- — What are the assembly holes intended for?

- — Design features of the device.

- - Operating principle.

- — Varieties of climbing cats.

- — Algorithm for checking the device.

- — Conditions and rules for using climbing cats.

- — Rating of the 12 best monter holes and claws for 2021.

- — Which monter's holes and claws are best to choose?

Fitter claws and manholes are used when lifting a worker onto an overhead power line support.

They are indispensable when carrying out electrical repair work, and serve as a kind of alternative to aerial platforms. The products differ from each other in design and characteristics. To understand which models are better, a rating of the best monter's manholes and claws was compiled. Installer's manholes are designed for comfortable electrical work on high power transmission line supports. It is not always possible to use a bucket truck near power poles for one reason or another. Therefore, you won’t be able to climb to a height except for the fitter’s claws. In addition, this option is less expensive when servicing electrical networks

. After all, when using an aerial platform, it is necessary to additionally organize the work process, prepare the place where the equipment will be placed, and ground it. And these are all expenses.

The design of the manhole includes only two elements:

- Two steel elements

. They can be curved or located perpendicular to each other. It all depends on what cross section is provided for the supports.

- Spikes

. They are fixed to the arches. With their help, the device adheres to the surface of the pole.

These parts are attached to the foot platform, to which securing straps are attached. To make it as comfortable as possible for the worker to work and be in an upright position, slings and a harness are added to the structure. They do not allow the worker to slide down the pole. This set is designed to lift only one worker.

The principle of operation of assembly manholes occurs in the following sequence:

- The worker securely fastens the device to his shoes using straps.

- He then uses the grips to grab the post.

- Lifting up occurs due to variable rearrangement of the claw grips along the vertical cavity at an angle.

The operating principle is the same for structures designed for reinforced concrete pillars and for wooden supports. The only difference is that for the cat tree the semicircular grips and spikes are softer.

Depending on which power line support the products will be used on, there are several types of claws:

- For reinforced concrete pillars

. They are considered one of the most popular and sought-after cats among installers and electricians. The hole in the product is curved at a right angle. They are used when lifting along a support with a rectangular cross-section or in the shape of a trapezoid. The peculiarity of the design is that it can be selected to suit any cross-section of the pillar.

- For wooden supports

. The hole is made in the shape of a sickle, which is why they are also called sickle-shaped. The design is not adjustable, since the crescent hole has a fixed size.

There is another type of climbing cat - the dart frog. But their main purpose is to climb tree trunks. Therefore, fitters and electricians do not use them.

Before buying crampons for climbing, it is important to conduct an external inspection of the structure.

. This is necessary in order to visually notice possible damage. During such an inspection, pay attention to:

- how well and correctly the spikes are sharpened;

- the seams of the buckles are reliable and durable;

- removable plates must be intact and undamaged;

- belts must be sewn inextricably;

- reliable connection of the crescent element and the footrest itself.

In addition, the lock nut must be firmly clamped and the lock ring cotter pin must be present. The package must contain all the necessary belts and other fastening elements.

For safety reasons, during electrical installation work, each worker must know the operating rules

. Fitters are required to know and be able to properly use devices and tools during high-altitude work on power transmission towers.

- The design must be used exclusively on those poles that are specified in the product data sheet.

- Before starting work, it is necessary to check the manholes for damage or malfunctions.

- During the inspection, special attention is paid to welds, bolted connections, tenons and fasteners.

- Electricians who work at height are required to undergo special training and instructions, pass an exam and obtain the appropriate permit.

- Every 6 months, assembly claws must undergo a scheduled inspection. This will allow you to detect damage in a timely manner and correct it.

- If cracks or other examples of damage to integrity are found, the product is removed from service.

- If a grounding line is laid along the concrete supports, then climbing with claws is strictly prohibited.

- You cannot climb the pole without a safety belt.

In addition to the fitter's claws, the safety belt is checked for serviceability before work. There should be no other changes to the design itself. It must be complete.

The TOP included models of the best products that stood out for their characteristics, frequent purchases and reviews from satisfied consumers. Also, the advice and recommendations of experts were taken into account.

Structural elements of devices

The design of the devices consists of two elements:

- steel parts located perpendicular to each other or curved in a semicircle;

- spikes, with the help of which the device adheres to the surface of the pole.

The elements are attached to a special foot platform equipped with straps that secure the worker’s feet. To support the worker’s body in an upright position, the devices are supplied with slings and a harness that prevent a person from falling if the structure slips or is damaged. Such a device can be used to lift only one installer. For work in pairs or as part of a team of several workers, you should use an aerial platform.

Purpose and purpose

An electrician's manhole is a tool that allows an electrician to easily climb a vertical pole to carry out any type of work at height. This can be repair, installation, or preventative work.

Outwardly, they look like two hooks with teeth and straps attached to them, with the help of which the device is fixed on the leg. The tool works due to the rigidity of the metal from which it is made.

The diameter of the hook is larger than the size of the post. When the hook is perpendicular to the axis of the post , the leg can move up and down. When the hook is placed at an angle to the axis, movement becomes impossible. This is how the worker fixes his position at the desired height and begins work.

Brief description of the equipment

Modern manufacturers produce high-quality manholes for quick and safe climbing onto concrete supports. All of them have not only positive properties, but also distinctive performance characteristics. That is why experts divide such equipment into three main groups:

- Manholes on concrete. Designed for round and trapezoidal supports.

- Universal fitter claws. They are used for round metal and wooden poles (it is worth noting that in the modern world wooden poles are practically not used).

- Claw-holes. Equipped with a specific control solution, which is especially effective in relation to trapezoidal reinforced concrete pillars.

Claw-holes are considered the most popular, since their functionality can be used in relation to all standard supports. However, manholes are used only on those pillars that are indicated in the accompanying documentation. Of course, any electrical installation company should have quality claws at its disposal, especially if it is involved in the installation and maintenance of power lines.

Modern manholes are made exclusively from high-quality materials, so they can be used in almost any climatic conditions. They tolerate sudden temperature changes well (from -30˚С to +55˚С).

What it is?

Due to the specifics of manufacturing manholes, the equipment is used at ambient temperatures from -30 to +55˚С.

Claws or claws are special devices for lifting a worker onto a power line pole. They are fixed on a person’s legs and make it possible to gain a foothold on a support and stay in one position for the required amount of time. The structure of the manholes will be improved to increase the reliability of the equipment and the speed of climbing to the top. There are three groups of such devices:

It is convenient to climb the round pillars using universal equipment.

- Lazy. Designed for lifting reinforced concrete structures of round and trapezoidal shape in section.

- Universal hooks. The installation tools are suitable for round pillars made of concrete or wood. The latter have lost their relevance.

- Claw-holes. They differ in structure. Equipped with a specific control solution, especially effective in relation to trapezoidal reinforced concrete supports.

The latter devices are used more often than other types, because their specificity allows this device to be used to work with all types of standard supports. The use of manholes is permitted if this possibility is confirmed by accompanying documents. Each company specializing in electrical installation has its own set of tools for servicing power lines.

Areas of use

Multifunctional manholes on concrete supports are designed to quickly deliver an installer to a damaged power line. You simply cannot do without such equipment when laying and servicing the cable, especially if urgent repairs to the electrical network are needed. The team does not always have the opportunity to use large vehicles, which is why manholes are considered simply an irreplaceable option. The main challenges are often related to cramped buildings and difficult terrain.

Quite often, manholes are used to quickly replace LED lighting on street poles. This trend is due to the fact that there is a lot of work, and using specialized equipment is impractical. The huge advantage of this equipment is that the kit includes two strong feet, as well as a universal waist belt, which must be looped around the main post and fixed on the master’s belt using a powerful carabiner. This simply eliminates the possibility that the installer will somehow deviate from the support and disrupt the necessary platform grip.

Separately, it is worth noting that modern claws can be inserted and removed from the main part of the support without any effort; just a simple movement of the leg is enough. The presence of special studs significantly enhances the final grip. At the moment when the weight of the installer presses on the platform, each pin clings to the concrete, which increases contact with the surface.

Installer's claws for working on wooden supports

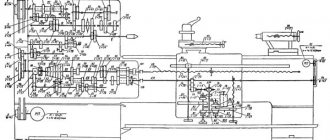

The design capabilities of assembler's claws for wooden supports, commercially produced in accordance with GOST 14331-77, are presented below:

- Type KM-1 – recommended support diameter 140...245 mm, throat 245±10 mm;

- Type KM-2 – recommended support diameter 220...315 mm, throat 315±10 mm;

- Type KM-3 - recommended support diameter 310...415 mm, throat 415±10 mm.

The platform of the KM series claws is stamped, with perforated holes, which makes it possible to increase the reliability of contact of the foot with the surface, while simultaneously reducing the weight of the platform. After stamping, the platform is hardened to a hardness of HRC 38…42. On one of the side surfaces of each platform there are ears for attaching steel arches. Along the remaining edges of the platform there are low sides, the presence of which prevents the electrician’s foot from accidentally slipping. To strengthen it during manufacturing, stiffening ribs are formed on the rear surface of the platform.

[xyz-ihs snippet=”seredina”] The fixing part of the arc rotates freely in the ears, ensuring the fixation of the spikes along the support at the time the line operator is lifted. The permissible play should be no higher than ±15º.

The quick-wearing part of repairman's claws are the spikes, despite the fact that their initial hardness after hardening is 45...50 HRC. For claws on wooden supports, spikes are always made with conical tips. Experiencing significant frictional stress, steel spikes become dull and deformed over time. The durability of carbide studs is much higher, but they are sensitive to impacts and bending loads. Replacing the studs is not difficult, since their fastening part is threaded. The rear part of the platform is also equipped with spikes of a similar design.

The leg of the working person is attached to the arch of the claw using straps. In order to ensure elasticity, their upper part is made of yuft, and the lower part is made of rawhide impregnated with animal fat. The stitching of the belt elements is carried out with nylon threads, and the thickness of the belt and the diameter of the threads are calculated for a load of at least 140...160 kg.

Design versions

The type of claws depends on the material of the support on which the electrician will climb, the diameter of the support and the mouth of the claws in their open position. All standard sizes are standardized in accordance with GOST 14331-77, TU34-09-10147-88, and TU 34-2412-77.

Installer's claws for lifting onto ordinary wooden supports, or supports with reinforced concrete attachments, include the following elements:

- Steel arches, the configuration of which can be in the form of a semicircle (for round supports) or an oval rectangle (for rectangular supports).

- Removable spikes with tips of various shapes.

- Platforms for the feet of the worker.

- Double-layer leather straps that secure the foot.

Structurally close to these products are the so-called fitter manholes. They are designed for lifting an electrician onto reinforced concrete supports, and therefore have a rectangular arc. Combined claws and manholes are also produced. With their help you can climb wooden, metal and reinforced concrete supports.

The operating principle of lineman's claws is based on the fact that, under the influence of gravity, the platform with the electric lineman's leg begins to slide down while simultaneously rotating around its axis. In this case, the arc enters into an obstacle with the surface of the support, and sticks its spikes into the material (for wood), or rests the end of the spike against reinforced concrete or steel. Since the spikes are made from hardened structural steel of grades not lower than 40X according to GOST 4543-81, self-jamming of the spike on reinforced concrete occurs without damage to the spike, and, therefore, is very reliable. In order to increase safety, the number of spikes is at least three. For the most critical applications, replaceable studs made of hard alloys such as VK 25 or VK 30 are produced.

With increasing load on the spikes, the force of fixing the claws or manholes increases.

Claw-holes for concrete, metal, round and polyhedral supports of overhead lines and communications

Professional claw-claws are equipped with a convenient screw mechanism for adjusting the width of the aluminum footrest base with rubber pads and tanned chrome straps.

Reliable adhesion to the reinforced concrete support is provided by profiled, arched, steel paws covered with rubber, anti-slip hoses.

Carabelli Srl's manhole claws are made from high-strength materials, thanks to which they do not bend under weight and do not slide off the poles.

Adjustable claws model 3005

| Dimensions | Ø SUPPORT | Weight, kg | |

| min. Ø, cm | Max. Ø, cm | ||

| 1 | 9 | 22 | 6,5 |

| 2 | 14 | 27 | 6,7 |

| 3 | 16 | 33 | 7,1 |

| 3S | 14 | 30 | 7,1 |

| 4 | 26 | 40 | 7,4 |

| 5 | 28 | 46 | 7,7 |

Non-adjustable claws model 3020

| Dimensions | Ø SUPPORT | Weight, kg | |

| min. Ø, cm | Max. Ø, cm | ||

| 1 | 8 | 16 | 4,2 |

| 2 | 12 | 20 | 4,3 |

| 3 | 16 | 24 | 4,5 |

| 4 | 18 | 28 | 4,7 |

| 5 | 22 | 34 | 5,1 |

carabelli-cis.com

Tree climbing devices

Tree climbing device

For those who have never tried lasagna, it is some kind of overseas, incomprehensible dish. And those who have tried lasagna at least once fall head over heels in love with it. And it’s not surprising, because lasagna is the most favorite dish in Italy and is very popular all over the world. There are as many recipes for lasagna as there are Italian chefs, because the ingredients of this dish are very diverse. This variety depends on the filling and type of cheese that is chosen for making lasagna. The filling of lasagna can be very diverse, including sausage products, various seafood, and all kinds of vegetables. Device for climbing trees There are even options for sweet fillings for lasagna made from fruits and berries. Essentially, lasagna is a matter of layering a base pasta with various fillings, cheeses and sauces. In this section you will find a recipe for making delicious lasagna at home.

We recommend reading: Cat Tapeworms Photos

Pasta (or base) for lasagna is not in short supply today and can be bought in any supermarket. But, of course, you will get the most delicious pasta if you prepare it yourself in a Tree Climbing Device at home. The peculiarity of its preparation is the choice of flour. First and second grade flour. You can find out what type of flour you have by reading the manufacturer's information on the packaging. So, you will need:

Knead the dough and leave it in the refrigerator for 20-30 minutes. After this, roll the dough into a sausage with your hands and cut into even pieces. The size of the pieces will determine the size of your lasagna. Roll each piece of dough into thin layers, and the thickness should not exceed 1.5-2.5 millimeters. The rolled out dough is cut into long and wide strips. That's all, the pasta, or base for lasagna, is ready. Next, you should arrange the pasta with various fillings layer by layer, pour the grated ingredients on top

Source

Crampons for climbing poles/trees

Check with your local power company. They have been on towers for a long time and do not climb poles. Maybe they will sell it. But talking to them is also not easy, you need skill.

I have about 15 50-year-old linden trees on my property. Height up to 20 meters. But they got very upset. I want to trim it so that some snag thread doesn’t break off due to the strong wind. From below up to 3 meters I picked it up. Maybe we can really hire a tower?

I have about 15 50-year-old linden trees on my property. Height up to 20 meters. But they got very upset. I want to trim it so that some snag thread doesn’t break off due to the strong wind. From below up to 3 meters I picked it up. Maybe we can really hire a tower?

Hiring a tower is expensive, but safe. My neighbor's trees were cut down piece by piece - 10-12 thousand rubles each. A long stepladder (I bought 3 sections at Murlon for 10) and a hacksaw in hand. But be sure to have insurance.

“Campons” for electricians can be bought in specialty clothing stores - Vostok-Service, for example, they sell three or four types.

there is another name - gaffs (maybe with one f). You can ask the guys at the industrial site. ru branch technology of working on trees. Alps are also used. cats (maybe not expensive ones from the USSR). They also work without crampons on ropes (but here the Alpa or speliology technique is needed). In general, they correctly noted that arboriculture is a very dangerous job. Tumble like hell.

“Installation holes”, like Karavanbashi’s message, definitely won’t work. They are designed for smooth posts, without bark and large knots. Plus, the installer climbs onto any pole with a safety belt. I can’t imagine how to intercept normally, with a barrel diameter of 80 cm.

Plus, if you cut branches, it will all fall down, onto your partner or onto the stairs. Dangerous. It is cheaper for life and health to hire professionals.

According to the safety rules, it is allowed to carry out work from ladders and stepladders.

Source

General design of installation manholes

The most common in their design are mounting claws used for wooden poles. They have two main parts:

- metal hook;

- belt.

The mounting hook has the shape of a sickle, trapezoid or rectangle. The hook is equipped with spikes for a strong grip on the support. The claws are usually made from high-strength steel and can be treated with anti-corrosion paint, which increases their service life. Belts are made from thick two-layer leather, sewn in two layers, or from many layers of special rawhide or yuft, stitched with heavy-duty nylon thread. In the case of climbing concrete pillars, climbing claws of a universal design are used.

For concrete poles, universal electrician's claws are suitable for trapezoidal shaped poles. Such manholes can be supplemented with carbide inserts that reduce slippage and wear of the claws. The total weight of the manholes is from 3 to 5 kilograms. On concrete pillars, the constructor's claws look like this: a step, an adjusting insert, an engagement bracket and a fastening belt. The mounting hook is made of a metal pipe and equipped with fasteners. The footrest has plates with recesses for securing two layers of clamps.

Maintenance claws are quite simple; just grab the shoes tightly with the straps and fasten them. The lifting of the installer is carried out as a result of the self-fixing of hooks with spikes onto the pole. Moreover, the greater the weight of a person on the claw platform, the more reliable the fixation on the pole.

Fitter manholes LMC

The model is designed to move along reinforced concrete city supports. The claw opening is 310 +/- 5 mm

. The product has an additional strap, due to which the foot is well supported in the heel area. With this strap, the heel is firmly pressed to the base.

Such installation manholes for reinforced concrete supports can withstand loads of up to 180 kgf for five minutes. The package includes documents for the device and 8 belts (leather). Can be used in the temperature range from -40°C to +50°C. Lifting of the claw occurs to a height of 175 mm

.

Pros:

- mechanically strong product;

- an additional belt is provided;

- wide operating temperature range;

- reliable fixation of the leg.

Minuses:

- heavy weight compared to the models under consideration;

- high price.

Selection rules

When considering the models offered by manufacturers, you need to evaluate the following details:

For quality products, the seller must have an appropriate certificate.

- Price segment. It is dangerous to skimp on installation equipment. A low price may be a sign of poor quality materials from which the equipment is made. It is recommended to consider models from the middle and highest price categories.

- Company manufacturer. You should not choose a model from an unknown manufacturer. It is better to give preference to a trusted company.

- Qualitative indicators. A product of any type must have a certificate of compliance with TU and GOST. Metal parts must not be damaged. It is important to check that the seams are even and the thickness of the belts is at least 3 mm. The stitching on leather elements must be securely fastened.

The finished equipment indicates the release date of the product, trademark and batch number. Every six months, devices are checked for wear. A corresponding marking with the result is left on the hole. If the tools are used without errors, then they are allowed to work for at least a year. The more damage to the hooks, the lower the level of safety.

Safety during work

Who is assigned group 2 electrical safety?

Both the installer and the other person using the claws must adhere to the following safety rules:

- In order to minimize the risk of falling, it is necessary to use a safety (safety) belt, with which the worker must fasten himself to the pole;

- To avoid electric shock and head injuries, it is imperative to use a protective helmet, special dielectric gloves, and overalls;

- The shoes to which the manholes are fastened must fit tightly on the feet: before putting on the manholes, they are carefully laced or fastened;

- Before you start lifting, be sure to check the stability of the support.

When using tree climbers, be sure to have a safety rope attached to a strong branch.

Design and principle of operation

The simplest manholes for concrete supports consist of 2 elements for attaching to shoes, each of which consists of the following main components:

- Oval foot support with transverse reinforcements;

- 2 straps holding the foot on the platform;

- “Sickle” is a rectangular grip with 4 conical spikes attached at an angle of approximately 600 to the supporting platform.

Climbing onto a reinforced concrete pole using a similar device occurs as follows:

- The electrician securely fixes the manholes on his shoes using belts;

- Approaching the pillar, he grabs it with the grips of each of the elements of the claws;

- The electrician climbs the pole, thanks to the fact that the claw grips, which he alternately rearranges in the vertical plane, located at an angle to the supporting platforms, bite into the concrete with their spikes and prevent slipping.

Using a similar principle, electrical claws designed for this type of support help you climb onto a wooden pole. Their only differences from the crampons used for concrete pillars are the semicircular shape of the grips and softer spikes.

Fitter claws SIBIN 11579

The design is made of hardened tool steel, with leather straps. Used during various repair and installation works. Used for lifting onto wooden poles

. The durability of the product is ensured by high-quality materials that are wear-resistant.

The kit includes one pair of claws, a pair of fastening straps and 10 spikes. They stand out for their low weight (4.5 kg). Product parameters: 500x900x250 mm

. The peculiarity of the model is its universal size. Footrest with dimensions 227x118 mm. Statistical load from 180 kg. The hole opening is 250 mm.

Pros:

- high wear resistance;

- spikes made of hardened tool steel;

- power parts are made in the shape of a sickle;

- suitable for any shoe size;

- good claw solution.

Minuses:

- Can only be used when working with wooden supports.

For individuals:

1. Contact us by phone or send a request on our website

2. Come to our office or warehouse to conclude an agreement and receive equipment

3. If you have local registration, present your passport and driver’s license or driver’s license and registration certificate for the car to conclude a rental agreement

4. In the absence of local registration or the absence of the above documents, the equipment is issued with a small cash deposit

5. Conclude an agreement, pay for rental, pick up equipment.

FAQ

Question No. 1. Under what conditions should claws and manholes be stored?

Storage conditions can have a serious impact on the performance of devices. The optimal temperature is considered to be from -20 to 30°C with normal humidity. To prevent corrosion, devices must be protected from precipitation.

Question No. 2. Do nails need special care?

The rigging devices do not require any special maintenance. At the end of the work, they must be cleaned of dirt - wiped with a rag.

Question No. 3. Under what extreme temperature conditions can claws be used?

Claws, as well as manholes, can be used at temperatures from -40 to 50°C, that is, in almost any weather and under any conditions.

Question No. 4. Does the cost of manholes necessarily indicate their quality?

Yes, as a rule, when making devices that are too cheap, the highest quality metal is used. If it is not possible to purchase expensive claws, it is better to stick to the average price offer.

Assembly claws KLM-2

This model was also included in the rating of the best claws and manholes. It is necessary when working at height on supports with a 190 mm solution

. The design is made of durable material, which ensures long-term use and wear resistance. Fitter claws can be used at temperatures from -40°C to +50°C.

During testing, an operational load of 180 kgf per manhole was proven

. In the model, the claw lift is 165 mm. Compared to the models in question, this is not such a big increase. But it is enough for normal and correct lifting of the worker along the support. The foot in the design is securely fixed to the footrest due to the fourth belt. With its help, the leg is secured at the heel.

Pros:

- low price for the set;

- wide operating temperature range at which the claws can be used;

- good operational load indicators;

- The price fully corresponds to the declared characteristics.

Minuses:

- small claw opening compared to the models under consideration;

- small claw lift;

- use only on reinforced concrete pillars;

- Almost 5 kg of structure weight will cause discomfort during prolonged use.

One-day

Acuvue 1-Day TruEye (30 lenses)

pros

- convenient packaging

- not felt before the eyes

Minuses

- price

- not suitable for everyone

From 1500 ₽

This option is a godsend for those who want natural and natural contact between lenses and eyes, without inflammation and redness. The silicone hydrogel base allows oxygen to pass through, so the visual organs are able to “breathe”. HYDRACLEAR® technology is responsible for constant hydration and ultra-smoothness of the lenses. In addition, 1-DAY ACUVUE TRUEYE has the highest level of protection against dangerous UV rays among all ophthalmic products. Indispensable for travel: in the evening the used pair is disposed of, and in the morning a new one is put on.

Dailies (Alcon) Total1 (90 lenses)

pros

- wear all day without discomfort

- eyes don't dry

Minuses

- high price

From 4490 ₽

Very comfortable one-day stays. Particularly good in the summer under sunglasses, during allergy season, and convenient on vacation. The lenses have received many rave reviews.

Installer's claws for working on wooden supports

The design capabilities of assembler's claws for wooden supports, commercially produced in accordance with GOST 14331-77, are presented below:

- Type KM-1 – recommended support diameter 140...245 mm, throat 245±10 mm;

- Type KM-2 – recommended support diameter 220...315 mm, throat 315±10 mm;

- Type KM-3 - recommended support diameter 310...415 mm, throat 415±10 mm.

The platform of the KM series claws is stamped, with perforated holes, which makes it possible to increase the reliability of contact of the foot with the surface, while simultaneously reducing the weight of the platform. After stamping, the platform is hardened to a hardness of HRC 38…42. On one of the side surfaces of each platform there are ears for attaching steel arches. Along the remaining edges of the platform there are low sides, the presence of which prevents the electrician’s foot from accidentally slipping. To strengthen it during manufacturing, stiffening ribs are formed on the rear surface of the platform.

The fixing part of the arc rotates freely in the ears, ensuring the fixation of the spikes along the support at the moment of lifting the electric line operator. The permissible play should be no higher than ±15º.

The quick-wearing part of repairman's claws are the spikes, despite the fact that their initial hardness after hardening is 45...50 HRC. For claws on wooden supports, spikes are always made with conical tips. Experiencing significant frictional stress, steel spikes become dull and deformed over time. The durability of carbide studs is much higher, but they are sensitive to impacts and bending loads. Replacing the studs is not difficult, since their fastening part is threaded. The rear part of the platform is also equipped with spikes of a similar design.

The leg of the working person is attached to the arch of the claw using straps. In order to ensure elasticity, their upper part is made of yuft, and the lower part is made of rawhide impregnated with animal fat. The stitching of the belt elements is carried out with nylon threads, and the thickness of the belt and the diameter of the threads are calculated for a load of at least 140...160 kg.

Read also: Changing the batteries in a screwdriver to li ion

Electrical installation work is characterized by increased danger, which is why it is accompanied by the use of various auxiliary tools. Electrician's claws are one of those devices that are indispensable in the work of an electrician. These devices are designed specifically for lifting overhead power lines onto supports. Structurally, they look like two curved steel elements with spikes that facilitate tight adhesion to the support. Curved metal parts are attached to foot platforms equipped with straps to secure the worker's feet. A retaining harness and lanyard should always be included with the fitter's claws. Without these elements, it is impossible to provide stable support for the electrician and prevent him from falling in an unforeseen situation.

The purpose of assembly claws is electrical installation work on repairing or checking overhead power lines and other lines suspended on supports. Claws are a simple replacement for an aerial platform, which is used to lift personnel for electrical installation work.

Advantages of monter's claws:

- practicality;

- convenient use;

- reducing the cost of maintaining electrical networks.

For comparison: the use of an aerial platform greatly complicates the organization of work on repair or inspection of overhead power lines and increases monetary costs (fuel and lubricant costs, equipment maintenance).

Often, assembly claws are used when it is impossible to use an aerial platform due to lack of space for equipment or for other reasons. It should be remembered that the use of electrician's claws is possible only by one electrician. If the work requires the presence of several craftsmen, then an aerial platform is simply necessary.

What types of claws are there?

Power line supports, as you know, are different. So, they differ from each other in the type of section.

For example, reinforced concrete supports are in the shape of a trapezoid or rectangle, round or polygonal, cylindrical or conical.

Thus, for each support certain assembly claws are required:

- sickle-shaped claws (KM-1, KM-2, KM-3, etc.) are suitable for climbing onto wooden supports, as well as with reinforced concrete attachments. This type of product cannot be adjusted and is also fixed in size;

- assembly manholes (LU-1, LU-2, etc.) are an analogue of claws, but there are slight differences in design and scope of use. The part that clings to the support and is called the manhole itself, is curved at right angles. Such products are used for lifting onto rectangular or trapezoidal reinforced concrete supports. The opening of the manholes is adjustable, which allows you to select the size for a specific support.

Read also: Minimum diameter of V-belt pulley

There are also installation manholes that are designed directly for supports of various shapes.

Installer claws are used with power line supports with voltages of 0.4 kV, 6 kV, 10 kV, 35 kV. Certain products can be used for lifting power transmission towers above 110 kV.

How to use monter's claws correctly?

Any electrical installation work is accompanied by a high risk of harm to health. This is why it is necessary to follow certain safety measures.

Initially, it is necessary to carry out a number of standard organizational issues: coordination of work, paperwork, preparation of the work site, obtaining permission to perform these works. The main danger is that high voltage may suddenly be applied to live parts.

When working at height, it is important to observe the correct use of electrical protective equipment. Thus, assembly manholes are used only with those supports for which they are directly intended.

Assembly claw sets must undergo periodic inspection to identify breakages and defects.

Before use, the electrician must check the integrity and serviceability of the claws: whether the buckles and belts are reliable, whether the bolted joints are intact, whether there are cotter pins and lock nuts, seams, spikes and clamps.

Under no circumstances should you use manholes that have cracks in the metal or other damage.

Electricians must be trained in steeplejack work and have proof of this in their certificate.

Using claws, you need to use a fitter's belt in parallel.

The support, before being lifted onto it, must also be tested for stability and integrity.

It is prohibited to lift onto a support through which the ground fault current passed. Also, you cannot independently change the design of products and their components.

The Planet Electric retail chain has in its assortment linemen's manholes (claws).

Fitter claws are a special kit designed for lifting a person onto an overhead power line support. Monter's claws are two steel elements curved in a semicircle or at right angles with spikes, with the help of which a hook is provided with a support. These elements are connected to foot platforms, which have special straps that secure the feet of the electrician climbing onto the support.

The set of claws also includes a special retaining harness and slings, with the help of which the person is supported on the support, and also prevents the possible fall of the worker in the event of slipping or damage to the claws.

Installer's claws are designed to perform electrical installation work on repair or inspection of structural elements of overhead power lines, cable lines suspended on supports, communication lines, street lighting networks, as well as for lifting onto supports for other purposes.

Claws are an alternative to aerial platform, which is used to lift personnel to perform electrical work on power line towers. Significant advantages of linemen's claws are their practicality, ease of use, as well as a reduction in the overall cost of maintaining electrical networks. In the case of using an aerial platform, the process of organizing work becomes more complicated, there is a need to spend additional time on arranging equipment and its grounding, and money is spent on fuel and lubricants and on equipment maintenance.

Also, linemen's claws are used in cases where it is not possible to use an aerial platform due to lack of space to place the equipment near a power line support or for other reasons.

But at the same time, the assembly claws are used to lift only one electrician onto the support. Therefore, if it is necessary to carry out work on a support by two persons, you cannot do without an aerial platform.

Below we will consider what types of claws there are, depending on the design, and also provide recommendations for their use.

Types of monter claws

Power line supports come in various types, in particular the type of section. Reinforced concrete supports can be trapezoidal, rectangular, round, multi-faceted, cylindrical and conical. In some areas, there are still old wooden supports with a round cross-section, as well as wooden supports with reinforced concrete attachments of various sections.

Read also: Canopies for wooden gates

Accordingly, to lift onto different supports, claws of different designs are needed. Let's look at the main types of claws.

Sickle-shaped claws of types KM-1, KM-2, KM-3, etc. are used for climbing onto wooden supports, including those with reinforced concrete attachments, as well as onto communication line supports. The crescent shaped claws are usually not adjustable. The sickle, through which the support is hooked, has a fixed size.

There are also so-called assembly manholes (universal manholes - LU-1, LU-2, etc.) - essentially these are the same claws, the only difference is their design features and, accordingly, their areas of application. The element that clings to the support, the so-called manhole, is curved at right angles. These kits are used for lifting onto reinforced concrete supports of trapezoidal and rectangular cross-section. The opening of the manholes is usually adjustable and allows you to adjust the size of the manhole to reinforced concrete supports of various sizes.

There are separate types of manholes designed for climbing reinforced concrete supports of conical, cylindrical and multifaceted shapes.

Installer's claws and manholes are used, as a rule, for lifting power line supports of voltage classes 0.4/6/10/35 kV. It is possible to use manholes for climbing onto standardized supports of power lines of 110 kV and above.

Instructions for using monter's claws (manholes)

Let's consider the basic recommendations regarding the performance of electrical installation work using installer's claws (manholes).

First of all, it should be noted that if it is necessary to carry out any work in electrical networks, in particular on power lines, it is necessary to take the necessary safety measures.

The direct execution of work is preceded by a number of standard organizational measures, including coordination of work, preparation of the necessary documentation, preparation of the workplace, as well as permission to carry out work. All of the above measures are very important and the safety of workers performing the work directly depends on the correctness of their implementation.

In this case, the danger lies in the fact that, from the consumer or power source, voltage may be applied to the live parts on which the electrician works - to the wires of the overhead power line.

It is also very important to be able to correctly use electrical protective insulating equipment and personal protective equipment that will be used when performing work on power lines.

Installer's claws and manholes must be used only for those types of supports that are indicated in their passport data.

Sets of claws (manholes) must be periodically, in the order established by the enterprise (usually once every six months), submitted for inspection in order to timely identify defects.

Before each work, the claws (manholes) should be checked for integrity, serviceability and the availability of relevant data on the date of the next test. In this case, attention is paid to the reliability of the buckles and the belts themselves, the integrity of bolted connections, the presence of cotter pins and locknuts, the integrity of welds, spikes, and fasteners. It is prohibited to use claws (holes), metal cracks, burrs and other integrity violations.

Workers who carry out work using fitters' claws and climbers must undergo additional training, knowledge testing and have a record in their certificate of the ability to independently perform steeplejack work.

When performing work using lineman's claws, it is necessary to additionally use a safety lineman's belt.

Before climbing onto the support, you must check its integrity and stability. It is prohibited to climb onto a support through which ground fault currents flow.

It is prohibited to make any changes to the design of the claws (manholes), their belts, harnesses and slings.

Electrician's manholes, their types and application

Depending on their purpose, concrete power line supports can have different cross-sectional shapes:

- centrifuged (round);

- rectangular;

- trapezoidal;

- polygonal.

Types of electrical supports for power lines

Each type of support (see photo) has its own design of devices for safe and convenient maintenance of lighting elements.

Classification and purpose of the tool

Installation manholes, regardless of the type of work performed, must be equipped as follows:

- sickle (hook);

- thorns;

- step;

- leather straps to firmly secure the fitter's feet.

Electrical installation manholes

The sickle is the working part of the device, made of pipes of the required diameter with fastening elements (spikes) attached to it. The footrest looks like a flat metal structure. The installer's foot is secured using durable leather straps with clamps attached to the body of the footrest.

All parts of the devices are designed for safe operation within temperatures from -40 to +50°C, and with proper use they retain their positive performance characteristics for 36 months.

Depending on the type of work and the shape of the lighting stand, installation manholes for concrete have several varieties:

- KLM (1–2) - claws of Laza montera. They are used for servicing trapezoidal and rectangular lighting poles. Hook opening 160–180 mm. The weight of the sets is respectively 3.7–5.4 kg.

Manholes KLM-1

- LMC - manholes on concrete for climbing and descending round or multifaceted pillars. The opening of the working part is 305 mm. Set weight 4.20 kg. Permissible force 180 kgf/unit.

Device for centrifuged supports

- LU - universal manholes with the ability to adjust the gripper opening. Grip opening 175–190 mm. The structure is adjusted using two bolts located on the device body. Product weight 5.8 kg.

LU-2

Necessary conditions for safe use of devices

The instructions for performing electrical installation work with your own hands provide for the following conditions:

- An electrician performing work at height must undergo training at a specialized center and obtain the necessary certificate allowing independent work.

- Before starting work, you must carefully inspect the device and make sure that all connections are secure, including the condition of the belts for securing the tool.

- The fixing belts must be made of two-layer fat-impregnated leather for installation work in any climatic conditions. The required belt thickness is 3 mm or more. The belt buckle must be made with a protective and decorative coating.

- Metal elements of manholes should not have cracks, dents, breaks or sharp burrs. Welding seams of connections must be smooth without visible defects. Working spikes should not be beveled and have the required geometric shape.

- The spikes of the device must move freely in the horizontal plane, but at the same time, the vertical play should not exceed 1 mm.

Safety belt

Attention! – carrying out repair work on reinforced concrete supports, using manholes, without a safety belt is prohibited.

The video explains the rules of claw climbing and climbing.

Defects in mounting claws

The main defects that can be found in an electrician's claws include the following:

- Cracks – such damage includes a violation of the integrity of the metal structures of the supporting platform, grip;

- Burrs are sharp edges of cracks in metal parts that, in contact with belts, can cause damage;

- Tears and fraying of retaining belts - with prolonged use, the material of the belts, gradually losing strength, begins to tear and separate into fibers, which is visually manifested in the form of terryness and clearly visible transverse tears;

- Deformation and reduction in the strength of the studs - caused by natural fatigue of the metal, this defect manifests itself in the partial or complete loss of this element of its main functions.

Note! If one of the above-described defects is detected in factory-made models, experts recommend not to repair them yourself, but to take them to a specialized workshop for repairs. It is prohibited to use such installation equipment even with minimal damage.

10. Claw-holes KCO (analogue of LMC)

Another electrician's manholes that make it easier to work on overhead power line supports. This is an improved version of the LMC. The set includes leather straps along with the product. Construction material – durable steel

.

The studs have a carbide insert. Product weight – 5 kg. May cause slight discomfort with prolonged use. The manhole opening of 315 mm

is very good data that ensures convenient operation.

Pros:

- wide opening of manholes;

- durable material of construction;

- durable studs with carbide insert.

Minuses:

- slightly heavy;

- high cost for this model.

Application

Storage Features

The use of installation equipment for climbing on supports without a safety belt is prohibited.

Such equipment is used only in conjunction with a safety belt. It is allowed to store equipment at temperatures from -20˚С to +30˚С. You cannot leave instruments outside in the open air, as precipitation negatively affects their quality indicators. Storage in areas with high humidity or direct sunlight is prohibited. Recommended conditions are a ventilated warehouse and average air temperature. It is forbidden to carry out repairs yourself, without knowledge and experience. If the hooks appear defective, they cannot be used.

Checking the serviceability of hooks

Before starting work, the equipment is tested as follows:

- All parts are inspected. The strength of the belts and the condition of the spikes are specified.

- The spikes are tested on a wooden support of the appropriate diameter.

- The occurrence of deformation is checked by measuring the studs and grout before and after the test.

- Manholes are removed from service if they are deformed.

A wooden support is required to test the equipment.

( 2 ratings, average 4 out of 5 )

Scheduled inspection

Each type of equipment that is used by craftsmen to carry out electrical installation manipulations must be subject to routine inspection and heavy load testing. This category also includes pole holes. When a product passes a static load test, a certain force (more than 1350 N) is applied to the fixing belts. In this case, it is important to note that the load line must pass through the center of the footrest. In addition, experts have developed a step-by-step guide that will help novice technicians properly maintain cats:

- First of all, it is necessary to inspect the manholes. The technician must check the fastening of all parts (sickle, spikes), as well as the reliability of the stitching of the belts and the strength of the buckles. It is worth noting that each tenon must be secured with a special lock nut, which is clamped all the way and sharpened in the correct direction.

- The reliability of the spike should be checked on a regular pole, the diameter of which should be equal to the number of the claw.

- Experts assure that a high-quality spike can easily withstand a load of up to 140 kilograms without any deformation or damage to the welds. In addition, under the influence of such a load, buckles and belts should not be damaged.

- As for possible deformations, they need to be checked exclusively by measuring the rise of the tenon and the solution of the equipment before and after undergoing scheduled tests.

- At the final stage, all manholes on which defects have formed after mechanical loads must be removed.

Manufacturers note that concrete manholes are considered mandatory equipment for installers who professionally install and repair power lines. When purchasing such equipment, you should always pay attention to the fact that such devices must not only be of high quality, but also completely safe for use.

The employee must study all regulatory documents that describe in detail the requirements and rules for the use of cats. You should not neglect these rules, as such behavior is fraught with serious injury and damage to the limbs.