The popularity of aluminum cookware is evidenced by the fact that in our country alone there are about three dozen factories that mass-produce cookware from this metal. Let's take a closer look at why this happens.

The popularity of aluminum cookware is evidenced by the fact that in our country alone there are about three dozen factories that mass-produce cookware from this metal.

What is aluminum

The silvery-white metal, which ranks 13th on the periodic table, is called aluminum. In the earth's crust, it occupies 8% of the volume; in addition, it ranks third in distribution after oxygen and silicon.

Is aluminum harmful to the body?

Studies conducted by scientists from different countries and at different times have proven that the accumulation of aluminum in the body leads to the death of brain cells, provokes arthritis and anemia, complicates the work of some glands, and this leads to difficulties in the production of certain enzymes, for example, gastric . The presence of excess aluminum in the human body ensures the growth of osteoporosis and rickets. By the way, many people believe that an aluminum juice cooker is harmful to health.

This can be explained by the fact that some aluminum compounds are insoluble in water or acids. They complicate the absorption of phosphates in the intestinal tract.

Aluminum in modern buildings

Many modern buildings - office towers, concert halls, shopping centers, museums, airport terminals, train stations, football stadiums and simply residential buildings - owe their attractive shape to aluminum. It is aluminum profiles and panels that give architects unlimited opportunities for creativity and creating the most incredible forms.

However, aluminum in buildings is not only facades, translucent or ventilated cladding. In many buildings, a considerable number of building elements of the outer shell are also made of aluminum alloys (Figure 9):

- windows, doors and shutters;

- balcony railings;

- Garage Doors;

- ventilation ducts;

- gutters;

- solar panels;

- roof.

Figure 9 - Aluminum building elements in modern buildings [3]

In addition, aluminum alloys are widely used inside buildings. This is for example:

- doors;

- elevator cabins;

- floors and ceilings;

- furniture;

- partitions;

- signs;

- blinds.

Production of aluminum cookware

For the production of aluminum cookware, traditional technologies are used, namely stamping and casting. In addition to traditional cookware, many manufacturers produce cookware with a coating applied to its surface, in particular, Teflon. Coatings of this type guarantee that semi-finished products will not burn during cooking.

For the production of aluminum cookware, traditional technologies are used, namely stamping and casting.

For the production of kitchen utensils, it is permissible to use only those alloys that are listed in GOST 1583–93 and some others, in particular, AK7, AK5M2, AK9, AK12. The ingots intended for the production of tableware must have the letter “P” stamped on them.

Stamped ware

To produce stamped dishes, sheet metal is used, which, after processing on a press, takes on the required shape. By the way, the small mass of aluminum allows us to produce large-volume kitchen utensils, for example, 50-liter pots.

To produce stamped dishes, sheet metal is used, which, after processing on a press, takes on the required shape.

Cast ware

Cast aluminum cookware is the most expensive. To obtain the finished product, aluminum ingots are melted and poured into prepared molds. This production technology does not change the composition of the metal, which has a positive effect on the thermal conductivity of the cookware and its resistance to deformation, including temperature.

Dishes produced by casting are able to retain heat longer and heat up evenly.

Cast utensils are heavier than those made using stamping and are very similar in appearance to cast iron. Dishes produced by casting are able to retain heat longer and heat up evenly. This technology is used for the production of cauldrons, pots, etc.

Features of aluminum

The metal itself is white in color and chemically reactive. Reacting with air, an oxide film is formed on its surface, which protects it from moisture and other negative factors that act as irritants. This reaction not only acts as an advantage of the metal, but is also in some way a disadvantage, adjusting the casting process.

The following discusses the advantages and disadvantages of enamelling, anodized and other types of aluminum, as well as its classification.

This video will introduce you to the features of aluminum:

Advantages and disadvantages

Due to its structure and characteristics, aluminum has the following advantages:

- Light weight;

- Corrosion resistance;

- High sound absorption coefficient;

- Environmental Safety;

- Resistance to temperature changes;

- Durability;

- Possibility of adjusting characteristics due to impurities.

As for the disadvantages, we can only note the high cost compared to other metals. However, the advantages make this feature less significant.

Classification

Aluminum is rarely used in its pure form; in order to obtain the necessary functions and technical characteristics, special impurities are added to the metal.

If the tensile strength of pure metal is 90 MPa, then by adding alloying components (magnesium, zinc, etc.) this figure can be increased to 700 MPa. Such aluminum alloys can be divided into two groups:

- Deformable alloys. To produce them, the metal is initially poured into special ingots, which are then processed under high pressure using one of the methods.

- Casting alloys. They are characterized by a high silicon content and the need for casting into ready-made molds.

We will talk about the melting and boiling point of aluminum, other chemical properties and characteristics of the metal below.

Types of aluminum cookware

The popularity of aluminum cookware has led to manufacturers mastering the production of a wide range of these products. Below is a description of some types.

With color coating

Dishes made from this metal have a uniform silver color, but some manufacturers produce dishes painted in different colors. To give it color, manufacturers use different methods, in particular:

- Apply a protective film;

- Enamels and varnishes are used;

- Organic paints are used;

- Some manufacturers produce cookware made from anodized aluminum.

Manufacturers use different methods to add color to dishes.

Recently, porcelain suspension has been used as a coating. It gives kitchen utensils an attractive appearance and acts as a protective layer.

With thickened bottom

Using dishes with a thick bottom, you can always prepare tasty and healthy food. The thick bottom ensures uniform heating of the entire vessel, and this allows you to cook food without burning.

Using dishes with a thick bottom, you can always prepare tasty and healthy food.

Frying pans with grooved bottom

Manufacturers produce dishes with a grooved bottom. This type of cookware allows you to fry steaks and fish. You can cook vegetables.

Excess fat flows into the free space between the ribs, and therefore semi-finished products do not burn.

Semi-finished products do not lose their beneficial qualities, partly because the same steak touches the surface of the dish only on elevated surfaces. Excess fat flows into the free space between the ribs, and therefore semi-finished products do not burn.

With stone or marble coating

To improve the efficiency of cookware and prevent food from burning, a coating is applied to the work surface. Among the many options, stone is considered optimal; sometimes it is called marble. Stone chips are added to the composition of this coating. It does not contain synthetics and is therefore considered environmentally friendly. The duration of use of kitchen utensils with such a coating reaches 15 years.

The composition of this coating includes stone chips.

Ceramic coating

Just like stone, only natural materials are used to make this material. This allows us to classify it as safe, however, the composition contains hardeners that can release some unsafe compounds, but in minute quantities.

To make this material, only natural materials are used.

Non-stick coating

The very first coating was developed based on Teflon. In appearance it resembles paraffin. Placed on the work surface of the utensil, it provides it with non-stick characteristics. But recent studies have shown that such a coating is unsafe, and therefore such utensils are prohibited for use in the countries of the European Union.

When placed on the work surface of the utensil, Teflon provides it with non-stick characteristics.

Disposable aluminum tableware

Such utensils are convenient and practical. Cookware of this class is used when cooking using an oven. You can wrap it in foil, and then the semi-finished products will not burn. This dish can be used for storing food.

Cookware of this class is used when cooking using an oven.

Advantages and disadvantages

When using cookware made from aluminum, you must strictly follow the rules of use. Modern cookware eliminates metal contact with pure aluminum. This is provided by a thin oxide film located on the surface of the metal. In addition to this, protection is also provided by coatings applied during the manufacture of cookware at the factory.

The key advantages of this cookware include low cost, high corrosion resistance, and fairly easy maintenance. But at the same time, it is recommended to use it for preparing food from products containing high levels of acids.

The key advantages of this cookware include low cost, high corrosion resistance, and fairly easy maintenance.

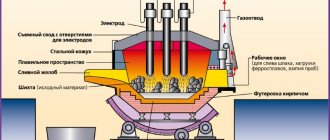

Receipt

In industry, aluminum is produced by electrolysis of a solution of aluminum oxide Al2O3 in molten cryolite Na3AlF6 at a temperature of 950 °C. The electrolysis bath is made in the form of an iron box, the hearth and side walls are lined with plates of a mixture of carbon and graphite (serve as the cathode), and fired plates of carbon mass (anode) are lowered into the bath from above. When passing a constant electric current Al2O3 decomposes into Al, which accumulates on the hearth, and O2, which forms carbon oxides CO and CO2 with the anode material. Molten A., containing approx. 1% impurities, poured into molds or cast by continuous method. From it electrolytic. by refining, high purity A is obtained - no more than 0.05% of impurities. When producing aluminum by zone smelting, the content of nitrogen and sulfur should not exceed 10–4%, any other impurities – 10–5%. A. production is associated with high energy consumption. World production of A. is approx. 25 million tons/year (2002).

What can you cook in aluminum cookware?

There are no clear prohibitions on cooking certain products in aluminum utensils. But practice shows that it is undesirable to cook potatoes, beets, etc. It is not recommended to prepare semi-finished products that contain a high amount of alkali or acid.

Is it possible to make jam?

When making jam, a large amount of acid is released, which destroys the oxide film. This results in the release of pure aluminum into the jam. As noted above, aluminum does not benefit humans.

When making jam, a large amount of acid is released, which destroys the oxide film.

Structural properties of aluminum

Aluminum alloys as structural materials have a number of advantages that give them the opportunity to compete with steel in some types of building structures. These advantages are provided by the physical properties of aluminum alloys, as well as the production process of aluminum products, primarily aluminum extrusion.

When searching for areas of application of aluminum in construction, the following features of the properties of aluminum alloys as structural materials should be taken into account [1]:

1) Aluminum alloys represent a large family of structural materials. The strength properties of some of them are comparable to the mechanical properties of low-carbon steels. See more details Construction aluminum alloys.

2) The elastic modulus of aluminum and its alloys is approximately three times less than that of steels (Figure 1).

3) Immediately after the elastic section of the tensile curve, aluminum alloys have a strain-hardening section without a yield plateau (unlike steels) (Figure 1).

4) The relative tensile elongation of aluminum alloys ranges from 8 to 12%, which is lower than that of carbon steels (above 20%) (Figure 1).

5) Due to the low modulus of elasticity, elements made of aluminum alloys are less resistant to compressive loads than steel ones.

6) Structures made of aluminum alloys are more sensitive to temperature changes than steel ones, since the coefficient of thermal expansion of aluminum is approximately twice as high as that of steel.

7) Residual stresses that arise as a result of thermal deformations are 30% lower than in steel structures. This is because these residual stresses are proportional to the product of the coefficient of thermal expansion and the elastic modulus (α E).

The corrosion resistance of many aluminum alloys makes it possible to use them without additional corrosion protection, even in aggressive environments. See more Corrosion of building aluminum

The corrosion resistance of many aluminum alloys makes it possible to use them without additional corrosion protection, even in aggressive environments. See more Corrosion of building aluminum

9) The low weight of aluminum alloys provides advantages in reducing the weight of structures compared to steel. The extent of this benefit is reduced in part by the need to compensate for the lower elastic modulus of aluminum.

10) Aluminum itself is not prone to brittle fracture, however, for aluminum structures in general, this problem needs to be given special attention.

11) The aluminum extrusion process makes it possible to produce profiles with a cross section that provides them with maximum rigidity and functionality (Figure 2).

12) For fastening aluminum elements, bolted and riveted connections, as well as welding, are used.

Figure 1 - Comparison of typical tensile curves of aluminum alloys and low-carbon steels [1].

Figure 2 - Typical extruded aluminum profiles [1]

Why you can’t store food in aluminum containers

Discussions about the use of utensils made of this metal continue to this day. As many years of experience tell us, cooking is one thing, but storing food is another. During long-term storage, a reaction may begin between the products and metal compounds will penetrate into them. Of course, if you strictly follow the procedure for using the utensils, the risk is minimized, but how often do we follow the rules?

Why you can’t pick berries in aluminum dishes

When picking berries, it is advisable to use enamel-coated dishes. During the picking of berries, the latter release juice, which contains a certain amount of acid. It has a destructive effect on the oxide film covering the metal surface.

When picking berries, it is advisable to use enamel-coated dishes.

Why you can’t store alkaline and acidic solutions

Precisely because alkalis and acids have a destructive effect on the protective film, such products should not be stored in aluminum containers.

After cooking the cabbage soup, it makes sense to immediately pour it into an enamel bowl.

How to care for aluminum cookware

The main thing you should not do is wash aluminum cookware using cleaning products that contain abrasives. It is also unacceptable to use chemically active substances.

The main thing that is unacceptable is to wash aluminum cookware using cleaning products that contain abrasive substances.

So, we figured out the pros and cons of such a material for cookware as aluminum. If you follow the above recommendations, aluminum cookware will serve you well.