Varieties of equal-flange steel angles

Equal angle corners are divided into several categories depending on the manufacturing method and the raw materials used for their production. All geometric parameters, as well as permissible deviations for them, are regulated by two regulatory documents:

- GOST 8509-93 (production of hot-rolled equal-flange angles);

- GOST 19771-93 (production of equal-flange steel angles obtained by bending).

You can familiarize yourself with the GOST requirements and the range of hot-rolled and bent equal-flange steel angles by downloading the relevant documents in pdf format from the links below.

GOST 8509-93 Hot-rolled equal flange steel angles. Assortment Download GOST 19771-93 Equal-flange bent steel angles. Assortment Download

The difference between equal-shelf and unequal-shelf products is that the former have shelves of the same dimensions (width), while the latter have different shelves. Hot-rolled corner profiles are manufactured using the following technology: a hot billet is rolled between the shafts of a special rolling mill, where, under pressure, it is formed into a product with the required geometric shape and dimensions.

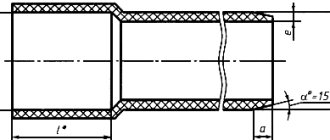

In order to produce a metal corner of the bent type, rolled sheets of the appropriate size are bent on roll forming equipment or on pipe mills. Due to the peculiarities of their production, hot-rolled profiles are characterized by higher strength, but bent corners also have their advantages: high dimensional accuracy, light weight, wide range.

Equal angle corner is a popular material both in industrial construction and in private households

The range of equal angle angles includes products from:

- high strength steel;

- alloyed, high-alloy steel;

- alloys characterized by increased heat resistance, heat resistance and corrosion resistance.

The most common material for the production of bent angles is also carbon steel, the characteristics of which must comply with GOST 380-94.

Length errors

Among other things, GOST regulates the maximum deviations of the corner for this parameter. The latter should not be more than:

- 30 mm for a corner 4 m long;

- 40 mm for products up to 6 m;

- 70 mm for corners from 6 to 12 m long.

At the customer's request, these parameters can be changed towards greater accuracy (40 mm for products 4-7 m plus 5 mm for each meter of length over 7 m). GOSTs regulate not only the dimensions of metal equal and unequal angles, their weight and maximum deviations, but also the degree of their curvature. After all, high-quality products must be smooth. The maximum value of the corner curvature according to GOST should not exceed 0.4% of the length. At the request of the customer, enterprises engaged in the production of rolled metal produce products with a curvature of no more than 0.2% of the length. GOST does not allow twisting of the angle around the axis.

Main characteristics

Using the assortment table for equal-flange steel angles, you can find out their various parameters: weight of one linear meter; profile cross-sectional area and other dimensions. To calculate the mass of a hot-rolled or bent profile, the density of the material from which it is made is taken as 7850 kg/m3.

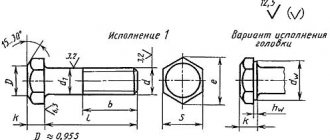

The radii of curvature of the profile of equal-flange steel angles, given in the table with the assortment, are not controlled parameters, but they are necessary for calibrating products. In the assortment table, the following designations of sizes and other parameters that characterize steel angles are used:

- t – shelf wall thickness;

- X0, Y0 – distances from the outer edges of the corner flanges to its center of gravity;

- R – radius of curvature;

- b – shelf width;

- r – radius of curvature of the edges of the shelves;

- I – moment of inertia;

- i – radius of gyration;

- F – profile cross-sectional area;

- Ixy is the moment of inertia that is developed by centrifugal forces.

Designations of the main geometric parameters of hot-rolled angles. Below is a table of the assortment of this type of rolled metal

Equal-flange steel angles can be of normal precision (marked with the letter “B”) and high-precision (marked with the letter “A”). GOST allows the following deviations in the width of shelves:

- for products No. 2–4.5 – ±1 mm;

- No. 5–9 – ±1.5 mm;

- No. 10–15 – ±2 mm;

- No. 16–20 – ±3 mm;

- No. 22–25 – ±4 mm.

The corner flanges must be perpendicular to each other within the tolerances according to the table

The thickness of the flange of an equal-flange steel angle in accordance with GOST may have the following deviations, measured in millimeters (see table).

The customer of a batch of equal-flange steel angles can agree with the product manufacturer that instead of permissible deviations in wall thickness, a tolerance for deviations in the mass of the product will be used, which can be for profiles:

- No. 2–7.5: from –5 to +3% (classes “A” and “B”);

- with No. over 7.5: ±2.5% (class “A”), from – 5 to +3% (class “B”).

Deviations in corner sizes depending on class

According to the provisions of GOST, steel angles belonging to the category of equal flanges can be supplied to the customer with a length of 3–12 m. By prior agreement between the customer and the manufacturer, these products can be supplied with a length exceeding 12 meters. Thus, GOST stipulates the possibility of tempering equal-flange steel angles of the following sizes in the longitudinal direction:

- measured length;

- measured size with the inclusion of products of unmeasured length in the batch (the number of such corners should not exceed 5% of the total volume);

- length, which is a multiple of the measured length;

- a length that is a multiple of the measured length, when the batch contains angles of unmeasured length (their number should not exceed 5% of the total volume);

- unmeasured length;

- length, located in an unmeasured interval.

An educational video from Soviet times, covering in detail the nuances of the production of long rolled metal products.

For the length of measured steel angles and products whose length is a multiple of the measured length, GOST establishes the following permissible deviations:

- no more than 4 meters – 30 mm;

- from 4 to 6 meters – 50 mm;

- over 6 meters – 70 mm;

- from 4 to 7 meters (at customer’s request) – 40 mm;

- over 7 meters (by prior agreement with the customer) - 5 mm for each additional meter of product.

Assortment of hot rolled angles

The high strength of these products ensures their use in creating structures that operate under severe loads. The range of equal flange hot-rolled angles is regulated by GOST 8509-93. The standard provides for two classes of rolling accuracy:

- A – increased;

- B – ordinary.

In the production of angle steel, carbon steel of ordinary quality and high-quality structural steel are used. For the manufacture of critical structures and elements of machines and mechanisms, angles made of low-alloy steels of type 09G2S, 10HSND are used. Such products can be used in a wide temperature range (-70...+450°C), therefore they are in demand in regions with harsh climates.

| Shelf width, mm | Shelf thickness, mm | Weight of 1 meter, kg | Shelf width, mm | Shelf thickness, mm | Weight of 1 meter, kg |

| 20 | 3 | 0,89 | 63 | 4 | 3,9 |

| 4 | 1,15 | 5 | 4,81 | ||

| 25 | 3 | 1,12 | 6 | 5,72 | |

| 4 | 1,46 | 70 | 5 | 5,38 | |

| 30 | 3 | 1,36 | 6 | 6,39 | |

| 4 | 1,78 | 7 | 7,39 | ||

| 35 | 3 | 1,6 | 75 | 5 | 5,8 |

| 4 | 2,1 | 6 | 6,89 | ||

| 5 | 2,58 | 7 | 7,96 | ||

| 40 | 3 | 1,85 | 8 | 9,02 | |

| 4 | 2,42 | 80 | 6 | 7,36 | |

| 5 | 2,98 | 7 | 8,51 | ||

| 45 | 3 | 2,08 | 8 | 9,65 | |

| 4 | 2,73 | 90 | 7 | 9,64 | |

| 5 | 3,37 | 8 | 10,93 | ||

| 50 | 3 | 2,32 | 9 | 12,2 | |

| 4 | 3,05 | 100 | 7 | 10,79 | |

| 5 | 3,77 | 8 | 12,25 | ||

| 6 | 4,47 | 10 | 15,1 |

Metal corner weight - formulas and table

The weight of 1 m linear equal and unequal angle can be determined from the table or using a simplified formula:

M = (A+B)*t*ρ, in which

This is interesting: Cutter for a metal lathe, what are they: types (types), markings, designation

M – mass of 1 linear meter, kg;

A – shelf width, m;

B – width of the second shelf, m, for equal-shelf products A=B;

t – flange thickness, m;

ρ – average steel density equal to 7850 kg/m3.

Another option for determining the weight of a corner is an online calculator, which, when entering data, shows a tabular value of the weight of the metal product. If there is no table value, the calculator calculates the mass using a simplified formula.

Table of mass of hot-rolled equal-flanged and unequal-flanged angles

| Width of corner shelves and their thickness, mm | Section length, m | Weight 1 m, kg | Cut weight, kg |

| 25x25x3 | 6 | 1,12 | 6,72 |

| 25x25x4 | 6 | 1,46 | 8,76 |

| 32x32x3 | 6 | 1,46 | 8,76 |

| 32x32x4 | 6 | 1,93 | 11,58 |

| 35x35x4 | 6 | 2,1 | 12,6 |

| 40x40x4 | 6 | 2,42 | 14,52 |

| 50x50x5 | 6 | 3,77 | 22,62 |

| 50x50x5 | 11,7 | 3,77 | 44,1 |

| 63x63x5 | 6 | 4,81 | 28,86 |

| 63x63x6 | 6 | 5,72 | 34,32 |

| 63x40x5 | 6 | 3,91 | 23,46 |

| 70x70x5 | 6 | 5,38 | 32,28 |

| 75x75x5 | 6 | 5,8 | 34,8 |

| 75x75x6 | 6 | 6,39 | 38,34 |

| 75x75x8 | 6 | 9,02 | 54,12 |

| 75x50x6 | 6 | 5,69 | 34,14 |

| 80x80x6 | 6 | 7,36 | 44,16 |

| 90x90x6 | 12 | 8,33 | 99,96 |

| 90x90x7 | 12 | 9,64 | 115,68 |

| 90x90x8 | 12 | 10,93 | 131,16 |

| 100x100x7 | 12 | 10,79 | 129,48 |

| 100x100x8 | 12 | 12,25 | 147,0 |

| 100x100x10 | 12 | 15,1 | 181,2 |

| 100x63x6 | 6 | 7,53 | 45,18 |

| 100x63x8 | 6 | 9,87 | 59,22 |

| 125x125x8 | 12 | 15,6 | 187,2 |

| 125x125x9 | 12 | 17,3 | 207,6 |

| 125x125x10 | 12 | 19,1 | 229,2 |

| 125x90x8 | 12 | 13,5 | 162,0 |

| 140x140x9 | 12 | 19,41 | 232,92 |

| 140x140x10 | 12 | 21,45 | 257,04 |

| 160x160x10 | 12 | 24,67 | 296,04 |

| 200x200x12 | 12 | 36,97 | 443,64 |

Dimensions of corners and reference values for axes

Cross-sectional area and reference values are calculated based on nominal dimensions. Steel density is 7.85 g/cm3.

The radii of curvature indicated in the figure and table are given for caliber construction and are not controlled on the profile.

| Corner no. | b | t | R | r | F, cm2 | Reference values for axes | Weight 1 m, kg | ||||||||||||

| x - x | x0 — x0 | y0 - y0 | Ixy, cm4 | x0,cm | |||||||||||||||

| mm | Ix, cm4 | Wx, cm3 | ix,cm | Ix0max, cm4 | ix0max, cm | Iy0min,cm 4 | Wy0, cm 3 | iy0min,cm | |||||||||||

| 2 | 20 | 3 | 3,5 | 1,2 | 1,13 | 0,40 | 0,28 | 0,59 | 0,63 | 0,75 | 0,17 | 0,20 | 0,39 | 0,23 | 0,60 | 0,89 | |||

| 4 | 3,5 | 1,2 | 1,46 | 0,50 | 0,37 | 0,58 | 0,78 | 0,73 | 0,22 | 0,24 | 0,38 | 0,28 | 0,64 | 1,15 | |||||

| 2,5 | 25 | 3 | 3,5 | 1,2 | 1,43 | 0,81 | 0,46 | 0,75 | 1,29 | 0,95 | 0,34 | 0,33 | 0,49 | 0,47 | 0,73 | 1,12 | |||

| 4 | 3,5 | 1,2 | 1,86 | 1,03 | 0,59 | 0,74 | 1,62 | 0,93 | 0,44 | 0,41 | 0,48 | 0,59 | 0,76 | 1,46 | |||||

| 2,8 | 28 | 3 | 4,0 | 1,3 | 1,62 | 1,16 | 0,58 | 0,85 | 1,84 | 1,07 | 0,48 | 0,42 | 0,55 | 0,68 | 0,80 | 1,27 | |||

| 3 | 30 | 3 | 4,0 | 1,3 | 1,74 | 1,45 | 0,67 | 0,91 | 2,30 | 1,15 | 0,60 | 0,53 | 0,59 | 0,85 | 0,85 | 1,36 | |||

| 4 | 4,0 | 1,3 | 2,27 | 1,84 | 0,87 | 0,90 | 2,92 | 1,13 | 0,77 | 0,61 | 0,58 | 1,08 | 0,89 | 1,78 | |||||

| 3,2 | 32 | 3 | 4,5 | 1,5 | 1,86 | 1,77 | 0,77 | 0,97 | 2,80 | 1,23 | 0,74 | 0,59 | 0,63 | 1,03 | 0,89 | 1,46 | |||

| 4 | 4,5 | 1,5 | 2,43 | 2,26 | 1,00 | 0,96 | 3,58 | 1,21 | 0,94 | 0,71 | 0,62 | 1,32 | 0,94 | 1,91 | |||||

| 3,5 | 35 | 3 | 4,5 | 1,5 | 2,04 | 2,35 | 0,93 | 1,07 | 3,72 | 1,35 | 0,97 | 0,71 | 0,69 | 1,37 | 0,97 | 1,60 | |||

| 4 | 4,5 | 1,5 | 2,67 | 3,01 | 1,21 | 1,06 | 4,76 | 1,33 | 1,25 | 0,88 | 0,68 | 1,75 | 1,01 | 2,10 | |||||

| 5 | 4,5 | 1,5 | 3,28 | 3,61 | 1,47 | 1,05 | 5,71 | 1,32 | 1,52 | 1,02 | 0,68 | 2,10 | 1,05 | 2,58 | |||||

| 4 | 40 | 3 | 5,0 | 1,7 | 2,35 | 3,55 | 1,22 | 1,23 | 5,63 | 1,55 | 1,47 | 0,95 | 0,79 | 2,08 | 1,09 | 1,85 | |||

| 4 | 5,0 | 1,7 | 3,08 | 4,58 | 1,60 | 1,22 | 7,26 | 1,53 | 1,90 | 1,19 | 0,78 | 2,68 | 1,13 | 2,42 | |||||

| 5 | 5,0 | 1,7 | 3,79 | 5,53 | 1,95 | 1,21 | 8,75 | 1,52 | 2,30 | 1,39 | 0,78 | 3,22 | 1,17 | 2,98 | |||||

| 4,5 | 45 | 3 | 5,0 | 1,7 | 2,65 | 5,13 | 1,56 | 1,39 | 8,13 | 1,75 | 2,12 | 1,24 | 0,89 | 3,00 | 1,21 | 2,08 | |||

| 4 | 5,0 | 1,7 | 3,48 | 6,63 | 2,04 | 1,38 | 10,52 | 1,74 | 2,74 | 1,54 | 0,89 | 3,89 | 1,26 | 2,73 | |||||

| 5 | 5,0 | 1,7 | 4,29 | 8,03 | 2,51 | 1,37 | 12,74 | 1,72 | 3,33 | 1,81 | 0,88 | 4,71 | 1,30 | 3,37 | |||||

| 5 | 50 | 3 | 5,5 | 1,8 | 2,96 | 7,11 | 1,94 | 1,55 | 11,27 | 1,95 | 2,95 | 1,57 | 1,00 | 4,16 | 1,33 | 2,32 | |||

| 4 | 5,5 | 1,8 | 3,89 | 9,21 | 2,54 | 1,54 | 14,63 | 1,94 | 3,80 | 1,95 | 0,99 | 5,42 | 1,38 | 3,05 | |||||

| 5 | 5,5 | 1,8 | 4,80 | 11,20 | 3,13 | 1,53 | 17,77 | 1,92 | 4,63 | 2,30 | 0,98 | 6,57 | 1,42 | 3,77 | |||||

| 6 | 5,5 | 1,8 | 5,69 | 13,07 | 3,69 | 1,52 | 20,72 | 1,91 | 5,43 | 2,63 | 0,98 | 7,65 | 1,46 | 4,47 | |||||

| 5,6 | 56 | 4 | 6,0 | 2,0 | 4,38 | 13,10 | 3,21 | 1,73 | 20,79 | 2,18 | 5,41 | 2,52 | 1,11 | 7,69 | 1,52 | 3,44 | |||

| 5 | 6,0 | 2,0 | 5,41 | 15,97 | 3,96 | 1,72 | 25,36 | 2,16 | 6,59 | 2,97 | 1,10 | 9,41 | 1,57 | 4,25 | |||||

| 6,3 | 63 | 4 | 7,0 | 2,3 | 4,96 | 18,86 | 4,09 | 1,95 | 29,90 | 2,45 | 7,81 | 3,26 | 1,25 | 11,00 | 1,69 | 3,90 | |||

| 5 | 7,0 | 2,3 | 6,13 | 23,10 | 5,05 | 1,94 | 36,80 | 2,44 | 9,52 | 3,87 | 1,25 | 13,70 | 1,74 | 4,81 | |||||

| 6 | 7,0 | 2,3 | 7,28 | 27,06 | 5,98 | 1,93 | 42,91 | 2,43 | 11,18 | 4,44 | 1,24 | 15,90 | 1,78 | 5,72 | |||||

| 7 | 70 | 4,5 | 8,0 | 2,7 | 6,20 | 29,04 | 5,67 | 2,16 | 46,03 | 2,72 | 12,04 | 4,53 | 1,39 | 17,00 | 1,88 | 4,87 | |||

| 5 | 8,0 | 2,7 | 6,86 | 31,94 | 6,27 | 2,16 | 50,67 | 2,72 | 13,22 | 4,92 | 1,39 | 18,70 | 1,90 | 5,38 | |||||

| 6 | 8,0 | 2,7 | 8,15 | 37,58 | 7,43 | 2,15 | 59,64 | 2,71 | 15,52 | 5,66 | 1,38 | 22,10 | 1,94 | 6,39 | |||||

| 7 | 8,0 | 2,7 | 9,42 | 42,98 | 8,57 | 2,14 | 68,19 | 2,69 | 17,77 | 6,31 | 1,37 | 25,20 | 1,99 | 7,39 | |||||

| 8 | 8,0 | 2,7 | 10,67 | 48,16 | 9,68 | 2,12 | 76,35 | 2,68 | 19,97 | 6,99 | 1,37 | 28,20 | 2,02 | 8,37 | |||||

| 7,5 | 75 | 5 | 9,0 | 3,0 | 7,39 | 39,53 | 7,21 | 2,31 | 62,65 | 7,91 | 16,41 | 5,74 | 1,49 | 23,10 | 2,02 | 5,80 | |||

| 6 | 9,0 | 3,0 | 8,78 | 46,57 | 8,57 | 2,30 | 73,87 | 2,90 | 19,28 | 6,62 | 1,48 | 27,30 | 2,06 | 6,89 | |||||

| 7 | 9,0 | 3,0 | 10,15 | 53,34 | 9,89 | 2,29 | 84,61 | 2,89 | 22,07 | 7,43 | 1,47 | 31,20 | 2,10 | 7,96 | |||||

| 8 | 9,0 | 3,0 | 11,50 | 59,84 | 11,18 | 2,28 | 94,89 | 2,87 | 24,80 | 8,16 | 1,47 | 35,00 | 2,15 | 9,02 | |||||

| 9 | 9,0 | 3,0 | 12,83 | 66,10 | 12,43 | 2,27 | 104,72 | 2,86 | 27,48 | 8,91 | 1,46 | 38,60 | 2,18 | 10,07 | |||||

| 8 | 80 | 5,5 | 9,0 | 3,0 | 8,63 | 52,68 | 9,03 | 2,47 | 83,56 | 3,11 | 21,80 | 7,10 | 1,59 | 30,90 | 2,17 | 6,78 | |||

| 6 | 9,0 | 3,0 | 9,38 | 56,97 | 9,80 | 2,47 | 90,40 | 3,11 | 23,54 | 7,60 | 1,58 | 33,40 | 2,19 | 7,36 | |||||

| 7 | 9,0 | 3,0 | 10,85 | 65,31 | 11,32 | 2,45 | 103,60 | 3,09 | 26,97 | 8,55 | 1,58 | 38,30 | 2,23 | 8,51 | |||||

| 8 | 9,0 | 3,0 | 12,30 | 73,36 | 12,80 | 2,44 | 116,39 | 3,08 | 30,32 | 9,44 | 1,57 | 43,00 | 2,27 | 9,65 | |||||

| 9 | 90 | 6 | 10,0 | 3,3 | 10,61 | 82,10 | 12,49 | 2,78 | 130,00 | 3,50 | 33,97 | 9,88 | 1,79 | 48,10 | 2,43 | 8,33 | |||

| 7 | 10,0 | 3,3 | 12,28 | 94,30 | 14,45 | 2,77 | 149,67 | 3,49 | 38,94 | 11,15 | 1,78 | 55,40 | 2,47 | 9,64 | |||||

| 8 | 10,0 | 3,3 | 13,93 | 106,11 | 16,36 | 2,76 | 168,42 | 3,48 | 43,80 | 12,34 | 1,77 | 62,30 | 2,51 | 10,93 | |||||

| 9 | 10,0 | 3,3 | 15,60 | 118,00 | 18,29 | 2,75 | 186,00 | 3,46 | 48,60 | 13,48 | 1,77 | 68,00 | 2,55 | 12,20 | |||||

| 10 | 100 | 6,5 | 12,0 | 4,0 | 12,82 | 122,10 | 16,69 | 3,09 | 193,46 | 3,89 | 50,73 | 13,38 | 1,99 | 71,40 | 2,68 | 10,06 | |||

| 7 | 12,0 | 4,0 | 13,75 | 130,59 | 17,90 | 3,08 | 207,01 | 3,88 | 54,16 | 14,13 | 1,98 | 76,40 | 2,71 | 10,79 | |||||

| 8 | 12,0 | 4,0 | 15,60 | 147,19 | 20,30 | 3,07 | 233,46 | 3,87 | 60,92 | 15,66 | 1,98 | 86,30 | 2,75 | 12,25 | |||||

| 10 | 12,0 | 4,0 | 19,24 | 178,95 | 24,97 | 3,05 | 283,83 | 3,84 | 74,08 | 18,51 | 1,96 | 110,00 | 2,83 | 15,10 | |||||

| 12 | 12,0 | 4,0 | 22,80 | 208,90 | 29,47 | 3,03 | 330,95 | 3,81 | 86,84 | 21,10 | 1,95 | 122,00 | 2,91 | 17,90 | |||||

| 14 | 12,0 | 4,0 | 26,28 | 237,15 | 33,83 | 3,00 | 374,98 | 3,78 | 99,32 | 23,49 | 1,94 | 138,00 | 2,99 | 20,63 | |||||

| 16 | 12,0 | 4,0 | 29,68 | 263,82 | 38,04 | 2,98 | 416,04 | 3,74 | 111,61 | 25,79 | 1,94 | 152,00 | 3,06 | 23,30 | |||||

| 11 | 110 | 7 | 12,0 | 4,0 | 15,15 | 175,61 | 21,83 | 3,40 | 278,54 | 4,29 | 72,68 | 17,36 | 2,19 | 106,00 | 2,96 | 11,89 | |||

| 8 | 12,0 | 4,0 | 17,20 | 198,17 | 24,77 | 3,39 | 314,51 | 4,28 | 81,83 | 19,29 | 2,18 | 116,00 | 3,00 | 13,50 | |||||

| 12,5 | 125 | 8 | 14,0 | 4,6 | 19,69 | 294,36 | 32,20 | 3,87 | 466,76 | 4,87 | 121,98 | 25,67 | 2,49 | 172,00 | 3,36 | 15,46 | |||

| 9 | 14,0 | 4,6 | 22,00 | 327,48 | 36,00 | 3,86 | 520,00 | 4,86 | 135,88 | 28,26 | 2,48 | 192,00 | 3,40 | 17,30 | |||||

| 10 | 14,0 | 4,6 | 24,33 | 359,82 | 39,74 | 3,85 | 571,04 | 4,84 | 148,59 | 30,45 | 2,47 | 211,00 | 3,45 | 19,10 | |||||

| 12 | 14,0 | 4,6 | 28,89 | 422,23 | 47,06 | 3,82 | 670,02 | 4,82 | 174,43 | 34,94 | 2,46 | 248,00 | 3,53 | 22,68 | |||||

| 14 | 14,0 | 4,6 | 33,37 | 481,76 | 54,17 | 3,80 | 763,90 | 4,78 | 199,62 | 39,10 | 2,45 | 282,00 | 3,61 | 26,20 | |||||

| 16 | 14,0 | 4,6 | 37,77 | 538,56 | 61,09 | 3,78 | 852,84 | 4,75 | 224,29 | 43,10 | 2,44 | 315,00 | 3,68 | 29,65 | |||||

| 14 | 140 | 9 | 14,0 | 4,6 | 24,72 | 465,72 | 45,55 | 4,34 | 739,42 | 5,47 | 192,03 | 35,92 | 2,79 | 274,00 | 3,76 | 19,41 | |||

| 10 | 14,0 | 4,6 | 27,33 | 512,29 | 50,32 | 4,33 | 813,62 | 5,46 | 210,96 | 39,05 | 2,78 | 301,00 | 3,82 | 21,45 | |||||

| 12 | 14,0 | 4,6 | 32,49 | 602,49 | 59,66 | 4,31 | 956,98 | 5,43 | 248,01 | 44,97 | 2,76 | 354,00 | 3,90 | 25,50 | |||||

| 16 | 160 | 10 | 16,0 | 5,3 | 31,43 | 774,24 | 66,19 | 4,96 | 1229,10 | 6,25 | 319,33 | 52,52 | 3,19 | 455,00 | 4,30 | 24,67 | |||

| 11 | 16,0 | 5,3 | 34,42 | 844,21 | 72,44 | 4,95 | 1340,06 | 6,24 | 347,77 | 56,53 | 3,18 | 496,00 | 4,35 | 27,02 | |||||

| 12 | 16,0 | 5,3 | 37,39 | 912,89 | 78,62 | 4,94 | 1450,00 | 6,23 | 375,78 | 60,53 | 3,17 | 537,00 | 4,39 | 29,35 | |||||

| 14 | 16,0 | 5,3 | 43,57 | 1046,47 | 90,77 | 4,92 | 1662,13 | 6,20 | 430,81 | 68,15 | 3,16 | 615,00 | 4,47 | 34,20 | |||||

| 16 | 16,0 | 5,3 | 49,07 | 1175,19 | 102,64 | 4,89 | 1865,73 | 6,17 | 484,64 | 75,92 | 3,14 | 690,00 | 4,55 | 38,52 | |||||

| 18 | 16,0 | 5,3 | 54,79 | 1290,24 | 114,24 | 4,87 | 2061,03 | 6,13 | 537,46 | 82,08 | 3,13 | 771,00 | 4,63 | 43,01 | |||||

| 20 | 16,0 | 5,3 | 60,40 | 1418,85 | 125,60 | 4,85 | 2248,26 | 6,10 | 589,43 | 90,02 | 3,12 | 830,00 | 4,70 | 47,41 | |||||

| 18 | 180 | 11 | 16,0 | 5,3 | 38,80 | 1216,44 | 92,47 | 5,60 | 1933,10 | 7,06 | 499,78 | 72,86 | 3,59 | 716,00 | 4,85 | 30,47 | |||

| 12 | 16,0 | 5,3 | 42,19 | 1316,62 | 100,41 | 5,59 | 2092,78 | 7,04 | 540,45 | 78,15 | 3,58 | 776,00 | 4,89 | 33,12 | |||||

| 20 | 200 | 12 | 18,0 | 6,0 | 47,10 | 1822,78 | 124,61 | 6,22 | 2896,16 | 7,84 | 749,40 | 98,68 | 3,99 | 1073,00 | 5,37 | 36,97 | |||

| 13 | 18,0 | 6,0 | 50,85 | 1960,77 | 134,44 | 6,21 | 3116,18 | 7,83 | 805,35 | 105,07 | 3,98 | 1156,00 | 5,42 | 39,92 | |||||

| 14 | 18,0 | 6,0 | 54,60 | 2097,00 | 144,17 | 6,20 | 3333,00 | 7,81 | 861,00 | 111,50 | 3,97 | 1236,00 | 5,46 | 42,80 | |||||

| 16 | 18,0 | 6,0 | 61,98 | 2362,57 | 163,37 | 6,17 | 3755,39 | 7,78 | 969,74 | 123,77 | 3,96 | 1393,00 | 5,54 | 48,65 | |||||

| 20 | 18,0 | 6,0 | 76,54 | 2871,47 | 200,37 | 6,12 | 4860,42 | 7,72 | 1181,92 | 146,62 | 3,93 | 1689,00 | 5,70 | 60,08 | |||||

| 25 | 18,0 | 6,0 | 94,29 | 3466,21 | 245,59 | 6,06 | 5494,04 | 7,63 | 1438,38 | 172,68 | 3,91 | 2028,00 | 5,89 | 74,02 | |||||

| 30 | 18,0 | 6,0 | 111,54 | 4019,60 | 288,57 | 6,00 | 6351,05 | 7,55 | 1698,16 | 193,06 | 3,89 | 2332,00 | 6,07 | 87,56 | |||||

| 22 | 220 | 14 | 21,0 | 7,0 | 60,38 | 2814,36 | 175,18 | 6,83 | 4470,15 | 8,60 | 1158,56 | 138,62 | 4,38 | 1655,00 | 5,91 | 47,40 | |||

| 16 | 21,0 | 7,0 | 68,58 | 3175,44 | 198,71 | 6,80 | 5045,37 | 8,58 | 1305,52 | 153,34 | 4,36 | 1869,00 | 6,02 | 53,83 | |||||

| 25 | 250 | 16 | 24,0 | 8,0 | 78,40 | 4717,10 | 258,43 | 7,76 | 7492,10 | 9,78 | 1942,09 | 203,45 | 4,98 | 2775,00 | 6,75 | 61,55 | |||

| 18 | 24,0 | 8,0 | 87,72 | 5247,24 | 288,82 | 7,73 | 8336,69 | 9,75 | 2157,78 | 223,39 | 4,96 | 3089,00 | 6,83 | 68,86 | |||||

| 20 | 24,0 | 8,0 | 96,96 | 5764,87 | 318,76 | 7,71 | 9159,73 | 9,72 | 2370,01 | 242,52 | 4,94 | 3395,00 | 6,91 | 76,11 | |||||

| 22 | 24,0 | 8,0 | 106,12 | 6270,32 | 348,26 | 7,69 | 9961,30 | 9,69 | 2579,04 | 260,52 | 4,93 | 3691,00 | 7,00 | 83,31 | |||||

| 25 | 24,0 | 8,0 | 119,71 | 7006,39 | 391,72 | 7,65 | 11125,52 | 9,64 | 2887,26 | 287,14 | 4,91 | 4119,00 | 7,11 | 93,97 | |||||

| 28 | 24,0 | 8,0 | 133,12 | 7716,86 | 434,25 | 7,61 | 12243,84 | 9,59 | 3189,89 | 311,98 | 4,90 | 4527,00 | 7,23 | 104,50 | |||||

| 30 | 24,0 | 8,0 | 141,96 | 8176,82 | 462,11 | 7,59 | 12964,66 | 9,56 | 3388,98 | 327,82 | 4,89 | 4788,00 | 7,31 | 111,44 | |||||

| 35 | 24,0 | 8,0 | 163,71 | 9281,05 | 530,11 | 7,53 | 14682,73 | 9,47 | 3879,37 | 366,13 | 4,87 | 5401,68 | 7,53 | 128,51 | |||||

This is interesting: Carbon (carbon) steel and its types. Production and Application

Shelf width and weight

What dimensions can a metal corner actually have? GOST regulates primarily the ratio of the width of the shelves of these products, their thickness and weight. The first indicator varies from 20 to 200 mm. The thickness of the products can reach 16 mm. What exactly should be the ratio of the width of the shelves and the weight of 1 linear meter of the product, see the table below.

| Shelf width (mm) | Thickness of steel used for manufacturing (mm) | Weight (kg) |

| 30 | 3-4 | 1.36-1.78 |

| 35 | 3, 4 or 5 | 1.6, 2.1 or 2.58 |

| 40 | 3-5 | 1.85, 2.42, 2.98 |

| 50 | 3, 4, 5, 6 | 2.32, 3.05, 3.77 |

| 70 | 4.5, 5, 6, 7, 8 | 4.87, 5.38, 6.39, 7.39, 8.37 |

Above are the ratios of values for equal flange products. As you can see, with the same width of the shelves, their thickness can be different. The weight of the product changes accordingly. The dimensions of the metal unequal corner, or rather, the width of its “shelves,” can also vary within the range of 20-200 mm. The ratio of this parameter and the weight of products in this case is regulated by GOST and is indicated in special tables.

Advantages and disadvantages of hot-rolled angles

Hot rolled steel has a number of advantages, which include:

- scope of application – including at large enterprises for bulk and regular orders;

- Sizes are not limited;

- performance characteristic - maximum speed;

- Products with thick walls can be processed.

In addition to the advantages, hot rolled steel also has several disadvantages. Firstly, the high cost of equipment. Secondly, installing such equipment will require a large amount of free space.

Characteristics of isosceles angles

High-precision steel, alloy metal or stable, heat-resistant compounds are used as raw materials for production.

The advantage is the affordable price, as well as the versatility of quality and wide scope of application. Moreover, such products are resistant to corrosion processes, do not deform, are not exposed to temperature and are well welded.

- Welding of metal structures

- Features of cold rolled sheets - production technology, features, dimensions, properties and markings

- Technical features of hot-rolled sheet - classification, manufacturing method, application options and processing features

Metal corners can be used for fastening, in mechanical engineering, installation of metal structures, for monolithic structures, in agriculture.

Equal corners are an excellent option for stairs.

The corner can be made from non-ferrous metals, for example, aluminum or magnesium products. Moreover, the corners made of non-ferrous metal will be pressed or bent.

Characteristics of an unequal angle

The scope of application is no less wide. Moreover, metal corners are often used as a decorative addition.

The main purpose is to use it to strengthen various structures. As well as use in the production of military equipment. Furniture metal corners are quite popular.

- Instructions on how to choose an I-beam: characteristics, dimensions, calculation of parameters and loads on the beam

- We choose VGP pipes wisely: standard sizes, selection tips and characteristics of water and gas pipes

- How to select and calculate a channel - rules of use, size tables, calculation of loads and selection of profile weight

This is interesting: Steel nitriding: process technology, equipment

I would like to name the small mass as the main advantage.

GOST standards specifying the assortment of equal angle angles

In addition to such parameters as the manufacturing method and the geometric dimensions of the corner, specified by the product range, the mentioned products are usually divided according to the use case (this sets the requirements for the materials from which the corner is made).

The main materials for the production of this type of long products are steel:

- Ordinary quality carbon, produced according to standard 380-2005 (GOST);

- Low alloy, high strength (standard 19281-89).

For each of these types, its own standard has been developed that specifies the specifications for its production. Based on this parameter, our customers have the following available for purchase:

- Equal-flange steel angle, intended for installation of steel building structures, complying with the interstate standard of the EAEU 27772-2015 (GOST);

- Angles manufactured according to standard 19281-2014 (GOST), made of low-alloy or high-quality non-alloy steels

Manufacturing in accordance with the provisions of the standards:

- 535-2005 (GOST). Refers to products of special and general use. Manufactured from carbon steel alloys of so-called “general” quality;

- 5521-93 (GOST as amended on April 16, 2003). They are in demand, first of all, by the shipbuilding industries (alloys of increased and normal strength). A corner manufactured in accordance with standard 52927-2015 (GOST R) has a similar purpose;

- 6713-91. An angle manufactured in accordance with this standard is used in bridge construction (low-alloy structural alloys are used in its manufacture). A corner made in accordance with standard 55374-2012 (GOST R) has a similar purpose.

Equal angle corner GOST 8509-93

This rental has the following technical parameters

| Options | Minimum value | Maximum value |

| Shelf width, mm | 20 | 250 |

| Shelf thickness, mm | 3.0 | 35 |

| Weight of 1 linear m, kg | 0.88 | 128 |

| Cross-sectional area, cm2 | 1.12 | 163 |

The maximum permissible deviations in the width of the shelf should be no more than:

- 1 mm for shelves up to 50 mm;

- 5 mm for shelves up to 100 mm;

- 2 mm for shelves up to 150 mm;

- 3 mm for shelves up to 200 mm.

Rolling accuracy can be of two types: A (high) or B (normal).

The length of the product, according to GOST, can be from 4 to 12 meters. In this regard, there are several types of length:

- Measured;

- Measured with unmeasured lengths (up to 5% of the total weight in the batch);

- Multiple dimensional;

- Multiple measured with unmeasured lengths (up to 5% of the total weight in the batch);

- Unmeasured.

- Limited within unlimited limits.

If necessary and in agreement with the manufacturer, the minimum length of the corner can be from 3 m, and the maximum - more than 12 m.

Angle angle GOST 8510-86

This standard clearly establishes the parameters of the mass of rolled products, as well as its dimensions:

| Options | Min | Max |

| Pen width, mm | 25 | 200 |

| Butt width, mm | 16 | 125 |

| Shelf thickness, mm | 3.0 | 16 |

| Weight 1 m, kg | 0.91 | 39.07 |

| Cross-sectional area, cm2 | 1.16 | 49.77 |

The maximum permissible deviations in the width of the shelves (feather/pad) and their thickness should be no more than:

- 0/0.3 mm for shelves up to 50/32 mm;

- 5/0.4 mm for shelves up to 90/56 mm;

- 0/0.4 mm for shelves up to 160/100 mm;

- 0/0.5 mm for shelves up to 200/150 mm.

Rolling accuracy can be of two types: A (high) or B (normal).

The length of the corner according to the guest can be from 4 to 12 meters. In this regard, there are several types of length:

- Measured;

- Measured with unmeasured lengths (up to 5% of the total weight in the batch);

- Multiple dimensional;

- Multiple measured with unmeasured lengths (up to 5% of the total weight in the batch);

- Unmeasured.

- Limited within unlimited limits.

If necessary and in agreement with the manufacturer, the maximum length of the product can be more than 12 m.

Such rolled products are made from hot- and cold-rolled steel on special roll forming mills. They can also have shelves of the same or different sizes (feather and butt), so they have their own standards.

For production we use carbon steel grades of regular and high quality with a tensile strength of up to 47 kgf/mm2 and over 47 kgf/mm2

Equal flange bent corner GOST 19771-93

In terms of size and weight, bent equal-flange angles can have the following values:

| Options | Made of steel with tensile strength up to 47 kgf/mm2 | Made of steel with a tensile strength of more than 47 kgf/mm2 | ||

| Min | Max | Min | Max | |

| Shelf width, mm | 36 | 120 | 55 | 160 |

| Shelf thickness, mm | 3.0 | 6.0 | 3.0 | 4.0 |

| Weight of 1 linear m, kg | 1.57 | 10.78 | 2.43 | 11.10 |

| Cross-sectional area, cm2 | 2.0 | 13.78 | 3.10 | 12.43 |

Bent equal angles differ in profiling accuracy into three categories:

- A. High accuracy;

- B. increased.

- B. Regular.

The length of the product, according to GOST, can be from 3 to 12 meters. In this regard, there are several types of length:

- Measured;

- Measured from unmeasured (up to 7% of the total mass in the batch);

- Multiple dimensional;

- Multiple measured with unmeasured (up to 7% of the total mass in the batch);

- Unmeasured.

The error in the width of the shelves should not exceed 0.75 mm 1.5 mm for high-precision corners and from 1.5 to 3.0 mm for products of normal precision.

Metal angle length

According to this parameter, products are classified into dimensional and non-dimensional. There is also a corner of multiple length and limited. Measured products can have a length of 6, 7, 9, 10, 11 or 12 m. Their cost depends on weight (that is, the consumer pays not per unit of product, but for the total weight of the purchase or, in extreme cases, per meter). An unmeasured corner can be of any length. In this case, this indicator varies from 4 to 12 m. Most often, building materials of this type are not too long, since they are often just scraps of measured products.

Sometimes, when manufacturing various kinds of frames, load-bearing structures, etc., it is required that the dimensions of the metal corner be non-standard. In this case, the consumer has the opportunity to order products longer than 12 m.