Features of the range

The construction market offers products for assembling utility lines made of polymer materials. Each has its own assembly technology. When installing networks, some need to be soldered, others need to be twisted, and others need to be glued together. This must be taken into account when planning the laying of pipelines.

PVC pipes (polyvinyl chloride)

They are used for transporting liquid compounds (water, oil products, acids), tolerate high temperatures well, are not afraid of frost, have strong walls, and do not collapse under high pressure. Plastic is completely harmless: it is non-toxic, water passing through such pipes does not change its properties, does not become cloudy, its taste and color remain the same, it does not smell of anything.

The inner walls are smooth, no deposits form on their walls Source masterseptika.ru

There are three types of plastic pipes on sale:

- some are intended for gaseous media;

- others can transport a liquid carrier without pressure;

- the third are pressure ones.

Considering that the water in the communications of an apartment building is supplied under high pressure, it is advisable to choose a third type of plastic pipes for assembling utility networks. They are gray in color. The marking must contain the GOST number (51613-2000). Such products can withstand pressure from six to sixteen atmospheres. The maximum length of such pipes is six meters, the diameter can be from 16 to 630 mm.

Pressure ones are gray Source www.omniplast.nl

They have their advantages and disadvantages. The advantages include:

- high resistance to chemicals;

- good throughput (over time, nothing sticks to the inner walls, the lumen of the pipes does not narrow, so water under pressure easily travels the path from the distribution station to the consumer’s tap);

- light weight (a pipeline assembled using plastic pipes will weigh several times less than a system for the installation of which metal pipes were used);

- no risk of corrosion;

- long service life;

- the possibility of laying a utility network inside the soil;

- low thermal conductivity.

Such PVC pipes for water supply are most suitable. They cannot be used for heating installations. When laying externally, it is important to thermally insulate the line (if the air temperature drops below -15 degrees, the water in pipes without thermal insulation will freeze). Frosts have a negative effect on the plasticity of such products. They can be easily scratched during assembly. These are the main disadvantages of the choice.

Special insulation for street highways Source i4.photo.2gis.com

See also: Catalog of 7 by 9 house projects.

PVC pipes are difficult to connect to a pipeline made of another material. This problem forces us to completely change engineering systems and make them completely identical. High-quality products are produced by Italian and German manufacturers. Their products are expensive. There are Turkish pipes on the market, they are much cheaper, but when examining the proposed material, it is often possible to identify roughness and unevenness on their surface; the wall does not always have a constant thickness. This then negatively affects the operation of the assembled highway. Its service life is noticeably reduced.

Polypropylene

Which polypropylene pipe products are suitable for heated environments? Undoubtedly, the excellent technical characteristics are the reason that this rolled tubular product has taken a leading position in the number of applications. The temperature at which the polypropylene line can operate reaches + 95 degrees Celsius.

Polypropylene (PP) pipes for hot water, the technical characteristics of which make these products optimally suitable for installation in a hot water supply network, have an important drawback. This is a high thermal expansion factor.

In such situations, it is necessary to take the installation seriously, and in particular the fastening of the polypropylene line. Otherwise, a significant deformation change in the PP of rolled pipes for working with hot water will appear.

To level out the linear increase, manufacturers began to produce reinforced polypropylene pipes for hot water. In these networks, the expansion of PP material under the influence of high temperature is significantly reduced.

A new material – cross-linked polypropylene – deserves special attention.

Pipes for hot water made of cross-linked polyethylene have appeared on sale quite recently. But consumers noticed their distinctive capabilities very quickly. Unlike simple polyethylene, PP assortment can be successfully used for pumping high-temperature media, since it is not afraid of high temperatures.

According to manufacturers, polypropylene pipelines will last a century. Also, installation work is greatly simplified by the high flexibility of cross-linked polypropylene.

Among the advantages of PP systems are low price and reliable connections. Even a novice master can construct a PP highway. And the mounted system can be hidden under the cladding or in grooves.

Diameters

If the question is: “How to distinguish polypropylene pipes for hot and cold water?”, then the answer is very simple. Marking on products will help with this, but with the volume of pipe products everything is a little more complicated.

Watch the video

What diameters do professionals recommend for plastic pipe products for hot liquid? Many argue that only a professional can correctly determine the diameter of a hot water pipe, because during this work many factors must be taken into account.

It is very important to correctly calculate the required fluid flow, the length of the plastic system, the resistance indicator and much more. For these reasons, this stage of action is best left to specialists. For plastic wiring, half-inch pipe products are most often used, and for the installation of risers, a three-quarter assortment is used. If the water flow is large, then the volume of the plastic riser is increased to one inch.

Watch the video

A variety of plastic products allows you to choose the material most suitable for the job. This range is installed in apartments; hot water pipes are also ideal for installation in the country house.

If a plastic line has become unusable, replacing it will not be difficult. You don't need to hire professional plumbers for this. With little skill, such actions can be easily performed with your own hands.

Low-pressure polyethylene

Metallized or fiberglass pipes for hot water have proven themselves to be the best. But technology does not stand still, and manufacturers are constantly offering new materials. Such new products include low-density polyethylene (HDPE).

It replaced the old metal and cast iron structures recently. HDPE pipe for hot water has the following advantages.

- Resistance of HDPE products to corrosive formations.

- Little weight.

- Ease of installation work.

- Long period of operation.

- HDPE pipes are installed when installing a hot water supply network to design a drain and gas supply line. Depending on the liquid being used, you need to select plastic pipes for hot water according to the marking and type of product. The diameter and dimensions of the walls are taken into account.

The main advantage of the HDPE system is its ability to pump water for drinking. The most popular of the described assortment options are tubular products of 20 - 60 mm.

HDPE polyethylene pipe products for hot environments are often placed in the heating network. To ensure that products do not lose their initial properties over time, it is recommended to choose polyethylene labeled PE 100 and PE 80.

These hot water pipes can be installed in a bathhouse, in a heating network in an apartment, in a country house or cottage. In any room, these polyethylene products will not lose their high technical characteristics and long service life.

According to GOST, such polyethylene pipe materials for hot water are required to be marked with a blue stripe. It notifies that these products can be used to supply water to a residential building, and are designed for a working pressure level in a polyethylene network from ten to sixteen atmospheres.

Polypropylene pipes

The material for their manufacture is obtained through a chemical reaction that occurs when polypropylene is mixed with a metal catalyst. The substance is forced under high pressure through the extruder. The result is a solid product with unique physical properties. It begins to melt only at a temperature of 175 degrees, so polypropylene plastic pipes are most often used for heating, although they are ideal for cold water supply.

White polypropylene products Source vodakanazer.ru

They can be laid in rooms with a high humidity threshold or even submerged in water; they are not afraid of rust. Polypropylene is a good insulator, it does not allow electricity to pass through, it is not afraid of stray currents, as are galvanic couples. But they also have their own operational features.

If they are constantly exposed to the sun's rays, the material will lose strength over time and turn yellow. This can be avoided when pipes are laid inside the wall or then masked with decorative panels. It is important to remember that polypropylene is a fragile material; if you accidentally drop a hammer on the product, it will damage the line. Eliminating these risks will extend the service life of the water supply system to one hundred years.

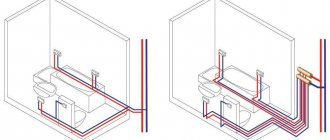

When installing flat areas, special couplings are used to connect individual elements. Triangles are used for turns. Tees are used to create a branch of the water supply system.

Highway created using polypropylene products Source elkomplus.su

See also: Catalog of companies that specialize in septic tanks and autonomous sewage systems.

It is important to know how to properly solder plastic pipes made of polypropylene. To do this, you need to have special equipment on hand: a jigsaw for cutting and a welding machine. While it is heating up, experts advise taking the necessary measurements, cleaning and degreasing the ends of the cut pipes.

Then make marks on them with a pencil, to which the ends of the heated sleeve will reach. The pipe along with the fitting is put on it. Both elements are heated simultaneously, the connection of plastic pipes is made with great force, and the elements cannot be rotated relative to each other. During the first few seconds, it is still possible to adjust the joint, but then, after the plastic has cooled, it will not be possible to correct anything.

Characteristics that determine the size of pipes for water supply

When talking about pipe sizes, we usually mean a combination of the following parameters.

- External diameter - usually specified by the manufacturer.

- Internal diameter is an important characteristic for parts of a plumbing system, measured in inches. It should not be different for pipes and fittings connected to each other.

- Nominal diameter (DN) - is a nominal value that is used when installing all parts of the water supply system. It is an averaged parameter, close in value to the diameter of the lumen.

- Product wall thickness.

- Length of the product.

Video description

The video describes in detail what markings polypropylene products have and how plastic pipes are installed and soldered:

Polyethylene pipes

They are made from polymerized ethylene and have all the advantages of plastic pipes, but they have one distinctive feature - high plasticity. Products are sold in rolls. Using them, you can construct engineering communications of complex shapes. They cannot transport hot water (it softens the polyethylene, which can cause the line to rupture). Low-pressure polyethylene pipes (LDPE) are ideal for assembling drinking water supply systems; water in them can be transported under a pressure of no higher than 10 atmospheres.

Roll of polyethylene products Source i4.photo.2gis.com

Selecting the diameter of plastic pipes

The optimal size of the elements of the plumbing system depends on many factors:

- water pipe length;

- number of connections and joints;

- number of turns;

- number of water intake points;

- water pressure in a particular system.

USEFUL INFORMATION: The tap is leaking, how to fix the faucet in the kitchen with your own hands?

The good news for non-professionals installing their own water supply system is the opportunity to abandon complex calculations and use standard solutions.

The length of the plumbing system can be taken as a determining parameter:

- for systems with a length not exceeding 10 m, pipes with a clearance of 20 mm are more often used;

- for 10-30 meter systems, products of 25 mm diameter are usually taken;

- lengths greater than 30 meters require the use of a 32mm diameter.

If we are talking about intra-apartment wiring, then everything is much simpler. Since the water supply in the apartment is short, in most cases products with the following internal diameters are suitable:

- 15 mm or half inch;

- 10 mm or 3/8 inch.

The following dimensions are chosen for the riser:

- 20 mm or 3/4 inch;

- 25 mm or 1 inch.

A larger diameter may be needed in the following cases:

- If the water supply system has a complex structure, has a large number of turns, joints and is characterized by variable pressure;

- If water is constantly used in large quantities.

Prices for water supply polyethylene pipes in Inzhplast.

Inzhplast company is a reliable supplier of HDPE pipes for water supply.

Work with trusted partners who can guarantee the quality of the products supplied and favorable conditions.

When we are asked which pipes we recommend for the construction of drinking water supply networks, we always say that the correct choice is PE pipe. Why do we think this? Because we have been in this industry for several years, and during this time we have gained enormous experience and helped build more than one serious facility where our customers used these water pipes.

Pros and cons of pp pipes

Plastic has the main advantage - it has a long service life. Such pipes are more resistant to external irritants than their metal counterparts. They are not susceptible to corrosive formations and salt and other formations on the walls.

Plastic pipes have become widespread not so long ago and it is difficult to determine exactly how long they will last. Manufacturers claim a service life of 50 years.

New generation plastics are made from environmentally friendly substances that do not have a negative impact on the environment. They are not able to change the properties of the liquid. The material has low thermal conductivity, so they are able to maintain heat. It is also believed that due to the good density of the pipe walls, noise from the water flow is suppressed.

The only downside of plastic is that not all types of pipes may be suitable for hot water supply. But thanks to the latest technology, there are plastic pipes that can withstand temperatures up to ninety degrees Celsius.

Announce the entire list

Here is a list of polymer materials for the installation of pressure engineering pipelines that have gained any noticeable popularity in the modern Russian market:

| Image | Description |

| Polypropylene (PPR). Plastic pipes made from it for cold and hot water supply are supplied in straight sections; they are produced unreinforced, with reinforcement with mineral fiber and aluminum (foil about 0.5 mm thick or mesh). |

| Polyethylene (PE). Due to its limited heat resistance, it is used only in cold water. For small diameter pipes, they are supplied in coils. Plastic is extremely elastic, and retains this property at low temperatures. |

| Polyvinyl chloride (PVC). And in this case, the limited heat resistance limits the scope of use of cold water pipes. They are less flexible than polyethylene and are sold only in straight lengths. |

| Cross-linked polyethylene (PEX). Supplied in coils; combines the elasticity of ordinary polyethylene with much higher mechanical strength and heat resistance due to cross-linking - chemical or radiation treatment that forms cross-links between polymer molecules. It has a rather exotic property - molecular memory: if you stretch the pipe, it will quickly return to its previous size. |

| Thermally modified (heat-resistant) polyethylene (PERT). Elastic, sold in coils. It differs from cross-linked polyethylene in slightly lower tensile strength with the same pipeline wall thickness and increased heat resistance. |

The video in this article will help you learn more about how to choose high-quality plastic pipes.