- a brittle transition metal of a bluish-white color (tarnishes in air, becoming covered with a thin layer of zinc oxide). Essential (irreplaceable) microelement of human tissues. In terms of quantitative ratio in the body, it ranks second, after iron, in place. It plays a key role in the regeneration of damaged tissues, since without zinc the synthesis of nucleic acids and proteins is disrupted.

- Structure

- Properties

- Reserves and production

- Origin

- Application

- Classification

- Physical properties

- Optical properties

- Crystallographic properties

See also:

Ice

— structure and physical properties

PROPERTIES

At room temperature it is fragile; when the plate is bent, a cracking sound is heard from the friction of the crystallites (usually stronger than the “cry of tin”). Has a low melting point. The volume of metal during melting increases in accordance with the decrease in density. With increasing temperature, the kinetic viscosity and electrical conductivity of zinc decrease and its electrical resistivity increases. At 100-150 °C zinc is plastic. Impurities, even minor ones, dramatically increase the fragility of zinc. Is diamagnetic.

Hydrometallurgical methods for obtaining zinc

Currently, much attention is paid to a more complete use of the components of zinc-containing raw materials, the introduction of dump-free technology, and the production of high-grade zinc. To solve these problems in the production of zinc, a hydrometallurgical method is used for processing zinc concentrates according to a technological scheme.

The hydrometallurgical method is based on the leaching of zinc oxide with dilute sulfuric acid from a pre-burnt concentrate (cinder):

ZnO + H2SO4 = ZnSO4 + H2O

Zinc is separated from solution by electrolytic reduction at the cathode. At this time, sulfuric acid is regenerated at the anode, which makes it possible to use the spent electrolyte as a solvent when leaching cinder.

Since many accompanying impurity elements (copper, cadmium, nickel, cobalt and others) pass into the solution during leaching, the solution is thoroughly cleaned before electrolysis. The purer the solution supplied for electrolysis, the higher quality commercial zinc is obtained.

During electrolysis the following reaction occurs:

ZnSO4 + H2O = Zn + H2SO4 + 0.5O2

Despite the multi-stage nature, the hydrometallurgical method has many advantages: high complexity of the use of raw materials, production of high-grade zinc that does not require refining, high overall recovery of zinc and other valuable components into the corresponding products, elimination or significant reduction in coke consumption. In world practice, up to 85% of zinc-containing raw materials are currently processed using this method.

RESERVES AND PRODUCTION

The average zinc content in the earth's crust is 8.3·10-3%; in basic igneous rocks it is slightly higher (1.3·10-2%) than in acidic rocks (6·10-3%). Zinc is an energetic aquatic migrant; its migration in thermal waters along with lead is especially typical. Zinc sulfides, which are of industrial importance, precipitate from these waters. Zinc also migrates vigorously in surface and underground waters; the main precipitant for it is hydrogen sulfide; sorption by clays and other processes play a lesser role.

Zinc deposits are known in Iran, Australia, Bolivia, and Kazakhstan. In Russia, the largest producer of lead-zinc concentrates is JSC MMC Dalpolimetal

Zinc is extracted from polymetallic ores containing 1-4% Zn in the form of sulfide, as well as Cu, Pb, Ag, Au, Cd, Bi. Ores are enriched by selective flotation, obtaining zinc concentrates (50-60% Zn) and at the same time lead, copper, and sometimes also pyrite concentrates. The main method of obtaining zinc is electrolytic (hydrometallurgical). Calcined concentrates are treated with sulfuric acid; the resulting sulfate solution is cleaned of impurities (by precipitating them with zinc dust) and subjected to electrolysis in baths tightly lined inside with lead or vinyl plastic. Zinc is deposited on aluminum cathodes, from which it is removed (stripped off) daily and melted in induction furnaces.

Zinc: production

The main raw material for zinc mining is polymetallic ore containing Zn sulfide in an amount of 1-4%. Subsequently, this raw material is enriched by selective flotation, which makes it possible to obtain zinc concentrate (up to 50-60% Zn). It is placed in a furnace, converting the sulfide into ZnO oxide. Then the distillation (pyrometallurgical) method for obtaining pure Zn is usually used: the concentrate is fired and sintered to a state of granularity and gas permeability, after which it is reduced with coke or coal at a temperature of 1200-1300°C. A simple formula shows how to obtain zinc from zinc oxide:

ZnO+С=Zn+CO

This method allows you to achieve 98.7 percent purity of the metal. If a purity of 99.995% is required, a technologically more complex purification of the concentrate by rectification is used.

ORIGIN

Zinc does not occur in nature as a native metal. There are 66 known zinc minerals, in particular zincite, sphalerite, willemite, calamine, smithsonite, and franklinite. The most common mineral is sphalerite, or zinc blende. The main component of the mineral is zinc sulfide ZnS, and various impurities give this substance all kinds of colors. Due to the difficulty of identifying this mineral, it is called blende (ancient Greek σφαλερός - deceptive). Zinc blende is considered the primary mineral from which other minerals of element No. 30 were formed: smithsonite ZnCO3, zincite ZnO, calamine 2ZnO · SiO2 · H2O. In Altai you can often find striped “chipmunk” ore - a mixture of zinc blende and brown spar. From a distance, a piece of such ore really looks like a hidden striped animal.

Chemical properties

The external electronic configuration of one zinc atom can be written as 3 d 104 s 2. The metal is active and is an energetic reducing agent. At a temperature of 100 C, it becomes covered in open air with a film consisting of basic carbonates and becomes very dull. When exposed to carbon dioxide and high humidity, the element begins to deteriorate. In an oxygen or normal environment, when exposed to high heat, zinc burns, producing a bluish flame and white smoke, which consists of zinc oxide. The dry elements of fluorine, bromine and chlorine have a flammable effect on zinc, but only with the participation of water vapor.

When a metal and strong mineral acids combine, the former dissolves, especially if the mixture is heated, resulting in the formation of the corresponding salts. Alkalis, melts and solutions oxidize the substance, resulting in the formation of zincites, soluble in water, and hydrogen is released. The intensity of the effects of acids and alkalis depends on the presence of impurities in zinc. The more “clean” the metal, the weaker it interacts due to hydrogen overvoltage.

APPLICATION

Pure zinc metal is used to recover precious metals mined by underground leaching (gold, silver). In addition, zinc is used to extract silver, gold (and other metals) from crude lead in the form of zinc-silver-gold intermetallic compounds (so-called “silver foam”), which are then processed by conventional refining methods.

It is used to protect steel from corrosion (galvanization of surfaces not subject to mechanical stress, or metallization - for bridges, tanks, metal structures).

Zinc is used as a material for the negative electrode in chemical power sources, that is, in batteries and accumulators.

Zinc plates are widely used in printing, in particular, for printing illustrations in large-circulation publications. For this purpose, zincography has been used since the 19th century - making cliches on a zinc plate by etching the design in it with acid. Impurities, with the exception of a small amount of lead, impair the etching process. Before etching, the zinc plate is annealed and rolled in a heated state.

Zinc is added to many hard solders to reduce their melting point.

Zinc oxide is widely used in medicine as an antiseptic and anti-inflammatory agent. Zinc oxide is also used to produce paint - zinc white.

Zinc is an important component of brass. Zinc alloys with aluminum and magnesium (ZAM, ZAMAK), due to their relatively high mechanical and very high casting qualities, are very widely used in mechanical engineering for precision casting. In particular, in the arms industry, pistol bolts are sometimes cast from the ZAMAK (-3, −5) alloy, especially those designed for the use of weak or traumatic cartridges. Also, all kinds of technical accessories are cast from zinc alloys, such as car handles, carburetor bodies, scale models and all kinds of miniatures, as well as any other products that require precise casting with acceptable strength.

Zinc chloride is an important flux for metal soldering and a component in fiber production.

Zinc telluride, selenide, phosphide, and sulfide are widely used semiconductors. Zinc sulfide is an integral part of many phosphors. Zinc phosphide is used as a rodent poison.

Zinc selenide is used to make optical glasses with very low absorption coefficients in the mid-infrared region, such as in carbon dioxide lasers.

Zinc - Zn

| Molecular weight | 65.39 g/mol |

| origin of name | The word "zinc" first appears in the writings of Paracelsus, who called this metal the word "zincum" or "zinken" in the book Liber Mineralium II |

| IMA status | valid, first described before 1959 (before IMA) |

Metal properties

Our fragile hero is a bluish-white transition metal. In air it quickly oxidizes and darkens from an oxide film.

In the periodic table, this chemical element is in group 12 (according to the old classification, in group II of the fourth period).

Features of Zinc:

- atomic number 30;

- atomic mass 65.38 g/mol;

- metallic shine;

- opacity;

- density 7.14 g/cm3;

- The crystal lattice structure is hexagonal.

The chemical properties of zinc are determined by its “temperament”. It is far from alkaline earth metals, but it readily reacts. In reactions it exhibits oxidation states 0; +2.

- Zinc is a good reducing agent and active metal.

- Our hero readily reacts with dilute nitric acid and concentrated sulfuric and nitric acids.

- With halogens in the presence of water vapor may ignite.

- Forms hydrocomplexes with alkali solutions.

- At red heat temperatures (550-600°C) it reacts with water and hydrogen sulfide. The reaction releases hydrogen.

We recommend: Green gems: TOP-18

Interaction with metals occurs in a molten state, but this has little to do with chemical reactions.

| Properties of the atom | |

| Name, symbol, number | Zinc / Zincum (Zn), 30 |

| Atomic mass (molar mass) | 65.38(2)[1] a. e.m. (g/mol) |

| Electronic configuration | [Ar] 3d10 4s2 |

| Atomic radius | 138 pm |

| Chemical properties | |

| Covalent radius | 125 pm |

| Ion radius | (+2e) 74 pm |

| Electronegativity | 1.65 (Pauling scale) |

| Electrode potential | -0.76 V |

| Oxidation states | 0; +2 |

| Ionization energy (first electron) | 905.8(9.39) kJ/mol (eV) |

| Thermodynamic properties of a simple substance | |

| Density (at normal conditions) | 7.133 g/cm³ |

| Melting temperature | 419.6 °C |

| Boiling temperature | 906.2 °C |

| Ud. heat of fusion | 7.28 kJ/mol |

| Ud. heat of vaporization | 114.8 kJ/mol |

| Molar heat capacity | 25.4[2] J/(K mol) |

| Molar volume | 9.2 cm³/mol |

| Crystal lattice of a simple substance | |

| Lattice structure | hexagonal |

| Lattice parameters | a=2.6648 c=4.9468 Å |

| c/a ratio | 1,856 |

| Debye temperature | 234K |

| Other characteristics | |

| Thermal conductivity | (300 K) 116 W/(m K) |

| CAS number | 7440-66-6 |

Physical properties of zinc:

- The melting and boiling points are 427 and 907 ºС, respectively.

- Heating to 100-150 degrees makes it possible to roll and stretch metal; The more impurities in a metal, the more brittle it becomes.

- If you want to hear a “tin scream”, bend and unbend a bar or metal plate. True, it doesn’t sound much like a scream, more like a crackling or creaking sound. But for a simple trick at a party it will do.

In nature, a metal consists of five isotopes:

- Zn64;

- Zn66;

- Zn67;

- Zn68;

- Zn70.

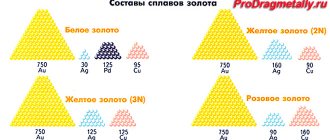

A mixture of metals is an alloy

Alloys for industrial use contain Zn-Al and Zn-Al-Cu. Magnesium is almost always added to the composition (no more than 0.1%). Zinc alloys are divided into antifriction and casting.

- Brands of antifriction alloys: TsAM9-1.5; TsAM10-5.

- Foundry grades: TsA4, TsA4M1, TsA30M5.

PHYSICAL PROPERTIES

| Mineral color | white metal |

| Stroke color | white and slightly grayish |

| Transparency | opaque |

| Shine | metal |

| Cleavage | very perfect for 0001 |

| Hardness (Mohs scale) | 2 |

| Strength | fragile |

| Kink | jagged |

| Density (measured) | 6.9 – 7.2 g/cm3 |

| Radioactivity (GRapi) | 0 |

| Magnetism | diamagnetic |