The basements of any building, apartment or private, are guaranteed to be protected from flooding if the drainage pump is functioning properly. After rainstorms, water supply network breaks, or due to clogging of the drainage system, this particular part of the building often ends up flooded. And this is a direct path to the development of an unsanitary environment in the house and to accelerating the destruction of the foundation. A drainage pump can clean up water spills. We will understand the principle of operation, as well as the design of this equipment, in our article.

Drainage pumps - indispensable in case of flooding

Basic information

The drainage pump easily pumps liquids from:

- Kotlovanov;

- Swimming pools;

- Trenches;

- Filtration wells;

- Stokov;

The drainage option is suitable for pumping out waste caused by a dishwasher, overflowing bathtub, toilet, shower, etc.

Also, the equipment can be installed in a well on the site of a private house. It is capable of functioning autonomously, stationary. Often the product is placed next to the liquid and pumped out using a regular hose.

The drainage system can be used in a private household. But at the same time, the equipment is also used by utility services performing emergency repair work. The products are purchased by builders. The devices are as easy as possible to use. Each manufacturer completes the product with full instructions, which will tell you in detail how and under what circumstances you can use the product.

Vibration type models

This version also comes in surface and submersible types, but differs significantly from vortex pumps in design and principle of operation. Let us note the following points:

- The design has an electric motor, which creates not a rotating, but a reciprocating motion.

- A rod is rigidly attached to the moving element of the pump, at the end of which there is a piston made of rubber or other soft material.

- The rod and piston are located in a sealed housing. The electric motor is isolated from the working chamber, since water ingress can cause a short circuit.

- The rod has a shock absorber that ensures its reverse movement.

- Water inlet and outlet pipes are connected to the working chamber.

- A mechanism for grinding impurities may be located at the inlet pipe.

The operating principle of the vibration pump is as follows:

- When electricity is supplied, the moving element of the electric motor begins to rapidly reciprocate.

- When the rod is at the dead center, when the working chamber has the largest volume, air rarefaction occurs. As a result, water enters the chamber.

- During the reverse movement, when the attractive force from the motor disappears, water is pushed out.

- In order to prevent loss of pressure in the system, a valve system is installed.

Unlike the impeller, the rod and cylinder can withstand the impact of a fairly large fraction of impurities. Therefore, many models do not have a chopper. Most vibrating models can pump liquid with the highest percentage of impurities.

Main advantages and disadvantages of drainage pumps

The advantages include:

- The devices can be installed autonomously and permanently, which greatly simplifies the work.

- There is a float switch inside that controls the water filling level.

- Production is carried out from extremely durable materials, which guarantees maximum service life. Thanks to this, even after a period of time, the body will show no signs of corrosion or other damage caused by external irritants.

- The pumps have compact dimensions (light weight), which simplifies the process of transporting them.

- The user is able to pump out water containing solid particles. Even fibers and materials resulting from non-aggressive chemical reactions are perfectly recycled.

- Modern models are distinguished by high performance and good maximum immersion depth.

- There is no need for special labor-intensive care.

There are few disadvantages. The most serious is dependence on power grids.

The device will not function without a constant supply of power. Please consider this fact before purchasing.

How to know when it's time to cleanse.

The main indicators of source contamination is a violation of the characteristics of the liquid.

Leaves indicate that the owners are not taking good care of the mine.

The most common ones are:

- The water loses its transparency. Different levels of cloudiness can be caused by depressurization of the connecting joints of the rings. Bottom filters become clogged with small particles of earth and clay.

- Presence of foreign objects. Garbage, leaves, etc. The absence or damage to the mine hatch is responsible for this. The well must be protected from dust and debris.

- The water darkened. Darkening of the liquid indicates infrequent operation of the well. There is no natural renewal, water stagnation occurs and pathogenic bacteria actively multiply.

- Acquiring a green tint. The reason is the active development of small algae. When sunlight enters the mine, microorganisms grow, turning the natural source into a swamp. The reason for this is a loose fit of the lid.

- An admixture of rust. Brown shades indicate excess iron levels. If such water is allowed to sit, a reddish coating will form on the surfaces of the vessel. The natural cause is an incorrectly calculated fluid intake level. Regular well cleaning will not fix this. Additional filtration systems will be required.

- Foreign odor and taste. Depressurization of the mine and, as a consequence, the influx of wastewater, lead to an unpleasant odor and taste.

Cleaning begins after identifying the source of contamination.

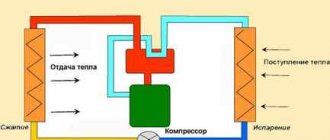

The principle of operation of the station and its design

You understand why a sump pump is needed. Now you need to understand the principle of operation of the drainage pump.

The product is responsible for removing moisture from the station to the reservoir storing water. The station operates as efficiently as possible if the standard of solid fractions entering the structure is observed. Most models have a float switch that monitors the water level in the tank.

The product’s operation is clearly demonstrated in the video:

Drainage pumps vary in maximum immersion depth and withstand temperature. Take these specifications into account when choosing the right model. And for a visual analysis of the device, be sure to look at the schematic arrangement of its elements.

Product classification

There are two main types:

- Submersible;

- Superficial.

The first ones are installed in the pool, sump. There are no specialized pipes (hoses) here. Water is pumped into a specially prepared tank. The moisture comes through the small hole in the drain pump. For this purpose, products are equipped with specialized filters that are capable of passing only fractions of a certain size.

Surface products have a significant difference. Installation is carried out next to pits, as well as wells. The water flows through special hoses. Models with liquid level control are available. They are equipped with a special float. There are products without a switch; they operate exclusively stationary.

Product selection

The modern market is overflowing with models from various manufacturers. The choice of a drainage pump is complicated by the mention of multiple characteristics, parameters, and properties. Looking to purchase a small, portable model? Take a look at Bison ZNPG-1100-S. This compact device is capable of processing inclusions no larger than 35 mm. The product can drain a small pond or reservoir. Used for irrigation of gardens and vegetable gardens. There is a special fuse inside that protects against various breakdowns.

The Patriot f 900 deserves special attention. The model is highly powerful and is capable of processing large particles with a diameter of up to 30 mm. There is an automatic lock. The device is distinguished by its reliability and long service life.

When choosing a product, pay attention to:

- Maximum (minimum) power;

- Temperature, maximum flow;

- The presence of a float switch;

- Available control methods.

Features of the right choice

Several key features need to be highlighted. Miniature drainage systems are used exclusively in the private sector for small tasks (pumping melt water). Therefore, when choosing, be sure to consider the scope of application of the equipment.

For repair and construction work, models with higher performance are required. Check the diameter of inclusions that may enter the station. Some products can only function with clean water.

Drainage pumps are characterized by increased power, which allows them to cope with most tasks. Take into account the storage conditions of the equipment and the frequency of its use. Another important parameter is the cost of equipment.

It is worth noting that in recent years, domestically produced products have improved significantly, and their prices are quite attractive. Often similar imported and domestically made drainage pumps have identical characteristics.

Types of well cleaning equipment

To clean the well with your own hands, you can use either a submersible or surface drainage pump.

Submersible pumps lower water. This equipment is characterized by:

- increased productivity;

- long operational period;

- small in size;

- light weight;

- versatility (used both for pumping dirty water and pumping clean water);

- presence of float protection.

The disadvantages of submersible pumps include:

- impossibility of pumping water from a depth of more than 20 m;

- insufficient water pressure;

- lack of water purification function.

Advantages of a surface mounted drainage pump:

- maximum powerful pressure;

- increased reliability (does not come into contact with water);

- uninterrupted operation throughout the day;

- the ability to install equipment anywhere on the land plot;

- affordable price.

"Disadvantages" of surface pumps:

- too noisy work;

- impossibility of pumping water from a depth exceeding 8 m;

- availability of technical skills related to the operation of equipment (checking the correct rotation of engine elements, high-quality connection of pipes).

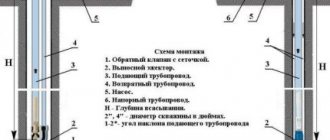

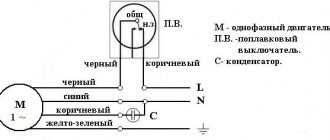

Installation features and connection diagram

Installation is quite simple. It is highly recommended to check the direction of rotation of the product before purchasing. This can be done by connecting the electrical circuit and measuring the flow. Afterwards, turn off the structure, change the phases and repeat the previous step. Compare the two numbers you receive. The best option will be correct.

Drain pump connection diagram

Have you purchased a submersible pool structure? Then be sure to equip the device with a filter that serves as a barrier to debris and fibers. Before installation, it is advisable to place a sheet of metal or bricks under the station.

Cleaning and deepening a well using drainage pumps

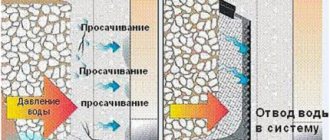

It happens that after many years of operation, a well accumulates less and less water. This factor causes great inconvenience, especially in the hot summer. However, we should not forget that the accumulation of water is often a seasonal factor. In winter, the water level always decreases, and in spring and autumn it increases significantly due to thaw and frequent heavy rains. But sometimes poor water accumulation is due to siltation occurring at the bottom.

It is quite easy to recognize siltation. You just need to take a closer look at the water level and its condition more often. The presence of grains of sand in the water certainly indicates siltation and the need to take emergency cleaning measures. There are many ways and options for cleaning the bottom of a well, but the main goal is one - to achieve good water accumulation. It is best to further deepen the pothole by one concrete ring. Such a measure will improve the accumulation of water and get rid of subsequent problems with siltation.

Before cleaning, you need to carefully prepare and have everything available (concrete ring, drainage pump, buckets, shovels, strong rope, flint stones, etc.). The procedure is carried out by at least two people, and a reliable drainage pump is used.

The work of cleaning and deepening the well must be done quickly and in stages. The main thing is to remove the structures above the rings so that they do not interfere and get to work.

- Using a drainage pump, pump out as much water as possible from the well.

- Install a ladder that will allow you to get to the bottom safely.

- Remove all silt and clay from the bottom of the well to the waterproof layer (which is hard and dry clay). It's better to do this with a bucket. It is better to lift it with a rope.

- As water appears, remove it using a pump.

- Gradually dig out the first ring. The soil is removed (usually clay) with a bucket.

- When the top ring reaches a height of 20 cm above ground level, you need to install an additional ring (you can use an adhesive solution to securely fasten the rings together). There should be no one in the well at the time of installation of the ring.

- Now the lower ring of the well is dug out until the upper ring settles to the desired level.

- The bottom must be leveled and water must be constantly removed with a drainage pump.

- Using a bucket with a rope, flint stones are lowered into the well, which are tightly and neatly laid at the bottom in a layer of at least 30 cm. Flint stones do not allow the bottom to silt. They form a kind of filter, thanks to which they perfectly purify water.

This cleaning method will increase the accumulation of water. Flint stones perfectly purify water, making it more useful.

Application area

The operating principle of an electric drainage pump corresponds to centrifugal types; it is distinguished from submersible devices for collecting water from great depths by some design changes. Electric drainage pumps can be used for the following work:

- Pumping water from any depth in case of flooding of premises below ground level: basements, cellars, warehouses, storage facilities, underground garages.

- A drainage pump can pump out water from swimming pools, ponds and artificial reservoirs when they are contaminated; with their help, you can quickly fill the reservoir again.

- Using a drainer, it is convenient to water plants in garden plots directly, or by filling large containers for further drip irrigation.

- Temporarily use instead of a deep-well pump to collect clean water, but it should be taken into account that the efficiency of a drainage pump is significantly less than special electric pumping equipment for water supply.

- It is convenient to use a submersible electric pump to pump water out of drainage pits inside and outside buildings in automatic mode - when connected, they begin pumping water after filling the pit to a certain level and stop working after it is emptied.

- Due to their design features, drainage pumping devices are used to clean wells, wells and ponds - they operate at great depths and are capable of sucking out dirty water with large fractions.

- If necessary, the drainer can be used not for its intended purpose, but as an electric fecal pump for cleaning sewer, cesspool and waste pits from heavily contaminated waste. The device does not have a shredder, so it will have to be connected through an additional filter.