastic or wooden parts. • Velvet – No. 4-5. Needed for final processing. Due to the notches (from 80 pieces per 1 cm), this type ideally polishes the surface, removing small chips and burrs. In addition to the types of files, it is also important to understand the type of cuts. There are five types in total: 1. Simple single abrasive coating. Needed for soft metal. 2. Double coating. Reinforced notching is used to process steel, bronze and cast iron. 3. Cross. The notch has a cross appearance. This file is available with teeth for rough cutting and fine teeth for grinding. 4. Spot. A notch of burrs that is convenient for processing wood, rubber, leather, etc. 5. Arc milling. For hard wood and non-ferrous metals. Thanks to this abrasive coating, the treated surface is of good quality and can be easily sanded with a fine abrasive.

Sharpening a cutting tool using a file

The group of cutting tools includes cutters, cutters, axes, saws and many others. The operating mode and the material from which the cutting tool is made determine the frequency of its sharpening. This operation is performed in two passes. The first is the sharpening itself, the second is bringing the cutting edge to the necessary requirements. That is, it must be brought into working condition. The cutting edge must be sharpened at a certain angle, it must have a certain shape. These parameters are determined by the material of the part.

Sharpening a shovel with a file

During the finishing process, burrs formed during the primary sharpening process are removed from the cutting edge.

For finishing cutting tools, products with fine notches are used. These can be files, bars and other abrasive materials. Finishing operations can be performed either using special equipment or manually.

Which notch to choose

When choosing any tool, first of all you need to understand what goals should be achieved when processing the part. Files are most often used to remove layers of material. Undoubtedly, if we are talking about removing material within 0.1 mm, then it makes sense to use files with a notch of No. 0 or No. 1.

File with cut No. 3 for metal

To perform more delicate work, for example, preparing the surface for coating, you can use a tool with a notch No. 2 - No. 4.

To perform work related to threading the cutting edge, grinding the surface and other particularly precise work, so-called velvet tools are used.

How to make a file handle

Those who often use a file in their work sooner or later are faced with the fact that its handle becomes unusable and therefore the question of replacing it arises. Of course, you can go to a hardware store and buy a ready-made part. But this is not always the best solution. As a rule, they sell handles made of plastic or unknown types of wood. This is why many people prefer to make pens with their own hands.

Material selection

Practice shows that the optimal material for a handle can be considered materials such as walnut, maple. These are quite durable materials; in addition, they have an attractive texture.

Handle walnut

But in addition to the material for the handle itself, you will need to select glue. To connect the component parts of the tool, it is advisable to use adhesives based on epoxy resin.

How to make it

To make a handle, you can use a lathe. If this is not possible, then you can remember your childhood and sharpen it with a knife.

When making a handle, it makes sense to maintain the following dimensions:

- working part diameter 25 – 30 mm;

- working part length 120 – 150 mm;

The depth of the hole for securing the tool shank should be slightly longer than the shank itself.

The final operation in the manufacture of a file handle is to treat its surface using abrasive sandpaper. This is necessary so that there are no burrs left on the surface of the handle that could dig into the worker’s hand.