When using cutters, chips and roundings may form on the cutting edges, the plane of contact between the two parts of the tool may not coincide, and the contact density along the length may be lost. As a result, they become impossible to cut. Therefore, to restore functionality, it is important to know how to sharpen your wire cutters.

Sharpening side cutters on a machine

Equipment

What are the advantages of sharpening wire cutters using professional equipment:

- high turning speed;

- precision angle adjustment, clear fixation of the position of the sharpening discs relative to the cutting part being sharpened;

- the ability to fully automate work on CNC equipment;

- safety during processing;

- setting the engine speed.

Many machines are equipped with quick-release mechanisms for abrasive discs and manipulators for quickly changing the position of the tool being sharpened. Brand manufacturers include a set of grinding wheels of various grain sizes, allowing for coarse or fine grinding.

Due to the high processing speed and automatic sharpening quality control, increased efficiency is achieved when performing similar tasks. The number of changeable settings is minimal.

Professional equipment is of the following types:

- mechanical, equipped with diamond-coated abrasive discs, due to which the strength of the metal is preserved, the edges are sharpened, and the service life is not significantly reduced;

- laser, allow you to quickly remove metal from the edges, but make it fragile.

The choice of a specific machine depends on the requirements for the quality and speed of sharpening the wire cutters.

How to use wire cutters?

When using this tool, you need to know some rules and features. Metal cutters are installed on the elements being cut or bitten, usually at an angle of 90 degrees. There is no need to be zealous while working; the device, both in the initial position and when performing work, must always be in a free grip, otherwise unwanted forces may occur on the cutting blades. Be sure to monitor the cutting and movement of the tool while working.

If the device moves in a direction that is not safe for people, then you must immediately release the handle or simply turn it in a different direction. If you need to cut massive elements, and this could be beams or hinges, then it is better to do the work in a recess; it is often provided in the cutting part of the tool. During operations, the cutting parts must be closed, and if they diverge, the work is suspended, otherwise a breakage may occur in the jaws of the pliers. When cutting massive elements with large tools, you need an assistant who will support or move the bitten elements to a safe distance.

Sharpening tools at home

At home, step-by-step sharpening of wire cutters using a file is performed as follows:

- The presence of play is checked; if there is any, it is necessary to seal the connection in a way that depends on its type.

- The surfaces at the joints are cleaned using sandpaper. To do this, it is folded so that it can go into all places. The operation is performed first on one side and then on the other.

- The plane of the cutting edge is sharpened. To do this, place the tool on a flat surface, fix it, and then use smooth movements of the file in the same direction to cut the cutting part from the inside.

- The corners of the blades are sharpening. The cutters are located on the edge of the table and are fixed manually.

- The outer parts of the blades are sharpened.

- The “cheeks” are polished.

- Final edge polishing is carried out along the cutting edges.

- The cutting quality is checked. If it is of poor quality, then all stages of turning are performed again.

- Apply a thin layer of lubricant to the junction of the pliers, and, if necessary, to store the tool, to the entire working part.

The quality of sharpening is checked as follows:

- After processing the edges, the nippers must be securely fastened so that there is no play between the two parts.

- Take thin polyethylene and stretch it in a convenient way.

- Cuts with pliers. The edges should be smooth without burrs or torn parts. The cutting line must be continuous.

Do-it-yourself tool sharpening

Tools

To sharpen tweezers, you will need to prepare the following tools:

- vice;

- diamond-coated needle file;

- core;

- small hammer;

- screwdriver;

- anvil and a flat metal surface;

- 2 pieces of cardboard;

- calipers.

Sharpening level

Checking the sharpening level is carried out as follows:

- The polyethylene sheet is fixed so that the edge is smooth. The cutting edge is placed over the stretched film. An incision is made; there should be no torn or pulled parts.

- The stretch film is fixed in a similar way, then the blades are closed along the entire length. The cut should be smooth, without snags or bends.

- A non-woven cloth allows you to determine the presence of burrs on a metal edge. With high-quality assembly and sharpening of the tweezers, an even cut is obtained.

- Vinyl gloves are pulled between the edges of the tweezers, then pulled down. If the cutting is smooth and there are no pulled edges, sharpening can be considered completed.

Selecting all the tools in advance will allow you to complete all stages of sharpening the tweezers without any problems.

Why do we need wire cutters?

The main purpose for which cable cutters are used is to cut wires and wires or other components. They are also needed when it is necessary to make small cuts in metal or plastic during installation or dismantling of equipment. This tool can easily cut wires of any diameter, but not too large. In order to make the work easier, when cutting the wires, you need to keep them very close to the hinges of the cutters. Basically, two types of nippers are used in work: side and end .

For side cutters, the handles are always located in the same plane as the cutting edges or jaws; a small angle is possible between them. These cutters also have a second name – side cutters. When the cutting edges are perpendicular to the planes of the handles, the tool is called an end cutter. If we compare the design of wire cutters with scissors, we can note that the main difference is in the interlocking cutting jaws. Nippers vary in shape and size. If you need to cut very thick wires, then you need to use professional power cutters. Such tools have a second name - bolt cutters.

Cuticle scissors: how to choose good and high-quality ones?

When using cutters, chips and roundings may form on the cutting edges, the plane of contact between the two parts of the tool may not coincide, and the contact density along the length may be lost. As a result, they become impossible to cut. Therefore, to restore functionality, it is important to know how to sharpen your wire cutters. Side cutters can be sharpened in the following ways:

- manually, using human power and hand tools for processing;

- using power tools.

- file;

- sandpaper;

- sharpening stone.

You can tell when your pliers need to be sharpened by the following signs:

- the cutting is not completed completely, connected parts of the material remain;

- you need to put in a lot of effort when working;

- burrs are visible on the edges.

Professional sharpening of manicure instruments

The most reliable way to sharpen nail scissors or tweezers is to take them to a nail technician. Having once splurged on expensive and high-quality tweezers, do not even try to straighten the cutting edge yourself at home without experience - you will completely ruin it!

The price of the service ranges from 200 - 500 rubles, a good sharpening will last at least six months - a year, if you do not do manicure professionally.

Consider the cost of the tool, possible risks and the cost of sharpening.

Purpose and capabilities of cutters

Nippers are a metalworking cutting tool of the articulated pliers type, designed for cutting wire, nails, rods of various metals and other similar products.

When performing electrical installation, plumbing and various construction works, it often becomes necessary to obtain pieces of wire and cables of different lengths, cut off nail heads, etc. All these works are most simply and quickly performed with a special cutting tool - wire cutters.

Using wire cutters you can perform various operations:

- Working with electrical cables - obtaining sections of the required length, removing excess wires in twists, removing old wires during repairs, etc.;

- Working with metal wire in construction (including when knitting reinforcement), for packaging and securing cargo on vehicles, during unloading operations, etc.;

- Working with fasteners - dismantling and destroying nails or screws, cutting plastic and metal clamps, etc.;

- Performing various auxiliary operations - removing insulation from electrical wires, cutting plastic parts, and others.

Nippers, along with a hammer, pliers and a drill, are an indispensable tool that makes many jobs easier. However, a truly high-quality result with minimal time investment can be achieved only with the correct selection of nippers. To make the right choice of this tool, you need to understand its existing types, design and characteristics.

- 390 ₽

- 880 ₽

- 265 ₽

- 860 ₽

- 550 ₽

- 170 ₽

- 1 240 ₽

- 570 ₽

- 1 155 ₽

- 555 ₽

Types, design and functionality of wire cutters

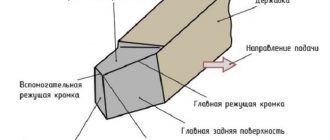

All cutters on the market today have a fundamentally identical design: these are two steel levers hingedly connected by a cylindrical wedged axis. Each lever is divided into three zones:

Myths about sharpening

Laser sharpening of manicure tools - there is no such term, there is - diamond sharpening.

A self-sharpening tool is a fiction, the same phenomenon as a perpetual motion machine. Nothing lasts forever: there can only be a well-processed tool that lasts longer.

There is no Solingen company, there is the German city of Solingen, where tweezers and other goods were made. And the company could be Zinger, or Jaguar, or any other.

Craftsmen without a specific place of work, “nomads” with their tools, in most cases provide poor-quality service, and in addition, they can completely damage the tool. Trust only masters who have reviews. If you have no idea how to restore the item to working condition, let a professional sharpen the tool.

For a more complete picture of the service provided, we suggest you watch the video.

If you want to sharpen a manicure instrument (scissors, scrapers, tweezers, clippers) or have it repaired in Moscow, then contact one of the repair shops.

- Moscow, metro Molodezhnaya (10 seconds from the metro), st. Yartsevskaya, 25A, Tramplin shopping center, 2nd floor, from 9:00 to 22:00, lunch from 14:00 to 15:00.

- Moscow, metro Planernaya (30 seconds from the metro), st. Planernaya, 7, transport hub "Planernaya" (2nd floor). Every day from 10:00 to 21:00.

You can also call the courier by phone 7 (495) 645-35-03 so as not to come to the workshop yourself.

Call us! The quality of the work of our specialists is confirmed by numerous reviews from satisfied clients, including employees of numerous well-known beauty salons in the capital.

Price list.

Types of side cutters

There are 4 main types of side cutters:

- Standard ones are the most popular type of side cutters. Can be purchased at most stores that sell building materials or household goods. Suitable for wires or wires up to 2.5 mm thick.

- Reinforced (or bolt cutters) - necessary for professional needs for mechanics and installers. The jaws of these pliers are made of high-strength alloy hardened steel.

- Miniature - needed by workers involved in network equipment. Suitable for cutting small wires in hard-to-reach places

- High-voltage - these pliers are used by electricians when working under voltages reaching thousands of volts. They have dielectric handles made of plastic.

Tweezers

If your tweezers, which you use to pluck your eyebrows, no longer grip the hairs properly (they cannot be used to pull out short hairs or grab vellus hairs), then you need to sharpen the tool. A similar situation can happen with tweezers for eyelash extensions.

After sharpening these devices, pay attention to the following points:

- After the sharpening procedure, the edges of the tweezers should fit together perfectly, leaving no cracks or any gaps, much less distortions.

- There should be no burrs or protruding elements on the tweezer jaws. The working surface should be rounded, this will help you avoid injury to the skin while pulling out hairs.

- Please note that the tweezers should be sharpened in such a way as to grab the hairs and not bite them. Otherwise, the hair will not be pulled out by the roots, but cut off. And soon the correction will have to be repeated. This rule also applies to tweezers for eyelash extensions. Having this drawback, this device will not be able to capture an artificial eyelash, but will simply cut it off.

If these tweezers become deformed during use, they are carefully bent or straightened, returning them to their original appearance.

What are side cutters used for?

The tool easily copes with cutting through aluminum or copper wires and other conductors connected to the network. Protection against electric shock is provided by special insulation on the handles. The operating principle of side cutters is to increase the force on the biting jaws by acting on the lever. To do this, just hold the handles of the structure with your hand.

Areas of work where side cutters are used:

- installation;

- electrical;

- repair.

The list of tasks that a tool can handle depends on whether it belongs to one type or another. Standard cutters cut plastic, metal, and wire. Dielectric devices are used primarily for laying cable lines.

The quality of cutting with a tool depends on how correctly it is used. When working with a thin conductor, the material is placed in the area of the tips of the cutting elements. The thick wire is placed closer to the swivel joint.

Types, design and functionality of wire cutters

All cutters on the market today have a fundamentally identical design: these are two steel levers hingedly connected by a cylindrical wedged axis. Each lever is divided into three zones:

- The front part is a head with a sponge on which a cutting edge is formed;

- The middle part, located at a short distance from the head, is a round thickening with a hole for the axis;

- The back part has an extended handle for hand gripping.

READ MORE: Pipe vices review of models for chain and pneumatic pipes for clamping as well as benchtop and bench options How to choose

The levers are connected by a hinge asymmetrically - the distance from the hinge to the cutting edges is 10-15% of the total length of the cutters. This design ensures that the force applied to the handles increases several times, allowing you to bite through metal rods, wires, nails and other hard products.

The levers are identical in design, but differ in the design of the hinge part. Usually, in the right lever there is a conical hole with corrugation for mounting the axle with its fixation from rotation, and in the left lever there is a corresponding conical hole for riveting the axle. However, many modern cutters use axles of a more complex design - with fixation using a bolt or screw, with a center offset depending on the diameter of the wire, and others.

Side cutters (side cutters)

End cutters

Based on the location of the cutting edges, cutters are divided into two large groups:

- Lateral (side cutters) - the edges are located along the axis of the handles or at a slight angle to them;

- End - the edges are located perpendicular to the axis of the handles.

In both cases, the cutting edges are sharpened at an angle of 60 degrees. Moreover, in side cutters, the edges formed during sharpening are arranged asymmetrically - one edge is always larger than the other, which facilitates the process of cutting the rods. In end cutters, the cutting edges are almost symmetrical.

The levers of the pliers are made of tool steels U7, U7A, 8HF and similar; the cutting edges can be subjected to heat treatment to increase their hardness (this parameter lies in the range of 55-61 HRC). There are cutters with surfacing on cutting edges made of high-speed steels and hard alloys (most often from Pobedit).

To protect the pliers from negative environmental influences, various types of coatings are applied to their levers - oxide and phosphate, followed by painting with nitro enamels, chrome, zinc and cadmium. A separate group includes tools with insulating handles - the handles of such pliers have plastic or rubber linings that protect people from electric shock.

Nippers are available in lengths from 125 to 200 mm (side cutters - standard range 125, 140, 160, 180 and 200 mm; end cutters - 125, 160, 180 and 200 mm), however, many manufacturers offer tools in smaller (from 115 mm) and enlarged ( up to 300 mm and more) sizes. The length of foreign-made tools is mostly standardized in an inch dimensional grid, which only in some positions coincides with the Russian one (for example, 4.5 inches - 125 mm).

Nippers can have various auxiliary functionality:

- Twisted or flat springs that automatically expand the levers when the force on the handles is reduced;

- Adjusting screw to limit the amount of convergence of the cutting edges (precision pliers);

- Additional cutting edges at the hinge, recesses for stripping wires, a wedge (nail puller) and other elements.

Construction pliers

In addition, there are various special-purpose nippers - reinforced, with a variable gap between the cutting edges, etc. Wire cutters also include the so-called construction pliers, which are used for cutting and bending wire, nails and other products. However, unlike nippers, the handles of construction pliers have a ball for sinking nail heads into the material and a wedge for pulling out nails.

In Russia, the design and characteristics of wire cutters are regulated by GOST 28037-89. And tools with insulated handles must additionally comply with the GOST 11516-94 (IEC 900-87) standard, which sets the requirements for hand tools for performing electrical installation work under voltage of 1000-1500 V.