A little history

A device for fastening sheet materials is called a stationery stapler . Stitching occurs using a thin wire that pierces several pieces at once. The owner of the first such device was the French king Louis 15 in the 18th century. It was rarely used as a tool; it was more used as a toy.

A century later, when the rapid development of science and industry began, and with it the office, through the efforts of John McGill, who improved this mechanism, the stapler came into use among all bureaucrats in the world.

Types of staplers

Devices that perform the functions of fastening sheet materials are usually divided into construction, furniture and office. However, the difference between the first two is only symbolic. Therefore, the classification can be taken as follows:

- Device for office needs.

- Construction stapler (tacker).

- Special device for baguettes, corrugated cardboard boxes, etc.

A stationery stapler not only pierces sheets, but also bends staples from the inside. This is the only difference in the operating principle. Therefore, it makes sense to get acquainted with the device using a construction sample as an example.

How to choose a stapler

First, you need to decide how often you will use the device. If the application is active, then you can opt for more reliable metal models. If not, then plastic options will do.

Secondly, you need to take into account the power of the device. The higher it is, the more pages the stapler can sew.

Finally, when choosing a device, it is important to remember that certain models cannot work under weight. Otherwise, all the staples will fall out of them.

346 total views, 1 views today

780200cookie-checkHow to choose a stationery stapler?no

Fastening tools for construction

The principle of operation of a construction stapler is similar to the process of driving nails. With its help, the staple passes through the top layer or more than one (the total thickness should not be greater than the length of the staple leg). In the extreme material, the ends of the wires remain sticking out on the reverse side, like the point of a nail that has come out. Using friction, the sheets stick to the last layer.

A richer classification among methods of driving a device. In this category they are:

- Mechanical hammer and lever.

- Pneumatic.

- Network electrical.

- Rechargeable.

The most popular devices are mechanical lever ones.

Hammers have not become so widespread because of their operating principle - with a blow. Therefore, with their help it is not always possible to accurately drive the bracket into place. And it needs a lot of space to spread out. In terms of impact force, both mechanical options are inferior to the electric one, which, in turn, is inferior to the pneumatic one. The battery-powered device has an undeniable advantage in use - autonomy. However, the price and considerable weight, which quickly tires your hands, offset this advantage.

Stapler. Types and device. Operation and application. Peculiarities

A stapler is a compact tool designed to connect various elements using metal staples. There are two types of staplers - stationery and installation. Stationery ones are designed for fastening paper sheets, and mounting ones are for connecting solid materials, the density of which does not interfere with the passage of fasteners.

Stationery stapler

Stationery staplers provide end-to-end fastening of sheets of paper with staples and subsequent bending of their tails. Thanks to this, the reliability of the connection increases significantly. The operating principle of this device is very simple. A plate with staples loaded into the feed tray is subjected to point pressure, as a result of which one of them breaks off. It cuts into paper sheets, piercing them through, after which its tails rest against a special rigid plate that has indentations, which leads to their bending at a given angle.

A standard office-type stapler is designed to work with staples 6 and 8 mm high. Their rigidity is quite sufficient for punching up to 50 sheets. For more serious tasks, large devices are used that work with tall staples made of thick wire. Large staplers are designed for staples up to 26 mm high.

Fasteners for staplers are sold in packages. Each of which contains 20 plates, consisting of 50 brackets connected in a row. Thus, the pack is enough to carry out 1 thousand fixations.

To achieve high-quality joining of sheets of paper, it is not so much the design of the stapler itself that is important, but rather the use of high-quality consumables. A cheap tool that works with good fasteners will be significantly better than an expensive one with cheap consumables installed. Still, it cannot be said that the cost and quality of the instrument itself does not matter.

Cheap ones work well at first, but over time they begin to jam as a result of the reduced efficiency of the spring that feeds the staples. In addition, the extrusion mechanism may become deformed, as a result of which the impact begins not on one bracket, but on several at once. As a result, the tool becomes clogged as a result of several fasteners simultaneous exiting through the narrow feed slot.

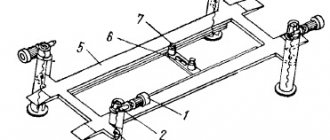

With most staplers, the staple is extruded directly by a special plate, which extends when you press on the body of the device with your hand. Expensive and large devices designed for punching cardboard and large quantities of sheets have a more advanced design. They have an additional spring that acts as an amplifier. A special shoulder mechanism increases the force obtained from pressing, resulting in the release of the staple with less strain on the hands.

Additional features of office staplers

At first glance, a stationery stapler seems to be a completely simple design, which is unlikely to have any additional uses. This is wrong. For example, few people know that the plate into which the tails of the staples rest before bending can turn over. It has two installation positions. In the first, the technological recesses for bending the tails are close to each other, and in the second they are wider. In the first position, the staples are bent inward, after which their tails cut tightly into the sheets of paper being connected on the opposite side. In the second position of the plate, when the recesses are widely spaced, the staples bend outward. This type of fastening is used in cases where you need to temporarily attach a stack of paper, but in the future it will have to be disconnected. This fastening method provides reliable fixation, but at the same time, minimal effort is required to remove the bracket.

Also, many models of office staplers can open up, as a result of which their shape turns from an acute angle into a straight line. This technical solution in the design is made for the purpose of driving staples into the surface without bending them, which is necessary when attaching paper sheets to various materials. For example, using a tool in this position, you can attach a notice to a board or tree trunk.

Some varieties of the instrument have a protruding pointed plate at the opposite end. It is necessary to remove previously clogged staples. To do this, you need to drive it under the installed staple and pull the stapler towards you. It is worth noting that this method is quite productive, but not the best. It is much more convenient to use a special tool called an anti-stapler.

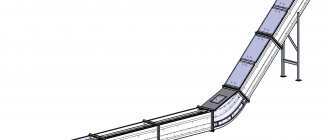

Mounting staplers

The mounting stapler is used for nailing various materials with staples. The reliability of such a connection is in no way inferior to small nails, while the nailed material receives a larger pressing area than the head of a nail or screw can provide. This is especially important in cases where fabric or plastic film needs to be fixed.

There are three types of mounting staplers:

- Mechanical.

- Electrical.

- Pneumatic.

Mechanical stapler

Is the most popular. This is facilitated by its low cost, thanks to which everyone can afford it. It can be used anywhere because it does not need to be connected to an electrical outlet or a compressor. Its design is very simple and has much in common with a stationery stapler. The only difference is that the mounting models have a much more powerful spring, the erection of which to strike the staples is carried out by a special mechanism with a handle. When you squeeze the trigger mechanism with your palm, one operation is carried out.

It should be noted that a mechanical stapler quite often fails to cope with the task. The spring used in it wears out over time and becomes softer. As a result, the staple can only penetrate halfway into the material. Often it warps to the side and simply becomes deformed. These problems are especially common in the cheap segment. As for expensive devices, they last much longer. The disadvantage of all mechanical staplers is the need to apply significant effort to hammer each staple. If you need to make several dozen fastenings, then this is not a problem, but when you have to work for a long time, your hand gets very tired.

When working with a mechanical mounting stapler, you need to take into account that you should not place more than one plate of staples into the loading slot at the same time. Even if some of the consumables were used in the instrument, until they are completely exhausted, adding other brackets is not recommended. This is due to the fact that the optimal stroke width of the feed compression spring will be disrupted. As a result, over time it will begin to press less and less, which will lead to jamming of the staples inside the tray.

Electric stapler

It also has a spring in its design. Its construction is carried out by an electric drive. Thanks to this, working with such devices is much easier, although the tool itself is heavier than a mechanical one. It should be noted that despite reducing the load on the hands, such devices also have their drawbacks. First of all, this concerns the electrical wire, which constantly gets in the way. Relatively recently, battery-powered models have appeared that do not need to be connected to the network. This significantly expanded the range of operation of such devices, but still led to an increase in the weight of the instrument.

Electric devices belong to a more expensive price segment than manual ones. They have high productivity, so they are often used in various industries. In particular, they are used in furniture upholstery. This tool is especially popular among craftsmen who reupholster furniture at the client’s home. Using such a stapler allows you to work quickly, and there is no need to carry a compressor, which is necessary when using more powerful pneumatic equipment.

The electric stapler has an additional degree of protection to prevent the staple from accidentally flying out when the button is pressed. Before refilling an electric stapler, you must unplug it from the outlet. Otherwise there is a risk of injury. In addition, many models have a locking mechanism that will not allow you to open the tray to install a plate with fasteners while the device is connected to the network. Some devices have a special “rev” button, which allows you to put the device into safe mode and open the loading tray.

Pneumatic stapler

Squeezes out staples using compressed air from a compressor. This is a fairly lightweight device that provides high driving speed. Such devices can usually be found in factories. They are used to knock together furniture, attach upholstery, and also pack various items into crates for transportation or storage. Pneumatic devices have high force, so they are able to penetrate very hard materials. In this regard, when working with this type, it is necessary to strictly follow safety rules.

Types of staples

All kinds of staples are used to fasten various materials. The most popular are staples in the shape of the letter P. There are also staples in the shape of a T and inverted semicircular U-shaped ones. For fastening pipeline cables, semicircular types are used, the sizes of staplers are for staplers. They come in two types of markings:

- In the form of a semicircle with a diameter of 4.5 millimeters, a stem height of 9-11 millimeters and a standard thickness of 1.25 mm. This is a type S or number 28 paperclip.

- Fasteners type L or number 36 have a slightly larger diameter (6 mm). Legs with a height of 9-10 millimeters of standard height

The most commonly used devices are staplers using U-shaped staples. They are distinguished by the following indicators:

- Diameter.

- Leg length.

- Length and thickness of the back.

The length of the leg determines how reliable the connection will be and the overall thickness of the fastened part.

For thick connections you need a more powerful tool; a weak one may not penetrate the entire foot and the fastening will fall apart. Thin back paper clips are needed for invisible fastening. Most often they are used in professional instruments.

Raw materials for paper clips

The different purposes of the staples also determine the different materials for the production of these consumables. They must meet various requirements: rigidity, corrosion resistance, etc. Therefore, all brackets are metal.

Aluminum fasteners

These are the cheapest, but at the same time acceptable quality, paper clips.

That is why tools using such fasteners are the best-selling. In addition, they do not rust. But other qualities make their use limited in comparison with analogues from other materials. Their main drawback is their low strength. This makes it impossible to use them in particularly critical structures associated with heavy loads and stress. But they are very suitable for joining cardboard, paper and similar materials.

Copper staples

Compared to aluminum, their strength is higher. Like the previous ones, they withstand corrosion and when used, the aesthetic side of the fastener will not suffer: they do not leave rusty marks. However, due to their high cost compared to aluminum ones, they are not as popular.

Steel products

They come in two types: hardened and unhardened.

Products of the first type are more expensive, which is compensated by their high reliability and durability. Both types of products suffer from oxidation and corrosion. Stainless and galvanized paper clips are the most reliable and durable. All companies producing such products produce the majority of their products from such raw materials.

Staples made of any metal can be sharpened or unsharpened. It is clear that sharpened paper clips will fit into any surface more easily. For working with hand tools, this is very important, since you will have to spend less effort to hammer. For large volumes of work, it is better to choose sharp paper clips.

Device repair

If, after several months of active use, your pocket or desktop stapler breaks down, then it would be better to purchase a new one instead . But sometimes problems occur with this tool that can be fixed without resorting to drastic measures.

- First, you should disassemble the tool - to do this, remove the body and pull the clip out of the groove. This will help you make sure that there are some stuck staples at the exit point that are preventing the unit from working properly. Most often, it is because of this that staplers stop functioning normally.

- To restore the functionality of the device, you need to remove all stuck staples. To make this easier for you, we recommend using tweezers or a thin screwdriver. But be careful not to hit the groove, spring and pusher, which can be broken very easily.

- Now you can start assembling the stapler. First, install the spring in its original place, followed by the housing and press on the upper part, first aligning it with the lower one, with such force that they are connected.

Popular consumables for stitchers

The most popular types and sizes of staples for construction staplers are 53 and 140 numbers. The first has the following values:

- The height of the leg is 4-14 millimeters.

- The back is 0.7 mm thick.

- Width 11.3 mm.

For 140 paper clips, respectively, the height is 6-14 mm, the width is 10.6 mm, and the thickness is 1.25 mm.

There are staples for office staplers, the types and sizes of which are determined by the number of sheets punched in one cycle. The most common type of paper clip is 10. For other series, this will be a fractional number, where the first digit is its number, the second is the height of the leg. Therefore, when purchasing these products, you need to know which products are suitable for this particular stapler model. The tenth series has a leg length of 9 millimeters, and the smallest one, the 21st, is 7 mm. The maximum size of the bracket is 24 with a leg of 8 or 6 millimeters.

In our country, the size of the stapler is regulated. GOST 28161–89 contains all the data on fastening for papers in a special table.

Some tips

Experienced users do not have problems installing brackets. For everyone else, there is a description in the instructions for the device, and a video on the Internet. In short, the process will look like this:

- Remove the spring pusher from the housing.

- Place the required number of paper clips into the holder with the tips facing down.

- Insert the clamp back.

- Close the lid.

For fruitful work, the amount of fasteners should be purchased with a reserve, so as not to go to the store for additional paper clips.

When purchasing a device for fastening with staples, the first thing you pay attention to is the quality of workmanship and the safety of working with it. It is better to pay attention to the products of well-known manufacturers who value their reputation. The basis of safety is the impossibility of spontaneous operation of the stapler. In branded instruments it is present in almost one hundred percent of products.

It's good to have a control window. Thanks to it, it is possible to control the presence of staples in the holder.

A comfortable, ergonomic handle has long become an integral part of a high-quality device.

Some manufacturers supply devices with adjustable impact force. This allows you to avoid damaging the surface during operation.

It is also important to remember the standard size of paper clips suitable for this model.

Aluminum clips are best suited for fastening vapor barriers. For lining - made of stainless steel.

The question often arises as to why a furniture stapler bends staples. It is likely that they were of poor quality. Or the furniture covering does not penetrate due to a malfunction of the stapler or hard covering.

With a reliable and high-quality tool, every operation will be performed quickly and comfortably. Therefore, you should not save on purchasing such a device, so as not to waste effort and money working with second-rate devices.

Varieties

Today, manufacturers produce many types of paper fastening devices. Among the rare options, pocket staplers should be highlighted. This product differs from all others in its compact size, which allows you to place this stapler in the palm of your hand. Most often, their body is made of plastic. Using such a tool, you can stitch a small number of sheets of paper at the same time.

Such products are popular among consumers due to their low cost. However, before you decide to purchase one, you should know that they are not suitable for intensive work . If you use it too often, it will soon break down and you will have to look for a replacement.

Office employees most often purchase desktop staplers. But you should know that you should not connect sheets of paper by weight with them. They must be located on a hard, level surface. If you carefully examine their body, you will see a special anti-slip coating in the lower part, which prevents them from moving around the table even during load.

The large stationery stapler stands out among its fellows due to its large dimensions. Its design uses a special lever that serves as the main working element. By pressing on it, you can fasten the required number of sheets of paper . The most powerful models can simultaneously connect no more than 260 sheets. Manufacturers often add special devices to them for removing bent staples. There are also models with a special fixing bar, which allows the user to independently select the fastening depth.

What is a stapler and what is its purpose?

A device for fastening (“stitching”) papers is a stationery stapler. This small device is designed to “stitch” several sheets of paper using a thin steel wire (bent in the form of a staple).

The first stapler appeared in the eighteenth century in France with its ruler, Louis the Fifteenth. However, back then staplers were more of an interesting curiosity than an important device.

But John McGill in the mid-nineteenth century (when science, as well as bureaucracy, began to actively develop) saw prospects in the production of staplers and, having slightly modified the model of the time of Louis the Fifteenth, patented this device. Soon, John McGill's brass stapler, capable of reliably and, most importantly, quickly fastening sheets of paper, became an incredibly popular device.

How to use?

After purchasing a stapler, you should carefully read the instructions for use. First you need to fill it with a batch of staples. To do this, move the spring back and place a set of staples in a special groove. Now the tool is ready for use, while not forgetting to follow basic safety rules.

The taker is applied to the place where the connection will be made. Then press the trigger button or lever. If everything is done correctly, you can hear the click of the spring and see the staple entering the material. In order to evenly distribute the staples, you can mark the places with a pencil or felt-tip pen.

During work, the material is always supported by hand so that it does not move. From time to time you need to monitor the number of staples so as not to be left without them at the most inopportune moment (it is better to purchase in reserve).

Before using a construction stapler , you should set the regulator to the required position using a screw. You need to practice on a piece of rough material, and only then start finishing work. Using the regulator, you can adjust the insertion depth of the staple.

After finishing work, the handle is always put on safety to avoid an unexpected shot. Like all tools, a stapler can break. Most often the drummer fails. You can give it its original shape yourself. To do this you will need a vice and a file.

What advantages does a construction stapler ?

- does not require significant physical effort; - installation does not take long compared to work using nails and a hammer; — one hand is involved in the process, and the other can actively help; — you can work even in the most uncomfortable positions (on a stepladder, in tight places); — damage to workpieces is excluded, there is no vibration, chips or scratches; — multifunctional, which allows you to use a variety of sources; — a small number of moving parts increases reliability and duration of operation/maintenance; — working elements (staples, nails, studs) are not subject to corrosion; - a unique safety indicator, sharp parts are hidden under the main casing, so there is no fear of injury or damage.

The construction market has pleased the consumer with an interesting stapler model. It only works when it comes into contact with the material. This means that unnecessary injuries at work can be avoided. If you accidentally or involuntarily press the lever (button), the shot will not fire.

An additional option has also been added in the form of a viewing window, which allows you to control the amount of the working element. The handle is made with precise consideration of the physiological characteristics of the hand, and the hand gets less tired.

Added a function that regulates the impact force. This feature is useful when working with fragile materials. This essential tool will definitely be needed at home, for example, to repair furniture elements (fix or replace loose material, etc.).

Types of staplers by purpose

Many years have passed since the appearance of the stapler, and during this time its design has been improved. Therefore, today there are several types of this device.

The cheapest and most common are pocket office staplers. They are small in size and can hold no more than ten sheets. As a rule, staples for a “10” stapler are placed in them. They are intended for stitching sheets on the road. For example, when you go to the bank, you need to fill out documents. They are also often used by schoolchildren and students to secure their essays. That is why very often pocket staplers have a bright, even slightly “toy” design.

The price of such devices is low, as is their service life.

Desktop staplers are very similar in appearance to pocket staplers, but they are more powerful and larger in size. As a rule, they are used in offices or small companies, as well as in schools and universities for “stitching” documentation. Depending on the model, they can fasten ten or more sheets.

Specialized office staplers have a slightly different design than previous varieties.

They have a lever to press, since such a stapler can sew about two hundred and fifty sheets at a time. Therefore, it uses longer and sharper staples for the stapler. The price of such a device is quite high, so it is often used in large offices, as well as in printing houses.

All of the above models were of the mechanical type. There is also an automatic stationery stapler. It reacts to movement, and when turned on, to staple papers, you just need to push them into the special hole of the stapler. This device runs on AA batteries or mains power.

At the end of the twentieth century, a new stapler was also invented by Christian Berger, which “staples” documents using paper tape cut from the sheets being stapled themselves. This device does not require staples.

There is also a construction stapler. However, unlike stationery, although it uses staples, it does not stitch them through or bend them. In other words, the staples of a construction stapler act as curved nails.

In addition to construction staplers, there are also packaging and industrial staplers.

Stapling Types

Stationery staplers can be divided according to the method of fastening sheets. Among them, the most common option, which is often used by office workers, is closed-type stapler devices. During operation, this tool bends the edges of the staple inward. This method provides the most reliable connection of sheets. Therefore, it is not surprising that such staplers are the most popular.

There are also open type staplers. They differ from devices with a closed stitching method in that they bend the staples outward. They are indispensable when you need to temporarily stitch paper sheets. Subsequently, the fastened sheets can be easily separated, and no traces remain on them.

Some office workers sometimes purchase staplers with straight staples for work. It makes sense to use them when there is a need to fix sheets of paper on a special board with a soft surface. For example , it could be a base made of cork.

Staples

Staples are small U-shaped wire products that are used to “stitch” papers together.

Depending on their purpose, they vary in length, width, and also in the metal from which they are made. To help them stitch papers better, the ends of the staple legs are always pointed.

In early models, the staples had to be inserted one at a time. However, in the twentieth century, the Boston Wire Sticther Co. I came up with a way to fasten staples for a stapler with glue. The types and sizes of staples no longer mattered. Fastened with glue, they were easily tucked into the device, simplifying its use. Since then, all staples have been sold as glued strips that can be easily inserted into a stapler.

Dimensions of staples for office staplers

Each stapler has a specific staple size. It all depends on the number of sheets that need to be stitched.

The most common staples for a stapler are "10". Most other staples that differ from the “10” standard have two numbers in the name. The first is the number, and the second is the length of the pointed leg of the staple.

Most staples for office staplers have the same length of the leg, but the size may differ. Therefore, before you buy staples for a stapler (their prices are usually low), you need to carefully read their size on the packaging of the device.

The smallest office staple has a size “21” - a length of 7 mm, while in the traditional “10” it is 9 mm. The largest office staple is “24”, and the length of its legs can be either 6 mm or 8 mm. So you need to be very careful when buying.

The most common staples for staplers (8 mm leg length): “24/8”, “26/8”. With a leg length of 6 mm – “24/6”, “26/6”.

Staples for construction stapler

Unlike a stationery stapler, in a construction stapler the most common staple size is “53” (width 11.4 mm, length 4-14 mm). They are suitable for most construction equipment, regardless of their subtypes. By the way, many construction staplers, due to their universal design, can use several types of staples at once.

For more durable “stitching” of wooden and other surfaces, staples numbered “36”, “140”, “300” and “500” are used. Since the length of the legs for all these numbers can be very different, you need to read the accompanying documentation very carefully.

Prices for staples for staplers

As a rule, the cost of staples is quite small - about 15-30 rubles per thousand pieces of size “10” (office staplers). Staples in sizes “24” or “26” cost a little more - 30-60 rubles per thousand pieces. Specialized staples designed for a specific stapler model are more expensive. As a rule, the price is regulated by the manufacturer, and there is often a large markup for the brand.

As for staples for construction staplers, due to the use of more expensive materials in their manufacture, they are more expensive than office staples. Thus, the most common size “53” costs on average about 300 rubles per thousand pieces. Other sizes, as well as specialized brackets, cost more.

Application

First of all, a construction stapler performs two main tasks. The first is that one material is nailed to another. The base can be wood, plastic or their derivatives.

It is to the base that anything is attached. The second task is to fasten equivalent elements, while bending the bracket. In both the first and second cases, the connections are quite reliable.

The stapler is used not only in construction, but also at the production level. For example, furniture craftsmen speak only positively about this miracle tool. Decorators also often resort to using a tacker (stapler).

They especially love battery-powered tackers. Also now the manufacturer pleases customers with professional-grade construction staplers . They are designed for more complex tasks and can handle large quantities of material.

What tasks can a tacker perform?

* Fastening sheet sample materials to frames (plywood, foil, tin, fibreboard, chipboard, OSB and so on); * Preparation of modular parts, sheathing and auxiliary systems; * Installation of bitumen tiles and roofing felt; * Fastening insulation systems: film, membranes, insulation; * Cladding work with plastic, siding or lining; * Installation of plank floors on tongue and groove; * Auxiliary fastening of carpet covering; * Application during installation of electrical cables (low current or power); * Installation of structures for greenhouses and greenhouses; * Reliable connection of corrugated cardboard; * Assistance during the assembly of packaging material or pallets; * Fastening small parts during construction or repair; * Drapery and joining of various parts for upholstered furniture.

How staples are inserted into a stationery stapler

Having found out what types of staples there are for a stapler, their sizes, it’s worth figuring out how to insert them into the device itself.

In most of these devices, in order to insert glued staples, you need to open the top cover by moving the spring. Then place the staples in the vacated compartment and release the spring, which will immediately fix them. Next, you need to close the cover of the stapler and check on any sheet of paper whether it works. If sheets of paper are not stitched as they should (a staple is bent, two are used at once, or something else), you need to check the correctness of the threading, as well as the size.

How to insert staples into a construction stapler

The most commonly used construction mechanical stapler. Threading staples into it is a process quite similar to using a stationery device. To insert glued staples, you need to pull out the spring in the lower section. Next, carefully place them in the open connector and secure it by inserting the spring back all the way.

After completing the installation of the brackets, you need to check the operation of the device.

Today, a stapler, along with a hole punch and a binder, has become an integral attribute of every office, as well as a workshop (if it concerns the construction type). It is not difficult even for a child to select staples for any of these devices, as well as to thread them. The most important thing is to clearly know the size and type of staples used and not to neglect safety rules.

Choosing an electric stapler

Staplers (staplers, staplers, tackers) are used in all cases when you need to attach something that can be pierced with a metal staple to something into which this staple can be driven.

Three types of staplers are available:

- mechanical - a manual, low-performance mechanism that requires physical effort during operation and is used mainly for occasional use in the garden and household or when working with papers in the office;

- pneumatic - works on compressed air, and since a compressor is needed, this model has not become widespread in everyday life. Used mainly in industrial production;

- electric is the most practical option for a stapler. Despite its fairly decent weight, it is widely used for all types of work and all types of materials.

This article is intended for those who are considering purchasing an electric stapler. We'll tell you how to choose the model that suits you best.