GOST 8568-77 is the main state standard that regulates the production of steel sheets with rhombic and lenticular corrugation made by hot deformation. This standard applies to both regular and stainless steel, so if you are interested in stainless steel sheets, this standard will be useful to you.

After reading this regulatory document, you will have an idea of the product range, technical requirements, acceptance rules, and testing methods for this type of rolled metal. This can help you in choosing quality products to buy.

Assortment

The first thing that interests the buyer is the size. GOST 8568-77 contains a range of sheets with rhombic and lentil corrugation. The following sizes are available for production: thickness from 2.5 to 12 mm , width from 600 to 2200 mm , length from 1400 to 8000 mm with gradation of 50 mm. However, it is also possible to manufacture products of other sizes.

A corrugated sheet differs from a regular sheet by the presence of special protrusions on the surface. These protrusions have their own technological purpose and it is because of them that consumers purchase this type of rolled metal. However, some may not know how to tell the difference between diamond and lenticular fluting.

In practice it is very simple: just look at the pattern of the textured surface .

- With rhombic corrugation, convex lines are clearly visible on the surface, which, intersecting, form diamond-shaped niches. These convex lines have clear boundaries and are continuous throughout the entire length.

- In the case of lentil corrugation, protrusions are located in a certain way on the surface of the sheet. They resemble small slides and are located at right angles to each other. These projections are short and flatter.

The most popular among buyers are sheets with lentil corrugation. They have a more pleasant appearance and therefore can be used for more tasks.

When purchasing, it is important to take into account that the corrugation is applied to the surface on only one side!

The standard regulates the following parameters for each sheet size: thickness, width, weight of one square meter and size deviations. Parameters such as the width of the base of the grooves, the angle at the top of the grooves, the length of the grooves, the radius of their curvature, and their location on the plane are indicated in the standard, but are not controlled . They are given as a reference material for making tools.

In terms of manufacturing accuracy, two manufacturing options are available: high (letter A in the marking) and normal precision (letter B in the marking). The difference between them is the size of the permissible deviations. For high-precision products, they are significantly lower than for normal-precision products. Therefore, if such a parameter as accuracy is important for your project, it is recommended to purchase category A products.

You can see the list of acceptable sizes and their corresponding maximum deviations in the table below.

When measuring thickness, it is important to know that the thickness is considered to be the base of the sheet without taking into account the height of the corrugation.

If the product is manufactured in sheet rolling mills, its base may be thickened in the middle part. This thickening should be no more than +0.2 mm plus maximum deviation.

The mass of one square meter is calculated with a ribbed height equal to 0.2 thickness, a small diamond diagonal equal to 27.5 mm, a large diamond diagonal equal to 65 mm, and a steel density of 7.85 g/cm3.

It is important to know that corrugated steel with one-sided corrugation is also produced in the form of rolls.

GOST 8568-77

This standard applies to hot-rolled steel sheets with one-sided rhombic and lenticular corrugation for general purposes.

ASSORTMENT

1.1a. Rolled sheets by thickness are produced:

- high accuracy - A,

- normal accuracy - V.

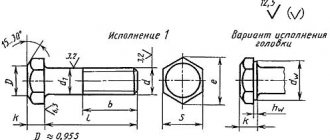

1.1. The shape, dimensions, maximum deviations and weight of 1 m2 of sheet with rhombic and lenticular corrugation must correspond to those indicated in the drawing. 1, 2 and in the table.

Picture 1

Figure 2

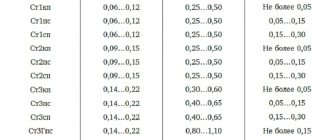

TABLE 1

Notes:

1. The thickness of sheets with one-sided rhombic and lentil corrugation is determined by the thickness of the base of the sheet s in millimeters.

2 For sheets rolled in sheet rolling mills, in the middle part of the sheet width, a base thickness of 0.2 mm above the plus limit deviation is allowed.

3. The width of the base of the grooves b, the angle at the top of the grooves j, the diagonals of the rhombus t1 + t2, the angle of location of the grooves on the plane of the sheet j1, the distance between the grooves t, the length of the grooves l, the radius of curvature of the grooves R on finished sheets are not controlled and are given for calculations when tool making.

4. The weight of 1 m2 of sheet is determined by the nominal dimensions of the sheets, the height of the corrugations equal to 0.2 sheet thickness, the small diagonal of the rhombus equal to 27.5 mm, the larger diagonal of the rhombus equal to 65 mm. Steel density 7.85 g/cm3.

1.2. Corrugated steel is produced in sheets and rolls with one-sided rhombic or lenticular corrugation.

1.3. The height of the corrugations on the sheets should be 0.2-0.3 of the thickness of the base of the sheet, but not less than 0.5 mm. At the consumer's request, sheets with a base thickness of 5 mm or more must have a ribbed height of at least 1.0 mm.

1.4. Sheets with rhombic corrugation are made with diamond diagonals (25-30) C (60-70) mm. The configuration of the corrugations and the location of the large diagonals of the diamond along or across the sheet are set by the manufacturer.

At the request of the consumer, it is allowed to produce a sheet with a different ratio of the diagonals of the rhombus.

1.5. Lentil corrugated sheets are manufactured with a distance between corrugations of 20, 25 and 30 mm.

1.6. Sheets are manufactured in widths from 600 to 2200 mm and lengths from 1400 to 8000 mm with a gradation of 50 mm.

1.7. At the request of the consumer, it is possible to produce sheets of other sizes.

1.8. Sheets are produced according to sizes:

- indicating dimensions for thickness in accordance with the dimensions indicated in the table, and for width and length within the limits specified in clause 1.6 - form I;

- with indication of thickness dimensions within the limits specified in the table, without indication of width and length dimensions - form II;

- indicating dimensions that are multiples in width and length of the dimensions specified by the consumer within the limits established in clause 1.6 - form III;

- indicating the measured dimensions within the limits specified in clause 1.6 - form IV.

1.9. Maximum deviations in the length and width of sheets are in accordance with GOST 19903-74.

At the request of the consumer, sheets and rolls are manufactured with maximum deviations:

- +20 mm - in width for rolled products over 1000 mm with uncut edges;

- +15 mm - in length for sheets over 2000 to 6000 mm and over with a thickness of 4.0 and 5.0 mm;

- +25 mm - with a thickness of 6.0; 8.0; 10.0 and 12.0 mm.

- 1.10. Deviations from flatness - according to GOST 19903-74 for normal and improved flatness.

- 1.11. (Deleted)

- 1.12. Requirements for steel produced in rolls, as well as the width of the rolls, are in accordance with GOST 19903-74.

Examples of symbols

Hot rolled sheet of steel grade St3sp according to GOST 380-88 with one-sided rhombic corrugation, size 3.0C1000C2000 mm, normal thickness accuracy, improved flatness with rolled edge:

Rhombus sheet V-K-PU-3.0C1000C2000 St3sp GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil leaf V-K-PU-3.0C1000C2000 St3sp GOST 8568-77

Hot-rolled steel grade St3sp according to GOST 380-88 with one-sided rhombic corrugation, size 3.0C1000 mm, high precision, with rolled edge:

Roll rhombus A-K-3.0C1000 St3sp GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil roll A-K-3.0C1000 St3sp GOST 8568-77

TECHNICAL REQUIREMENTS

2.1. Sheets and rolls are manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Sheets and rolls are made from carbon steel of ordinary quality, grades St0, St1, St2 and St3 (boiling, calm and semi-quiet) with a chemical composition in accordance with GOST 380-88.

By agreement between the manufacturer and the consumer, it is allowed to produce rolled sheets without rationing the content of chromium, nickel, and copper.

2.3. At the request of the consumer, it is possible to produce sheets from rolled products of other brands.

2.4. Sheets rolled on sheet rolling mills are cut on four sides.

2.5. Sheets and coils rolled on a continuous rolling mill may be supplied with rolled longitudinal edges.

The notches on the edges should not extend the sheet beyond the nominal dimensions in width.

2.6. The surface of the sheets should be free of rolled and ingot films, indentations, scale shells, rolled bubbles, cracks and dirt. There should be no delamination on the edges of the sheets.

2.7. Ripples, scale, rust, prints, and individual films are allowed on the surface of the sheets, the depth of which does not exceed the maximum deviations in thickness.

ACCEPTANCE RULES

3.1. Sheets and rolls are accepted in batches. The batch consists of sheets of one type of corrugation. Determination of the batch according to GOST 14637-79.

3.2. To control the size and quality of the surface, two sheets or one roll are selected from the batch.

3.3. If unsatisfactory control results are obtained for at least one of the indicators, repeated control is carried out on a sample selected in accordance with GOST 7566-81.

TEST METHODS

4.1. Surface inspection is carried out without the use of magnifying devices.

4.2. The thickness of the base of the sheets and the height of the corrugations are measured at a distance of at least 100 mm from the corners and 40 mm from the edges.

The dimensions at any measured point should not take the sheet thickness beyond the maximum deviations.

4.3. The height of the corrugations h is determined as the difference between the dimensions of the total thickness of the sheet s + h and the thickness of the base of the sheet s.

LABELING, PACKAGING, TRANSPORTATION AND STORAGE

5.1. Labeling, packaging, transportation and storage - in accordance with GOST 7566-81.

Corrugation sizes

As for the height of the riffles, the standard states that it should be in the range of 0.1 - 0.3 thickness , but not less than 0.5 mm. If the consumer requires thick sheets (5 mm or more), then it is allowed to increase the minimum height of the corrugations to 1 mm, but only by agreement.

For sheets with rhombic corrugation, the diagonals of the rhombus can have a length of (25 - 30) x (60 - 70) mm, however, it is possible to produce corrugations with other dimensions upon agreement. The location of large diagonals along or across the sheet is set by the manufacturer.

For sheets with lentil corrugations, the distance between the corrugations can be 20, 25 or 30 mm.

TECHNICAL REQUIREMENTS

2.1. Sheets and rolls are manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Sheets and rolls are made from carbon steel of ordinary quality, grades St0, St1, St2 and StZ (boiling, calm and semi-quiet) with a chemical composition in accordance with GOST 380. By agreement between the manufacturer and the consumer, it is allowed to produce rolled sheets without rationing the content of chromium, nickel, and copper.

2.1, 2.2. (Changed edition, Amendment No. 4).

2.3. At the request of the consumer, it is possible to produce sheets from steel of other grades. (Changed edition, Amendment No. 3).

2.4. Sheets rolled on sheet rolling mills are cut on four sides.

2.5. Sheets and coils rolled on a continuous rolling mill may be supplied with rolled longitudinal edges. The notches on the edges should not extend the sheet beyond the nominal dimensions in width.

2.4, 2.5. (Changed edition, Amendment No. 1).

2.6. The surface of the sheets should be free of rolled and ingot films, indentations, scale shells, rolled bubbles, cracks and dirt. There should be no delamination on the edges of the sheets.

2.7. Ripples, scale, rust, prints, and individual films are allowed on the surface of the sheets, the depth of which does not exceed the maximum deviations in thickness.

Legend

Looking at the symbol, at first it is difficult to make out what all these letters and numbers mean. However, it is not as difficult as it seems at first glance.

- The first step is to mark the product. The type of product is indicated: sheet or roll and type of corrugation.

- Next comes an indication of the manufacturing accuracy: A – high precision, B – normal.

- After this, the edge type is indicated. K - rolled.

- Then come the dimensions: thickness x width x length (or thickness x width in the case of a roll)

- At the very end the steel grade and GOST are indicated.

Features and types of material

The shape of the grooves themselves and their specific location influence the type of production of these products. The industry produces several varieties of such rolled metal:

- Rhombic sheet GOST 8568–77 with applied corrugation. It is distinguished by the diagonals of the rhombus, which are arranged in a certain sequence. They are divided into several types: large, with dimensions of 60−70 mm; standard - 25−30 mm.

- Lentil steel sheet GOST 8568–77. The product is distinguished by its grooves, made in the form of an oval, very similar to plant grains. The riffles are inclined 90 degrees in relation to each subsequent oval. The angle of inclination is 45 degrees relative to each surface of the corrugated sheet GOST 8568–77. Adjacent riffles are separated by a distance of 20–30 mm.

- The industry also produces other types of corrugated products. These include, for example, a quintet. But this type of corrugation has not become widespread.

Each corrugated sheet has a specific purpose.

Therefore, it is manufactured according to certain technical parameters. These include the length:

- Measured;

- Unmeasured;

- Multiple of measured;

- Measured, having a remainder equal to 10% of the entire batch.

The accuracy of manufacturing corrugated steel GOST 8568–77 is also affected by the thickness of the sheet. Rolled metal with corrugations can be of several types:

- High accuracy - A;

- Normal - V.

Acceptance and Testing

After the production process is completed, it is time to accept the batches. The batch must contain rental of one type of corrugation. That is, there cannot be a single lentil sheet in a batch of diamond sheets. The definition of a batch must be taken from GOST 14637 .

To take the necessary measurements, one roll or two sheets are taken from the batch. If during the quality determination process at least one unsatisfactory result is obtained, a second stage of testing is carried out. For this stage, sampling is carried out according to GOST 7566.

Measurements to determine the thickness of the base and the height of the corrugations are made at a distance of at least 100 mm from the corners and 40 mm from the edges.

The height of the corrugations is determined by subtracting the thickness of the base of the sheet from the total thickness.

General points

Steel sheets with different types of corrugation are produced by hot rolling. First, the workpiece is heated to high temperatures, then passed through heavy rollers on which a special pattern is applied. Subsequently, it creates a corrugation, which remains on one side of the rolled metal. The height of the riffle should be no higher than half a millimeter. In this case, it should be equal to 0.1–0.3 of the thickness of the base of the sheet without corrugation. For the production of such products, the same standard provides for aluminum, as well as the following types of steel:

- St0, St1, St2, St3.

- Stainless steel AISI 409, AISI 321, AISI 301, AISI 201, AISI 430, AISI 316, AISI 304.

The resulting rolled metal can be of high (A) and normal (B) accuracy classes. Deviations in size are allowed by a maximum of 0.2 mm. According to the technical specifications, there may be nicks on the side edges of the sheets. This is a common occurrence after pruning them. In this case, much attention is paid to surface quality. There should be no cracks, dirt, scale or any other defects.

Steel sheets are rolled on such machines