The nuances of stripping insulation

When choosing a method for removing the insulating coating, it is necessary to take into account its features. Insulation can be single plastic or multilayer. Resins, fabrics, and non-flammable dielectrics are used as the latter.

The procedure involves the use of sharp instruments. They can damage the wire, damage the insulation where it is not needed, and narrow the cross-section. If you use a tool ineptly, you cannot avoid injury.

To reduce all risks to a minimum, special tools and techniques for working with them have been developed.

How to clean cable insulation: several effective ways

Several methods are used to remove the insulating coating:

- manual stripping;

- burning;

- use of special equipment.

Manual stripping involves using a knife (a regular stationery or construction knife will do) or a hammer. The principle of operation is quite simple: you need to carefully cut the insulation along the core, take it to the side and trim it. This method, which allows you to clean the wire, is a rather labor-intensive process and requires skills and experience. And its use is rational if the volume of scrap metal is small. Otherwise, reflow will be the best alternative.

Firing is a fairly effective method to quickly remove insulation from copper or aluminum wire. However, when working, you should strictly adhere to safety precautions. Reflow must be carried out outdoors or in well-ventilated areas, since toxins are released when the winding is heated. The wire is laid on a horizontal surface and passed along the insulation with a soldering iron. After melting, it can be easily removed using ordinary pliers. It is important to remember that this technique, in addition to the advantages of saving time, also has its disadvantages, namely a negative impact on the environment and human health. In addition, it is not recommended to burn thin-stranded wires, since the metal burns out along with the insulation.

One of the most effective and safest ways to quickly clean cables is to use tools such as a side cutter or stripper. They allow you to significantly speed up work and are suitable for cleaning large quantities of scrap. A side cutter is a special wire cutter for cutting wires. The free end of the cable is clamped between the blades and gently pulled. The cutting edges should be directed strictly in the direction of movement of the tool, which allows you to remove the winding without much effort. If used incorrectly, the lead may break off along with the insulation.

A stripper will help automate and significantly speed up the process. To clean the wire for non-ferrous metal, you need to insert the end of the cable into a special hole, hold the handles of the stripper to cut through the winding, and pull the conductor out, thereby freeing it from the insulation. The advantages of the tool are ease of operation and the ability to clean both thick- and thin-core wires.

To clean large quantities of scrap metal, special equipment is also used, which is rented out by the collection points themselves.

Difference between wire and cable

When describing electrical wiring, the term “wire” or “cable” is often used as a conductor of current. To a person uninitiated in the intricacies of electrics, it may seem that this is one product. In fact, they are different.

A wire in the traditional sense is a cord with a small cross-section. Such a conductor can be single or multi-core. It may not have insulation at all, or if it does, it is light in the form of a tube. Removing it is not difficult at all.

The cable consists of a certain number of current carriers. They are connected into one unit, but do not touch each other and are enclosed in a shell made of a special material.

For a single-core wire, the cross-section is determined by one core; for a multi-core wire, the cross-sectional area is determined by the sum of the cross-sections of all cores. To improve the performance properties of the cable, a nylon thread is introduced into the middle.

Any conductor should be handled with care, especially aluminum conductors. Compared to copper, they are more fragile. Bending loads reduce the already small margin of safety of aluminum cores.

Some characteristics for comparison:

- density of aluminum - 2.7, copper - 8.9 t/mᶾ;

- multi-wire design is excluded for aluminum, but possible for copper;

- resistivity of aluminum is 0.0294, copper - 0.0175 Ohm x mm²/m.

Damage during stripping of aluminum cores further reduces their performance.

You can read more about the types of cables and wires in this material.

Which method of removing insulation from cables is preferable?

The methods listed above for eliminating insulation have stood the test of effectiveness over time and are actively used today. To understand which method is right for you, you need to consider several criteria. First of all, this concerns the batch size. If it is small, then you can clean the wires for non-ferrous metal using a regular knife, side cutter or stripper. If this is not possible, you should use the help of specialists. In addition, if you want to save time, it is also better to entrust the work to professionals.

Selling copper and aluminum wires is a very profitable business, allowing you not only to get rid of unnecessary metal trash, but also to make decent money. SDM LLC accepts scrap cables in Moscow on favorable terms. You can get acquainted with our services and price list in the corresponding section of the site.

| Copper | 550 /545/ 540 rub/kg |

| Bronze | 315 RUR/kg |

| Brass | 315 RUR/kg |

| Stainless steel | 55 RUR/kg |

| Aluminum el.tech/mix | 130 / 92 rub./kg |

| Used dry battery, used gel battery | 60 / 55 rub./kg |

| lead sheath clean/dirty | 110 / 101 rub./kg |

| Used copper cable (output) | 540 rub./kg |

| Used aluminum cable (output) | 125 RUR/kg |

| Used lead cable (output) | 100 rub./kg |

Types of insulating materials

There are single and double insulation.

For its production, various insulating materials are used:

- Plastics based on organic compounds. These are mainly thermal plastics that soften when heated. When burned, these plastics release various toxins into the environment.

- Thermosetting plastics. They become harder when heated. Insulation made from them is used only in special cases when the requirements for it are increased.

- Natural or artificial rubber of different types. It hardens when heated and supports combustion.

- Fabric based insulation. Withstands a fairly high degree of heating (maximum 400⁰) while maintaining insulating properties.

- Shielding braid. This is not insulation in the literal sense, since the braid does not act as insulation, but it provides protection against mechanical damage.

- Armor braid. Also serves as protection against damage

The choice of tools for removing insulation depends on the material from which it is made.

How to strip wires correctly?

There are some nuances in this process, without knowing which you can make mistakes with irreversible consequences.

The stripped area should not protrude beyond the joint. If a bare wire is left exposed, a person may accidentally touch it and suffer an electrical shock.

The insulation from the core must be removed from all sides. Compressing the remaining insulation will reduce the reliability of the fastening.

Improper stripping will result in short circuits and even fire.

How to properly strip wires of insulation

Wire stripping requirements:

- the stripped (bare) part must be completely hidden inside the connection;

- Insulation must be removed from all sides from the surface of the core.

Mistakes made by DIYers:

- DIYers often leave exposed wires exposed. If accidentally touched, a person can short-circuit these places and receive an electric shock;

- If fragments of insulation remain on the cores, then compressing it inside may not be sufficient for reliable fastening. When there is vibration, for example, electrical wiring in a car, the connection will loosen, the wire will come out of the terminals of the device, and a short circuit to ground will occur. The vehicle may catch fire.

Cutting insulation from wires using a knife

The knife is the most common tool, so it is used most often. It is necessary to expose not only individual conductors, but also cables that contain several wires. Therefore, at the first stage, the cable is cut along its length, the wires are routed in different directions, and then the outer sheath is cut across. If necessary, this operation is repeated.

To strip a wire of insulation, you need to set the blade almost parallel to the core, and then cut off a thin layer of insulation. Subsequently, slightly turning the conductor, cut off the remaining thin layers. By turning completely 360°, complete cutting of the coating is achieved. These steps are easy to perform if you need to strip fairly thick wires.

When stripping thin wires with a knife, you only need to cut through the insulation layer.

Attention! You cannot leave a mark from the blade on the surface of the conductor, since this is where the critical zone will appear. If bent, the conductor is susceptible to breaking. After circular cutting to a small depth, it is easy to strip the wires of insulation; it is removed from the surface in the form of a tube

After circular cutting to a shallow depth, it is easy to strip the wires of insulation; it is removed from the surface in the form of a tube.

Thick cable cores for high power supply are cleaned by cutting the plastic across and then along. Then the protective shell can be easily removed.

Popular methods of removing insulation

Practical skills play a big role in the process of stripping wire insulation. The main difficulties arise when working with thin wires, when every movement matters. Optimal pressure can only be achieved through practice.

The most commonly used methods for removing insulation are:

- using a knife;

- through side cutters;

- under the influence of high temperature;

- using a stripper.

Each option is preferable in specific circumstances.

Option No. 1 - using a knife to cut insulation

At home, a knife is most often used. When using this simple tool, it is important to choose the correct angle of the blade. The biggest mistake is cutting in a circle while keeping the cutting part perpendicular. In this case, it is difficult to avoid notching the core or breaking the secondary insulation.

The correct position of the knife is when the tool and the wire axis are in the same plane. First, cut the braid along the conductor. Next, separate the insulation, take it to the side and finally cut it off at the base.

Methods for cleaning copper cable

Conducting conductors are removed from insulation manually, by firing or using special tools. Each method has advantages and disadvantages. If you use a knife and hammer to clean live wires, you are wasting a lot of time and effort. This method is justified when you want to get a high reward for a small batch of recycled materials. buys non-ferrous metal from 1 kg.

Another option for removing insulation from a copper wire is heat treatment. When you bake the insulation, the conductor can become so damaged that the copper becomes unusable. Perform the procedure in a well-ventilated room.

To clean the cable using special tools, you will have to spend money on purchasing them. The purchase is justified when you sell non-ferrous cable scrap on an ongoing basis. If stripping the core is not part of your plans, you can contact MosVtorKabel and hand over the insulated copper cable.

New tools for removing insulation

More recently, four new products have been added to the range of insulation removal tools:

- plow knife for removing hard insulation;

- stripper for cutting insulation 2.9 – 6.6 mm² in the longitudinal direction;

- tool for working with wire insulation 0.05 – 2.5 mm²;

- tool for cutting wire insulation 0.25 – 6 mm².

All of them are produced by the US company Jonard Tools.

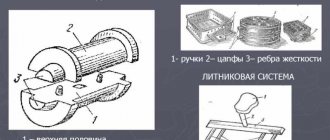

The new case-type stripper is equipped with five grooves with a diameter of 2.9 - 6.8 mm. There are blades on both the top and bottom. Cuts lengthwise wires, optical modules, protective tubes.

The stripper for removing the PVC insulating layer from cables with a diameter of 0.05 - 2.5 mm² is automatically adjusted to the required cross-section. When pressure is applied to the handle, the conductor is grabbed, the blades enter the insulation and tighten it.

The latest model is similar to the previous one, but works with wires of other sections.

Why clean the cable before scrapping?

Insulation made from paper, PVC and plastic is considered an additional blockage, so contractors try to get rid of it. Buyers value pure non-ferrous metal much more highly.

Reasons for stripping cable insulation:

- extraction of clean raw materials with a minimum percentage of clogging;

- obtaining a high income for the delivery of cable scrap;

- saving time and resources for processing secondary raw materials;

- quick weighing and evaluation of retail or wholesale lots.

Insulation is not an obstacle to scrapping wires. But by buying a batch of cables without it, he makes a better offer. Preference is given to cleaned wires without traces of firing. Deliverers try to clean the cable before delivery for financial reasons.

buys wires with insulation residues, traces of firing and in perfect condition. Offers free removal of batches of 5 tons or more. Buys scrap in Moscow every day until 21:00.

Advantages :

- quick acceptance of cable scrap;

- purchase of wires with and without insulation;

- instant payment of money;

- accurate batch weighing;

- fast and fair assessment;

- two scrap purchase points in Moscow;

- 12 hour work day.

Company managers know how much cleaned cable scrap costs today. They provide free consultation over the phone. They accept applications for the reception and removal of cable scrap in Moscow.

Recommendations for quick removal of insulation

There are non-standard situations from which it is difficult even for a specialist to get out. In this case, you have to make creative decisions and use the tools at hand. Let's look at a couple of examples.

Example No. 1 - damage to the wires leading to the plug

The method is used if, upon visual inspection, it is discovered that the charger has faulty thin wires leading to the plug. The main difficulty of the situation is not only the small cross-section, but also the multi-core cable. Another problematic point is that the wires are enclosed in a continuous braid, so the insulation serves not just as protection, but as a two or three-chamber collector.

To quickly remove the insulation in this case, experts use a thin blade taken from a razor cassette. The cable is secured using a clamp from a table lamp or a vice. The cable is divided into cores, and a blade is used to carefully make an incision in the right place, not too deep. Next, part of the layer is pryed off with a fingernail and carefully removed.

Example No. 2 - removing protection from a cable in a busy area

There is a need to remove cable protection in a loaded area of electrical networks.

First, using a tool, the outer sheath is removed by cutting it along the cable. Then, using pliers, the cores are removed one by one. The remaining insulating layer is simply cut off.

How to strip a wire while maintaining its properties

Let's start with simple methods.

Knife

A universal tool is used: a regular pen or office tool.

Improving the use of knives, many electricians make homemade devices for stripping insulation. For example, you can use a safety razor blade by simply screwing it to a clothespin.

Using holes of different diameters (on a clothespin), you get a universal tool for removing both the outer sheath and the coating directly on the conductors.

The simplest factory-made insulation stripping pliers work on this principle. The outer sheath is removed using calibrated holes, and conductors of small diameter are stripped using a blade with a molded hole.

Thermal method

If the question arises: how to quickly remove insulation from a wire, all means are good. Many craftsmen simply burn the ends of the conductors with a lighter or match. The method is not the best: Firstly, the cable may catch fire. Secondly, the remaining part of the shell loses its properties at a distance of 1–2 cm from the cleaned area. And finally, the conductor itself (copper or aluminum) is destroyed by such thermal effects.

If you need to quickly strip the wire, but there are no cutting tools, you can use a soldering iron. The tip of the conductor is burned with a hot tip, after which the insulation is easily removed.

There are thermal tools of industrial design.

Stripping the wires of insulation is carried out as follows: the heating elements are pressed to the cut point, the sheath is melted with a short pulse, the conductor remains untouched. Such devices can be stand-alone or part of soldering stations.

Advantage of wire thermocouples:

- Heating occurs pointwise; the copper or aluminum core does not change its properties.

- A thin melt line does not lead to waste of material.

- A sealed ring is formed around the shell, preventing the penetration of moisture.

The only limitation is the insulation material. Thermal stripping is used only in cables with polyvinyl chloride insulation. The fluoroplastic or rubber shell can only be removed mechanically.

Mechanical devices for stripping industrial wires

The most popular electrician tool is the “Insulation Stripping Complex”, known by the abbreviation KSI.

The operating principle is as follows:

During the initial compression of the pliers, the conductor is clamped between the grooved jaws (as in pliers), the other end is captured by the knife mechanism. The cutting attachment is spring-loaded and does not cut through the shell to the metal. This way the current-carrying core is guaranteed to be preserved. Next, the working levers are separated, and the notched sheath is removed from the wire.

The length of the area to be stripped is set using a limiter, against which the front wire rests when inserted into the tool.

There are certain restrictions: the tip cannot be too long. If you need to clean a long area, the process is repeated several times. In this case, the wire does not rest against the limiter, and the shifted section of the sheath is removed manually.

The complex copes well with both mono conductors and multi-core cores. There are restrictions on the diameter of the wire: a cable with a cross-section of more than 4.0 is almost impossible to process.

The next tool is simpler. End pliers for stripping insulation.

Designed for a diameter of up to 6.0 squares; it is difficult to expose a thicker wire manually. Between the cutting tips there is a screw stop, with which the diameter of the conductor is set. The distance between the grips is chosen to be slightly larger than the diameter of the current-carrying conductor. This is done to reduce the risk of damaging the metal. After squeezing the handles, the sheath is removed with a sharp movement along the wire. Working with such a device is not as convenient as with a CSI, but this is justified by its low cost.

Nippers, or the cutting sector of pliers, work in a similar way. Only stripping the wire with their help requires some skill.

The following device is designed to work with large diameter cables. This is a complex knife with a grip.

It can be used to strip wires of any length. First, a transverse incision is made, then a longitudinal one.

After which the sheath is easily removed without damaging the central conductor.

Stripping varnish-coated conductors

Such a conductor is used in transformer windings. Instead of a dielectric sheath, a thin varnish coating is applied to the copper core. The conductor is cleaned with a knife or sandpaper.

Tips for Safely Stripping Insulation

Electrical work is not easy. Therefore, even if you have certain knowledge, you must not forget that the damaged core will eventually fail.

For safety reasons, when removing insulation that is slightly longer than required, the excess must be cut off. Exposed veins are too dangerous.

It is not advisable for a home handyman to purchase expensive tools in order to use them several times while removing insulation. In most cases, simple means at hand are quite suitable.

When working with a tool, you need to be extremely careful and attentive. The insulation should be pressed down slowly to avoid damage to the cores.

Microscopic damage to the conductors is invisible, so it is better to do everything slowly, but correctly, so as not to have big problems later.

To ensure reliable and safe contact, you need to use special terminal blocks.

Contact when installing a piercing clamp will ensure the insulation is pierced. Sometimes that's enough.

Why cutting cables and wires is beneficial

If we approach this issue from a commercial point of view, then extracting metal from waste wire products can become a source of additional income. The average price at collection points for non-ferrous scrap metal per 1 kg is:

- copper – 400 rub.;

- brass – 240 rub.;

- lead - 100 rubles;

- aluminum – 110 rub.

Important! It is unprofitable to recycle cables and wires because processing enterprises incur the costs of removing the insulating coating from wire products to recover the metal. Therefore, delivery may cost more than the profit from delivering the insulated cable.

The metal of wires and cables contains a minimum of impurities, so it is valued much higher than any other type of scrap. With a skillful approach, you can quickly strip flexible electrical conductors in your home workshop. To do this, you will need special equipment - a cable cutting machine (stripper).

Conclusions and useful video on the topic

An overview of stripping tools - from the cheapest to the most expensive:

Whatever method you use to strip the insulation, you must remember that this work is dangerous. A careful and competent attitude to the tool used will help you avoid problems. Each product must be used in accordance with its intended purpose, with the utmost care.

What method do you use to strip insulation from wires? Please share your own experience with people who are faced with this task for the first time. Leave your comments, share your experience, ask questions in the block below the article.

Source

Removing insulation with pliers

Both regular pliers and side cutters are suitable here. This method is suitable for stripping the insulation of small cross-section wires.

We clamp the wire with the sharp edges of the pliers (1), but not too tightly so as not to crush the veins. Then we hold the wire with one hand (2), and with the other we pull the pliers - the insulation breaks and is removed.

Working with pliers or side cutters requires some skill, since when removing the insulation there is a chance of crushing or completely tearing off the core. To repair extension cords or other flexible cables, pliers are suitable, but to work with thick monocores you will have to use other devices.