As general information, it is worth saying that metal cutting is one of the types of metalworking. Other types of mechanical processing of metals include forging, bending, stamping, grinding, drilling, threading, etc., as well as chemical and thermal (thermal) methods. In other words, everything that allows us to obtain a product with the properties we need from a certain metal is metalworking.

The variety of methods for working with metals entails a variety of technical means. From files and chisels to CNC machines and industrial robots. You can get acquainted with the methods and machines themselves on the relevant websites; an example is the website of the Akron-System company, which is also interesting because it supplies not only equipment and components of different brands, but also offers the production of unique metal products according to our drawings.

In private house building and renovation, metal cutting is apparently the most popular type of work with metal products, along with drilling.

So, what do you need and can use if you need to cut a metal pipe, corner or rod, sheet or strip?

The tool and cutting method are selected depending on the thickness, type of metal, as well as the volume of work. The choice also depends on whether you have to cut metal without electricity or whether electricity is fine and, therefore, you can use a special tool.

Method 3 Use a vice and a hacksaw

This method is suitable for small volumes of work, with small cross-sectional sizes of a metal pipe, angle, iron strip, screw stud, etc.

Theoretically, you can manually saw off an iron pin five to seven centimeters in diameter or a fifty-fifty corner half a centimeter thick. True, this will take more than one hour of time and will require a lot of strength and endurance.

If you don’t have a hacksaw for metal, then sometimes a simple file will help, but rather not for cutting, but for cutting metal (for example, a thin rod for subsequent bending).

How to cut tiles and porcelain stoneware with a grinder without chipping

To avoid chipping when cutting tiles, it must be moistened with water. This will promptly reduce the temperature, which causes destruction. In this way, you can not only cut the tiles, but also cut out the necessary fragments. Another method is to use a stone cutting wheel. This circle does not crack or chip.

The situation with porcelain stoneware is a little more complicated. Porcelain tiles are somewhat thicker than regular tiles and are stronger. A manual tile cutter becomes dull very quickly without achieving results. Therefore, you can cut porcelain stoneware around the stone.

We make a contour cut along the drawn cutting line. Then another, a third. Until the uncut thickness of the material is less than the cut thickness. We move the porcelain tile to the edge of the table and break it with a sharp, but not very strong movement.

Method 4 We cut with an electric jigsaw and a metal file.

A jigsaw can be used for cutting, including shaped, thin (up to one or two millimeters thick) sheets of metal, as well as small cross-section corners, rods, pipes, etc.

The cutting speed is low, but quite high accuracy is achieved. When cutting more or less thick sheets of iron, it is recommended to lubricate the cutting surface with grease and a file.

Band saw cutting

Rarely does a metalworking exhibition go by without showing a new band saw machine. This popularity is due to the low cost of the equipment, ease of maintenance and acceptable performance. A band saw stretched on pulleys is used as a cutting tool.

The average cutting speed of the band saw machine (LSS) exceeds 100 mm/min. Modern models are equipped with electronics and a wide range of additional equipment, which makes it easy to adapt the machine to the production line.

When cutting on LPS, exact compliance with the specified parameters is ensured, and the cut site practically does not require additional processing (except for the production of high-precision products or products with a smooth surface). The machine is unpretentious to the type of material being processed - it cuts absolutely everything, and the cutting width is only 1.5 mm.

If, when determining the cutting speed and feed rate, it is not possible to use the manufacturer’s recommendations, then you can find out the optimal values by looking at the chips: thick chips with a blue tint are an indicator of the feed rate being too high, dusty chips – too low. At optimal conditions, the chips are slightly curly.

One of the most important conditions when working on automatic band saws is the precise selection of the pitch of the teeth of the cutting blade. Special tables will help you select the blade pitch that corresponds to the cross-section of the profile being cut. Feed rate and cutting speed are equally important.

One of the main advantages of LPS is the ability to cut at an angle. However, as in the previous case, it is impossible to obtain a figured cut using a LPS, and the dimensions of the workpieces are limited by the capabilities of the machine.

Method 5 Cutting with metal scissors

This method is suitable for cutting thin sheets of metal (preferably soft).

There is a trick that allows you to use scissors to cut an iron sheet 2-3 millimeters thick (depending on the strength of the cutter). We fix the scissors in a vice with one handle, and put a piece of pipe on the other (it should be longer than the handle itself). We get a lever and, as a result, a fairly powerful machine for cutting metals. We feed the iron or steel sheet onto the scissors, press hard on the pipe and... cut the metal.

Another way to increase the strength of the scissors is, again, using a hammer. It is worth noting that all this will most likely lead to a deterioration in the accuracy and evenness of the cut.

By the way, modern metal scissors are quite diverse in appearance and design, among them there are also electric scissors (however, they no longer resemble scissors in their appearance and in general this, one might say, is another way of cutting metal, about which see below).

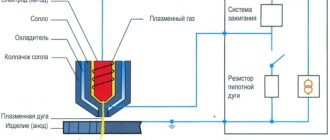

Plasma cutting of metal

Almost all of the disadvantages of oxy-fuel cutting can be eliminated when using plasma. The first machines for plasma cutting of metal appeared somewhere in the 50-60s of the last century. This equipment was so bulky and expensive that it was purchased mainly only by engineering giants. At the end of the last century, plasma cutting of metal became more accessible and is now widespread.

Plasma cutting of metal is carried out due to the intensive melting of the metal along the cut line by the heat of a compressed electric arc and the subsequent removal of liquid metal by a high-speed plasma flow. At its core, plasma is a fully or partially ionized gas with a temperature of 15,000 - 20,000°C. Accordingly, it is not difficult to guess that the productivity of plasma cutting will be many times higher than gas-oxygen cutting, the temperature of which reaches only 1,800°C.

Today, plasma cutting is the most effective method of cutting metal, which has a number of features that make it a leader in the field of metalworking. Thus, the process of cutting metal with plasma does not require refilling gas cylinders and their delivery, additives for cutting valuable metals or special compliance with fire safety measures. Plasma cutting requires only electricity and air, and nozzles and electrodes as consumables, so this type is one of the most economical methods.

Plasma cutting is economically feasible for processing:

- aluminum and alloys based on it up to 120 mm thick;

- copper up to 80 mm thick;

- alloy and carbon steels up to 50 mm thick;

- cast iron up to 90 mm thick.

With a metal thickness of 120 to 200 mm, plasma processing is possible, but in this case it is more profitable to use oxygen gas cutting.

In the process of cutting metal, characteristics such as thickness and thermal conductivity are extremely important. Accordingly, when selecting equipment, it is necessary to take into account a simple fact: the higher the thermal conductivity of the metal being cut, the greater the heat removal and the smaller the possible thickness of the processed sheet. For example, the thickness of a copper sheet should be less than a stainless steel sheet.

The advantage of plasma cutting is the increase in cutting speed. This fact allows this method to prevail over an oxygen burner, since the speed increases by 6-10 times, which is important when processing workpieces 40-60 mm thick.

Method 6. Cutting metal with a grinder

An angle grinder is an angle grinder on which various grinding, abrasive, and cutting wheels are installed. A special cutting disc is used for cutting metals. After cutting, the cut area is treated with a grinding disc.

A grinder today is perhaps the most productive tool for non-professional metal cutting. It makes it quite easy to cut both pipes, rods, corners, and (with some training) sheets of metal. See also more details about the types of working discs for grinders.

How to cut thick sheet metal smoothly

To cut thick sheet metal, it is advisable to use a grinder with a power of more than 1 kW. In this case, you need to cut the product using an angle grinder in the direction forward from its edge. First, you need to draw a line on the sheet along which the cut will be made. Then along the drawn line you need to place a steel corner or a flat wooden beam. Using clamps, the corner (beam) is firmly attached to the surface of the sheet.

Then, along the corner, strictly along the drawn line, you need to walk the angle grinder and make a small groove, the depth of which is about 1-2 mm. After completing this procedure, the angle can be dismantled and normal metal cutting can begin.

A groove made on its surface, along a marked line, will not allow the saw blade to move away from a predetermined trajectory, resulting in perfectly smooth edges at the cutting sites.

Important! When working with angle grinders, you must follow safety regulations and use personal protective equipment.

Also during work, it is necessary to take into account the direction of rotation of the grinder circle, as well as its size. You cannot install large discs (from 150 mm or more) on small angle grinders (125 mm) after first dismantling the protective casing.

Method 7 Cutting with a reciprocating saw

A reciprocating saw or electric hacksaw is a relatively new tool on our market. Like a jigsaw, this saw can change its blades, therefore, along with cutting wood, it is used for cutting soft and hard metals (stainless steel, aluminum), as well as aerated concrete, plastic, craton, etc. This tool is more powerful than a jigsaw. In addition, the saw is more mobile and does not require support during operation. Can be used for quickly cutting iron pipes with a diameter of 2-3 centimeters or more (see video below).

What and how to make a hole in a sheet of metal?

It all depends on the size of the hole. If the diameter is small, a drill will do. If large holes are needed, special drill bits are used. Pay attention to the material from which the horse-drawn horse is made. To process profiled sheets, you should use nozzles with a carbide coating. Processing should be carried out without increasing the temperature.

A jigsaw is used to make a large diameter hole. With this tool, cutting out a circle of large diameter will not be difficult. When working, use a saw with fine teeth

Method 8 Use a pipe cutter

At home, you can use handheld pipe cutters (for example, RidGid pipe cutters) to cut pipes. Using special cutter rollers or scissors, a pipe cutter allows you to cut pipes up to 10 centimeters or more in diameter. Moreover, with high quality and evenness of the cut, which is especially good for soft metals (for example, copper pipes). The disadvantage is its narrow purpose - it is used only for cutting pipes.

How to safely cut gas cylinders using an angle grinder

When designing homemade products, you always need a material that is better in quality than what is available in rolled metal. Craftsmen select recyclable materials in advance, which can be reused in their homework for many reasons. One example is an unusable gas cylinder. You can make many useful things from it, since the quality of the metal is much higher than what is on sale. In addition, knowing how to cut a gas cylinder with a grinder, you can get the desired workpiece with the required dimensions at a price that is significantly lower than new sheet metal.

Standard gas cylinder, which are manufactured by industry

Set of tools for work

To cut a propane tank, you need tools, without which it will be impossible to do this.

- Grinder (angle grinder).

- Cutting discs with a diameter that allows you to install an angle grinder .

- Drill.

- Drill. The first small diameter drill is for initial drilling, the second is for expanding the hole. Diameters can be arbitrary.

- Metal brush.

- A cord with chalk to mark the evenness of the lines.

- Size 2 or 3 pipe wrench.

- For personal protection you will need gloves, goggles, and a respirator.

How to make a corner of a ceiling plinth without a miter box

When pruning, sometimes you can do without a miter box. In some cases, this method is even more effective, since the miter box is designed for high evenness of the walls and ceiling. In reality, this is not always true.

- The element is placed so that its edge rests against the junction of two walls. Mark the position with a pencil. The same is done with the baseboard on the opposite side.

- At the junction of the wall and ceiling, the intersection points are connected and a diagonal is laid. It is then marked on the product itself. This is the mark for the cut.

- The blade is used to cut along the marked mowing line. When docked, they line up perfectly. Using the same technology, you can cut the material for external corners.

Method 9. We cut metal with a multifunctional power tool (Renovator multitool, multicutter).

A new, widely advertised tool that comes with different attachments, including those used for cutting metal.

One of the promoted tool names is the Renovator multitool. True, other manufacturers (including Bosch, Dewalt, Makita, etc.) do not use this name. Due to its versatility, you should not expect serious capabilities for cutting large-sized metals from a renovator. Best used for trimming protruding nails, screws and other small metal cutting, especially in hard-to-reach places.

Possible methods of cutting rails

Despite the apparent complexity of the operation, dividing a metal element into small sections is not difficult. To do this, you can use one of the following devices:

Each method is complicated in its own way, but the expected result (the rail cut into pieces) will be obtained. Now - in detail about each technique.

Cutting with a sewing needle

The method was popular in the last century, when there were no more convenient devices for cutting metal rails. In this case, the product was not sawed, but broke.

Principle of operation:

- the edges of the rail are installed on two supports with the base down;

- a thick sewing needle is placed perpendicular to the product at the intended fracture site;

- a sledgehammer makes a strong and precise blow to the place where the needle is attached, as a result of which the rail is cut in half.

Advantages of the method:

- rapidity;

- minimum of available means;

- low risk of injury;

- the ability to do the work alone.

Flaws:

- experience is required - it’s not easy to hit the right spot accurately;

- the cut line sometimes turns out to be crooked;

- it is necessary to strike only one precise blow; With several unsuccessful attempts, the integrity of the canvas will be compromised.

Method 10. Cutting with electric metal scissors

Electric shears are an excellent tool for cutting sheet metal, used by both professionals and amateurs. Relatively inexpensive models, for example, the Interskol brand, will help cut sheets up to 2 millimeters thick. More powerful professional versions can handle metal up to 3 mm thick or more.

Metal shears will be extremely useful for those who cut metal tiles, corrugated sheets, etc. After all, alternative cutting with a grinder, even using a special metal circle, spoils the protective layer of the metal tile. And scissors allow you to make a neat cut without affecting the protection of the metal.

Waterjet cutting of metal

Waterjet cutting is the most innovative and advanced metal cutting technology. The power of the water jet coming out of the nozzle under enormous pressure is truly amazing: it is capable of cutting up to 300 mm (!) of steel.

The heart of the waterjet cutting system is the ultra-high pressure pump. There are now experimental models of machines with water pressure of 6,000 bar. Passing through a ruby, sapphire or diamond nozzle just 0.1mm wide, water is accelerated to three times the speed of sound to produce a fine, focused jet that can process virtually all types of materials.

The speed of waterjet cutting is very high: for example, when cutting a stainless steel sheet with a thickness of 100 mm, it reaches 22 mm/min, and with a thickness of 1 mm – 2,700 mm/min. When cutting glass, the speed can be up to 11,000 mm/min.

When cutting soft materials, a clean stream of water is used, and by mixing garnet sand as an abrasive, materials of any hardness can be cut.

Experiments have been conducted abroad to compare the effectiveness of the waterjet cutting method with traditional technologies. Laser was chosen as the “strongest competitor”. Both installations cut packages from metal plates with a thickness of 0.3 mm each. As a result of the tests, it was found that when the thickness of the destructible package of plates is less than 6 mm, the laser cutting method turned out to be more efficient in terms of energy intensity and speed, and when the package thickness is over 6 mm, the waterjet cutting method is absolutely in the lead.

The most important advantage of water jet cutting technology over other types of processing is the absence of heating of the cut workpieces, i.e. no thermal effect on the material, which eliminates stress and deformation of the processed material. The result is amazingly high-quality cuts that do not require expensive post-processing.

Some materials cannot be cut by a laser due to reflection, and in the case of plasma cutting, when the material is not conductive. In this regard, waterjet cutting is a universal method, however, it involves getting the part wet, which can be critical for metals susceptible to corrosion.

Water cutting technology has another undeniable advantage - a hair-thin jet creates significantly less material loss compared to traditional processes.

A huge disadvantage of the waterjet metal cutting method is the extremely high cost of cutting: one hour of work on such a machine will cost you about 1,500 rubles. In addition, working parts wear out very quickly due to high pressure and require constant monitoring and repair. In general, if you decide to purchase a waterjet cutting machine, be prepared for ongoing high costs.

Method 11. Professional methods of metal cutting

These include plasma cutting, gas cutting, laser, water, using band saws, etc.

We can also use all these methods - if we contact a company or a professional who provides metal cutting services. Method 7 is good if large volumes of work are required, hard or, on the contrary, very soft metals, as well as large sizes of cut surfaces.

How to cut galvanized sheet

We offer you another series of answers to blog tasks. You can now surprise your friends with your experiments with scissors and your knowledge of at least two Chinese words. Day of the week Day of the week today is Thursday. The most convenient way to solve this problem was to draw a straight line with the days of the week; counting this way is much faster and easier.

o__o__o__o__o__o__o__o Sun Mon Tue Wed Thu Fri Sat Sun that same day we solved the problem about Mr. Smith (see link above): Mr. Smith Mr. Smith left the house when it was not raining. Smart dogs: 3 dogs found 1 bone each, and 4 dogs found 2 bones each.

It is convenient to solve this problem with children using a drawing - draw 7 heads and distribute the bones to them: first one at a time, and then the second. So, with the help of a drawing, everything becomes clear. Who is to blame? Tom is guilty. Wipers and snow The wipers ended up with one heap of snow.

But very big! How to cut a sheet of paper and crawl through it entirely Here's a video: Loading the player Linguistic task Strictly speaking, this is not a very linguistic task. The only linguistic thing about it is that the words are actually written in Chinese, and the wording “in a mixed order” is classic.

In fact, the whole point here is to carefully read the condition: “the translations are given in a mixed order,” and since there are only 2 words, then mix them up

only possible between each other.

Roller shears and sheet metal cutting features

In the metalworking industry, roller shears or knives are used to process sheet material. This tool is called knives because its operation is based on the use of two cutting discs.

The cutting process is based on the fact that rollers are pressed into the sheet material from two sides - top and bottom. In this case, it is cut without the use of any sharp knives.

The role of cutting and sharp knives is played by rollers, which touch the walls to each other on both sides.

Rollers not only cut sheet material, but also facilitate the process of moving the tool along the surface of the sheet. This means that cutting with a roller knife is not only convenient, but also effective. If we compare the operation of the device with hand scissors, the following advantages should be noted:

- Speed - cutting a sheet of steel with roller shears can be done in a matter of seconds, but using scissors requires a lot of time, which depends on the length of the material being cut

- Cut quality - the roller knife cuts not only quickly, but also with high quality. There are no chips, bends, bends, etc. at the site of the cut

- Physical fatigue - cutting with hand scissors requires physical effort, while using a roller tool eliminates this need. To cut, you only need to move the roller shears along the guides, thereby cutting the steel sheet

Roller shears are classified according to the types of knives into three types:

- They are located in parallel. The most popular type of cutting tool, which is intended exclusively for cutting material into strips, that is, cutting is performed in a straight direction

- They have one slope. They are intended for cutting not only even strips of sheet material, but also for cutting round and ring-type workpieces

- With several slopes. Such roller devices are intended directly for cutting workpieces of various shapes - ring, round, curved, etc.

After cutting, the edge of the material does not need additional processing, as it turns out smooth, without chips or burrs.

How to cut sheet metal at home

In industry, roller shears are used to cut factory-produced sheet metal. Their distinctive features are high accuracy, long service life, and the absence of the need to make them yourself.

Often in the household there is a need to obtain even strips of sheet steel, which are used for various purposes. If you need one strip, then there is no need to buy or make such a device, since you can use ordinary metal scissors.

If you need to cut the entire sheet or carry out cutting work regularly, then it is imperative to acquire a roller knife.

There is no justifiable sense in buying such a factory-made device, since the price ranges from 15 thousand rubles or more, which depends on the design, size and quality of the device.

Roller shears for cutting sheet metal can be made with your own hands at home, using available consumables for manufacturing.

Although this method requires time, it allows you to save money, resulting in a universal cutting tool for cutting sheets of stainless steel, galvanized steel, etc.

! It should be noted that roller shears are only suitable for cutting flat sheets, and they cannot be used to cut sheets with protrusions and recesses, for example, corrugated sheets in the transverse direction.

Features of making a tool yourself

If you are tired of cutting sheet metal with scissors or a grinder, then a roller cutter is an excellent alternative to replace these tools.

The advantages of this device include quiet operation and lack of energy consumption.

In addition, having such a device in your home arsenal, you can even make money when your neighbors need to cut sheet metal material.

The purchase of a tool is justified only in one case, when it is necessary to perform work in large quantities. And even in this case, you can make the device yourself to use it for professional purposes. There are many designs for the devices in question, so making a device yourself is not at all difficult if you understand the principle of operation of the device.

When making a homemade tool, the following properties must be taken into account:

- Cutting knives - there should be two of them, one located on top and the other on the bottom. Knives must be made of high-quality alloy, which has a strength higher than the materials being cut. Bearings that fully meet the described requirements are used as knives.

- Base - simultaneously acts as a surface on which the steel sheet is located, as well as a guide for moving the roller shears when cutting the sheet or cutting strips

- Body of the device - for manufacturing, a steel angle with a thickness of 3 mm and a wall size of 40-60 mm is usually used

- Auxiliary tools - they are designed to secure the sheet material to the table surface while cutting it

! The service life of homemade roller knives is quite high, and is almost equal to that of factory models. The service life of factory devices is at least 25 km, but provided that the thickness of the cut steel does not exceed 0.5 mm. The thicker the steel, the shorter the service life of the tool.

The service life of a homemade device is influenced by such an indicator as the quality of its manufacture. Moreover, this even applies to the quality of bearings, so if you get down to business, you will need an appropriate approach.

What to make a roller knife from

There are no difficulties with purchasing roller shears, since such a machine can be found in an online store and ordered.

The only difficulty is that you will have to shell out a considerable amount of money to purchase it, which will not pay off soon if you do not use such equipment often.

Making your own will not require any costs, but the biggest difficulty is choosing the necessary materials and assembling full-fledged roller shears from them.

Using a homemade machine allows you to cut the following types of materials:

- Cink Steel

- Stainless steel

- Aluminum

- Steel sheets up to 0.5 mm thick, for example, window slopes of metal-plastic windows

Bearings are used to make cutting knives. The diameter of these bearings depends on the size of the roller blade housing, but 20-30mm ball bearings are commonly used. In order for the bearings to ensure cutting of material, it is necessary to grind off their end faces, making them strictly at an angle of 90 degrees. The effectiveness of the tool depends on this.

! The diameter of the bearings affects the cutting speed. The larger the size of the bearings, the correspondingly higher the cutting speed.

Before you make a roller-type cutting tool, you need to understand its principle of use. The application is based on the fact that a homemade knife moves along guides. The corner part of a workbench or table is used as such guides.

The sheet to be cut is placed on the surface of the table, and in order for the cut to be smooth and neat, it should be fixed in a stationary position. This can be done using two clamps and a wooden block of appropriate length.

A block is placed on the sheet, and then it is fixed on both sides with clamps, thereby ensuring immobility during processing.

Instructions on how to make roller shears from bearings with your own hands

As already mentioned, there are many options for making a homemade roller cutting tool, but which one to choose for yourself depends not only on the capabilities, but also on the availability of the necessary consumables.

If you need a simple homemade roller knife, you can make it from bearings.

The manufacturing principle is simple, and first let’s figure out what tools and materials will be needed to make it:

- Two bearings 204 or 205. You can use other bearings that are available. They don't have to be the same size

- Corner 50-60 mm up to 30 cm long

- Threaded connectors, washers, nuts and other small consumables

- Steel tube from which to make a handle for roller shears

- The tools you will need are a welding machine, as well as a drill and grinder

When all the necessary materials are ready for work, you can get down to business. Instructions for making a roller knife yourself are as follows:

- First you need to prepare a corner, since it will act as a body on which additional elements will be placed

- We grind the edge of the bearings. Moreover, this must be done in such a way that the resulting edge has an acute angle. On both bearings it is necessary to “remove” the edge, since the possibility of using the roller shears for their intended purpose depends on this

- Next, you need to drill a hole in the corner and attach one bearing to it. A bolt with a countersunk head is used for fastening. A washer is also used to secure the bearing, which will ensure reliable pressure against the wall of the angle

- The bearing is attached so that its outer race protrudes 1-2 mm from above the edge of the angle. It is important to provide for the possibility of adjusting its contact with the second bearing by placing washers on the inside

- On the reverse side, when securing the bearing, it is necessary to ensure that the head of the fastening bolt is recessed into the base of the angle. This is necessary so that the homemade tool can move freely along the edge of the workbench. If you can’t drown the hat, you can make a groove for it in the workbench design, which is also quite appropriate when using homemade scissors

- The first part of the work at this stage is considered completed, so you should proceed to the manufacture of the second part. This is the handle, the second bearing, and also the sheet bender

- Using a similar corner that is 2 times shorter in length, you need to attach the second bearing to it. First, using a grinder, you need to cut the corner into the shape shown in the photo below.

- It is necessary to attach the bearing to the end part of the resulting workpiece by first drilling a hole

- Weld the corner piece to the main part as shown in the photo. It is important to take into account that the upper bearing must be in close contact with the lower bearing, and its outer race must be located at a distance of up to 1 mm from the base of the angle

- Finally, you need to attach the handle to the resulting installation so that it is convenient to work

The result is a homemade cutting tool for cutting metal sheets up to 0.5 mm thick. When using the device, it must be taken into account that it is intended exclusively for working with sheet materials.

During operation, the edge of the bearings will wear out, so it is advisable to provide during manufacturing the possibility of adjusting the contact of the bearings.

All the details of the manufacture and use of such a tool are in the video below.

! When you rotate one bearing by hand, the second should also rotate, which indicates that the homemade product was manufactured correctly. The greater the distance between the end parts of the bearings, the lower the quality of the tool.

In conclusion, as an example, it is worth giving an example of how much a factory roller blade costs, as well as what technical parameters it has. For example, consider a Trim Cutter 3017 brand machine and its technical parameters:

- Maximum sheet metal thickness - 0.7 mm

- The weight of the device is 4 kg

- Overall dimensions - 220x180x260 mm

- Cost from 25,000 rubles

Based on the above, it can be noted that making roller shears for cutting thin sheet metal with your own hands is not at all difficult. This does not require a lot of effort and consumables.

With just 3-4 hours of free time, you can make a highly effective cutting tool at home.

With roller shears, you don’t need to think about how to cut a metal sheet when installing window slopes or how to cut galvanized sheets into strips, since with it any similar work is carried out easily, quickly and efficiently.

DIY sheet metal cutting. How to evenly cut a sheet of metal using improvised materials. Cut out the circle and other shapes.

Sheet metal is a common building material used to make fences, gutters and canopies. You can often find ready-made galvanized steel products on sale, such as ridges or pipes for draining rainwater from the roof. But what if the product is of non-standard size and you need to cut sheet metal yourself?

It is important to know

Modern manufacturers offer a variety of equipment models, so finding a specific model of equipment in the regions is not difficult (as well as companies or specialists who will quickly and efficiently complete the work). But you need to remember some nuances.

Things to remember when cutting concrete:

- Wall saws are not used in multi-storey panel buildings due to the risk of flooding the lower floors with water. The machine is also not suitable for working in confined spaces and when it is necessary to perform small volumes of cutting.

- To reduce noise, you can cut openings in parts (at least 6 parts). The price of the work in this case increases and depends on the number of pieces cut out.

- All holes/openings in load-bearing structures are made only by certified companies and in strict accordance with the rules.

- Legalization of hatches/openings in load-bearing walls requires contacting government agencies with a full package of documents.

Cutting concrete without dust is a difficult task, which can only be partially realized. It is very difficult to completely get rid of dust, but its amount can be significantly reduced through the correct choice of equipment and attachments, cutting method, as well as the use of a construction vacuum cleaner and the creation of special devices for collecting dust.