Purpose and principle of operation of the filter well

The filter well is used as a natural purifier for wastewater. It is used in the absence of sewerage and the possibility of discharging household water into a reservoir intended for such waste.

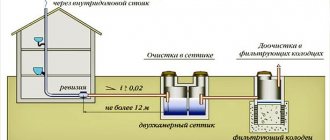

The picture explains the functioning of such a well

The domestic water purification system is quite simple.

Water from the house ends up in a septic tank or septic tank, where some of the heavy particles settle. Partially purified water is discharged through a pipe into a container.

A filter well for a septic tank is used not only as a place for water drainage, but also as an additional filter, where the last stage of cleaning ends and the liquid is absorbed into the ground. If the volume of household waste is no more than 1 cubic meter per day, then a cleaning tank is installed on the site as an independent structure. Otherwise, it performs the function of water treatment.

The structure is installed at a distance of 30 meters from the source of drinking water.

Installation of a filter well

First of all, it should be noted that the cleaning well is only suitable for certain types of soil.

Sandy soil, peat, loose rock soil that contains some clay are an excellent place for the natural filter to fully function. A filter well in clay will not fully perform its functions, since clay, by its nature, allows water to pass through very poorly. For soils that poorly purify and absorb liquid, there are other methods of water purification.

In addition, the soil also affects the area of the structure and its service life. The efficiency of the filter is achieved due to the depth of groundwater, which should be half a meter lower than the bottom of the well.

Advice. It is not worth installing a filter well if the groundwater level is high, since the water will not be able to be absorbed into the ground. It is also worth considering the depth of soil freezing in winter.

The filter well consists of:

- floors;

- walls (concrete, brick, tires, plastic barrels);

- bottom filter (crushed stone, brick, slag, gravel);

A bottom filter is a mound at the bottom about a meter high. Large particles are placed in the middle, and small ones around the perimeter.

Example of a bottom filter made of stone

Before entering the cleaning tank, wastewater is located in a septic tank. Then it moves through the pipe into the well.

The distance between the septic tank and the filter well should be 20 cm.

The walls for the well can be a barrel, brick, stone, standard concrete rings and tires. The main thing is that they have holes with a diameter of up to 10 cm and are located in a checkerboard pattern.

The filter container must be equipped with a ventilation pipe with a diameter of 10 cm. The pipe should be at a height of about a meter above ground level.

The standard dimensions of modern filter containers are 2 meters in diameter and 3 meters deep. They are built square or round in shape. A few years after the start of operation of the wastewater filter and the appearance of the first problems, everyone asks themselves the question of how to restore the filtration of the filter well.

And it stops letting water into the ground. To slow down this process, experts recommend installing several water sumps. And in case of severe silting, call a sewer truck.

We make such a well from available materials: bricks and tires

To install a filter well, a large pit is dug from brick. The formwork is installed and covered with bricks. The stone is placed at a short distance. A drainage layer is poured into the bottom of the container. And the top is closed with a wooden or plastic lid.

Example of a well made from used tires

A cheap and affordable option is to create a filter well from tires. Most often, car and tractor tires are chosen for this purpose. Such a structure is not durable, but can serve for the benefit of the environment for more than 10 years.

The process of arranging the container is quite simple.

First, a hole is dug the diameter of the tires and filled with crushed stone about 30 cm thick. Remains of brick and slag are also suitable. In addition, the space between the tires is filled with crushed stone. A hole is cut in the top tire for the pipe. To ensure waterproofing on the outside, tires are wrapped in thick polyethylene or roofing felt.

Installing a filter well is mandatory for any country house where there is no central sewerage system. This will help protect groundwater from contamination with dangerous chemical particles.

The video shows the process of building a filter well. Be sure to watch it.

Material for the well

Different materials can be used to organize wastewater treatment plants. When choosing, you must be guided by performance characteristics.

| Name | Concrete | Brick | Metal | Polymer |

| Strength | high | average | high | average |

| Corrosion | low | average | high | absent |

| Resistance to aggressive environment | high | average | low | high |

| Waterproofing | needed | needed | not required | not required |

| Installation time | average | long | fast | fast |

| Need of mechanisms | Yes | not required | Yes | not required |

| Lifetime | more than 50 years | about 30 years | about 10 years | more than 50 years |

| Price | average | high | high | average |

Based on the data indicated in the table, it is economically profitable to use concrete or polymer materials. The latter are durable, guarantee a high level of tightness, and are not subject to corrosion. They are easy to install, but their low weight can be a disadvantage, especially in heaving soils where the structure may be squeezed out.

How to make a filtration well

Absorption wells can be built from baked bricks or rubble stones, but their construction requires considerable effort. Therefore, more often the walls of the well are made of reinforced concrete rings. Today, plastic structures are also widespread. You can make them yourself from plastic pipes or buy ready-made ones.

Option No. 1 - brick structure

The brick structure can be either round or square. Usually round wells are built, which are most convenient to use. The structure for filtering sewage should be buried 2.5 meters into the ground, with a diameter of no more than 2 x 2 meters.

The pit is dug in such a way that between the ground and the outer walls of the well there will be a layer of crushed stone, gravel or broken brick up to 40 cm thick. The height of the backfill is one meter. The walls at the filter level must be water permeable.

To do this, the masonry to a height of one meter is not made solid, but with small holes ranging in size from 2 to 5 cm. They must be placed in a checkerboard pattern. After the structure is erected, crushed stone or gravel is poured into the cracks.

When building a well, it is necessary to make cracks in the masonry to allow purified water to exit into the ground.

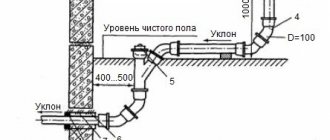

At the bottom of the structure, a filter layer of crushed stone or gravel is backfilled to a height of one meter. In this case, large fractions of the material are placed at the bottom, small ones at the top. The hole for the pipe through which drainage from the septic tank will flow is made in such a way that water flows in a stream from a height of 40-60 cm.

A plastic sheet must be placed in the area where the water flows to prevent the filter from being washed away. The structure is closed from above with a lid or hatch with a diameter of 70 cm. It is also necessary to make a ventilation pipe in the well with a cross-section of 10 cm. It should rise above the ground by 50-70 cm.

You will find step-by-step instructions for constructing a brick drainage pit.

Image gallery

Option No. 3 – a well made from old tires

The most inexpensive way to make a filter well is to make one from used tires. This design can provide filtration of sewage for a family of three. Basically, such a well is made in summer cottages, since in winter the rubber freezes and the activity of bacteria slows down, and at very low temperatures it stops altogether.

The well is made very simply - the tires are installed one on top of the other and fastened together with plastic clamps. The joints are coated with sealant. All other structural elements are made in the same order as in wells made of other materials.

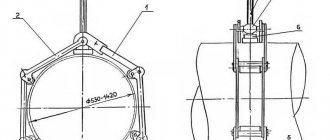

Scheme for installing an absorption well from old car tires. The number of tires is calculated based on their size and the required depth of the well

Option No. 4 - plastic filter containers

Today you can purchase ready-made filter wells made of plastic, equipped with everything necessary for effective wastewater treatment. Of course, they cost a lot, but they are reliable, convenient, easy to install and maintain. There are many companies producing such equipment on the market.

For example, the Russian company POLEX-FC, whose products received good consumer ratings. Filter wells are produced in different volumes (from 1200x1500 to 2000x3000 mm), which allows you to select a product based on the daily water consumption of an individual household.

The containers are made of corrosion-resistant durable plastic, the walls of the shaft are made of primary polyethylene. The lower compartment of the tank is covered with biofilm and filled with a filter layer of crushed stone, gravel and slag.

You will learn how to make a well from old tires from the following video:

Filter structures perform a very important function - they provide effective wastewater treatment and do not allow dirty, untreated water to enter the ground, which, when released into the soil, causes significant harm to the environment.

It’s not that difficult to make a filtration well yourself, but if you don’t want to bother with arranging it and you have the financial opportunity, you can buy a ready-made plastic well.

Preparing for work

To set up a sump you will need:

- shovel;

- construction mixer;

- solution container;

- hacksaw;

- tape measure, plumb line, level;

- putty knife;

- Bulgarian;

- technical knife or cutter;

- hammer;

- nails.

A sump tank made of concrete rings is the most reliable option for such a structure. The main difficulty in arranging the structure is the availability of special skills and the need to attract special equipment.

First you need to dig a pit the size of the sump. The soil at the bottom must be leveled and compacted tightly. Next, a cushion of sand and/or fine gravel is poured. Thickness - at least 10 cm.

Next, the bottom of the pit must be concreted. You can lay a finished concrete slab in the shape of a circle or install a ring with a bottom.

The rings must be installed evenly and carefully. It is better to use elements with a locking connection - this will ensure the reliability and tightness of the structure. In the upper ring it is necessary to first equip a hole for connecting the sewer pipe.

The joining seams on the inside of the tank must be cemented with a solution containing liquid glass. When the cement has set, the seams are additionally treated with special mastic.

The top cover is made of a concrete slab. It is necessary to equip it with an inspection hatch and a ventilation outlet.

The free space in the pit around the finished structure must be filled with soil and compacted. For decoration, you can use suitable items and landscape design options.

Car tires from large vehicles can also be used to create a sump. The rubber must be solid, all small cracks and/or holes must be carefully repaired.

The tires are laid evenly on top of each other in a specially dug pit. Arrange an inlet and outlet for water. All joints must be carefully sealed.

A concreted wastewater collection tank is installed in a specially dug rectangular pit. The walls and bottom must be leveled. Place a cushion of sand, gravel or crushed stone at the bottom.

Formwork is installed along the walls. Be sure to apply reinforcement from a rod with a diameter of 8 mm. Then the bottom and walls are filled with concrete. The concrete will dry for about a month.

The soil around the finished tank must be compacted, filling the free space completely, and compacted thoroughly, otherwise even minimal soil movement will cause cracks to appear.

A metal sump is a ready-made container to which a sewer and drainage pipe is connected. You can use a large metal drum, tank, and/or tank. The main thing is that the material of manufacture is protected from corrosive processes and rust.

The plastic tank is a lightweight, sealed design. Modern industry offers similar products of various sizes. The cost is low and the installation method is simple. Everything can be arranged on your own. The main thing is to thoroughly weight the plastic tank so that it does not rise when it is not completely filled.

A modern version of a tank for a home septic tank is a Eurocube. This is a rectangular container of various cubic capacity, designed for transporting and/or storing water and/or other liquids. The material of manufacture is multilayer plastic, on top of which a protective metal mesh is placed.

Decommissioned Eurocubes can be purchased at a relatively low price at various enterprises. The container weighs a little, there will be no problems with delivery. When installing a plastic sump, it is necessary to install a concrete slab base in the pit. She is placed on a sand cushion. You can build the formwork and make the screed in the usual way.

The Eurocube or other plastic container is attached to the concrete with a metal cable or special belts. To do this, metal parts are placed in the screed to secure the retaining elements.

The horizontal position of the installation is checked by a level. You can pour some water into a plastic tank. Special products with aerobic microorganisms will help get rid of the unpleasant odor as sewage accumulates.

A settling tank made from old barrels is also a good option for arranging a settling facility. A house for a seasonal holiday or a summer cottage, where there is no washing machine and bathtub, can be provided with a sump from 2 plastic barrels. First you need to dig a trench with the following parameters: depth at least 1 m, length - 6 m, width 1.5 m.

For the 1st barrel, you need to make a removable lid to remove settled solids. It also has an entrance for the sewer pipe. In barrel 2, a hole is made to connect a pipe through which clarified water will flow into the drainage system. Both containers are connected to each other by an overflow pipe.

The prepared barrels are placed in a trench. The lid of the first container should be 10 - 15 cm below the soil surface. The second container is placed 30 cm below 1 barrel.

Next, mandatory insulation of the system is carried out. Frozen water will create many problems and can ultimately destroy the entire structure.

Outlet pipes are laid into prepared drainage ditches at a slight angle of inclination. The free space is filled with bulk material (sand, crushed stone, fine gravel). A layer of soil is poured on top.

Video

See how the process of arranging a filtration well goes:

The design of the well can be arbitrary, but one condition must be met - compliance with the task of ensuring filtration of water, which can flow with varying intensity.

To select the most appropriate type of treatment facility in specific conditions, a number of circumstances should be taken into account, including: the presence of an aquifer, the presence of a conventional well, and soil type. IMAGE 1 illustrates the design of the filter well, as well as the standards that should be taken into account when deepening.

In some cases, certain circumstances do not allow the installation of a filter well, but if subjective and objective conditions favor the use of this cleaning element, the question of which side of the site is preferable to locate it will be quite logical. Thus, you can easily set up a filter system with your own hands on soils suitable for filtration, including: sandy, sandy loam, peat.

Image 1. Design of a filter well.

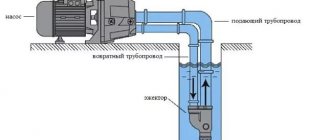

If you try to build such a filter in clay soil, there is a possibility that the system will not take root there. The filtration area is also important for the filter well, which can be equal to an indicator in the range of 1.5 m², which is true for sandy loam, and also 3 m² for sand. The larger the filtering area of the system, the longer its service life will be. IMAGE 2 shows how the walls of a well can be laid using bricks.

In order for the filter well to be able to fully cope with the assigned tasks, it must be located in an area below the level at which the filter bottom, which is a cushion made of crushed stone, is located. In this case, the distance from the bottom to the water should be no less than 0.5 m. The base of the system should be 1 m above the groundwater level. If the area is characterized by a high groundwater level, in this case it is preferable to abandon the installation of a filter well.

Installation Features

Installing a plastic septic tank is quite simple, the order of work is:

- The foundation pit is being prepared. To do this, dig a hole that is 20 cm larger than the dimensions of the plastic container. The depth should be such that after installation is completed, the lid covering the septic tank hatch remains above the ground surface. At the bottom of the pit, a layer of sand 15 cm high is poured and well compacted. In most cases, a reinforced concrete slab is laid in the pit to secure a light plastic structure on it. If you do not secure the septic tank to the slab, it may float when the soil water rises in the spring.

- Next, the septic tank is installed and communications are connected to it.

- To avoid deforming the body when filling the pit, it is necessary to fill the septic tank with water. Backfilling is done with sand mixed with dry cement. You need to pour the mixture in layers 20 cm high and compact it well;

- After installation is completed, the cover covering the hatch can be decorated. You can buy ready-made decor, for example, in the form of an artificial boulder, hollow inside, or make the decor yourself.

So, when installing a local sewage system, it is beneficial to use a reliable and sealed plastic septic tank. There are different options for plastic treatment plants, so in each specific case you can choose the most suitable model.

Do-it-yourself installation of a filter well for sewerage video

- wheelbarrow;

- shovel;

- hammer;

- construction knife;

- axe;

- hacksaw for wood and metal;

- roulette

- Organization of access road

. Having chosen a place for such a treatment device, you need to provide an access road to it. Over time, a lot of sludge forms at the bottom of its structure, and the filter ceases to cope with its purpose. In this case, you cannot do without the help of a sewer truck. - Excavation of a pit

. If reinforced concrete rings are used for the shaft walls, the process involves first installing the first ring. Then you need to dig up from inside the ring, throwing the earth out. The ring will gradually sink into the ground under the influence of its mass. After the first ring has descended underground to its full height, bricks are laid in which holes are provided in a checkerboard pattern. After this, the next ring is installed and digging of the pit continues. - Pipe installation

. It will carry wastewater coming out of the septic tank to the filter. It should be placed 10 cm above the bottom filter on a slope. - Arrangement of a filter pad

. For the bottom filter, the following is poured in the center: gravel, expanded clay, slag of large fractions, and its smaller particles near the walls. At a level of 15 cm from the bottom filter, a hole is made to the septic tank. - Floor installation

. It can be used as a plastic lid of a suitable diameter or a homemade wooden round ceiling. If the filtration device is used all year round, then it makes sense to install two covers with a gap between them. In this space it will be necessary to distribute insulation in the form of mineral wool or a sheet of polystyrene foam. To make it convenient to check the condition if necessary, a lockable hatch should be provided inside the filtration device, the diameter of which should be at least 70 cm.

After digging and arranging the mine, it is covered with a large layer of earth. In order not to spoil the landscape appearance of the site, this place must be decorated in any way you like.

The trend of fighting for the environment is gaining momentum. Few people think about the fact that wastewater leaving the house should be passed through a filter.

The discharge of dirty domestic water into the ground is strictly prohibited by the legislation of many countries.

To do this, it is recommended to dig and install purification underground fields, trenches and wells. The choice of structure depends on the condition of the soil and the depth of fresh water deposits.

Often, owners of suburban areas prefer filtering wells. They are effective and easier to install. In addition to solving problems with contaminated wastewater, filter wells for storm sewers are being installed.

Their goal is to free the area from excess liquid that has formed as a result of heavy rains and melting snow. Most often, such containers are constructed from plastic and reinforced concrete.

Filter field

In the private sector, this solution to the problem of wastewater disposal is less common. But there are a number of conditions when the organization of a drainage field is mandatory.

- The soil on the site, due to its characteristics, is not capable of intensively absorbing liquid. Consequently, with a volley discharge or a constant large volume of wastewater, the performance of the septic tank will decrease. Therefore, the filter elements are distributed over a large area, forming a drainage field.

- High groundwater level. In this case, the filter well is not able to perform its function due to the small layer of earth between its bottom and underground water. In addition, there is a high probability of periodic flooding of the mine, as a result of which sewage penetrates into the soil.

Essence of structures

At its core, a septic tank is a well that is used to collect or treat household wastewater in the absence of a centralized sewer system in private homes and suburban areas. The principle of its operation is based on gravitational settling and additional purification by biological methods using bioenzyme-based products.

In addition, soil filtration is widely used, both natural and forced. On the territory of the Russian Federation, when designing and constructing septic tanks, Code of Rules 32.13330.2012 “Updated edition of SNiP 2.04.03-85 Sewerage. External networks and structures."

When designing your own sewer system, it is very important to correctly determine the place where you can dig a well. There are a number of completely natural requirements for the placement of a septic tank that make it possible to exclude contamination of drinking water, nearby groundwater, contamination of residential areas, i.e.

aimed at ensuring sanitary safety.

First of all, strict standards are established that determine the minimum distance from the septic tank to vital facilities. The following requirements must be observed:

- the distance from the septic tank to a well with drinking water is 50 m;

- to a residential building - 5 m;

- to an open reservoir - 30 m;

- to the garden (fruit trees) - 4 m;

- to the road - 4 m.

The most important characteristic of septic tanks is volume. It is usually set at the rate of 200 liters of wastewater per inhabitant per day. Naturally, the total volume is calculated by multiplying this norm by the number of residents, and if people permanently live in the house, it is recommended to increase the planned volume of wells by 20%. Most of the useful volume should be in the first section of the device (up to 75%). The well for the septic tank should not be placed in a low area, because there is a risk of replenishing the tank due to the influx of sedimentary or melt water.

Septic tank made of concrete rings

A septic tank made of reinforced concrete rings will help solve the problem with the sewerage of private houses. Its turnkey cost is much cheaper than its plastic counterparts. The service life of such a septic tank is practically unlimited. In addition, this is an autonomous structure that only requires timely pumping out of waste.

During the settling of domestic wastewater, silt accumulates at the bottom of the receiving well. If it is not eliminated in a timely manner, the drainage well may become silted, which will lead to the septic tank overflowing. We recommend pumping out waste at least once every two years, and also using bioadditives for septic tanks and cesspools.

How we calculate the required septic tank at Ecovel

- We take into account the number of people who will use the sewer system

- We clarify the seasonality of residence on the site

The volume of one ring with a meter diameter and a height of 0.8 meters is 0.63 m3.

For one person with regular residence, a volume of 0.6 m3 is required. These data serve as guidelines for choosing a septic tank configuration.

If you are permanently living on the property, we recommend installing a concrete septic tank of three sections.

Main options for septic tanks

At Ekovel, we can draw up a septic tank diagram individually for you.

The price of a septic tank includes: material, delivery to the work site within 100 km from the Moscow Ring Road, unloading, digging of shafts, installation of rings, covers, overflows, concreting the bottom, rolling rings at a distance of up to 20 meters.

Features of installing a septic tank

- The distance from the septic tank receiving well to the sewage discharge site should be in the range from 5 to 20 meters. An increase in this distance entails a decrease in the effective volume of a septic tank made of reinforced concrete rings.

- According to operational standards, the working volume of the septic tank's receiving well must be 3 times greater than the maximum possible daily volume of sewer discharge.

- If the groundwater level in your area is located at a depth of less than 1 m from the surface of the earth, a septic tank made of concrete rings is unlikely to solve the sewage problem.

- In most areas of the Moscow region there is no need for our construction team to live. But if such an opportunity exists, this will reduce the construction time of a septic tank made of reinforced concrete rings.

- The rings are delivered by a manipulator. Therefore, it is necessary to allow special equipment to reach the site at least within 50 m from the installation site of the septic tank.

Close estimate example

| Rings KS10-8 (5 pcs) | 10000 rub |

| Covers PPL10-1 (2 pcs) | 8000 rub. |

| Installation of rings KS10-8 (5 pcs) | 12000 rub. |

| Installation of cover PPL10-1 (2 pcs) | 1800 rub. |

| Concreting the bottom | 1500 rub. |

| Overflow installation | 1700 rub. |

| TOTAL: | RUB 35,000 |

See all prices

Call and consult now

We will select the right septic tank option for your home or cottage, tell you about the advantages of various options and how the work is carried out.

Size calculation

The rate of water seepage through the soil depends on its type (clay, sand, black soil, etc.). On average, the consumption rate per person is about 125 liters. These two criteria are decisive when calculating the parameters of a well.

Let's look at this with an example:

- The soil is loam, the filtration rate is 50 l. per day per 1 m2.

- Accommodates 4 people - average consumption is 500 liters per day.

- There will be no stagnation of water over an area of 10 m2.

- The size of the well bottom is about 2–3 m2.

- To organize an effective drainage system, 3 collectors are needed.

If several collectors will be placed on the site, there should be a distance between them that is twice the size of the chamber.

Main types

There are several types of sewer filter structures that operate on a similar principle, but differ in scope.

- The drainage type of well is used as an addition to a complex drain system - an underground pipeline with perforation. The well serves to drain water from buildings and plots of land, and also filters silt and sand, allowing the water to be purified for discharge, for example, into a reservoir.

- To clean the septic tank, an additional filtration well is used, which has a thick filtration cushion (at least 60 cm, preferably 1 meter) made of several layers: sand, crushed stone, broken brick, waste slag.

- For open sewerage. Such wells are also called inspection wells. The owners have the opportunity to visually monitor the level of filling of the well. The filter material is located at the bottom. If the well fills quickly, its contents can be pumped out with a pump.

Design principles

A septic tank is a sealed container consisting of several sections. The single-section option is used extremely rarely; the most common designs include two or three sections.

Two-section septic tanks are used with a drainage volume of 10 m³/day, and three-chamber septic tanks - over 10 m³/day. As a rule, all sections are combined into one common body (metal, plastic or concrete), but a separate design is also possible.

Each section (chamber) performs specific functions. The first compartment directly enters the sewer drain. This zone provides rough treatment of waste liquid - gravitational sedimentation and mechanical filters. In other words, in section 1, large and heavy sewage precipitates under its own weight and is filtered by a mesh. At the bottom, sludge gradually forms from such components.

The second chamber is considered an anaerobic reactor. It decomposes compounds formed under the influence of detergents, personal hygiene products, and various organic matter of natural origin. Catalysts can be added to speed up the reaction. Section 3 of the septic tank plays the role of final treatment, where the final clarification of wastewater is ensured.

Here, with gravitational settling of suspended particles, a purification degree of over 62% is achieved. All sections are interconnected and have shut-off equipment that does not allow flow back. In the two-section version of the septic tank, the second chamber is eliminated.

- Filtration well. At the bottom of the last section, a natural filter is formed from layers of sand and crushed stone. The construction of such a system is permitted provided that the depth of groundwater exceeds the depth of the septic tank by at least 1 m, and the lower filter layer must be at a height of at least 50 cm above the water layer. This is the only way to ensure reliable soil post-treatment of runoff.

- Filtration trench. If the groundwater rises high or the soil is clayey, then the well cannot be deepened, and the discharge from the last septic tank occurs in the upper layers of the soil. In order to ensure filtration under such conditions, it is necessary to increase the filter area, which is achieved by forming a closed trench. It can be dug in an open way with a length of up to 10-15 m from the wells. Sand and gravel are laid at the bottom along the entire length, ensuring a gradual release of runoff into the soil.

- Filter field or absorption trench. This structure is formed from a system of drainage pipes, i.e. perforated pipes. They cover a significant area to ensure drip discharge. A filter field is being installed to meet increased sanitary requirements.

When designing septic wells, the following basic requirements are put forward:

- The first section must have the required volume and be completely sealed to prevent impurities from entering the soil. The sewer inlet is located at the top of the tank, while the outlet is located at the bottom of the section, but above the sediment. A mesh is installed at the outlet to trap large particles.

- In the second section, gaseous decay products of wastewater accumulate, so in addition to complete sealing from the soil, care should also be taken about insulation in the hatch area. To reduce the dangerous concentration of pathogenic microorganisms, antiseptics and specific compositions with beneficial microorganisms, in particular methanogenic bacteria, are introduced into this chamber.

- The last chamber must ensure the discharge of purified runoff into the soil, that is, it must have a filtration system.

Operating principle of sewer settling tanks ↑

In the process of settling water under the influence of gravitational forces, suspended substances and mechanical impurities are extracted from it, which, after sedimentation, are exposed to anaerobic microorganisms and turn into sludge. The clarified water flows further through the system, and the heavy fractions remain at the bottom of the well.

The efficiency of the settling tank is related to the flow rate of the wastewater. The longer the water sits in the well, the more suspended particles are filtered out. Therefore, much depends on the volume of the storage tank and the number of cleaning chambers.

The simplest one- and two-chamber sedimentation tanks for sewerage

Do-it-yourself septic tank, what is it and types

Installing an individual sewerage system on a private plot involves not only laying pipes from the house to the cesspool. Let's say more, it is the pit itself that does not have a place on the site.

Since the presence of such an object is prohibited by SNIP standards, SES authorities and, by the way, is considered a criminal offense in Russia. Because wastewater, feeding the soil, can freely seep into aquifers located high up. As a result, there is a risk of contamination of water taken from the horizon.

In addition, sewage can end up in nearby bodies of water, and simply become an unpleasant nuisance to both you and your neighbors.

In this case, a septic well is urgently needed on the site. What this system is, we will understand below.

A septic tank is a local wastewater treatment system that is installed at a given point on the site (most often at the bottom).

Septic wells look like huge chambers, divided into three sections by special partitions with a water seal.

There are openings on both sides of the tank, one of which is the inlet and the other the outlet. The lid of such a septic tank with a well is monolithic and has inspection hatches.

The principle of operation of a septic tank

A septic tank is a local wastewater treatment system that is installed at a given point on the site (most often at the bottom)

A well for a septic tank works to treat domestic wastewater and to discharge purified water into the ground. The system works like this:

- Domestic wastewater with impurities of feces, possible household waste (cleaning, small crumbs, etc.), as well as household chemicals, is discharged through a sewer pipe into the first chamber of the septic tank well. There the liquid settles, after which heavy debris settles to the bottom of the sand, while lighter debris remains on the surface of the water, forming a film.

- Then, through a hole with a water seal, the water separated from the debris and settled into the second chamber of the septic tank well. Here, under the influence of bacteria, water decomposes into gas, which is removed through the air duct, and water itself, which is already devoid of harmful compounds.

- After this, the purified water is sent to the third chamber, which has wells for the septic tank. Here, through a special drainage system, water purified from harmful compounds seeps into the ground and is removed by self-propelled water.

Important: all septic tanks and treatment wells require regular pumping of settled debris and feces from the first chamber. Only in this case will the tank be ready to receive large quantities of domestic wastewater

Types of septic tanks

You can make a homemade septic tank and well with your own hands using available materials (concrete, concrete rings, waste tires from heavy vehicles)

If you want to build wells for a septic tank on your site with your own hands, then you need to know that such a structure comes in two types:

- Factory - with a built-in anaerobic treatment system, simply with a fan);

- Homemade - such a septic tank and well can be made with your own hands from available materials (concrete, concrete rings, waste tires of heavy vehicles).

And if everything is clear with the first option (that is, to install it you just need to dig a pit and connect sewer pipes to it), then we consider the principle of installing a septic tank in a well with your own hands in more detail.

General procedure for arranging a settling tank

To make your own sump from the selected material, you need to do the following work:

- choose the right place;

- dig a pit;

- place a tank in the hole;

- install sewer pipes;

- connect to a second sump or drainage well;

- seal the joints;

- fill the free space around the tank with earth removed when digging a pit;

- compact and compact the soil;

- decorate the external entrance.

If all work is done correctly, there will be no problems with collecting and purifying used water. Maintenance and cleaning of the sump will not require any special costs.