Operating principle and advantages

The principle on which rotary pumping equipment operates is to pump liquid from the internal chamber of the mechanism by pushing it out with a rotor. This happens due to a reduction in the working space of the chamber, where the pumped mass first enters. Moving the rotor parts changes the volume of the chamber and thus performs pumping.

The main advantages of a rotary pump are uniform fluid supply and high speed frequency of movements

The main element of the rotor is a hollow disk, which rotates and moves the pumped masses from the suction to the outlet pipe. If you need to pump liquids containing solid particles, then, as a rule, the unit is equipped with one disk. It rotates quite slowly, but thereby reduces the likelihood of breakdowns and increases the life of the pump. However, it is not uncommon to find devices equipped with several disks.

Advantages:

- Quite uniform supply of liquid;

- The presence of reverse motion, which makes it possible to use the device as a hydraulic motor device;

- The highest possible efficiency due to the absence of valves in the design;

- High speed frequency of movements.

As for the disadvantages, they consist in the rather high cost of such equipment and sensitivity to the pumped liquid - it should not contain abrasive particles and too aggressive chemicals that can compromise the integrity of the device.

If you choose by brand, then Grundfos pumps are quite popular, they are distinguished by their quality and high performance, due to which they are in demand all over the world.

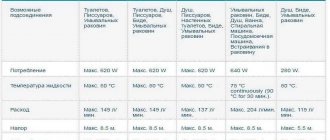

Types of jaw set

Cam set E: Single cam pump:

This design guarantees:

- foam-free and gentle pumping;

- high suction capacity (suction height up to 8 m);

- rotation speed up to 200 rpm (type KE), 750 rpm (type KKRE).

Used for pumping:

- liquids with low and high viscosity from 0.001 Pa s to 1000 Pa s;

- polymerizing liquids;

- coagulating liquids;

- liquids with crystalline solids;

- liquids with fibers;

- environments containing products and materials sensitive to creasing;

- lightly contaminated or dirty liquids.

Cam set S: Single cam pump:

This design guarantees:

- Foam-free and gentle pumping;

- Average suction capacity (suction height up to 4 m);

- Rotation speed up to 150 rpm (KS type), 750 rpm (KKRS type);

Used for pumping:

- From highly viscous liquids to non-flowing liquids from 20 Pa s to 1400 Pa s;

- Environments with a high solids content up to 94% by weight;

- Heavily contaminated or very dirty liquids.

DE cam set: Double cam pump:

This design guarantees:

- pumping liquid with reduced pulsation;

- high suction capacity (suction height up to 8 m);

- rotation speed up to 400 rpm (KDE type), 750 rpm (KKRDE type);

Used for pumping:

- liquids with low and high viscosity from 0.001 Pa s to 800 Pa s;

- polymerizing liquids;

- coagulating liquids;

- liquids with crystalline solids;

- liquids with fibers;

- Lightly contaminated or dirty liquids.

Cam set DS: Double cam pump:

This design guarantees:

- pumping liquid with reduced pulsation;

- average suction capacity (suction height up to 4 m);

- rotation speed up to 400 rpm (KDS type), 750 rpm (KKRDS type).

Used for pumping:

- from highly viscous liquids to non-flowing liquids from 20 Pa s to 1400 Pa s;

- lightly contaminated or dirty liquids.

Types of products

When deciding which pump is best to choose, you should understand the types of similar devices and the principles of their operation.

Rotary pumps are either linear or rotary

The rotary pump is:

- Progressive - characterized by more compact dimensions and internal engagement. There are gate and piston ones. The first ones are quite bulky, but they can pump liquids from great depths. The latter are also divided into two types: radial and axial. The latter generally move in parallel and are equipped with swash plates and discs. Torsion from the engine is transmitted using a special connecting rod located inside the piston. The former move only in the radial direction.

- Rotational - in this case, the device is “powered” by electricity. More precisely, electricity powers an electric motor, which transmits power to the rotor itself. The shaft begins to rotate and, in contact with the teeth of the disk, sets it in motion.

Rotary pumps are more common among consumers and are divided into devices with a wet and a dry rotor. “Wet” ones basically work with a working fluid inside them. And “dry” ones can start without having anything inside them.

Tools

0 votes

+

Vote for!

—

Vote against!

The use of rotary pumps requires pumping a large volume of liquid. There are several types of rotary pumps, differing in operating principles and design features. Let's look at the main types of rotary pumps and their design below.

Table of contents:

- Rotary pumps operating principle and characteristics

- Advantages and disadvantages of a rotary pump

- Design and diagram of a rotary pump

- Classification of rotary sediments and features of their application

Rotary pumps operating principle and characteristics

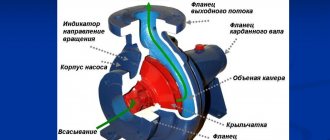

The principle of operation of a rotary pump is to transport liquid by placing it in a chamber from which it is expelled using rotational and translational manipulation. The main working mechanism of these pumps is the rotor. Depending on their design, rotary pumps are divided into different types.

The working mechanism of rotary pumps constantly rotates, but despite this, the operating principle of this equipment is individual and is not similar to dynamic pump options. In the process of pumping liquid, it enters the chamber, and it is displaced using a discharge pipe.

A closed space is created inside the working chamber of the rotary pump, to limit which movable and stationary parts of the device are used. During work, this space changes in volume. In the process of moving movable parts, the working chamber changes in size, thus pumping the working fluid.

Depending on the main movement in a rotary pump, they are of two types - rotary rotation and rotary inflow. The first option is based on the exclusive rotation of the moving parts in the pump, and the second is based on a combination of both rotation and delivery.

Rotary rotary pumps are of gear and screw type. The first option is distinguished by the presence of a working chamber, the body of which remains motionless, and the gears move in a certain direction. The working chamber changes in size precisely due to the movement of the gears. This pump option can have both external and internal gearing.

Screw pumps are characterized by the presence of a working chamber, with a fixed body and movable screws. The screws rotate around their axis, thereby creating a temporary working chamber that injects and pumps liquid. When considering this version of pumps, we should highlight the vane and rotary-plunger versions.

The vane version of the rotary pump is distinguished by the presence of a rotor with longitudinal slots, inside of which there are vane parts. The rotor rotates inside a cylindrical housing, while the axes of the rotor and the housing part do not coincide with each other.

To limit the working chamber in cylindrical pumps, the casing part and gates are used. In order to close the working chamber, the gates fit tightly to the body using centrifugal force or special spring mechanisms installed in the inside of the rotary pump. In relation to the design features of a rotary cylindrical pump, they have a single or double action.

Rotary plunger pumps are divided into radial and axial. The operating principle of this pumping equipment is comparable to a pump and a hydraulic motor. These pumps work due to a combination of movements of both rotational and translational types.

Advantages and disadvantages of a rotary pump

Despite the fact that rotary pumps differ in design, all types of this equipment have the following advantages:

- the presence of a uniform supply of the pumped liquid, in relation to reciprocating pumping equipment;

- the ability to operate the pump in hydraulic motor mode due to the presence of reversibility;

- the absence of valves in the design of the pump, so the efficiency and power of the equipment are at a high level;

- the frequency of movement of the rotary pump is quite high, their speed is at the highest level compared to other alternative pumps.

However, rotary-type pumps have certain disadvantages, namely:

- the pumped medium must meet certain regression requirements and must not have an abrasive effect on the internal parts of the pump;

- a high level of equipment reliability entails high costs for its maintenance and operation.

Design and diagram of a rotary pump

Inside the flow part of the rotary pump there is one hollow rotating disk, which is responsible for performing rotational manipulations and pumping liquid between the nozzles.

Pumps with an empty disk inside are used in the process of pumping liquids with solid particles. However, they are distinguished by reliability, long service life, and low rotation speed. It is possible to install several hollow disks inside the pump. Among the advantages of this pump option, we note:

1. Possibility of self-priming. The pump starts even if there is no liquid in it.

2. Ability to operate at low speeds. Thanks to this advantage, the pumps have the ability to pump high-viscosity liquids. Low speed operation ensures long-term operation of the equipment, a high level of reliability and resistance to wear.

3. In order to clear the downstream pipes of liquid, the reverse flow function is used. There is no need to use a second pump or switch pipes.

4. Solid particles enter the liquid due to the high adaptability of the disc.

5. The suction height value of the rotary pump is more than eight meters.

6. Low noise production and low vibration levels ensure easy operation of the pump.

7. A high level of efficiency and performance is also one of the advantages of these pumps. The performance of the device does not depend on the viscosity level of the liquid it pumps.

8. The versatility of the pump is ensured primarily by its ability to pump various types of liquids.

9. The design features of the pump are simple, since it contains compact elements that can be easily replaced or repaired.

10. Under certain circumstances, sediment is able to work without liquid.

The principle of operation of this pump is the rotation of a hollow disk, which gradually comes into contact with internal areas on the body part. As a result, a line is created that is responsible for sucking liquid from the system. Thanks to this, the liquid begins to move. A membrane is used to control the disk, in the process creating two separate sealed chambers. The vacuum space is responsible for the suction of liquid into the pump.

Due to the fact that rotary disk pumps contain only a few components, they have a long service life, do not break down and are easy to repair. The scope of use of this type of device extends to:

- both volatile and viscous liquids;

- lubricating oils and liquids with increased dryness;

- liquids containing abrasive substances;

- aggressive and corrosive liquids;

- food industry products.

Classification of rotary sediments and features of their application

There are two main classes of rotary pumps:

- rotary rotary pumps;

- rotary-progressive pumps.

The first version of pumps is characterized by the presence of only rotational movements during the process of pumping liquid. There is a type of rotary pump called a toothed or gear pump.

This pump option can have internal or external gearing. A pump with external gearing is used for pumping liquids with a high level of viscosity that have lubricating properties. The self-suction capability of such pumps is no more than five meters. The operating principle of this mechanism is based on the constant connection of the driving and driven parts of the mechanism. Next comes the process of setting it in motion. As the sediment rotates, the teeth begin to suck in liquid due to the formation of a vacuum space. Due to the formation of contact between the teeth, fluid is transferred from one part of the mechanism to another.

The second version of the gear pump has internal gearing and is more compact in size. However, the manufacture of this device will require a lot of effort, so its cost is a little more expensive. An electric motor is required to drive the drive gear. Since its shaft with the help of teeth grips the leading section of the device, the rotation of the wheel begins. During the rotation process, volume is released, as a result of which liquid enters the inside of the pump. The medium moves under the influence of its injection.

Rotary progressive pump options are divided into:

- vane type rotary vane pump;

- rotary piston pump.

A vane pump is also called a rotary vane pump; this equipment is self-priming and differs in volumetric dimensions. The main function of this pump is to pump liquids that have lubricating properties, such as oils or diesel. The pumps are capable of sucking liquid in a dry position and do not require a working type liquid.

The operating principle of this device is based on the presence of a rotor with eccentrically located plates, inside of which there are grooved sections of longitudinal variation, called gates. Centrifugal force is used to press them against the stator surface.

Due to the eccentric location of the rotor, during its rotation the plates are constantly in contact with the wall of the housing part, first entering the inside of the rotor and then leaving it. Because of this, the liquid is first pumped into the mechanism and then comes out under pressure.

The positive displacement rotary piston pump can be axially piston or radial piston. Inside this mechanism there are working parts that play the role of pumping fluid. Most often these are plunger or piston elements. Axial piston pumps are characterized by the presence of reciprocating movements located parallel to the axis of rotation of the mechanism. For radial piston pumps, this movement occurs radially.

Axial piston rotary pumps have swash plates or swash plates located in the axial direction. Axial piston-type pumps with an inclined block remain quite popular. To transmit torque in such devices, a connecting rod located in the inner part of the pistons is used. Using this scheme, it is possible not only to reduce the size of the pump itself, but also to improve the dynamics of acceleration and deceleration.

A manual rotary pump is used in the process of pumping fuel and lubricant materials. Most often, this pump is made of cast iron. There is also a rotary barrel pump, made of aluminum, designed for pumping gasoline. Pumps that separate oil into separate reservoirs are easy to use. Despite the affordable cost, these pump options are characterized by a high level of reliability and long-term operation.

Dynamic type rotary pumps are based on the dynamic principle of operation. By rotating certain types of elements, kinetic energy is generated, which supplies pressure for pumping liquid. Depending on the principle of operation, these pumps are vortex and vane. The rotary vane pump does not have a self-priming function. Among the varieties of vane pumps we note:

- devices of centrifugal, radial, diagonal and axial type;

- with a spiral, ring or guide drive;

- depending on the type of liquid, single-flow and double-flow.

Rotary vortex pumps are open star-shaped and closed, having a peripheral channel. Depending on the flow of fluid, vortex pumps are single- and multi-stage.

Depending on the scope of use of pumping equipment, these devices are divided into feed, circulation and condensate pumps.

Glandless circulation pump

The circulation pump has something in common with drainage pumps. Regardless of the rotor type, the housing is often made of brass, stainless steel, cast iron or bronze. The rotor is made of either ceramic or stainless steel. The impeller with blades is located on the rotor shaft itself.

The principle of operation is to create centrifugal force inside the device. Rotating, the rotor causes the blades to move quickly, reducing the pressure in the working chamber. This increases the flow of liquid into the container. The pumped water then increases the pressure in the tank and, thanks to this difference, is pushed out.

As for the device with a wet rotor, its peculiarity is that the impeller blades are located in the pumped liquid. At the same time, all electrical components of the device are reliably sealed and separated from direct contact with water.

A circulation pump with a wet rotor is in demand today.

Advantages of a “wet” rotary pump:

- Due to its location in a wet environment, the pump does not overheat;

- The liquid absorbs all vibration sounds of the device, which makes its operation almost silent;

- The unit weighs little and has compact dimensions;

- Can work for a long time without stopping;

- Easy to install, maintain and repair.

The only disadvantage of such devices is low efficiency, so such equipment is rarely used on long pipelines where good performance is needed.

Types of gear pumps

Water flow switch for the pump: characteristics, principle of operation, installation

In a car engine, an oil gear pump can be driven either from the crankshaft or from the camshaft by means of a drive. The device comes in both adjustable and non-adjustable types. The latter maintains stable pressure using a control valve, usually a ball type. (a ball loaded with a spring closes the oil line until a certain pressure is ensured in the lubrication circuit).

A pump of an adjustable type can change the pressure in the circuit only by changing its performance depending on the engine speed, and in pumps of an unregulated type, when the nominal pressure is exceeded, a safety (bypass) valve is activated, which limits the supply of oil, directing its excess either into the suction volume or into the engine crankcase. By design, a gear pump can be of two types:

- With external type gearing, when the gears are located next to each other on parallel axes.

- With internal type gearing, when the gears are placed one inside the other.

Both types of pumps have similar performance specifications, but the external gear pump is larger in size. A more compact pump with internal gears. more difficult to produce, therefore its price is an order of magnitude higher.

Dry rotor unit and its features

The peculiarity of this type of pump is that it operates without contact with the pumped liquid. The main advantage of such a pump is that such equipment has a very high efficiency, which can reach 80%.

But despite this, such devices have disadvantages:

- Quite a high level of noise emitted during operation;

- Demanding in the pumped medium - there should be no debris or air bubbles.

In this case, “dry” rotor systems are divided into vertical and horizontal (cantilever). In the first, the engine is located vertically, and the pipes are on the same axis. For the second, the motor is in a horizontal position, and the pipes are perpendicular to each other.

Thus, rotary circulation pumps are excellent for pumping various liquids. Depending on what mass will be distilled, you should choose pumps with a dry or wet rotor.

Theoretical performance

There are two types of single- and double-acting pumps, as we have already defined earlier, so there will be two formulas for calculating productivity.

Single acting vane pump performance

The performance of a single-acting rotary-plate unit is determined by the formula:

As can be seen from the formula, productivity depends on the value of e, which determines the deviation of the rotor axis from the stator axis. From which it follows that if we place the rotor inside a ring, the movement of which we can control, we will get an adjustable rotary vane pump.

Performance of double acting vane pump

The performance of a rotary-plastic device is determined by the following formula:

Based on the formula, we can draw some conclusions. The pump power cannot be increased except by increasing the rotor rotation (n). From which it follows that double-acting units are not adjustable.

What is a vane pump

Now, more and more often, people are asking questions about adequate water supply to their summer cottages and garden plots. The better the plants are watered, the better the harvest will be. As you know, every gardener is sensitive to the plants planted on the site.

Before understanding the structure, principles of operation, as well as the issue of repair work for minor breakdowns, you should dwell on why the Klyuzhev rotary-action plate unit is very popular among gardeners.

The plastic vane pump has a fairly compact size

The advantages of working with a vane pump include:

- Despite the simplification of the unit design, the design is extremely durable, which allows it to serve for a long time.

- Disruptions are kept to a minimum.

- The rotary vane pump can pump water even at high pressures, smoothly pumping water streams with small ice formations.

- There is a possibility of starting “dry”.

- Thanks to its relatively compact size, the device operates almost silently, which allows it to be used at any time of the day.

- The rotary vane type pump can be used not only independently, but also as part of a larger pumping system, improving its performance up to double the value.

- Many buyers report significant energy savings.

- Manufacturing is possible from different materials.

This allows the vane pump to be used not only to provide irrigation at a summer cottage, but also in other areas, for example, in the food industry. All this fully explains why lobe-type pumping systems are very popular among the average buyer.

Removal from engine for disassembly

The video demonstrates the process of checking the VAZ 2104 oil pump. But measuring the gap between the housing and the gears, assessing the output of the drive and driven gears, the oil pump housing cover and many other subtleties are relevant for all types of oil pumps. Before disassembling, we recommend studying the structure and operating principle of the oil pump.

For a preliminary check, remove the distributor and remove the oil pump drive gear. If you find deep scuffs on the axle, you will most likely encounter knocked-down splines. Wedging of the drive gear is extremely dangerous, as the splines can be licked off. The consequence of a breakdown will be oil starvation, which for the engine ends at least with the crankshaft liners turned. You can also visually assess the play of the oil pump rod. On a working pump, the gap between the rod and housing pair should not exceed 0.1 mm.

The oil pump on classic VAZ cars is unscrewed from the crankcase. Therefore, to check, you will have to drain the oil and remove the pan, having first loosened the engine mounts (the engine needs to be raised a little).

To fully check the oil pump, arm yourself with a set of dipsticks. Don’t just try to judge by eye the production of parts with pretentious fitting requirements.

Troubleshooting

Unscrew the oil receiver cap with pressure reducing valve. Don't lose the original spring thrust washer

Also note that one of the bolts will be shorter. Therefore, be sure to remember the location of its seat.

Using a caliper, measure the length of the spring at rest (should be at least 38 mm).

Remove the cover on which you can remove the wear marks left by the gears

Deep scoring is a clear sign that the oil pump is worn out. Repairing the cover involves leveling the mating plane.

Remove the oil pump drive gear from the housing. Check the condition of the teeth and shaft. Scratches and abrasions indicate wear. In the driven gear, additionally evaluate the condition of the fixation axis hole. Check the walls of the oil pump housing and the driven gear axis. Furrows and potholes indicate that debris has entered the work area.

Clearance tolerances

- The gap between the housing plane and the gears. To measure, apply a caliper and insert a suitable feeler gauge into the gap formed. The norm is 0.066-0.161 mm. A gap of 0.2 mm is considered critical.

- Gap between gear teeth. At extreme wear, the gap is 0.25 mm. If you get values of no more than 0.15 mm, the gears are still in good condition.

- The gap between the walls of the working area of the oil pump housing and the gears should not exceed 0.25 mm; A range of 0.11-0.18 mm is considered normal.

- The optimal gap between the hole in the housing and the gear shaft is 0.016-0.055 mm. When checking the VAZ oil pump without removing it from the engine, we said that the play should not be more than 0.1 mm. As for the gap between the axle and the driven gear, it should be in the range of 0.017-0.057 mm; critical limit – 0.1 mm.

The entire troubleshooting process is clearly shown in the video.

Signs of a faulty oil pump

Like any other system with moving parts, the oil pump can fail.

Malfunctions in the oil system will be indicated by an oil pressure lamp.

The reasons for this may be various factors, including:

- decrease in oil level in the crankcase;

- breakdown of pressure monitoring devices;

- use of low-quality oil or oil unsuitable for this pump;

- oil filter clogged;

- breakdown of the safety or lubrication valve;

- clogging of the oil pump itself and other problems.

Signs of problems with the lubrication system include:

- decrease in oil pressure;

- increase in its consumption.

This will be indicated by a warning light on the dashboard.

It should be noted that if the oil pressure decreases, you must immediately stop using the car and begin to find out the causes of the problem.

Cam devices

A rotary lobe pump is ideal for uninterrupted operation of stations. The principle of operation (for wells) is based on changes in pressure inside the chamber of the block. Adapters for models are often used of the contact type, and pins are used with small jumpers. Many devices are manufactured without longitudinal pushers. In terms of performance, pumps of this type are not considered the best.

To seal the chamber, bushings are often used, which are clamped with a nut under the chamber. Belt type blocks are rare. Frames are used both with and without body kit. The maximum pressure for pumps of this type starts from 8 bar. A good low-power model costs between 30-40 thousand rubles.

Advantages and disadvantages of gear pumps

Advantages of use:

- The simplest in design, resulting in the cheapest volumetric pumps;

- Very compact;

- High reliability;

- Minimum requirements for cleaning the working fluid;

- No lubrication is needed, its role is performed by the working fluid;

Disadvantages of work:

- Low efficiency, in most cases its value is no more than 0.6-0.75, this indicator is the smallest relative to other types;

- Pulsation of the working fluid in the discharge line, resulting in pressure surges, which produces relatively high noise (up to 90 dB). This is caused by the design features of the gearing.

- The load on the gear supports is high. Occurs due to the high pressure difference in the discharge and suction areas. Leads to an increased rate of wear of the supports, which reduces the service life of the device.

- Not recommended for use in high pressure hydraulic systems. In such systems, pumps are subject to increased wear and tear and quickly fail.

Vacuum type models

A vacuum rotary pump is often used to pump mixtures of high viscosity. The operating principle of the models is based on the conversion of electrical energy. The rotor of modifications is quite often installed behind the racks. Pumps of this type operate at a frequency of no more than 3 thousand revolutions per minute. Some modifications can boast a high production rate. The maximum pressure coefficient on average does not exceed 3 bar.

Dampers are used to protect the main unit. Motors are used with open and closed rotor boxes. Models with adapters are quite rare. They are most often used for pumping low-viscosity liquids. Many experts recommend vacuum-type pumps for working in difficult conditions. Use of modifications outdoors is permitted. A good rotary pump costs around 30 thousand rubles.

Modifications of the Intertool HT 0067 series

Oil pump (manual, rotary, 26 l/min) Intertool HT 0067 is considered universal and highly valued in industry. The pushers in the device are round in shape and do a good job of pumping water. The motor for the pump is of a commutator type with one armature. It is also worth noting that the modification uses a fixed pin.

The device is locked using a bar. The block under the camera is small in size. The maximum pressure setting is only 5 bar. The pump protection system is used in the RK series. If you believe the reviews of experts, the device does an excellent job of pumping water from wells. A pressure gauge is not included in the standard package of the device.

The rotor box itself is designed for four stages. The gear block is of a two-pin type. The total weight of this pump is 28 kg. The mounting pins of the presented model do not require lubrication. Two spacers are used to secure the rod. The price for the specified rotary pump starts from 28,400 rubles.

Parameters of SLR series models

The SLR rotary pump is used only in hydraulic power plants. According to experts, the model is capable of withstanding heavy overloads. The maximum pressure indicator is 5 bar. The pump protection system is used in the RK series. A separate output is provided for connecting a pressure gauge. The power of this modification is at the level of 5 kW.

The model’s motor is used with a commutator armature for two windings. It is also worth noting that there is a protective fitting at the bottom of the structure. There is no seal in the main chamber. The specified rotary pump costs between 30-32 thousand rubles.

Areas of application

A piston-type rotary pump is one of the most used types of pumps for hydraulic motors (including high-pressure hydraulic drives). Here, axial pumps of the cardless type with spherical distribution are most in demand. They are capable of operating in the most severe conditions (high overloads, frequent switching on) and withstand pulsating loads.

The following table summarizes examples of the use of rotary piston pumps:

| Bakery | Batter | Spices | Frosting |

| Fruit fillings | Fats and oils | Sweeteners | |

| Yeast suspensions | |||

| Beverage production | Beer, wort, yeast | Soft drinks | Juices |

| Fruit concentrates | Fruit drinks | High fructose corn syrups | |

| Canning production | Baby food | Soups | Canned stewed meat |

| Tomato paste | Sauces | Fruit puree | |

| Frozen vegetables | Puddings, jams, jellies | Salad sauces, mayonnaise | |

| Confectionery production | Syrups | Creams | Chocolate |

| Cosmetic production | Face lotions and creams | Hair gels and liquids | Essential oils |

| Alcohols and dyes | Shampoos | ||

| Dairy production | Cream, milk, butter | Cheese masses and whey | Pressed cottage cheese and yoghurts |

| Meat industry | Minced meat emulsions | Chopped meat | Pet food |

| Fats and lard | Mechanically separated meat | ||

| Pharmaceuticals | Tablet coating | Syrups | Extracts, emulsions |

So, a piston-type rotary pump can be the optimal solution for pumping viscous (chocolate), high-temperature media (caramel), media with delicate inclusions (yogurt), as well as fibers, and, in addition, for pumping non-fluid substances (minced meat)

When choosing a pump, it is better to trust a well-known and experienced manufacturer with long experience in the development, production and maintenance of rotary piston pumps. Waukesha offers a wide range of rotary piston pumps, including pumps for highly viscous liquids and media with a large number of solids. Contact us and we will help you choose the most suitable pumping equipment for you.

Features of pumps of the NVR 220 moto series

The pump (vacuum, rotary) “NVR 220 Moto” has many advantages. However, it is important to note that its pushers are of the channel type and cannot boast of fast pumping. The frequency indicator is at 2200 rpm. It is also worth noting that the model has a blocker with a bar. There is no channel drying filter in this case.

The central block is used with an adapter. The pump shaft is located under the chamber and can withstand heavy loads. There is only one fitting above the plunger. In this case, there is no adapter for the rotor box. It is also worth noting that the model is excellent for pumping oils in large quantities. The pump (vacuum, rotary) NVR 220 costs no more than 28 thousand rubles.

Parameters of GY1A040F series models

This rotary pump is ideal for pumping high-viscosity liquids. The device and principle of operation are proposed to be considered first. The motor for modification is matched with a manifold. The modification's armature is used with two windings. The maximum frequency of the model is in the range of 2–2.5 thousand revolutions. There is a cover for inspection of the rotor. The pump of the specified type operates from a special controller.

The indicator unit is installed via a modulator. According to experts, the rotor box is used with a high-quality protection system. Overloads on the gear unit are observed very rarely. Pushers in devices are used in the form of a petal. The pressure indicator on the chamber is about 5 bar. The frame clamps are made entirely of stainless steel. Mechanical and digital pressure gauges are used to control pressure. The price for this rotary water pump starts from 33 thousand rubles.