A water well is most often used as a source of water for autonomous water supply. It can be used seasonally or year-round. If you plan to draw water in winter, you need to think about how to insulate the well for the winter and avoid problems with water interruptions, equipment breakdowns and pipe ruptures.

We will tell you how to thermally insulate an independent water source, eliminating the formation of ice plugs in the system. Here you will learn how to insulate a mine shaft and the water lines extending from it. Our advice will help you decide on the best method and material for insulation.

The article thoroughly examines the basic rules and subtleties of organizing a system for protecting an independent water supply from freezing. For a visual understanding of the topic, diagrams, photo illustrations, and video tutorials are attached.

Insulation of a source at the dacha during the construction phase

Only the upper section of the trunk needs to be isolated. Various materials are used for this:

- liquid polyurethane foam;

- shrink film;

- sawdust;

- foam shavings;

- foam boards;

- upper layers of soil peat.

At the moment of drilling the hole, before lowering the uppermost sections of the pipe, they are insulated. For example, they cover it with heat-resistant adhesive tape at least 1.5 - 2.5 centimeters thick, then lower it into place.

Instead of adhesive tape, you can use the air heat protection method. It is known that air in a closed position conducts neither heat nor cold. Therefore, if a small air space is provided between the pipe wall and the ground, the mine will not freeze in winter.

Making your own needle and drilling a well

Holes up to 5 mm in diameter are drilled in a steel pipe with a cross-section similar to a drill column. To preserve the integrity of the body, they are made in a checkerboard pattern.

Along the pipe there are support rods made of steel wire. This is done to create an opening between the pipe and the outer winding.

We twist a V-shaped wire on top of the rods. This node creates an external filter. The entire structure - wrapped wire, support rods and pipe body - is fixed by welding.

The needle tip is installed at the end of the pipe. To ensure that the filter does not collapse while moving through the ground, it is necessary to make its outer diameter slightly larger than the filter cross-section.

Percussion drilling

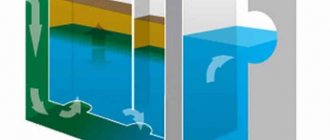

Caisson

One of the options for thermal insulation of a well is chamber protection. Depending on the material from which it is made, insulation is made from various materials.

For reinforced concrete rings, sawdust, peat, reeds, and mineral insulation are used. If the concrete caisson is square, the use of Penoflex slab is allowed. For factory cameras made of plastic or durable fiberglass, as well as polyethylene, mineral wool or glass wool is used. The thickness of the insulation layer is at least 30 mm.

Useful tips

- To select insulation, it is recommended to take into account the location of the future well. The climate in the region is taken into account (the depth of soil and soil freezing depends on it), the level of groundwater, the location of the well under the premises or on the land itself.

- It is recommended to take into account the location of the sewerage system.

- It is better to do drainage on the land to get rid of groundwater.

- If insulation material is used, polystyrene foam, which has specific properties, is most suitable.

Previous entry Installation of a well pump

Next entry Selecting equipment for a well with a caisson

Without caisson

Water supply equipment, filters and related electronics are located in the house or a separate room - this does not mean that the shaft does not need to be insulated. There are several ways to insulate a source without a caisson:

- Thermal protection of the mine shaft with wood chips or sawdust. The pipe is dug around its entire circumference to a depth of 2 - 2.5 meters. The width of the trench is 30 - 40 centimeters. Then a mesh with a large cell is wound to provide an air gap between the wall and the insulation. Next, the material (sawdust or peat) is gradually filled in. You cannot compact the insulation; it is better to let it stand for a while, and after shrinking, add more. A durable lid made of wood or metal is placed on top.

- Thermal insulation with mineral wool. They dig a trench in the same way and stretch the mesh. Then several layers of glass wool or mineral wool are wound onto the pipe. It is better to use a 5 cm thick mat. The final insulation layer is 35 cm.

- Insulation with liquid polyurethane foam is a little simpler. No need to wrap the mesh. A special device is simply lowered into the pit and polyurethane foam is sprayed layer by layer onto the surface of the pipe.

- Heating with electric cable. The principle is to use a special heating cable, which is tightly wound to the well pipe. A non-flammable film must be wrapped over the heating element and additional waterproofing is provided.

Emergency option - resuscitation with boiling water

If extreme frosts or power outages cause the well to freeze, you can try to revive it with boiling water. To melt an ice plug in a well, you need to take a metal tube with a diameter of 10 mm. Then put a rubber hose on this tube and connect a funnel to it. The tube is lowered into the well until it stops at the ice plug. Then they begin to pour boiling water into the funnel. Under the influence of hot water, the ice will gradually begin to melt, and the tube will smoothly go down. In a few minutes it will be possible to clear the well of any ice that has formed.

If the well is in order, but water does not flow into the house due to frozen pipes coming from the pump, then a decision is made to replace them. If the walls of the water pipe have not cracked under the influence of frozen water, then you can try inserting a heating wire directly into the pipe using a special device. In this case, a cable is selected that can be used in water supply systems.

We insulate the inlet water pipe

In addition to the mine itself, the pipeline entering the well and the house also needs thermal insulation. As a rule, in a dacha, the main line leading from the source to the house is laid shallow. This is due to the technically narrow capabilities of the work. That is why it has to be additionally insulated.

Method one into another

Take a plastic or metal pipe with a diameter larger than a water pipe. We will lay it on the base in a trench and lead it to the well, house and equipment. In fact, it will act as a sleeve or case.

There is no need to put it into the mine shaft, 10 centimeters inside is enough, that’s what we will isolate. To facilitate the process, 20–25 centimeters of sawdust are first poured into the trench, on which the pipe is laid. Soft insulation, glass wool, or penoflex is thrown on top. The structure can be covered with soil. We insert a water pipe into the case, leading it into the house and the well.

The air cushion between the insulated sleeve and the water pipe will create an additional barrier to the cold.

Important: for additional waterproofing, the case with insulation is wrapped with roofing felt or polyethylene.

Thermal insulation using penoflex

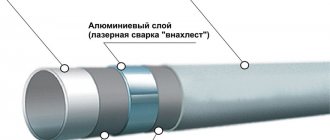

Modern material, flexible and durable. It looks like cylinders from 3 to 6 meters long. They vary in thickness and density. There is a penoflex for each pipe diameter. In this case, there is no need to use a sleeve. The pipe is completely insulated before installation, gluing all joints with metallized tape. Insulation of highways underground using Penoflex technology is possible at a depth of 70 centimeters.

How to close a well for the winter?

This procedure depends on the type of structure. Preparation is slightly different for a regular well, a design with an adapter, and an Abyssinian needle.

Conservation of a conventional source

Before closing the well for the winter, turn off the water supply, then drain it from the water supply and all plumbing fixtures, including water heaters (boiler). The liquid is removed using valves that are embedded in the lower sections of the water supply system, at turns, and inclines. During this operation, do not forget to get rid of the water remaining in the shower hoses and watering cans, in the siphons of the sink, sink and bathtub.

Water is poured out of the tank. All liquid is also pumped out of the toilet siphon, then antifreeze is poured into it to get rid of the sewer smell. Just like plumbing, a septic tank requires pumping and preparation. The pumping station is moved to a place intended for its storage. It is then blown with air using a pump or hand pump to completely remove any remaining moisture.

As for the submersible pump, it does not need to be removed. Since the unit is located at a considerable depth, it is not in danger of freezing. The last stage of the operation is draining the water into the well. To do this, open the check valve located after the pump. There are models of well pumps in which this element is already built-in.

Conservation of the Abyssinian well

The water in the Abyssinian needle is also below the ground freezing level. In this case, the main tasks are two stages - draining water from the system and organizing reliable protection of the mouth.

First, remove the pump, then disconnect the hose, put both elements in a warm and dry room. Water is drained from the pipeline and, if necessary, purged with air. The head is screwed onto the thread, then it is waterproofed with a plastic cap or thick plastic film.

If the well has an adapter

Downhole adapter is a device that ensures a tight connection between the pipe and the source. This design is more complicated, but well preparation in this case is reduced to a minimum of actions. First, power is turned off from the installed pump. Then one of the faucets in the building is opened. When the pressure in the system drops to 0.5 bar, the drain valve will open and the liquid will begin to flow out of the system to the source.

In any case, it is recommended to disinfect the well before wintering. For this purpose, prepare a solution from bleach powder and water (per meter of well - 30 g per 10 l). This drug will disinfect the liquid, rid it of organic debris, and prevent the proliferation of pathogenic microorganisms. Before using the source, such water is pumped out.

Do-it-yourself casing insulation

During the actual installation of the casing, it is impossible to insulate it properly.

Therefore, insulation of the water well occurs after installation. Thermal protection of the mine shaft along the inner wall of the pipe will lead to a mandatory narrowing of the bore diameter, so the casing is insulated only from the outside.

First step. We dig the source from all sides in a circle to a depth of three meters. It should be counted from the top cut of the earthen embankment. We strengthen the soil walls with wooden panels or boards. You can also use metal sheets by twisting them around the trench.

Second step. Having compacted the base of the pit, we pour insulating material onto the bottom.

It can be anything, even old down jackets or padded jackets. The insulation must be laid carefully, pressing tightly against each other.

Advantages and disadvantages

Among the advantages of Abyssinian wells are:

- Relatively cheap. You can do the work yourself.

- The necessary components are widely available.

- Fast production. Setting up a well with all the components in place will take literally a couple of hours.

- Ease of arrangement. A well requires limited space. Any area of the yard, as well as a basement or garage, is suitable.

- No special drilling equipment is required for the work. Such equipment usually requires special access roads and special transport.

- Long service life. However, this statement is only realistic for properly equipped wells.

Minuses:

- Construction of an Abyssinian well is not practical in areas where there are layers of clay and limestone. The work will not be economically viable.

- It is impossible to install a submersible pump in a small diameter pipe that is installed for a well. Therefore, a pumping station is needed to raise water.

- Construction of a well becomes more complicated if the distance to the water surface is more than 8 meters. To set up a pumping station, you will need a pit with a caisson, which can also be installed in the basement of the house. The pumping station will not be able to lift water from deep aquifers.

Before starting work, you need to study the area. On the ground, you need to find out the depth of the aquifers. In addition to choosing a location, it is important to choose the time for work, since the water level changes from season to season.

Constant heating electric cable

In places with deep freezing of the ground and high ground water level, which freeze in winter, additional protection is required. Heating cord is divided into two categories:

- With installation inside the pipeline.

- Outer winding.

To lay the cable inside the pipe, a special tee is installed at different angles. It is completely sealed. After installing the line, a cord is inserted into it, which runs along the entire length of the thread and exits through a tee on both sides of the pipe. A prerequisite is subsequent thermal insulation of the pipe from the outside. The cable is reinforced with additional waterproofing and is safe. Mandatory installation of a thermostat is required to avoid excessive energy consumption.

The external heating cord is attached to the pipe along its entire length with tape or plastic clamps. We glue the entire cable with tape, then lay the thermal insulation. The cord should not sag or come off; only its tight contact with the pipeline will ensure good heating. The well can also be insulated with a cable, but due to the fact that the diameter of the casing is much larger, the cord is wrapped around it. Steps of five centimeters.

Cable electric heating

To protect downhole equipment and supply pipes from freezing, special electric heaters are sometimes used. This relatively expensive, but very effective method is used for heating wells that do not have a caisson, as well as in regions with very low winter temperatures.

The operating principle of the first type of heaters is in many ways similar to the operating principle of the so-called heated floor. Such a heater is mounted near the well directly inside the casing.

The second type of heater , a heating cable, is more versatile. It is used to heat both underground and above-ground water pipes, and it can be located both outside and inside the pipe.

To save energy, such heating systems are sometimes equipped with a temperature sensor that turns off the current supply when the optimal temperature is reached.

Using improvised means

Sawdust, straw, peat or even dry leaves are often used as insulation.

The pit around the source is reinforced with boards or sheets of metal. Waterproofing material is laid between the soil and the shield. Heaped sawdust is poured into the trench and allowed to settle for a couple of days. The depth of the warm chamber is up to 2 meters, and the width is 40 - 50 centimeters. Do not compact sawdust or straw. Air should remain in the insulation. You also need to ensure that the material at hand is dry and crumbly.