What is patination?

This technique came to us from Italy. People have noticed that changes in brass, copper, and bronze that occur over time give the metal a special appearance. Initially, the patina was not applied, but simply waited for everything to happen naturally. But the result was unpredictable, and too much time could pass. Therefore, they began to use the application of patina using chemicals (acids and various oxidizing agents).

Before and after patination of brass

Today, patination is different in that the substances applied to the metal give the item the necessary shade, but do not oxidize the metal product.

The most common shades for patination:

- Old silver.

- Noble copper (greenish tint).

- Red gold.

There are also more radical colors, for example, a bluish tint, which is successfully used on brass products. Red and lilac colors are also found, but they are used less frequently due to their unusual nature.

In addition to brass, products made of copper, bronze, silver, as well as wooden products can be patinated.

Patination (aging) of brass and copper

I wrote an article based on my own experiences with aging brass.

I hope this information will be useful to someone.

Thanks for the tip Nyura! I wasn’t able to answer you in a personal message. ______________ So: In this article I want to share my own experience in aging brass. Brass is an alloy of copper and zinc, so this method will work for copper wire as well. First of all, let's take care of safety precautions. We will put on rubber gloves, a respirator (I just tied my nose and mouth with a towel and we will carry out all the work outdoors, or at least on the balcony. We will also need a glass jar (which must be thrown away later) and water. First of all, we need a brass or copper product prepare - clean the surface from oxides and grease. This can be easily done using gasoline, white spirit or solvent. We moisten cotton wool or a cotton rag with this substance and rub the product thoroughly. This treatment will remove all traces of grease. This is very important, since the grease film will retain reaction of the patination solution with copper. You can no longer handle the product with your bare hands - fingerprints will definitely remain on it and the patina will lie unevenly. Rinse the treated product with water, put it aside and prepare the solution. Take a liter glass jar, pour about 600 milliliters of water into it, temperature not important, but in hot water the reaction should proceed faster.Pour about two heaped tablespoons of copper oxychloride into the water. This substance is used as a fertilizer and is sold in the appropriate departments of stores under the abbreviated name HOM. A popular and widely used fertilizer. The copper oxychloride solution is opaque and has a very beautiful blue-green color. Let's stir it with something unnecessary. Pour about 100 milliliters of ammonia into the solution. It is sold in pharmacies in convenient 50-milliliter bottles. The solution is ready, it smells terrible, but we didn’t forget to put on a respirator! We immerse our product in it and hold it for about 30 seconds. We take it out and inspect it. If the desired effect is not achieved, repeat the procedure. For a more uniform result, I advise you to stir the solution, or hang the product on a wire and dangle it in the solution.

I wasn’t able to answer you in a personal message. ______________ So: In this article I want to share my own experience in aging brass. Brass is an alloy of copper and zinc, so this method will work for copper wire as well. First of all, let's take care of safety precautions. We will put on rubber gloves, a respirator (I just tied my nose and mouth with a towel and we will carry out all the work outdoors, or at least on the balcony. We will also need a glass jar (which must be thrown away later) and water. First of all, we need a brass or copper product prepare - clean the surface from oxides and grease. This can be easily done using gasoline, white spirit or solvent. We moisten cotton wool or a cotton rag with this substance and rub the product thoroughly. This treatment will remove all traces of grease. This is very important, since the grease film will retain reaction of the patination solution with copper. You can no longer handle the product with your bare hands - fingerprints will definitely remain on it and the patina will lie unevenly. Rinse the treated product with water, put it aside and prepare the solution. Take a liter glass jar, pour about 600 milliliters of water into it, temperature not important, but in hot water the reaction should proceed faster.Pour about two heaped tablespoons of copper oxychloride into the water. This substance is used as a fertilizer and is sold in the appropriate departments of stores under the abbreviated name HOM. A popular and widely used fertilizer. The copper oxychloride solution is opaque and has a very beautiful blue-green color. Let's stir it with something unnecessary. Pour about 100 milliliters of ammonia into the solution. It is sold in pharmacies in convenient 50-milliliter bottles. The solution is ready, it smells terrible, but we didn’t forget to put on a respirator! We immerse our product in it and hold it for about 30 seconds. We take it out and inspect it. If the desired effect is not achieved, repeat the procedure. For a more uniform result, I advise you to stir the solution, or hang the product on a wire and dangle it in the solution.

It is impossible to indicate the exact time - it all depends on the temperature and concentration of the solution, as well as on the amount of copper in the alloy. With the given quantities, within three to five minutes I got what you can see in the photo below. Now all that remains is to rinse the product, dry it and review the results of your chemical experiments.

The patina obtained using copper oxychloride has a very beautiful olive-brown tint. If the product was overexposed in the solution and it became completely black, then it can be returned to its original state with a solution of Trilon B. Just keep in mind that Trilon corrodes zinc faster than copper, so the surface will become a little more porous and susceptible to further coating. Usually the products are polished so that the patina remains only in the recesses of the ornament. Before using Trilon, try polishing the product; most of the patina will be erased. How to polish: the best assistant is the back of a kitchen sponge. This material is also sold in the form of separate napkins. Then you can apply GOI paste and cloth. If you are polishing a product, I recommend opening it with varnish so that the exposed fresh metal on the protruding parts does not turn green over time. Since I work with filigree brass with pliers, I varnish finished products, because during the work the varnish coating will still be damaged. Varnish can't bend, it can crack :-). I use pure polyurethane made in the USA. It creates a very durable, scratch- and wear-resistant coating. Does not turn yellow, does not react with acids and alkalis. Once dry, the varnish is safe even for infants.

The varnish is used for wood, stone and metal. One of these days we plan to conduct an experiment on using this varnish on top of polymer clay.

What will you need for work?

Patination is done using paint that is intended for this purpose. The material is sold in powder, and the master can choose the color to his taste. In addition to paint, you will need:

- Liquid solvent.

- A brush or a pair of sponges.

- Trays or containers for patina (plastic or glass, the main thing is not metal).

- The product being worked on.

It is important to understand that the master will work with chemicals, and therefore compliance with safety rules comes first.

To age brass, it is necessary to work in a room with ventilation and exhaust hood, so as not to be poisoned by fumes of toxic substances. The process itself is carried out wearing gloves and a mask.

If the substance used in the work gets on the skin, you should immediately apply a soda slurry to the area. If redness, burns or other changes occur on the skin, you should immediately consult a doctor.

How to age brass at home? You just need to follow the instructions and observe safety regulations.

Patination of brass at home

Blackening brass at home

You can blacken brass yourself using various means. But you must act carefully, strictly following the instructions, so as not to spoil the metal.

Preparation for the procedure

Most products used to blacken brass are toxic and can be harmful to human health. They must be stored in tightly sealed containers to prevent toxic fumes from evaporating.

Patination must be carried out in a cabinet with ventilation. The cabinet doors must be kept slightly open to ensure effective exhaust of vapors during operation.

Before patination, the product must be prepared. To do this, thoroughly clean the work surface from any dirt. First, rinse in warm water and then treat with a degreaser.

After completing the procedure, the product must be washed again and placed on sawdust. They will absorb remaining moisture without damaging the surface of the material. Using sawdust for drying is considered a more gentle method than using fabric for this. After all, mechanical drying can damage a thin layer of patina. In addition, this method does not completely remove moisture.

Uses of potassium sulfide

This is a common method of blackening brass. During it, you can use potassium sulfide in different states of aggregation - liquid, solid, gel. It must first be diluted with water in a ratio of 1:16. If potassium sulfide is used in a solid state, it must first be crushed to a powder, and only then filled with liquid.

Blackening of brass can be done using potassium sulfide

It is also necessary to prepare a soda solution. Sodium carbonate must also be diluted in a ratio of 1:16. First, place the product in a solution of potassium sulfide. Leave for a while and then place in a soda solution. This is necessary in order to stop the reaction.

Blackening with copper sulfate solution

The use of copper sulfate allows you to create a golden-brown patina on the surface of the processed material. The film will have a moderate gloss. To do this, take 20 g of copper sulfate, 5 g of potassium permanganate (potassium permanganate) and add a liter of water.

The solution should be at room temperature. It must be applied to the surface of the brass product, carefully treating all the cracks. After a day, it must be thoroughly washed under running hot water. Dry in sawdust and then repeat the procedure again. In total, you need to repeat the operation 3-4 times in a row.

When the patination is complete, the surface of the product should be polished with a dry cloth. You can also soak the product in a solution of potassium permanganate for 4-5 minutes. The solution must be heated to a temperature of 95 degrees. It is the use of potassium permanganate that makes it possible to obtain a reddish tint of patina.

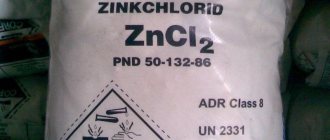

Also, when blackening copper, you can use another composition based on copper sulfate (copper sulfate containing 5 molecules of water). Combine 25% copper sulfate and zinc chloride and 50% water. Place the product to be treated in the resulting solution for several minutes. Then take it out and leave it in the air for a day. After this, rinse thoroughly with hot water.

The use of ammonia

Ammonia is an excellent means for blackening brass and brass products. You can use the combined method, combining several ingredients at once. To blacken brass in this way you must use:

- Copper sulfate. It is greenish-blue crystals. Sold in hardware stores.

- Baking soda. You can also use calcined.

- Ammonia. It is a 10% aqueous solution of ammonia and has a pungent odor. Sold in pharmacies, available without a prescription.

- Water.

Ammonia - a means for blackening brass

Take two containers, pour 50 ml of boiled water into each container at least at room temperature. Add copper sulfate to one container and soda to another. The solution should be saturated, so the substance is added until it stops dissolving in water. The liquid for blackening brass with copper sulfate will need to be filtered.

Pour the copper sulfate solution into the third container and begin adding the soda solution in small portions. A reaction will begin with the formation of a large amount of foam. You can add a new portion of soda solution only after bubbles stop appearing.

Leave the resulting mixture for several hours. There should be some water left on its surface and it should be removed. Then pour the mixture into an old frying pan and cook until the moisture has completely evaporated. The result should be a light green powder. It must be placed in a ceramic mortar and ground with a pestle until a powder forms.

Pour 50 ml of ammonia into the fourth container and pour the resulting powder into it. The result will be a dark turquoise solution. This is where patination is carried out.

Surface preparation

The first point is preparing the surface for work. First of all, we remove the manifestations of corrosion - the patina will not stick to them. Then remove chips, burrs, and potholes. The product is sanded to a smooth surface. To do this, use coarse, then fine sandpaper. After leveling, the master applies a primer. It is better to do this not with a brush, but with a spray can.

To improve the appearance, many craftsmen first paint the product in a dark color, and only then apply a patina. In this case, the paint must dry completely. Most often, black is used as a base. Any shade of patina looks advantageous on it, regardless of the choice of the artist.

Brass color change

Sale of bronze, brass and other things. 8-903-798-09-70

https://bronza555.ru/

Other posts about changing the color of brass and bronze can be found in the tags: Blackening of brass and Patination

Brass.

Brown and black color.

| Water | 1 l |

| Hyposulfite (Na2S2O3) | 60 g |

| Acid (HNO3, HCI, H2SO4) | 5 g |

| Quickly lower it into the solution and take it out after a few seconds. The solution works very quickly; you cannot keep the part in the solution for too long. Good for 20 min. Rub the coating with oil. |

Under gold.

| Water | 1 l |

| Hyposulfite (Na2S2O4) | 200-225 g |

| Lead acetate [lead sugar, Pb(CH3COO)2]) | 20-25 g |

| Lemon acid | 25-30 g |

| The process lasts 2-3 minutes. at 15-25°C. As exposure increases, the color changes from golden to red and then purple. |

Patina paint technique

The patina can be applied with a brush or sponge. Important! The tool used to apply the patina must be dry. Otherwise, streaks and drops will form on the metal, which will ruin the entire appearance. By applying strokes of varying depths and directions, you can achieve an unusual design. Next to the master there should be a bottle of solvent and a small amount of base paint to correct minor errors. When working with a sponge, do not press it tightly against the product so that the pores do not become imprinted.

How to age brass with vinegar

Patination of copper, as well as other methods of its decorative processing (including at home), can make products made from this metal more attractive and give them a touch of noble antiquity. Items made not only from copper, but also from its alloys such as bronze and brass can be subjected to this treatment.

Using various methods of patination of copper alloys, you can achieve completely different shades

Patination and oxidation

The surface of many metals (and copper is one of them), when interacting with the surrounding air and various chemicals, begins to become covered with a thin layer of oxides and oxides.

This process, which also leads to a change in the color of the metal surface, is called oxidation.

For the most part, the process of metal oxidation occurs naturally, but people have learned to cause it artificially, in industrial or home conditions, which is done to give the product an aged look.

Oxidation should not be confused with patination, a process whose essence lies in the fact that a thin layer of sulfur or chloride compounds is formed on the surface of the metal when interacting with various chemical elements. Patination, which, like oxidation, is accompanied by a change in the color of copper and bronze, can also be performed artificially using special compounds.

Copper aging occurs naturally over time or immediately when the surface is treated with any preparations.

If under natural conditions the process of oxidation and patination of copper or bronze can take years, then when using special solutions, patination occurs in a very short period of time.

The surface of a product placed in such a solution literally changes its color before our eyes, acquiring a touch of noble antiquity.

Using various chemical compositions, you can perform such procedures as blackening of copper, patination of objects made of copper and bronze, and blackening of brass in production and even at home.

Preparation for processing

Having decided to perform patination or oxidation, you should not only carefully study the question of how to age brass, bronze or blacken copper, but also provide the necessary safety measures.

The vast majority of chemical compounds that are used to carry out such procedures are very toxic and emit vapors that pose a significant danger to human health.

Therefore, to store such substances both in industrial and at home conditions, you should use vessels with well-ground stoppers, which will prevent toxic vapors from entering the surrounding air.

Keep chemicals out of the reach of children

The procedure itself, carried out to change the color of the surface of a product under the influence of chemicals on it, should be performed in a special cabinet to which exhaust ventilation is connected.

It should be borne in mind that the doors of such a cabinet should be slightly open during the process of oxidation or patination, which will ensure effective extraction of harmful vapors from its interior.

Products made of copper, brass and bronze should be thoroughly cleaned, degreased and washed in warm water before patination. After the patination or oxidation procedure itself, the treated objects are also washed and placed in sawdust to dry.

Using sawdust is a more gentle drying method, since performing such a procedure with a fabric material can damage the thin film of the formed patina, which has not yet been fixed with varnish.

In addition, using fabric after patination, it is almost impossible to efficiently remove moisture from the recesses on relief surfaces, and sawdust can easily be pulled out.

The varnished surface can be polished with a felt pad.

Changes in color of copper and its alloys from gray to black

The grey, dark gray or black color of copper and its alloys makes the appearance of the product more attractive and presentable.

To obtain these colors, the degree of saturation of which can be adjusted, you need the “liver of sulfur” composition that has been used for decades.

It got its name due to the fact that during the cooking process it must sinter, that is, turn into a caked mass.

To make such a composition for patination at home, you must perform the following steps:

- one part of powdered sulfur is mixed with two parts of potash;

- the resulting mixture is placed in a tin can, which then must be put on fire;

- After waiting for the powder to melt and start sintering, it is necessary to maintain this process for 15 minutes.

To prepare sulfur liver you will need soda and sulfur

During the sintering process of the powder, a blue-green flame may flare up on its surface, which does not need to be knocked down, since it will not deteriorate the quality characteristics of the sulfur liver.

After sintering is completed and completely cooled, the resulting mass should be crushed to a powder state.

This powder, if placed in a glass jar with a tight-fitting lid, can be stored for a long time.

In order to patina various metal alloys using liver sulfur, several basic methods are used.

This method involves the use of an aqueous solution of liver sulfur. It can be used to change the color of products made from the following materials:

- copper;

- sterling silver;

- bronze and brass.

The colors that can be used to paint the surfaces of products using this method also vary:

- copper and silver - purple, blue (very difficult to obtain), gray, brown-gray, black;

- brass and bronze – soft golden.

Testing the solution on copper, bronze and brass gives different effects

If you did not know before how to age copper and form a durable patina film on the surface of this metal, distinguished by a rich black color, use this method. To implement it, a copper product is placed in a solution consisting of a liter of water and 1–20 grams of liver sulfur powder.

To color copper light gray, the solution is prepared according to a different recipe: 2-3 grams of sodium chloride and liver sulfur are dissolved in 1 liter of water.

A copper product is placed in the resulting solution, the color change of which should be carefully monitored.

After the color of the metal acquires the desired tone, the object to be patinated must be washed with water and dried in sawdust.

The duration of treatment of copper jewelry with a solution depends on the desired blackening effect

To patina copper, you can also use a solution prepared according to the following recipe: ammonia is added to a saturated aqueous solution of copper sulfate and this is done until the liquid becomes transparent and bright blue. The cleaned and degreased product to be processed is placed in such a solution for several minutes, after which it is removed and subjected to slight heating. After such manipulations, the copper should acquire a rich black color.

To use this method, which also allows you to qualitatively blacken copper even at home, the object being processed must be cleaned with fine sandpaper.

Do not touch the cleaned surface with your hands to prevent grease stains from forming on it. After preliminary preparation for patination, the object is treated with a solution of platinum chloride or completely immersed in it.

A small amount of hydrochloric acid can be added to such a solution, if it does not cause an acidic reaction.

A durable oxide film, distinguished by a rich black color, can be formed on the surface of a copper product by immersing it in a composition prepared from nitric acid and copper metal. To make the color change of the copper part more intense, this solution can be further heated.

Getting a patina of other colors

To form an oxide film of a different color on copper, you can even use one of the following methods at home.

To obtain a red-brown oxide film, the copper product is placed for several minutes in a composition prepared from one part of copper sulfate, one part of zinc chloride and two parts of water.

Using the example of one part, you can see how the shade changes depending on the duration of stay in the solution

To obtain such a patina, a copper object must be placed in a solution consisting of one liter of water and 20 grams of ammonium sulfide. By changing the heating temperature of the processed product before patination, you can adjust the intensity of coloring.

To give the surface of a copper product a light brown color, it is necessary to treat it with a mixture of sodium chromium (124 g/liter), nitric (15.5 g/liter) and hydrochloric (4.65 g/liter) acids, 18% ammonium sulfide ( 3–5 g/liter). This solution is applied with a brush and left for four to five hours.

Cover the surfaces of the part until you achieve the desired shade

To obtain a surface of this color, the copper part is placed in a hot solution for 5–25 minutes (90–95°

), which contains ammonium persulfate (9.25 g/liter) and caustic soda (50 g/liter). The procedure is repeated 2-3 times to achieve the desired effect.

Range from olive to brown

For patination, a copper product is placed for 10–15 minutes in a heated aqueous solution of berthollet salt (50–70 g/l), copper nitrate (40–50 g/l) and ammonium chloride (80–100 g/l).

The most popular method of creating a green patina is to immerse a copper object in a composition prepared from water (1 liter), copper sulfate (50 g) and potassium permanganate (5 g).

There are many more methods that allow you to create a patina of various shades of green, brown-black, golden, golden brown with crimson tarnish and others.

How to clean brass at home

Bronze and brass are primarily used in the production of art products, interior parts and jewelry. Before the invention of steel, these were the most popular types of metal. Over time, such items require cleaning, as they develop a greenish or black coating. You can restore brass to its original appearance at home or in a workshop.

Do-it-yourself cleaning of brass products

A freshly cast bronze object has a characteristic dark yellow color. Over time, it begins to darken, lose its shine and gradually the product becomes black. Plaque occurs as a result of the interaction of a metal surface with water or air.

Before cleaning brass or bronze at home, you should examine the item carefully. It can be all brass or alloy. Some items have a lacquered finish. Taking into account the specific composition, methods and detergents are selected.

Before cleaning, the product must be thoroughly rinsed in a solution of water and a mild washing gel. Immerse the item in a container with this composition for half an hour. Then, using a soft brush or cloth, remove all dirt, greenish deposits and blackness from it.

Only after preliminary light cleansing can you proceed to the main stage of the process.

Cleaning products for brass and bronze products

A product for effectively cleaning bronze and brass can be of plant or mineral origin. Chemical compounds and even food products are used. Not every method is suitable at home.

The product will shine again if you use a brass cleaner containing oxalic acid. You need to smear the object well with it and leave it for a while.

As a result of the reaction to the washing solution, a dark coating forms on the surface - it can be easily washed off with a brush and running water. After washing, the product should be generously sprinkled with soda.

Then rinse again and thoroughly rub until shiny.

Patination or how to age metal

Patination is a technique for “aging” the surface of metal or wood, which is achieved by applying dyes based on various acids. As a result, the products acquire a special charm and the spirit of antiquity.

Before carrying out manipulations, working surfaces are put in order, then treated with a special primer from a spray can, which allows the paint to better adhere to the surface.

Patination of metal requires time and patience; we will look further at how to apply patina paint to the surface and what effect can be achieved.

What you need for work

The very meaning of the word “patina” has nothing to do with the dyeing process. It is of Italian origin and refers to the film that forms on metal after prolonged interaction with oxygen.

Initially, you had to wait a long time for the metal to oxidize itself, and the result was completely unpredictable; now this technique can be reproduced at home with your own hands using the following materials:

- patina of the color you like (in powder);

- liquid solvent;

- brush (size 2-3) or sponge;

- small plastic or glass trays (do not take metal ones, they can interact with the paint);

- metal product that you want to decorate.

Pay attention to safety precautions! Patination products involve working with chemical oxidizing agents, solvents and require special care.

It is recommended not to work in confined spaces without respiratory protection. It is better to work in the fresh air, in rooms with good ventilation (with open windows, an exhaust fan on, a draft). If acid gets on the surface of the skin, immediately rinse under running water and then apply a paste of baking soda. If rashes, burns or any skin changes occur, consult a doctor immediately!

Protect your hands! Always patina with gloves.

Patination colors

On different metal surfaces, completely different color schemes can be achieved by patination. The most common patina color is greenish, which is produced by the oxidation of copper. On other metal surfaces, the resulting shade may be completely different:

- Rich yellow or ocher color on steel surfaces.

- Chocolate brown on brass and bronze items.

- Dark gray on silver items.

The choice of dry patina for metal work is quite varied. Powder is sold in almost every hardware store. Most common colors:

- aged silver;

- natural or oxidized copper;

- red gold.

Brighter radical colors are also available, for example, blue, lilac, red, allowing you to achieve an original effect on the surface of various metals.

Surface preparation

Decorative application of patina requires careful preparation of the surface being treated; the metal must be perfectly smooth. There should be no signs of corrosion on it; it will not allow the surface to be well primed; the top layers will quickly bubble and peel off.

All burrs must be removed, chips and potholes must be filled and sanded with sandpaper (first coarse, then finer).

The prepared product is coated with a special primer (most conveniently, from a spray can), and then metal patina paint is applied to it.

Please note that the patina effect looks best on items painted with dark, especially black paint. The painted product must dry well, otherwise the patina will not adhere well and you will not achieve the desired effect.

Patina paint application technique

There are two ways to age metal: applying patina with a brush or sponge. By placing dissolved paint on the tip of a brush, you can achieve completely different textures, directional strokes and different depths of paint. Do not wet the brush before starting work; it must be dry; a wet brush will cause smudges and drops on the metal being processed.

Do not take a brush that is too large or small - the optimal bristle size is 2-3 cm. The sponge gives a “dusty” effect, but do not press it too hard, otherwise pores will be imprinted on the surface being treated.

Keep a napkin with solvent and some of the base paint with which the product is painted at the ready. Working with the patina should be virtually error-free. Repeatedly applying patina to metal in the same place gives an unsightly “flat” effect. When painting individual elements, be careful: if you accidentally “smeared” something nearby, simply paint over this area with background paint.