After a massive transition from cast iron sewer pipes to plastic ones, a problem arose related to increased noise in the operation of sewer networks. Noise effects from the movement of wastewater in pipelines can negatively affect the microclimate in the house and cause inconvenience to residents. To solve problems with excessive noise, you can use the so-called silent drainage system. Silent internal sewerage, included in the premium segment, is made of thick-walled polypropylene pipes with a special filler to reduce noise levels.

The cause of noise in the sewer system

Specific sound effects appear primarily due to the noise that is created by the liquid when moving through sewer pipes. In the process of recycling waste water, waste products or food particles, the sewer line is only partially filled. When passing pipe junctions and corners, drains that are unevenly distributed cause noise. In addition to this, the noise level of sewer pipes also depends on compliance with sewerage installation technology, the correct design of the system, and the literacy of its operation.

At the same time, cast iron pipelines, which were widely used in our country previously, despite all their shortcomings, coped with this effect without any particular difficulties. The reason for this was the large (relative to plastic) thickness of the pipe and the properties of the cast iron itself. With the advent of polymer pipes, the situation has changed. The small thickness of the walls, the tendency to vibration and the light weight of plastic pipes have become the reasons for the amplification of sounds during the movement of wastewater. However, along with this, a solution appeared - a silent wastewater removal system.

Branded Low Noise Sewage Products

There are brands that have proven themselves to be of excellent quality and have a strong foothold in the domestic sewer products market.

Vavin Asto and ASTOLAN

In recent years, market offers have surprised us with a wide selection of branded silent sewage systems. Among the available examples for installation, we can note, for example, a product under the Vavin Asto brand.

The company manufactures and sells polypropylene pipes and fittings based on ASTOLAN, a material modified with mineral additives.

The low-noise sewer system produced by Wavin Asto (a set of pipes and fittings) is a ready-made solution that takes into account all the nuances of sound insulation. All that remains is to assemble the system in accordance with the instructions and enjoy the comfort

Thanks to the modification, engineers were able to increase the wall density of sewer pipes to 1.9 g/cm3 and enhance indicators such as viscosity and specific gravity. As a result, virtually silent sewage systems “Vavin Asto” appeared.

According to company representatives, there is no vibration noise during system operation. The penetration of sewer sounds through airspace is also excluded.

German quality Ostendorf

Another example of a modern noise-free system is sewerage based on pipes and fittings of the Ostendorf brand. The base material is the same, mineral-modified polypropylene.

But the density indicators in this case are somewhat inferior - 1.6 g/cm3. At the same time, the temperature parameters of the Ostendorf sewer system are higher - up to 100ºС, and pH values are in the range of 2-12.

The German company Ostendorf offers to use engineering solutions that guarantee silence in the house. German technologies for the manufacture of sewer pipes and fittings eliminate the occurrence of technical noise above established standards

characterized not only as low noise. All production elements are characterized by a high degree of corrosion resistance, durability, and resistance to aggressive environments. An extensive range of shaped parts and pipes ensures the creation of communications for various purposes.

Rehau and REHAU RAUPIANO Plus

Systems also show a high percentage of popularity. In particular, the product REHAU RAUPIANO Plus is persistently advertised. The technological approach, however, is not much different from the two previous firms.

In the fight against noise, Rehau also places emphasis on the production of multilayer plastic pipes, on reinforcing the wall thickness of corner fittings, and on the production of so-called “noise-absorbing” clamps.

Parts for the installation of a domestic sewage system, produced under the Rehau brand, are made taking into account effective sound insulation. Sewage installation based on Rehau parts promises a quiet life

The practice of operating such a sewer system shows a noise reduction of approximately 25-30%. If desired, similar indicators can be achieved if standard work on sound insulation of a domestic sewage system is performed using available insulating materials.

The following article, which contains a lot of useful information, will introduce you to guidelines for choosing the best pipes for installing an internal sewer system.

Types of noise

Sewage liquid and household waste, moving along the sewer line, upon contact with pipes, can create several types of noise: • Impact noise

.

Occurs when drains come into contact with walls. The loudest sounds in this case appear in places where pipes narrow, at turns, and during vertical discharges into the riser; • Structure-borne noise

.

It occurs as a sound wave strives to overcome obstacles in the form of pipe walls, floor slabs and partitions of buildings; • Airborne sound

that occurs when water passes through an empty pipe.

Practice shows that residents of the first floors suffer the most from the noise of sewerage. In apartments on the ground floors, you can clearly hear neighbors upstairs flushing the toilet tank or taking a bath or shower. Walls and floor slabs are not a significant barrier to sound.

Installation details that affect noise levels

Under no circumstances should machine oils or similar lubricants be used as a lubricant for connection elements. All of them have a negative impact on the structure of rubber seals.

Rubber loses its technical properties, cracks and structural irregularities appear on the seals. Such a compaction not only becomes a source of increased noise, but also threatens to burst at any moment.

The connection of polypropylene pipes is preceded by lubrication of the areas directly involved in the contact. A specialized water-based gel (lubricant) is used as a lubricant.

It must be remembered that connections “straight pipe - socket” are always installed taking into account the installation of the edge of the socket against the flow of waste. Under such conditions, maximum smoothness of the internal surface of the sewer line is ensured, which in turn is accompanied by a low flow noise level.

The noise characteristics of the sewerage system are also affected by the slope of the pipes. It is not recommended to deviate from established standards and norms that determine the amount of slope depending on the diameter of the sewer hose.

For pipes with a diameter of up to 50 mm, the slope value is no more than 35 mm; for diameters from 50 to 100 mm, a slope of no more than 20 mm is recommended. Pipelines with a diameter of 150 mm or more are installed with a slope of no more than 8 mm.

Turns of pipeline lines, as well as branches, are made by installing oblique tees or half bends (angles 30-45º). The principle of constructing networks in this way helps reduce sewer noise.

The effect of noise suppression during volley discharges into the sewer system is especially noticeable. In addition, the smooth bends of the turns create better conditions in case of cleaning the system with a sewer cable.

The correct (incorrect) execution of turns in the domestic sewage system is one of those factors that influences the increase (decrease) of noise. During installation, it is recommended to adhere to the technique of creating smooth turns and bends

Plastic pipelines on straight horizontal sections should be fixed with clips, support clamps, and hangers every 7-9 meters. If you deviate from these requirements, there is a risk that after some time of operation you will end up with sagging areas in such areas.

Pipeline sagging is a change in the parameters of the movement of wastewater and, as a result, an increase in noise level. At socket joints, fastening is carried out by default.

Basic elements of silent sewerage

• Silent pipelines

. As a rule, they are made of materials of different densities, which allows achieving a significant noise absorption effect. The outer layer of such pipes is made of rigid polypropylene, and to produce the inner layer, polypropylene is mixed with special mineral additives;

• Shaped parts

— are produced with significantly increased wall thicknesses and more powerful rubber seals. Some premium segment manufacturers (for example, Uponor), in order to minimize parasitic noise, place a special system of ribs on the fittings of internal sewerage systems, increasing the strength of the product and reducing vibrations;

• Fasteners

. To install silent sewers, compensating clamps are used - fastening devices that compensate for the vibration of the sewer pipeline at the time of waste liquid passage. For example, in the REHAU Raupiano system, clamps are a must; without them, the entire system goes into the expensive but ordinary civil sewer section. As a result, it is strictly forbidden to embed such a system in partitions, floors, etc.;

• Additional sound-absorbing materials

: polystyrene foam or polyethylene foam. Using these materials, specialists create an additional layer that absorbs sounds.

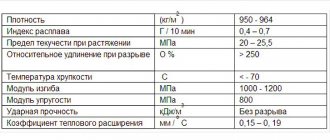

Characteristics

The positive characteristics include the following:

- Excellent insulating properties. Thanks to this, the noise-absorbing system dampens extraneous sounds to a normal level.

- Easy installation. Silent sewer pipes are equipped with special nozzles, fasteners and devices. This makes assembling the system easy and quick.

- Long service life. Low-noise sewerage can work flawlessly for more than 50 years.

- Light weight. The source material for the production of pipes that absorb sound from the sewer system is lightweight. Therefore, transportation and installation of the pipeline is not particularly difficult. In this case, installation of pipe sections at high altitudes is allowed.

- Resistance to mechanical damage. Thanks to this property, the operational period of the entire sewer system significantly increases.

- Pipeline strength. Silent sewer pipes are firmly and reliably fixed to the base, which avoids fluctuations and vibration of the pipeline.

Rules for installing silent sewer systems

Sound insulation of the sewer network should be taken into account at the design stage of utility networks. This is due to the fact that in most modern buildings the installation of communications is carried out in a closed way. In the future, to carry out work, it may be necessary to open the finishing layer. To protect against noise, several important rules must be observed: • Pipes are not allowed to pass through inter-apartment walls; • It is necessary to use special elastic sleeves made of porous polyethylene when laying pipes through interfloor ceilings; • The soundproofing material chosen by engineers to create a silent sewer system must allow pipe deformation and temperature changes in the room without the formation of gaps and through cracks; • Cavities in interior wall panels must be filled with non-shrinkage concrete.

It is important to note that quiet sewage systems are indispensable in buildings constructed using prefabricated technologies - panel, frame, modular, prefabricated panel, sandwich panel, block containers or light metal structures.

Sound-absorbing materials

To reduce noise levels, a wide range of high-quality materials are available on the market: • Soundproofing tape

.

The material is made of polyethylene foam and has an adhesive layer on one side. Thanks to this, it can be easily and conveniently attached to any vertical and horizontal surfaces. Soundproofing tape is resistant to corrosion processes, does not collapse under the influence of high temperatures, protects against moisture and reliably prevents the spread of noise through connecting elements; • Soundproofing membrane

, which is made from polymer and natural components.

It is characterized by great flexibility, high strength and durability. The principle of operation of a soundproofing membrane is to create a protective barrier around the pipeline that reflects the sound wave; • Sound insulation with aluminum foil

, which can provide high sound insulation even with a small thickness. The first layer of material absorbs sound waves, and the second reflects. Experts use various materials in their practice. Their choice depends primarily on characteristics, soundproofing effect, cost and installation method.