(2 votes, average: 4,00 out of 5)

Greetings. In this article I will talk about how to make an ultrasonic bath with your own hands using simple schemes. In addition, you will learn about what this device is, why it is needed and how effective it is in operation.

You can make an ultrasonic bath with your own hands at home. It will come to the rescue when cleaning objects from rust, dirt and plaque. All we need for this is to take into account the production technology of the device and not deviate from the general rules and recommendations. An ultrasonic device allows you to effectively remove contaminants from a variety of parts, components and tools in the shortest possible time. Also, a huge advantage of this device is that it can clean those products for which mechanical cleaning is strictly prohibited.

Modern inexpensive ultrasonic cleaner for household use

How to do it yourself?

From the name it is clear that we are talking about ultrasound.

Everyone remembers this term from physics lessons - high-frequency sound waves. Human hearing does not catch or recognize them. When exposed to liquids, a large number of bubbles are formed, which explode if the pressure is increased. In other words, a cavitation process can be achieved. Small bubbles become larger the higher the pressure.

The inventors of the ultrasonic bath took this phenomenon as a basis. The product that is going to be cleaned is placed in a container with the required liquid solution. The device starts up, and many bursting bubbles act on contaminated parts, devices, surfaces, scrupulously removing plaque and stains from them, and clearing them of grease.

Before you start making an ultrasonic bath, you need to find out what materials you will need:

- container, preferably porcelain or ceramic; you can take a stainless steel basin;

- a steel base on which all elements will be attached;

- pump for filling the bath with liquid;

- cassette or coil with ferrite rod;

- glass or plastic tube;

- pulse-based converter (to increase pressure);

- bath liquid;

- round magnet (suitable from old speakers).

You can start making the product. Before you begin assembly, thoroughly understand the principle of operation of the device, carefully study the characteristic features of its functioning. The process of creating an ultrasonic bath consists of several stages.

- We wind the coil with the ferrite rod onto the tube, but do not remove the pin (rod) itself and do not wind it to anything, leaving it hanging freely. A magnet is strung on one end - we get an ultrasound emitter.

- We fix the container in the frame - this is our bath.

- A hole is drilled at the bottom of the vessel and an emitter is inserted - a magnetostrictive transducer.

- We supplement the bath itself with two slots - for filling liquid and draining it.

- We install the pump.

- There must be a transformer available, which we glue strictly in the center of the bottom of the container.

- We solder the board and assemble the circuit.

- We connect the output converter to a 5 V winding.

This is interesting: Ultrasonic testing is a method for monitoring welded joints and seams

Principle of operation

From the name of this device it becomes clear what underlies its functioning. Ultrasound is a kind of vibration, the frequency of which exceeds 18 kHz. The liquid in such a bath is filled with a large number of bubbles, which burst under the influence of high pressure, creating an effect called cavitation.

How to use?

Do-it-yourself wooden bathtub

When using ultrasonic baths, you need to remember some rules:

- compliance with fire and electrical safety rules;

- mandatory external inspection of the device;

- It is strictly forbidden to touch the liquid and the part being cleaned while the unit is operating;

- if touching is necessary, it must be done with rubber gloves;

- the installation cannot be turned on if the bath is not filled with liquid;

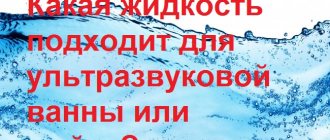

The self-made mechanism is easy to operate. Fill the container with a special liquid and the process of cleaning the product can begin. It is quite difficult to purchase a special liquid, but preparing it yourself is quite acceptable.

The choice of a specific liquid option depends on the scope of its use. Since one type is suitable for cleaning products made from one material, while the other will not clean these products at all. It is based on alcohol or water. When creating a solution, you need to choose a base.

Alcohol is most often used when cleaning circuit boards for electronic equipment and mobile phones. During the cleaning process, it does not short circuit transistors, chips and other parts with each other. When cleaning the surface from water-resistant compounds, they also resort to alcohol. When it comes to cleaning jewelry, use water. Water is a good cleanser; the effectiveness of its properties increases in combination with active substances. Soap solution, the simplest surfactant, is used in washing, washing automobile parts and injectors. Washing powders, dishwashing detergents or car shampoos are also used. Kerosene and gasoline are used in extremely rare cases

You need to work with them very carefully. The main thing in soft liquid products is the absence of aggressive and abrasive substances in the composition, which is the key to the integrity of parts and high performance indicators (no more than three minutes) of high-quality cleaning.

Rules for operating a homemade device

When using a bathtub you made yourself, you must follow safety rules when working with electrical appliances. You can only place objects in the solution by protecting your hands with rubber gloves. Otherwise, the aggressive environment may damage the skin or cause an allergic reaction.

The technical condition of the electrical circuit also requires checking - with prolonged use of the bath, short circuits and overheating of the transformer windings are possible. Small parts can be removed from contamination by placing them in a glass with a cleaning solution placed next to a RAS filled with clean water.

Field of application of ultrasonic baths

DIY quick-release clamp

Ultrasonic baths are widely used in many industrial areas. The demand for devices is due to obtaining more effective results compared to traditional cleaning methods.

The devices are actively used in the following areas:

- medicine – for sterilization of surgical and laboratory instruments;

- jewelry production - for purifying precious metals that have lost their attractive appearance;

- printing houses and repair of office equipment - for washing inkjet elements and print heads of printers, plotters, MFPs;

- mechanical engineering – to remove contaminants from large parts and assemblies;

- chemical industry - to accelerate reaction processes when mixing liquid solutions.

Car service employees use an ultrasonic bath when washing injectors, carburetors, filters, and injectors. When repairing computer equipment and mobile phones, such devices have proven themselves to be the most effective mechanisms. They are used to remove flux build-up from the smallest parts. It is advisable to remove plaque from all types of bathroom faucets and metal fasteners to them.

Ultrasonic cleaning bath manufacturing process

Making a firewood box at the dacha with your own hands

As mentioned earlier, such work must be carried out in strict accordance with a pre-prepared plan so that the final result is positive. The diagram of an ultrasonic bath, which is shown below, will help you understand the structure of a homemade device.

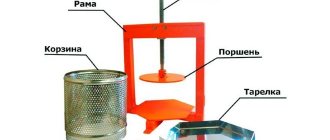

The installation process begins with the fact that the coil must be wound onto a prepared plastic or glass tube. A magnet should be placed on the remaining section of the rod. The resulting device is nothing more than a converter called magnetostrictive.

All the following actions must take place according to the following algorithm:

- A porcelain vessel should be installed in a steel frame.

- After this, the bottom of this part should be equipped with a hole, where the already manufactured converter should be placed.

- Then it is necessary to construct nozzles in the vessel design. These elements are designed to allow liquid to flow in through them and subsequently drain. If you plan to construct a large bathtub, it would be useful to take care of installing a pump that speeds up the flow of the solution.

- Upon completion of installation, a pulse transformer is installed, the main function of which is to increase the voltage. Any mechanism of this kind, taken from a TV or computer, is suitable for these purposes.

The work ends with checking the functioning of the ultrasonic bath. If the assembly process was carried out correctly, then the operation of such a device will save a significant part of the budget and will make it possible to thoroughly and efficiently clean all the necessary parts.

Greetings. In this article I will talk about how to make an ultrasonic bath with your own hands using simple schemes. In addition, you will learn about what this device is, why it is needed and how effective it is in operation.

What materials and tools are needed

It is not difficult to design a RAS, but before assembly it is necessary to prepare all the parts that will be needed during the work process. First, a board is made according to a special design. Using a soldering iron, all electrical elements of the structure will be connected into a circuit.

List of required materials:

- Metal vessel. The basis of the entire design, you can use a bowl or a small (1-2 liter) stainless steel pan.

- A container made of dielectric (ceramics or porcelain). Must be placed in a metal container and have a smooth surface without damage.

- Pulse transformer. Performs the function of amplifying and maintaining voltage at the required level.

- Round magnets. You will need 4-6 pieces, it doesn’t matter whether they are new or old (can be removed from unusable speakers).

- Non-conductive rod (eg glass).

- Magnetic coil with ferrite core.

- Plastic tube (2-3 cm in diameter). Designed for supplying and draining cleaning liquid.

- Epoxy adhesive. With its help, some parts are held together.

To ensure that the cleaning solution in the bath is continuously updated, the design is additionally equipped with a pump.

What is a device

An ultrasonic bath is a small container that uses ultrasonic waves during its operation. Such waves are too weak for human hearing to detect, but they are quite capable of successfully combating various types of pollution and even rust. Due to the influence of ultrasound, small air bubbles will form inside the container. Their number will increase and they will collide with each other. The result of the collision is a small impact, the force of which is sufficient to push dirt off the surface of the part.

As for the container, its size depends on what parts it is designed to work with. This parameter ranges from 0.5 to 30 liters.

Main selection criteria

In order for the purchased ultrasonic bath to work as efficiently as possible, you need to become familiar with some factors that influence the quality of its operation.

In addition, it is important to immediately decide which items will be cleaned, since the capacity of the device must correspond to the volume of items immersed in it.

Next, a few words should be said about how to make such a device for removing dirt from car injectors. It is these parts of the vehicle that most often require cleaning, so the specifics of the work need to be described in more detail.

Design Features

The main component of the system, the emitter, is responsible for the operation. Its purpose is to convert electrical energy into mechanical vibrations. The impact of energy occurs on the part through the wall of the device, as a result of which the cleaning process occurs. The ultrasonic bath includes a frequency generator, the device of which is responsible for generating waves by applying electrical vibrations.

Ultrasonic bath design

High-quality cleaning of parts is achieved by exposure to waves at a certain temperature. Heating elements control the temperature of the liquid in accordance with the specified parameters. Pulse operation requires control of processes occurring during ultrasonic processing of parts. Cleaning of parts is carried out in stages:

- the purified solution is poured into a container;

- the object is lowered, for better impact, stands are used so that the part is in the middle of the bowl;

- after turning on the device, bubbles form on the surface of the liquid;

- bubbles act on the part in hard-to-reach places, clearing dirt.

Processing of parts takes quite a long time, depending on the amount of contamination. Large quantities of deposits can be treated with ultrasound for up to 10 hours.

Application benefits

A device purchased or made by yourself has a number of advantages over mechanical impact on parts. The main positive aspects of using an ultrasonic bath:

- There is no waste of time, interaction with the part during the cleaning process is eliminated, only intermediate control is required.

- The chemical does not harm human health if certain conditions are met. It is enough to wear rubber gloves when in contact with the treated part.

- Mechanical cleaning cannot quickly and effectively get rid of plaque and dirt in hard-to-reach places. Ultrasound will help get to all the cracks and corners of the part without leaving any dirt.

- Exposure of a part to ultrasound reduces to zero the risk of resulting in a damaged part. Mechanical damage is excluded, which cannot be said about the mechanical cleaning method.

The scope of application of an ultrasonic bath is wide; the device is sold on special portals of household appliances or specialized retail outlets.

Positive and negative aspects of use

The Clean ultrasonic bath, like other models from different manufacturers, has a number of specific advantages:

- fairly high time savings, since cleaning the part takes an average of about 5 minutes;

- ultrasonic waves penetrate even the most inaccessible places, which is great for cleaning parts with complex shapes;

- since during operation there is no mechanical impact on the part, scratches and other defects will never appear on it;

- Naturally, to clean parts in this way you do not have to make any physical effort, which is quite important, especially on an industrial scale;

- In addition to cleaning, the machine also does a good job of polishing, which will help in some cases either restore the original appearance or even improve it.

However, there were some negative aspects:

- Such products are quite difficult to find. In the Russian Federation, purchasing such devices is difficult because they are not very common, and therefore you have to spend a lot of time to find a product that will have good reviews and the required characteristics.

- Price. Such a device has a fairly high price, which varies from 20,000 to 40,000 thousand rubles. In the industrial sphere, this is not too much money, but it will definitely pay off, but as for domestic use, it is better to make an ultrasonic bath with your own hands.

Manufacturing technology

Once you have all the parts and materials, you can begin the manufacturing process. The work begins by winding the coil onto a glass or plastic tube. In this case, the ferrite rod should hang freely; it does not need to be rigidly fixed. A magnet is attached to the end of the rod. The result of the work is the design of a magnetostrictive transducer or emitter.

Holes are drilled at the bottom of a ceramic or porcelain vessel. They are necessary for inserting a pre-fabricated emitter. After this, the vessel is fixed in the container. Next, you need to attach pipes for supplying and draining liquid.

The pulse transformer ensures more efficient operation of the device by increasing the voltage. The device can be taken from an old TV or computer.

After assembly, the experimental launch of the device begins. If a malfunction is detected, it can be corrected immediately. In this case, the following rules must be taken into account:

- Before starting, carry out an external inspection of the device;

- you cannot work with the unit in the absence of liquid - this can lead to the rod breaking into pieces;

- It is forbidden to touch the products that are in the vessel during the cleansing process.

Ultrasound requires extreme care while observing electrical and fire safety regulations. The times of scientific and technological progress are not in vain

Equipment works, breaks down, gets dirty. Sometimes you can extend the life of a product by simply cleaning the parts from accumulated dirt. Therefore, ultrasonic baths are gaining more and more popularity.

The times of scientific and technological progress are not in vain. Equipment works, breaks down, gets dirty. Sometimes you can extend the life of a product by simply cleaning the parts from accumulated dirt. Therefore, ultrasonic baths are becoming increasingly popular.

The main place of use of these devices is car service. But in many other industries they are also necessary. In computer repair shops, such a thing can be useful for cleaning the heads of dried printer cartridges. In hospitals, an ultrasonic bath can be used to clean surgical and optical instruments

, as well as instruments. And at home there is a need to always have such a device at hand. So the question arises for many people: where can I get a diagram of an ultrasonic bath to make it with my own hands?

How to wash the engine?

There is a wide range of car engine care products on the market.

But if you have finally made a firm decision to clean the engine compartment of your car from dirt, then you should know that engine cleaning products can be packaged in a wide variety of containers. Most often, aerosol cans and plastic bottles are used for this, allowing you to spray the cleaning product manually. Occasionally, cleaning products are also packaged in glass bottles.

Aerosols and bottles with hand sprayers are naturally the most convenient when washing a car engine. They allow you to direct a stream of liquid even to the most difficult to reach places, which cannot be achieved when using products packaged in conventional containers. On the other hand, glass or plastic bottles without sprayers are attractive due to their low cost, so if you are not afraid of applying a cleaning product using improvised means, you can also take a closer look at them.

Although in any case, when washing a car engine, it is more advisable to proceed from how densely the units are located in the engine compartment of your car. In older or relatively simple cars, the engine compartment is usually not filled very tightly, which allows it to be washed using bottles with a hand sprayer. In addition, this design of the bottle allows you to accurately dose the product, which allows you to use it in minimal quantities. But to clean the engine compartment of new cars, it is more advisable to use aerosols. With their help, even with a large amount of attachments, you can reach the most inaccessible places.

Quite often you can find detergent concentrates on the market. Using them most often is not very convenient, but if the engine of your car is very dirty, then to clean it it is easier to use a concentrated product that will allow you to clean even heavily contaminated areas in one go.

Please also note that products intended for cleaning the car body from dirt are not suitable for washing the engine. The fact is that most of them are acid-based, which can damage the metal parts of the engine.

Washing the engine compartment using diesel fuel looks even more barbaric. And even though this old-fashioned method is quite effective, it still has more disadvantages. Firstly, after such an engine wash, it will be very difficult to get rid of the smell of diesel fuel. And this applies not only to the car itself, but also to you. And secondly, this method is simply dangerous. Diesel fuel vapors ignite instantly under certain conditions.

The same can happen with gasoline, which some car enthusiasts also use to wash the engine. All it takes is a small spark, which may well be formed due to static electricity, and a fire cannot be avoided. At best, you will have to get away with a slight fright, and at worst, you will have to say goodbye to the car. Is it worth the risk?

Something else useful for you:

- How to dry clean a car interior with your own hands

- The headlight sweats: what to do and how to eliminate the cause

- What tools are needed for car repairs - the best universal kits

Purpose

An ultrasonic bath is designed to clean various objects from contamination in hard-to-reach places. These could be some items in washing machines, or, for example, precious jewelry. It is used in many areas of production.

Medicine . This bath is often used to sterilize surgical instruments. They are used in dentistry and even in gynecology. They also clean some elements in optical instruments that may be susceptible to corrosion. The safest way to clean them is an ultrasonic bath.

Jewelry production. Small manufacturers often use do-it-yourself designs. The service of cleaning jewelry that has lost its appearance is in great demand. So, plaque on silver or gold can be removed in just twenty or thirty minutes. At the same time, metal products will look like new.

Office equipment. In printing houses, this option is used to clean print heads. It is also used to remove dirt from printers and plotters. This allows you to significantly extend their service life.

Car service. Car service workers often use this cleaning option to wash various spare parts. The most common is cleaning the injectors. This mechanism is a regular valve, with its help the fuel supply is dosed. Contaminants from the nozzle are extremely difficult to remove, but an ultrasonic bath will cope with this task quickly without damaging the part.

Phones. Even a phone that has fallen into water can be given a second life. For this purpose, service centers use very small baths. The craftsmen remove all parts for which contact with water could be dangerous, and lower the board directly into the bath.

Industrial enterprises. Very often, ultrasonic cleaning is used in mechanical engineering. It is used to remove dirt from large parts and tools. In such enterprises, the baths are large, and cleaning can take several hours on end.

Also, any metal product can not only be cleaned, but also saved from aging. You just need to put it in the bath for a few minutes. At home, you can also clean various household appliances and give them a second life. But not every person has such a bathtub, and not everyone wants to buy it. Therefore, many people think about how to make it themselves.

Engine washing equipment and products

To wash the engine with your own hands, you will need detergents, available tools and materials. And in some cases it is advisable to use special equipment.

Detergents in car stores are presented in a wide range. Some are designed for cleaning the body, others are used for cleaning the interior

It is important for us to choose a special engine cleaning product.

You should not listen to the advice of your garage neighbors and use products such as gasoline, diesel fuel or Fairy to remove oil and dirt. They will, of course, remove some contaminants, but there is a danger of flammable materials igniting, as well as the possibility of damage to the rubber parts of the engine. For our purposes, it is better to purchase special auto chemicals from well-known manufacturers, for example:

- Liqui Moly (Motorraum-reiniger product);

- TurtleWax (High Tech Engine Clean);

- AT VNII Khimproekt (“Car shampoo for engines”);

- AutoStudio (“Cleaning agent for engines and units”).

For materials and tools when washing an engine manually, you will need a rag, a screwdriver, a scraper and paint brushes of different sizes. If you have a compressor and the appropriate attachments for it, you can not only spray liquid detergent, but also dry the motor after washing with a stream of compressed air.

It’s even better to use a Karcher-type high-pressure washer to wash the engine, but not every car enthusiast can afford this.

What is an ultrasonic bath?

High frequency waves can affect materials in aggressive environments. The principle of operation of an ultrasonic bath is to place parts in a special liquid, then the components move under the influence of waves. An increase in pressure leads to the process of cavitation at the molecular level; the resulting bubbles explode during the movement of atoms. You can learn how to use an ultrasonic bath from the product’s operating instructions; pressure is applied to various materials in the required proportions.

An ultrasonic bath consists of a liquid bowl made of stainless metal alloys. For home use or cleaning small products, a bath of up to a liter is used. Industrial production uses large volumes of bowls, which can be used to clean bulky objects. The frequency and range of ultrasonic waves operates in modes from 18 to 120 kHz; sounds at such levels are inaudible to humans. Exposure to ultrasound occurs in various areas, from hospitals to jewelry workshops; if you have certain skills, it is possible to make an ultrasonic bath with your own hands.

Types of pollution

Various application environments make the ultrasonic bath a versatile device. The mechanism has found its main application in car services and industries where it is necessary to remove the following types of contaminants:

- solid deposits that appear during the operation of mechanisms;

- protective film coatings are removed before connection by soldering or inside products that interfere with normal operation;

- oxidation and corrosive deposits.

In a homemade ultrasonic bath, it is possible to wash printed circuit boards and other radio materials. Before use, just immerse the part in liquid and start the process.

Terms of use

Before cleaning the necessary item, you need to familiarize yourself with the operating instructions for the device.

- The stainless steel tank must be filled with cleaning fluid. The choice of this very liquid depends on what type of contamination you have to work with.

- Place the item to be cleaned in the prepared solution. The liquid should cover it completely. It is very important that the container is filled to at least two-thirds of its volume.

- Connect the ultrasonic structure.

- Check whether bubbles have appeared or not. If yes, then the device is working.

- The time an item remains in the bath varies from several minutes to several hours. It depends on the degree of contamination.

- At the end of the cleaning procedure, you need to remove the item from the bath.

- Then disconnect the device from the mains and be sure to drain the water.

- The last stage is drying the ultrasonic bath.

The better you take care of such a structure, the longer it will last. After all, repairing it is a very troublesome task, and not always effective.

Peculiarities

Where jewelry precision and fine cleaning are required, ultrasonic baths are simply irreplaceable; they have a number of advantages compared to any other mechanical method of cleansing:

- There is no need to personally participate in the work; after loading the item into the bath, all that remains is to turn on the device;

- There is no direct skin contact with chemicals, no negative effects on health;

- The entire surface is cleaned - the smallest meshes, grooves, gaps where napkins, brushes, etc. cannot reach;

- Ultrasound does not leave marks, chips or other gross damage on the surface.

Ultrasound is able to clean sediment, paste residues, any corrosion, films, including protective films. Some stones and minerals are organic or sedimentary, making them somewhat sensitive to such treatment.

For this reason, you need to pay attention to corals, pearls, opals, malachites, emeralds, turquoise, tanzanites, lapis, and exclude them from the list of works: after an ultrasound bath, the “beauty” of the stone, its cutting and polishing is impaired

Codyson device

The Codyson CD-4810 ultrasonic bath, for example, is widely known in cosmetology. The main task of the device is to clean manicure attachments and tools. In addition, it can be used to perfectly clean other hand tools that have complex shapes or moving parts, such as scissors. The main characteristic for all units is vibration frequency, which determines the degree of cleaning. For this manufacturer, this parameter is 35 kHz. This is quite enough for the waves to cope with the cleansing of even hard-to-reach places.

Models from this company have a timer, the range of which varies from 1 to 30 minutes. It is located on the front panel, but it is protected from moisture and chemicals, which allows you not to worry about its failure due to the ingress of these substances. The material for making the bathtub in this case is high-quality plastic, and the cleaning tank itself is made of stainless steel. The volume of this model is 2 liters. This is quite enough for use in the field of cosmetology. It can be added that the bath is additionally equipped with a ceramic heating element, which has double protection and also a degassing function.

Brief technical parameters of the device are as follows:

- weight is 2.2 kg;

- total power 230 W (70 W is the power of the emitter, and 160 is the power of the heater);

- The maximum heating temperature during operation is 60 degrees Celsius.

Reviews about this device are quite good. Users say that the 2-liter tank volume is enough for all needs. The degassing function is also highly rated. Among the shortcomings, buyers noted that the kit does not include a hose for draining liquid.

Is it necessary and possible to wash a car engine?

When operating a car, owners often think about washing the power unit, since over time it becomes covered with dust and oil sometimes gets on it, as a result of which the appearance of the unit becomes not very attractive. Since engine washing is a responsible process, all the nuances are worth considering in more detail.

Why wash

Despite the fact that there are many supporters and opponents of engine washing, it is necessary to highlight the following negative aspects that arise due to contamination of the unit:

- deterioration of heat transfer. Due to the thick layer of dirt and dust, the engine housing is less cooled by the cooling fan;

- reduction in power. Due to poor heat transfer, motor power is reduced;

- increase in fuel consumption. A decrease in power is inextricably linked with an increase in fuel consumption. In addition, the service life of many engine components is reduced;

- increased fire hazard. The accumulation of contaminants on the outer surface of the power unit can cause spontaneous combustion, since dust and oil settle on the surface of the unit, which heats up during operation.

The listed problems indicate the need for periodic cleaning of the unit.

Engine contamination reduces heat transfer and power, increases fuel consumption

Frequency of the procedure

It is recommended to wash the engine in the following situations:

- in case of severe contamination of the unit due to failure of lip seals, pipes, etc.;

- in order to determine worn seals, as well as leaks of technical fluids;

- before major overhaul of the power unit;

- when preparing a car for sale.

From the above points it can be understood that the engine is washed only as a last resort. There is no specific frequency: it all depends on the operating conditions of the vehicle and its features.

The engine is washed when it is heavily contaminated with dust and oil.