Rubber-metal glue

| -> Chemical industry -> Adhesives -> Rubber-metal glue |

Today, the market offers a huge number of adhesives that allow you to connect metal, rubber, plastic, glass and other materials with each other.

It is impossible to imagine the production of some parts without rubber-metal adhesive. Two-component adhesive for gluing rubber to metal “works” in two ways: “cold” or “hot” fastening (the second method is also called cold vulcanization). Adhesive for cold vulcanization of rubber is used for the production of parts that are subject to heavy loads (car, airplane engines). “Cold” fastening is not so reliable and is more suitable for thermal insulation and sound insulation.

Bonding of rubber and metal is carried out in special forms. First, the parts are heated by electric current or steam. During this process, the rubber is vulcanized, deformed and easily attached to the metal.

Having analyzed the current proposals of the industrial industry, we came to the conclusion that the best options for gluing rubber and metal are products manufactured by Chemosil, Parlok and Sipiol. Note that a good effect is obtained from using the “troika” of adhesives: Chemosil 221, Chemosil 211 and glue 88 KR.

Let's consider the technology of such gluing.

- First apply the first coat (you will need Chemosil 211). Note that it is recommended to degrease the surface from the beginning. After 30-40 minutes the layer dries. To do this, it is necessary to comply with the following conditions: ambient temperature: 18-20°.

- Next we apply Chemosil 221, which also dries in half an hour.

- After this, the rubber blank is treated with a steel brush and degreased. The last, third, glue 88 KR is applied to the resulting surface. This type of fastening is extremely resistant to external influences of solvents, and is also characterized by high manufacturability, high fastening efficiency and cost-effectiveness, safety and environmental friendliness.

suggests you buy glue for gluing rubber to metal. Let us note that this company is certified and can deliver the necessary adhesive to any point in Russia and the Eurasian Economic Union countries. Polar LLC has been the official distributor of Lord GmbH since 2009, which produces adhesives for the production of rubber-plastic rubber-metal parts during the vulcanization process. The company's managers will be happy to answer your questions, calculate the cost and prepare an individual commercial offer.

General Published: 2021.08.03

To choose the right adhesive for rubber, many criteria should be taken into account. Almost every modern composition forms a seam of increased strength, but this depends not only on the ability of the product to adhere to the surfaces being bonded.

When choosing a composition intended for rubber products, you should consider:

- conditions under which gluing will be carried out (humidity, temperature);

- the load that the surface will subsequently experience;

- how thick, stiff or flexible the material is;

- what the appearance of the glued product should be;

- the degree of chemical aggressiveness of the glue used.

After determining the requirements for the finished product, you should select the criteria according to which the product will be selected.

Glue properties

Rubber adhesives are rubber-based products dissolved in special substances. After hardening, they remain elastic, so they are suitable for fastening materials of different structures. The composition may also contain other components that improve the properties of the glue:

- polymer resins;

- cross-linking agents;

- vulcanizing additives;

- plasticizers, etc.

The material is used in industry and for domestic purposes, and can be used as a high-strength sealant. High-quality glue will quickly fill the slightest holes and voids, cracks and seams, and the product will be tightly fastened. Distinctive properties of rubber adhesive:

- high adhesion;

- strength of the adhesive seam, absence of destruction over a long service life;

- resistance to temperatures (usually in the range -40...+100 degrees), aggressive substances, chemicals;

- seam flexibility;

- no unpleasant odor;

- transparency.

Some compounds are heat-resistant and can withstand even higher heat. Any rubber adhesive is waterproof; it prevents moisture from penetrating into the glued area.

Types of rubber glue

All rubber gluing agents can be divided depending on the proportion of dry residue (in%) into two groups:

- group A – 6-8%, compositions are more elastic;

- group B – 8-12%, products are less elastic after drying.

In addition to rubber, most modern adhesives contain several synthetic components that seriously improve the properties of the material. Based on their composition, adhesives are also divided into several types; their base can be as follows:

- Natural rubber. It is better not to use the product for joining complex parts and metal products - the level of adhesion is average, as is the resistance to temperature changes and natural factors.

- Chloroprene. Such adhesives, among other things, contain metal oxides, so they are excellent for gluing rubber to metal surfaces and making other complex connections.

- Nitrile butadiene rubber. Sulfur acts as a vulcanizing component in such products; thiurams are also included in the composition. The glue is super waterproof and has good adhesion to rubber and metal.

- Organosilicon components. Curing occurs with the participation of tetrabutoxylane. The product is only suitable for gluing rubber to rubber, for example, for repairing tires on a car.

Based on the type of container, all adhesives are divided into household and industrial. The former are produced in small tubes and bottles, the latter - in jars, buckets, drums, and their application to the surfaces to be bonded is usually carried out using special equipment.

Properties of a high-quality and reliable composition

A high-quality mixture will firmly connect the surfaces, fill voids, holes and seams, making the product airtight. Using a good product, you can repair tires, boats, rubber shoes, balls, tents, inflatable or water mattresses, and wetsuits.

Glue 4NB-UV

Characteristics of a good product:

- Resistance to moisture and high temperatures (from –40 to +100° C).

- Strength.

- Resistance to aggressive chemical compounds.

- Excellent filling capacity and flexibility.

- No unpleasant, pungent odor.

- Transparency.

Properties and types of adhesive compositions

Rubber and metal are combined with compounds based on rubber, which dissolves in special components. After hardening, the mass remains elastic, which allows it to tightly fasten materials with a heterogeneous structure. The composition can be supplemented:

- polymer resins;

- cross-linking agents;

- vulcanizing additives;

- plasticizers.

The glue is used in home and industrial settings. Fills small voids, cracks, seams. Often used as a sealant. Rubber glue is characterized by:

- high penetrating ability;

- seam strength during long-term use;

- resistance to high and low temperatures, aggressive components and chemicals;

- increased elasticity of the connection;

- neutral smell;

- transparency.

Any substance is waterproof and protects the glued area from moisture getting inside. There are heat-resistant compounds that can withstand temperatures above +100 °C.

There are two types of mixtures based on the amount of dry residue.

- Group A – flexible substance, 6-8%.

- Group B - after drying, a less flexible seam is formed, 8-12%.

Rubber compounds are classified according to the type of synthetic components.

- Rubber. Products based on natural rubber have average adhesive properties and are poorly resistant to temperature changes and the effects of natural factors. They glue simple metal elements together.

- Chloroprene. Metal oxides are added to them for reliable adhesion to the iron base.

- Butadiene-nitrile. The vulcanizing component is sulfur. Additionally there are thiurams. These are ultra-waterproof substances with good adhesion to rubber and metal parts.

- Organosilicon. The composition hardens with the participation of tetrabutoxylane. Used for gluing rubber together. Widely used in auto repair shops for tire repair.

Household adhesives are sold in small tubes or bottles. Industrial ones are packaged in cans, buckets or drums, and are applied only with special equipment.

Stamps

The following brands of glue can be used to tightly glue rubber to rubber:

- U425-3 is made on the basis of rubber with the addition of nefras and ethyl acetate, used for gluing with subsequent vulcanization of the material.

- 4NB-UV is a one-component, oil- and water-resistant adhesive, operating temperature range is from –40 to +60° C. It can be used for rubber vulcanization at +180° C. It is used for connecting surfaces of nitrile, natural, chloroprene rubber, and rubber-fabric materials , shoe repair and manufacturing, agricultural machinery production.

- Rubber adhesive 4508 has increased stickiness and water resistance, and forms an elastic seam. It is used in the production of rubber products, rubberized fabrics, and suits intended for special protection. The best composition for repairing PVC boats, fishing suits and leather goods.

Rubber glue 4508

You can make a good tool for gluing various rubber products with your own hands:

- Grind the soft rubber into small pieces and fill it with aviation (clean) gasoline.

- Leave the mixture to infuse for several days, after which filter the resulting mass.

- Let the mixture sit for a few more days in a warm place.

Application

For a strong and reliable connection of surfaces, it is necessary to strictly adhere to the manufacturer’s recommendations on the packaging when working.

There are 2 types of gluing:

- Hot. The connection is carried out at temperatures from +70 to +160° C, the procedure lasts only a few minutes.

- Cold. Gluing is carried out at room temperature, but the adhesive seam gains the strength stated by the manufacturer within 1-2 days.

Useful tips

Recommendations from experts will help you glue surfaces together efficiently:

- Some formulations thicken during long-term storage. There is no universal means for dilution. To avoid difficulties, check the expiration date when purchasing.

- The temperature in the room where the work is carried out should not be lower than +5° C.

- Before gluing, the surfaces must be cleaned of dust, dirt, degreased and thoroughly dried.

- The adhesive properties of the material will increase significantly if you sand them with sandpaper before applying the mixture.

- First you need to sand the surface (treat it with sandpaper) and only then degrease it.

- The best option for degreasing would be an easily evaporating solvent, such as gasoline or acetone.

- The composition should be applied with a brush, and if it is thick, then with a spatula.

- The minimum thickness of the adhesive layer is 2 mm.

- When repairing shoes and boats, a layer of 1 mm thick should be applied to the previously sanded surface. After this, put a piece of gauze, press it with a spatula and apply glue again, and only then firmly press the surfaces to be connected to each other.

- Any stains or excess product must be removed immediately using a spatula or knife.

- Keep the area to be glued under pressure (load) for at least several hours.

Low indoor humidity slows down the drying of the glue. A high-quality product sets within 30 minutes, and final hardening occurs after approximately 48 hours.

Due to its waterproofness, reliability and elasticity, rubber adhesive has a wide range of applications. Rubber cement is a connecting substance consisting of rubber and a special solvent. It may differ in composition and scope of application, so before purchasing, be sure to familiarize yourself with the characteristics and features of all types of this product.

Peculiarities

Most often, rubber adhesive is used to join elastic parts. The fact is that after hardening, the structure is really similar to rubber. However, when purchasing such glue, you need to try to ensure that its composition is similar to the parts being joined.

The composition of rubber glue can include not only natural rubber, but also synthetic rubber. Ethyl acetate, chlorine-containing or organic compounds can be used as a solvent. The recipes of all manufacturers are different, so the properties of glue from different brands may differ.

The main feature of rubber-based glue is that it can be used with paper, textile, glass, wood, metal and other materials. It is widely used in the footwear, furniture and automobile industries. However, this glue can also be purchased for household purposes.

Adhesive for metal and rubber

For a small gluing area - Loctite 401, Loctite 406, Loctite 480 For gluing rubber and metal over a large area - Terokal 2444, Teroson VR 5000

Loctite 401 – universal For acidic surfaces (e.g. chromed or galvanized metals) For porous materials such as wood, paper, leather, cork and fabric, etc. NSF Cleared

20 ml.

| In stock | 953 rub. | retail including VAT | |

| 50 ml. | In stock | 2020 rub. | Price reduced |

Loctite 406 – for rapid bonding of metal, wood, leather, plastics, rubbers, including ethylene propylene (EPDM) rubber, and elastomers . With primer Loctite 770 allows gluing difficult-to-glue materials

20 ml.

| In stock | 952 rub. | Price reduced | |

| 50 ml. | In stock | 2022 rub. | retail including VAT |

| 500 ml. | In stock | 14517 rub. | retail including VAT |

Loctite 480 - used where high impact resistance and peel strength For bonding metal to metal, rubber, magnets High resistance to wet environments . Has increased elasticity and tear strength .

20 ml.

| In stock | 1363 rub. | retail including VAT | |

| 50 ml. | In stock | 2999 rub. | Price reduced |

| 500 ml. | In stock | 17878 rub. | retail including VAT |

Terokal 2444 – contact adhesive based on polychloroprene for gluing rubber profiles and rubber materials to metal, wood, glue for rubber .

340 ml.

| In stock | 991 rub. | retail including VAT | |

| 5 kg. | In stock | 8489 rub. | retail including VAT |

Karosserie-Klebe-Spray / Teroson VR 5000 – high-strength adhesive spray for gluing leather, fabric to metal, wood .

400 ml.

| In stock | 1207 rub. | retail including VAT |

© LLC "WORLD OF GLUE" - full range of products Loctite, Hysol, Macroplast, Terostat, Frekote, Vibra-Tite

Types of rubber glue

Rubber glue is classified according to two criteria: the amount of dry residue and the composition of the rubber. At the moment, in accordance with GOST 2179-78 and TU, the amount of dry residue varies between 6-8% and 8-12%. Rubber glue, which contains 6-8% dry residue, is produced under brand A, respectively, quantitatively showing from 8-12% is typical for rubber glue under brand B.

Advice

If rubber glue complies with GOST, this guarantees quality and safety. Therefore, before purchasing, you should familiarize yourself with its quality certificate.

Liquid rubber has a broader classification based on the composition of the rubber it contains. Natural rubber adhesives are not suitable for use in some industrial applications, which is why special compounds based on synthetic material have been developed. The fact is that glue made from natural rubber has low resistance to exposure to aggressive environments and high temperatures.

The most common types of rubber glue include the following.

- Adhesive based on natural rubber. The vulcanizing agent in its composition is sulfur. Rubber glue is suitable for joining elements made of paper, leather and fabric.

- Chloroprene rubber adhesive. For vulcanization, divalent metal oxides are added to its composition. It has the most reliable joining abilities, so it is used for gluing parts made of metal, wood, glass and plastic.

- Adhesive containing nitrile butadiene rubber. Sulfur also acts as a vulcanizing agent, but only with the addition of a group of thiurams. This adhesive is water-resistant and is used for materials such as metal, wood, glass and ceramics.

- Adhesive based on silicone rubber. The hardening of such a compound is carried out only under the influence of tetrabutoxylane. Its range of action is limited: it is intended only for joining homogeneous rubber.

- Styrene butadiene rubber adhesive. Due to its weak adhesive ability, it is used only for industrial purposes, in particular for the manufacture of adhesive tape.

Other synthetic rubbers can also act as the basis for rubber glue, but their use is very limited. Therefore, they are not released to retail stores.

Properties and characteristics

The main difference between rubber glue is the formation of an elastic seam that maintains the plasticity of the structure. In its solid state, the adhesive is made from natural or synthetic rubber and has properties similar to rubber.

The recipe used by manufacturers is unique, and the composition depends on the operational and technical characteristics of the finished product:

- Waterproof adhesive for rubber, periodically in contact with water - repair of shoes, boats, leather goods.

- High-strength rubber adhesive, resistant to aggressive operating conditions, is used in construction and car repair.

- The quick-drying composition reduces the curing process of adhesive joints. It is not recommended for large-scale work, since there is no time for adjustments.

- Elastic rubber adhesive is used for gluing soft materials. After drying, the structure of the seam remains plastic, does not “tan”, and therefore does not crack during operation.

- The oil-resistant composition is used when working with gasoline-resistant and oil-resistant materials. An important property of adhesives BR-10, KR-5-18 is that they do not dissolve in the aggressive environment of fuels and lubricants and petroleum products.

Some manufacturers produce universal rubber adhesive that combines several properties, for example, water resistance, elasticity and oil resistance. Before purchasing a product, you need to study its technical characteristics and make sure that the composition is suitable for solving a specific task and can withstand further operating conditions.

Attention! Rubber-based adhesives must have high tensile strength, work in the temperature range of -50+70 degrees, be resistant to moisture, and not destroy the structure of the surfaces being treated.

In addition to classifying adhesives by volume of dry residue, mixtures are divided by type of rubber - natural and synthetic. Natural material weakly resists aggressive agents and elevated temperatures. Therefore, manufacturers produce rubber adhesives from synthetic rubbers that have improved performance characteristics.

All rubber adhesives can be divided into several types:

- Natural rubber. Sulfur acts as a vulcanizing agent. Suitable for gluing leather, paper, fabrics and rubber.

- Chloroprene adhesive for wooden, glass, plastic elements, gluing metal surfaces to rubber.

- Composition of nitrile butadiene rubber (vulcanizer – sulfur with thiurams). Gives rubber adhesive good water resistance.

- Products containing silicone rubber harden in the presence of tetrabutoxylane. Used for rubber with a homogeneous structure.

- Synthetic styrene-butadiene rubber has low adhesive properties and is used for industrial purposes.

- Two-component polyurethane adhesive is a solution of urethane rubber that is widely used in the shoe industry.

Read also: How to rewind electric motors video

Rubber adhesive 88 deserves special attention. It contains a mixture of rubber and phenol-formaldehyde resin in the form of two components. The universal product has good water and heat resistance, firmly bonds rubber to metal, wood, glass, concrete, leather, polymers and other materials. The glue consumption per 1 m2 is 300 g, the product is used in the automotive industry and construction.

On a note! In addition to the listed compositions, manufacturers produce adhesives based on polysulfides, fluorosiloxane, propylene oxides, and acrylate rubber. Mixtures are practically not used in everyday life, since they have a special purpose.

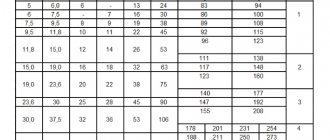

Brands and costs of rubber glue

In order to systematize the information and make it more accessible to ordinary users, all data on popular brands of glue, their application and cost are placed in the table.

| Brand | Characteristics | Material | Approximate price |

| Glue 88 SA | Waterproof, withstands temperatures from -500 to +700o C, does not interact with the surface of products and, accordingly, does not destroy them, protects wooden products from rotting and damage by parasites. | Suitable for products made of wood, metal, rubber, concrete, glass, textiles and leather. | 210 rubles per 1 liter |

| Rubber glue 4508 | Water resistance, elasticity, high connecting ability. | Used for products made of rubber, textiles, leather, paper, cardboard. | 250 rubles for 200g |

| Rubber glue grade A | Quick drying, easy to use, reliable. | Used for leather, textiles, paper, cardboard, rubber. | 198 rubles per 1 l |

| Universal glue “Moment-1” | Quick drying, reliability, versatility, ease of use. | Used for products made of wood, rubber, metal, felt, glass, PVC, plastic, ceramics. | 146 rubles for 125 ml |

The table below shows the approximate cost of the product. Prices for similar products may differ depending on the trade markup that is charged by the seller.

How to attach felt to metal?

Dear craftswomen, good afternoon!

I really want to make felt rings. Make a creative “bun” and attach it to a metal base for rings. Please tell me what kind of glue this can be done with or NOT glue. I’m sitting here, slightly puzzled.

If the area is flat, then it would be good to scratch it first for better adhesion of the glue to the surface. As an option - use a base with a strainer platform or an openwork one - you can sew on them

Still, it’s better to glue and sew at the same time, it will be more reliable.

OK, got it!! Thank you very much!

The platform, yes, is flat. Well, you can probably lay around a little later. above. what kind of glue would be better? I don’t have a glue gun ((((( “Moment”, for example, won’t corrode anything?

I’ll tell you a little secret))) In order to glue something with a glue gun, in fact, this gun is not really needed, if you have it, good, if not, it doesn’t matter. Take the glue for this gun, sold in the store, the tubes are translucent (probably seen more than once), a set costs about 30 rubles. Well, hold it over a lighter for a little while, it will melt and stick whatever you want to your health!

glue like “Second” from small tubes, but it’s better to test it first, some leave marks and the metal from such glue becomes hot, but it sticks very strongly))) but it’s better to use the base for the ring with a perforated removable disk - everything is sewn to the disk and the disk is inserted into a ring with clamps, the reverse side is very neat.

I glued the crystal for a moment, the felt stuck to the metal like crazy)))

Why such difficulties? After all, they sell ready-made bases for rings with holes through which it is easy to sew a felt “bun”.

This is how I made flower rings:

I glue felt flowers to any metal bases with Transparent Crystal instant glue, and I also use ready-made bases for rings, you can sew them on or you can glue them on.

I agree with the version of Moment Crystal transparent. Used for different purposes. It didn't work out for me with the pistol - it was rude. Crystal with a bang. I managed to wipe off the excess fresh stuff with acetone.

I wonder if you can use this “transparent crystal” glue to glue a handbag into a metal frame with kisses, and what does “transparent” mean if the glue leaks onto the fabric and you won’t be able to see it?

In moderate quantities it will not be visible, Mila. Metal glues, but I didn't glue the frame with it. And it’s exactly called Moment CRYSTAL universal adhesive TRANSPARENT Waterproof Polyurethane.

I have a base with a “strainer” (as they wrote here). I tried gluing it on a glue gun and for a moment it held well both ways. and so that the “insides” are not visible, I glue a piece of leather on the back - I hide the strainer pad inside through the slot.

Oh, so many tips!! Thank you all so much!! I will try different options

Thank you very much again!!

How to choose rubber glue?

To choose the right rubber adhesive, you need to clearly understand where it will be used. Before purchasing, you need to answer a number of questions that will allow you to identify the exact requirements for its properties and characteristics.

- Will the product be subject to heating or cooling? Different compounds can withstand different temperature ranges. Therefore, if you plan to use rubber glue in aggressive conditions, you should make sure that it is intended for these purposes.

- Will the product be subject to deformation, shock or vibration? Almost any rubber adhesive has high resistance to mechanical stress. But there are special varieties that have increased tensile strength.

- What size seam should be placed on the product? For thin joints, thinner compounds are chosen, for thick ones, thicker ones.

- What materials need to be glued? In order to choose the right glue, you need to carefully familiarize yourself with the area of its application.

- Will the glue come into contact with food? Many types of glue are extremely toxic. Therefore, for gluing dishes it is necessary to choose special safe compounds.

All properties of the glue can be found in its instructions for use. You can also ask for help from the seller, who can advise on the available range. The main thing is to correctly and fully provide him with all the necessary requirements for the product.

Instructions for use

First of all, you need to prepare the surface of the product. To do this, it must be cleaned and degreased. The fact is that various contaminants contribute to a decrease in the connecting ability and reliability of the composition. Simply put, the parts will soon have to be glued together again. Special cleaners or solvents are used to degrease the surface.

It is important to follow the instructions for use when using rubber glue. As a rule, it is indicated on the packaging or in a special insert. If the technology for using glue requires heating it to a certain temperature, then all manipulations should be carried out outdoors. To heat the composition, it is best to use a technical hair dryer.

Do not use rubber cement near an open flame. Almost all compositions are flammable, so safety precautions must be strictly observed.

Popular posts

- Chair for dressing table Chairs for dressing tables in Moscow - 189 Products Company from Moscow, delivery 29643 a In…

- Silicone sanitary sealant Silicone sanitary sealant white in Moscow - 1491 products Company from Moscow, delivery (tomorrow) 140...

- Shelf in the hallway Currently, there are a huge number of different options for shelves in the hallway, and this is directly ...

- Insulation of the floor in a wooden Insulation of the floor in a wooden house from below: materials and installation technology SHARE ON SOCIAL NETWORKS One of the common…