Polymer coating is used to increase the service life of metal surfaces and improve their certain characteristics, for example, resistance to corrosion. It is a combination of polymers, color pigments and other additives capable of forming a layer of protection for the metal from the negative effects of the environment.

Such a coating is formed by applying a special liquid or powder composition to the metal in a polymerization chamber. Most often, metal surfaces of fences, corrugated sheets and metal tiles are covered in this way.

The price of the coating is easily compensated by the durability of products made from it and their ability to withstand various negative environmental influences. In addition to practical value, it has an aesthetic appearance with a set of decorative qualities such as color, smoothness and shine. The latter is achieved thanks to a layer of primer with pre-treatment of the metal surface.

Today you can buy rolled metal coated with a polymer layer in several versions. Of the many existing types of coatings, the most common are polymer materials such as polyester, PVDF, plastisol and pural. Any of them is endowed with a number of advantages and is selected depending on the conditions of the upcoming operation of the structure.

What's the point?

To improve the performance properties of the metal, polymers are used that can react under certain conditions. Such coatings are dry compositions based on finely dispersed powder, to which hardeners, fillers and pigments are additionally added. It was not by chance that the polymer coating was chosen to increase the protective properties of the metal: metals conduct electric current, as a result, the charge is transferred to the product, resulting in the formation of an electrostatic field. It attracts powder particles, holding them on the surface of the workpiece. The peculiarity of the polymer coating is its high degree of resistance to any type of impact. Moreover, it is aesthetically pleasing.

How to choose paint

Polymer paint is chosen depending on the type of work, product and place of its further use. To decorate elements in the room, choose environmentally friendly dyes without a strong odor. To paint surfaces that will be used outside, polymer paints must be resistant to moisture, sun, and dust. It is recommended to choose quick-drying types of powder dyes. In addition, metal products require paints that protect against corrosion. You also need to decide which surface suits you - glossy or matte. Glossy is easier to clean and more practical. But matte can mask minor defects on the metal surface. You definitely need to look at the expiration date - the closer it is to the manufacturing date, the better.

How does polymerization take place?

The powder coating shop consists of several sections:

- Product preparation area: in order for the polymer coating to be applied correctly and evenly, the metal product is first thoroughly cleaned of dust, rust, and dirt. It is advisable to use effective sandblasting and phosphating. A mandatory step is degreasing the metal surface.

- Spray booths: The spray booth is where the actual painting is done. The chamber is thermal, it can heat up to a temperature of 200 degrees and warms up evenly. The powder begins to melt, due to which an even and smooth coating is formed over the entire surface of the metal, and its pores are filled.

- Polymerization of the product is carried out in a cooling chamber: here the temperature gradually drops and the polymer film becomes harder. After 24 hours, the polymer coating is ready for use.

Pural

Pural is made on the basis of polyurethane and modified polyamide. The pural coating has a silky-matte surface, high heat resistance and resistance to sudden temperature changes.

This material does not fade and is not destroyed under the influence of chemically aggressive environments. Pural is not as resistant to plastic deformation as plastisol, and is more expensive than polyester, but in terms of price-quality ratio it is the best option of all those presented above.

Pural coatings are most widespread in the production of roofing elements made of galvanized metal. Steel treated with pural acquires a beautiful appearance, high anti-corrosion characteristics and resistance to UV radiation.

Painting technology: what's the point?

Powder coating is applied in several stages. At the first stage, the surfaces are processed. It is very important that metal products are thoroughly cleaned of dirt and oxides, and degreasing the surface will promote improved adhesion. After preparation, the masking stage is performed, that is, those elements of the metal product that should not be exposed to the powder composition are hidden.

The parts to be processed are loaded onto a transport system and then sent to the painting booth. After spraying, a powder layer is formed on the metal. At the polymerization stage, a coating is formed, which is a melting of a layer of paint.

Metal application technology

Now let’s figure out how to properly paint metal with polymer paint.

The application technology is divided into several stages:

- Surface preparation.

- Coloring.

- Polymerization.

Preparation of the treated surface

Attention! The durability, service life, corrosion resistance and elasticity of the coating depend on the quality of surface treatment.

First, the product must be cleaned. There are two ways to clean the surface:

- mechanical cleaning;

- chemical cleaning.

Mechanical cleaning is the process of cleaning the surface with steel brushes and grinding discs, as well as an abrasive method. At high speed under pressure, small particles (shot, sand) fall onto the surface and break off rusty pieces, scale and other contaminants. This method significantly increases the adhesion of the coating.

Chemical cleaning is performed using various acids (hydrochloric, sulfuric, nitric, phosphoric). This type of cleaning is also called etching. This cleaning method is easier to apply, but after it it is necessary to rinse the cleaned surface of solutions.

After any cleaning, the surface is degreased with special detergents so that the degree of adhesion is as high as possible.

The last stage of preparation is passivation, that is, surface treatment with sodium nitrate and chromium compounds. Passivation will slow down or completely stop metal corrosion.

After all stages, the surface must be completely dry.

Coloring

Warning! During work, it is necessary to use special clothing and a respirator to protect the respiratory tract. If powder particles get inside, it can cause poisoning.

After drying, the product to be painted is transferred to the spraying chamber.

One of the most common methods of painting with polymer paint is electrostatic spraying. That is, an electrostatically charged powder is applied to a grounded product using a gun (applicator, spray gun). As a result, it sticks to the surface of the material.

Polymerization

After painting, the product is sent to a heat chamber, where it will be heated to a temperature of 140 to 200. Under the influence of temperature, the polymer melts and a film forms. The process lasts from 10 to 30 minutes.

After the polymerization process is completed, the product is allowed to cool, after which it will be ready for further use.

What are the features?

Metal treated with a polymer coating is characterized by reliability and increased strength. This is explained by the fact that a sealed monolithic film is formed, completely covering the surface of the product and firmly adhering to it. Thanks to the polymer coating, the metal has:

- high adhesion to the surface;

- high strength and wear resistance;

- long service life while maintaining original properties;

- rich color range;

- fast production cycle.

Polymer coating of metal is carried out on the basis of various materials and coloring powders. The choice of a specific substance depends on the purpose for which the coating is applied and how important the decorative properties are.

What form can polymer painting of metal take?

In addition to the color palette, the range of polymer paints consists of such products as:

- polyester polymer paints;

- epoxy polymer paints;

- polyurethane polymer paints;

- epoxy-polyester paints.

The main advantage of epoxy polymer painting of metal is the ideal balance between electrical insulation and physical and mechanical properties. High adhesion of the coating is ensured due to the chemical and mechanical stability of the composition. Metal products with epoxy polymer painting are not affected by acids, alkalis, oil, fuel materials, and moisture. This feature makes it possible to use this composition to protect the internal and external surfaces of main pipelines.

With epoxy polymer painting, a layer of 500 microns is formed on the metal surface, which creates a hard coating with high impact strength and elasticity. Low levels of weather resistance are the only disadvantages of this type of paint. Over time, some areas may become yellow or chalking, which is a cause of overheating.

- Area of use of epoxy polymer paints

The purpose of using epoxy polymer painting is to obtain a hard metal coating that is resistant to solvents and chemicals. The area of use of such mixtures is radio engineering and electrical engineering. The high electrical insulating properties of epoxy polymer painting allow it to be used for painting electrical cabinets, medical equipment, office fittings and metal household appliances.

- Area of use of polyester polymer paints

These mixtures are ideal for painting household items, garden, office and medical furniture made of metal, electrical equipment and sports equipment. Polyester polymer painting is very popular due to its excellent decorative qualities. Modern equipment and technologies make it possible to expand the color range of compositions and diversify the texture of the material.

- Areas of use of polyester and polyurethane polymer paints

Agricultural vehicles, metal travel accessories, car wheels, and aluminum profiles for window and door openings are processed using polymer polyester paint.

The versatility of these compositions determines the possibility of their wide use for interior and exterior work. After polymer painting of the metal, the product acquires a glossy surface with a 90% gloss level. An alternative would be a polyester blend with a matte or semi-matte finish.

Polyurethane polymer paints with a glossy finish have a beautiful shine and are resistant to precipitation, water, chemical solvents, fuel and mineral oils.

Their area of application is the protection of metal surfaces subject to abrasion, wear and friction. With their help, chemical equipment and containers for storing liquid chemicals and gaseous substances are processed. Polyurethane paints can be used as a primer before applying other polymer paint mixtures.

Polyester

Polyester is most often used for polymer coating of metal. This is an inexpensive material with a high level of flexibility and moldability, and it can also be used in any climatic conditions. The polyester-based polymer-coated sheet is resistant to ultraviolet radiation and corrosion. The material forms a high-quality and durable film on the surface, so that steel sheets are delivered intact under any transportation conditions.

Matte polyester is also widely used: the coating has a very small thickness, and the metal surface is matte. The peculiarity of this material is its high color fastness, good resistance to corrosion and mechanical stress.

Advantages

Regardless of the consistency of the paint, it has many advantages.

- High ability to penetrate even the smallest surface layer. Thanks to this, a protective layer is created on the item from water and corrosion.

- High resistance to sunlight. This quality allows you to protect the surface from fading and color abrasion.

- Resistance to mechanical and chemical damage, since polymers create a fairly thick layer on the object.

- Resistant to temperature changes.

- Affordable price.

- Economical. This paint can be applied in one layer, so one can is enough for a large area.

- Variety of types and wide range of colors. Due to this, this paint is widely used for decorating living spaces and antique objects.

- Versatility. Absolutely all types of surfaces—metal, wood, and glass—are subject to polymerization.

Thanks to its features, this paint is a worthy competitor in the paint market. And the variety of types and shades will allow the buyer to choose the desired option.

Plastisol

Another popular polymer coating for metal is plastisol. This decorative material contains polyvinyl chloride, plasticizers; Outwardly, it attracts attention with its embossed surface. This is the most expensive coating, and at the same time the most resistant to mechanical damage due to the large thickness of the coating. On the other hand, the material does not have high temperature resistance, and therefore the coating will deteriorate when exposed to sunlight at high temperatures. Due to the large thickness, the corrosion resistance of plastisol is high.

Steel with a polymer coating based on pural, which has a silky-matte structural surface, is popular. Resistance to temperature changes and chemicals makes this composition popular for metal processing.

Bestseller!

All-weather rubber paint. Made from synthetic rubbers. This product has increased adhesion to concrete surfaces and is characterized by increased wear resistance and coating strength. Waterproofing. Can be applied at temperatures down to minus 25C!!!

Universal all-weather rubber paint based on synthetic rubbers. Increased elasticity. Waterproofing. For swimming pools. For painting boats and boats. For sports fields and gyms. Resistant to sea water. For metal, concrete, wood and other surfaces. The color of the coating is matte, any color. Can be applied at temperatures down to minus 25C!!!

High-strength waterproofing rubber paint for all types of surfaces: concrete, metal, wood, stone, plaster, slate, etc. Acrylic. Water-dispersed.

Rubber heavy-duty paint Monolith with a self-cleaning effect (Lotus effect). For all types of substrates: concrete, wood, metal, brick, plaster.

Acrylic water-dispersed semi-matte varnish. Finish coating for metal, concrete, stone, tiles, wood, etc.

Paint Polymer Acrylic Concrete is an acrylic copolymer on an organic basis with stabilizing additives that enhance adhesion to concrete and asphalt, air curing catalysts that create the highest wear resistance, oil and petrol resistance and resistance to mineral oils and petroleum products. Can be applied at temperatures down to minus 25C!!!

Paint PolymerAcrylic Concrete Pro is an acrylic copolymer on an organic basis with stabilizing additives that enhance adhesion to concrete and asphalt, air curing catalysts that create the highest wear resistance, oil and petrol resistance and resistance to mineral oils and petroleum products. Made from polymer raw materials produced by BASF Corporation. This product has increased adhesion to all types of surfaces and is characterized by increased wear resistance and coating strength. Can be applied at temperatures down to minus 25C!!!

Universal primer - water-dispersive, hardening, deep penetration, has a dust-removing effect. Intended for external and internal work on concrete, plaster, drywall, dispersion and oil paints for applying water-based materials.

Polyurethane gloss varnish. (Matte varnish is available upon request) Final transparent coating on metal, concrete, stone, tiles, wood, etc.

Polyurethane one-component enamel for metal, concrete, wood, etc. Glossy finish in any color. For interior work.

Polyurethane two-component enamel for metal, concrete, wood, etc. Glossy finish in any color. For interior and exterior work. Increased weather resistance. For its beautiful glossy polymer coating, Universal Pro enamel is called “liquid plastic”. The service life of the coating on a properly prepared surface is 30 years.

High-strength waterproofing rubber paint for all types of surfaces: concrete, metal, wood, stone, plaster, slate, etc. Acrylic. Water-dispersed. With antifreeze. Application possible from -15C.

Paints for wood (plywood, OSB, slate, brick and plaster) must have waterproofing properties, but at the same time be “breathable” - release steam, preventing wood rotting. Have a fugicidal effect (prevent the formation of mold and mildew). Make it as difficult as possible for wood-boring beetles to penetrate the paintwork. We present the following compositions:

1. Water-based rubber paints with acrylic copolymers. Eco-friendly, practically odorless, diluted with plain water. The surface to be painted must first be primed.

2. Semi-matte acrylic varnish. Apply above 0C.

3. Polymer acrylic coatings on an organic basis. Can be painted from -25C. Does not require preliminary priming.

4. Rubber paints and liquid roofing have increased elasticity, the highest waterproofing properties and increased wear resistance. Can be painted from -25C. Does not require preliminary priming.

Characteristics of polymer-coated steel

Features of polymer-coated materials are strength, formability, and high corrosion resistance. After processing, the steel acquires a beautiful appearance, which can be given any colors and shades. Rolling is carried out in accordance with GOST, the polymer coating is of high quality. Painted rolled products can have a one- or two-layer coating; options are possible when the substance is applied on one or both sides. Thanks to the polymer coating, the performance properties of steel are improved:

- polymer-coated metal can be processed into finished products;

- the coating is distributed evenly over the surface, therefore the degree of protection is uniform;

- the absence of pores guarantees a good level of protective properties;

- steel has good adhesion;

- metal can retain its protective and decorative properties for more than 10 years.

From an economic point of view, galvanized steel with a polymer coating is more profitable: firstly, it contributes to high productivity and quality, since the cost of coating is reduced. Secondly, the buyer does not need to invest in additional steel treatment to protect its surface. Note that the anti-corrosion properties of galvanized steel, which is treated with a polymer coating, depend on the thickness of the layer. To increase the service life of steel products, they are additionally coated with two layers of polymer, which makes the protection of the metal even higher.

Alternative

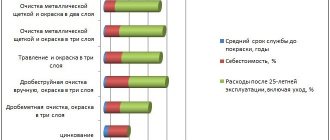

Is there a reasonable alternative to polymer paints for metal? We are, of course, not talking about the aesthetic side, but about the functional one - high-quality protection against corrosion.

At a minimum, the strength and durability of the coating obtained as a result of cold galvanizing is not inferior to polymers. A dispersion of fine zinc powder in an organic solvent with a small amount of binder, applied with a spray gun, roller or brush, after drying, forms a thin layer of zinc on the surface of the steel, protecting the base from corrosion.

Thus, Zinga electrically conductive paint can be used for long-term protection of metal structures operating outdoors and in contact with sea water.

Since we touched on unusual paints, let’s mention another class of them - the so-called fire-resistant coatings. Fire-retardant paints for metal - Polistil, Counterfire and their numerous analogues - swell when heated and form fire-resistant foam, which reliably insulates the painted structure.

Fire retardant paint Krauz.

Coating features

Polymer coating is a film that has a whole range of unique performance characteristics. Pre-painted rolled products are created on the basis of several types of polymers. Any material processed using this method - steel sheet or polymer-coated mesh - is impact resistant, corrosion resistant and has high adhesion. It is also important that powder coating allows you to make the metal surface of any color, including artificially aged, for example, in antique style.

Today, a popular method of painting rolled steel is Coil Coating. The essence of the method is that the coating is applied on an automated line, that is, rolled sheets are processed on the line, after which the coating is applied to them using roller machines. This technology has become widespread due to the fact that there is no loss of materials, and the line itself is more productive, and therefore profitable.

As with any other finishing work, you first need to prepare the surface, after which it is painted. This technology allows for high-quality processing of steel, aluminum and tinplate. Thus, a polymer coating is an opportunity to improve the performance properties of the metal, increase its protective properties and ensure long service life.

Advantages of polymer paints

Powder dyes have a number of advantages, due to which they can be used to process external and internal products made of different types of metal. The advantages of polymers include: – they are not afraid of mechanical damage: if the metal product is damaged or deformed, the color will simply take a new shape, remaining on the surface; – water and moisture resistance: the polymer coating does not lose its qualities, even if the product is in or under water for a long time; – resistance to UV rays: while other types of paints from sunlight can fade, collapse and lose all their properties, the polymer coating will remain just as durable and bright, nothing will happen to it even on the sunniest day; – can withstand fire and high temperatures: since polymer painting is carried out under strong thermal influence, the coating is not afraid of high temperatures in the future; You can even use powder paint to paint your grill and heating boiler. – not destroyed by chemicals.

Types of car body protection

Every day a car is exposed to many harmful factors. It could be rain and hail, the scorching rays of the sun, stones flying from under the wheels of passing cars, and dust. All this entails the appearance of small scratches, dents, abrasions, and fading of color. All this can happen not only with a cheap car. Even the most expensive brands are not protected from these troubles. But you can deal with them, and most importantly, modern technologies make it possible to prevent their occurrence and protect the car’s coating from rapid paint fading, scratches and chips. This became possible thanks to premium class services - polymer car coating.