The toilet is an integral part of the plumbing unit. Today it is an indispensable element in every home and apartment.

However, there are times when inconvenience may arise due to its incorrect functioning. The reason for possible unsatisfactory operation of the device is most often precisely problems with adjusting the float, which is located in the drain tank. There are several options here.

For example, there may simply not be enough water entering the tank to perform a proper flush, or, on the contrary, an excessive amount will accumulate. Therefore, it is worth considering the question of how to properly configure the operation of such an element.

- 2 Float adjustment

- 3 Water leaks into the toilet itself

Purpose and principle of operation of the float

A float is a hollow ball or cylinder, most often made of plastic, with air inside. The float does not sink, it constantly lies on the water. Following fluctuations in the liquid level, it can rise or fall, depending on the degree of filling of the tank.

When you press the flush button, water begins to flow into the toilet bowl. Following a decrease in its level, the float lowers. The rod associated with it transmits force to the valve. When a predetermined value is reached, the valve opens and water begins to flow into the tank.

Then the reverse process occurs. The water level begins to rise, and when the required value is reached, the valve closes automatically. Most cistern problems are caused by incorrect adjustment or errors during installation of this simple and cheap part.

How to adjust the cistern

We successfully assembled and installed the toilet. Today is an equally interesting and useful article - we will regulate the toilet cistern. This article will be useful to those who have a toilet with a button on top, the so-called modern toilets...

Why is adjustment needed?

It's simple - sometimes the toilet pours too much water, which means that your money is simply poured down the drain, because almost all of us have water meters. And the less we pour it, the more money we save. However, there is another side, when the tank does not wash away human waste well, the pressure is poor - weak and therefore you cannot wash anything away with it! Here you also need to adjust the toilet cistern.

Types of devices

With all the variety of flush tanks, there are only two main types of floats. You can find a ball or glass in the toilet cistern. The mechanisms differ markedly from each other, each of them has its own characteristics and scope of application.

Long pull ball

The system has been in use for many decades; it was the one that was implemented in the familiar Soviet cistern. It used a float with a long rod, often passing through the entire tank, as a device for regulating the water supply. Water supply was carried out according to a lateral scheme.

Comment! The ball is a convention. Depending on the model, the floats could be spherical, oval, have a shape close to a cube, or any volumetric part.

A float on a pull rod is practically not used nowadays; it can only be installed in antique designer models, sometimes in public places where a simple and cheap solution is required. Despite its irrelevance, the design has a number of advantages:

- easy to install;

- easy to adjust the float in the toilet tank;

- cheap to repair.

Plus, the cost of components is low; most problems can be solved by replacing the plastic float and adjusting the draft. The models have a number of significant disadvantages. The system is not suitable for compact tanks; it is difficult to fit a long rod into a small housing. It makes noise when draining, and malfunctions are common.

Cup

Almost all modern toilet models are equipped with glass-type floats. The system does not have a long rod, and the float is a cylinder that moves vertically along guides, thereby controlling the valve. The solution has the following advantages:

- minimum dimensions;

- fast and accurate operation;

- low noise level;

- wide selection of models.

The systems allow for efficient use of water, as they are designed for tanks with two flush buttons. This allows you to empty the tank completely or drain only some of it.

Floats are more difficult to install; often you have to completely remove the tank to do this; in addition, they are distinguished by a complex adjustment process, but this is guaranteed to pay off in ease of use and water savings.

Installation instructions

Like any plumbing fixture, the tank drain system fails over time. Often the cause is a float. Many people call a professional, which is reasonable, but you can do the replacement yourself. The operating algorithm directly depends on the type of device.

For models with traction

Changing the float valve for a toilet is not difficult; you don’t even have to dismantle the tank, but you need to start by deciding what exactly needs to be replaced. Plastic floats, floats with a rod, or a complete set of parts (float, rod and valve) are sold separately. Most often, the entire mechanism is replaced. It is inexpensive, repairs are not difficult, but the result is an almost new drainage system.

The operating algorithm is simple:

- turn off the water in the riser;

- empty the tank;

- disconnect the water supply;

- dismantle the old valve with float;

- clean the seat and install a replacement.

The supply hose is connected last. The work of installing the float is almost finished, but before starting operation it is necessary to turn on the water and carefully inspect the connection points and attachment points of the tank. If water does not flow out, all that remains is to adjust the valve and the repair is complete.

For glass-type floats

Installing floats of this type is a more labor-intensive process. The main difficulty is that it is easier to install the float before installing the tank itself. To avoid mistakes before starting work, it is important to read the manufacturer's instructions and follow their instructions.

Often during repairs, not only the float mechanism and fill valve are changed, but also the drainage system. This is a smart approach because you won't have to re-disassemble and reassemble the tank if you need to replace the drain valve.

In general, the work is performed according to the algorithm:

- Installation of a drain mechanism with large dimensions. Be sure to use the supplied seals and gaskets during installation. The mechanism is aligned along the axis of the tank and clamped from below with a nut.

- A filling valve with a float is being installed. It should be positioned vertically and not come into contact with the parts of the drain mechanism.

- Assembling the tank and installing it on the toilet.

Important! When working with the elements of the float mechanism, we must not forget that most of them are made of plastic. You need to unscrew and tighten threaded connections with all possible care, avoiding excessive pressure.

Main types of drainage equipment designs

First of all, they depend on the type of filling and drainage mechanisms. The water drainage functions are performed by lever, push-button and automatic products.

Lever

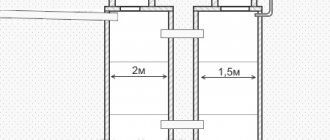

The float (1) controls the inlet valve (3) through the lever (2). The water level depends on the adjustment of the float lever on the valve lever (4). The water pressure during filling is adjusted at the valve using a set screw.

Lever models were the main models installed on toilets of the last century. They are still used in some places today. Lever devices are distinguished by their simplicity. The first products drained only at the moment of pressing, while the shut-off valve was manually held (by the “pull” - a chain or fishing line). Then came systems that use the siphon effect, which themselves control the flow after activation. But both the first and subsequent models are characterized by increased unregulated water consumption. In addition, such plumbing does not meet current aesthetic requirements.

Push-button

The toilet flush mechanism, made in a push-button version, is installed on most modern plumbing products. The predominant location of the button is at the top, on the covers of compact systems, and can also be on the wall for products installed in building structures. Their advantages, in addition to good aesthetics, lie in the ability to adjust the drain and overflow parameters. Push-button mechanisms also, once activated, hold the shut-off valve open without human intervention. And models with paired buttons allow full or partial discharge of liquid into the toilet.

Automatic

Today, there are rare and expensive products for draining water, which justify themselves when installed in luxury products or used in public places. Their work is controlled by infrared sensors.

Shut-off valves for the toilet, represented by filling mechanisms, work, as many years ago, using the principle of a refill valve, opened and closed by a float. In the classic version, the float transmits force to the valve of a faucet with a side connection through a horizontal rocker arm.

Floats that shut off the water supply through a system of levers.

However, now more often floats are installed that move along a vertical guide, cutting off the water supply through a system of levers for both the side supply and the bottom.

Important! Modern filling valves, due to their design features, allow you to collect water much faster than systems with a rocker arm.

DIY adjustment

Regardless of the type of float used, it must be reset after replacement or installation. It is not difficult to adjust the water level in a toilet cistern with a button or an outdated design with a long pull, but the work will require perseverance and a responsible approach. We must not forget that incorrect adjustment will lead to irrational water consumption, and sometimes contribute to an accident.

Ball-shaped models

To adjust the ball-type float, you do not need to drain or shut off the water. To do this, just remove the tank cap and bend the rod with your hands. By moving the float, you need to ensure that the valve opens and closes at the required liquid level. The method is only suitable for models in which the ball is attached to a flexible metal rod.

You can often find mechanisms in which the thrust is two rigid plates made of plastic or metal. You can't count on strength here - you can break it. Models must have a fixing screw with a wing nut. You need to loosen it, select the desired angle and tighten it again.

After adjustment, all that remains is to drain the water and refill the tank; if necessary, repeat the adjustment.

Glass type floats

The task of adjusting the glass is to raise it or lower it along the guide to the required height. In expensive models from famous manufacturers, a scale is applied to the slider, which allows you to determine the level before installation begins. If there is no scale, you will have to experiment.

The adjustment technology directly depends on the specific model. To adjust the water level in the flush tanks of toilets with bottom connections, you need to drain the water, inspect the float, find the adjusting screw on it and, turning it, select the optimal filling level of the tank.

Toilet float: device, adjustment, malfunctions, replacement

One of the most important sanitary facilities in every home or apartment is, of course, the toilet. Currently, no restroom can do without this product. However, repeated use of the device during the day contributes to the occurrence of minor problems in the drain mechanism.

Problems with the toilet tank are often associated with the displacement of the float valve, which regulates the flow of water into the bowl, and this, in turn, leads to unwanted leakage. At the same time, it is quite possible to eliminate the accident and organize the operation of the flushing mechanism independently.

The device of the flush tank Adjusting the toilet float Malfunctions of the flush device and their elimination

Tank drain device

Regardless of the toilet model, it consists of a ceramic bowl, which is fixed to the wall or floor, and a water tank located slightly above it. The drain tank has an internal device that controls the processes of filling and flushing water, and also regulates its maximum permissible level in the system.

The toilet flush tank consists of two main mechanisms - filling and draining.

Let's look at each of them in more detail.

- Filler . This device controls the water filling level to a “critical” specified level. Auxiliary elements of filling plumbing are a shut-off valve and a float on a plastic or metal lever.

- Descent . The main purpose of such a mechanism is to drain water into a ceramic bowl. The principle of operation of the device is as follows: when you lift the drain siphon using the handle, the resource is instantly supplied to the bowl of the device.

Currently, flush cisterns are produced in two types: with manual drainage and automated. In the first case, the resource is supplied after acting on the drain lever, and in the second, the liquid is supplied automatically at specified time intervals.

For home conditions, as a rule, the best option is to use the first type of plumbing fixture. At the same time, budget models of these devices are often equipped with a side water supply, while imported ones are equipped with a bottom one.

Tank drain device

Adjusting the toilet float

Displacement of the float mechanism, as a rule, leads to tank leaks. In order to eliminate this problem, the drainage system is adjusted.

Adjustment of the internal structure of the toilet is carried out in the following sequence.

- Changing the float thrust . The device is a metal rod that holds the entire mechanism. To lower the water level, the float is lowered down; to increase it, it is raised up.

- Adjusting the tap . After filling the container to the required level, secure the float coupling in a lower position. To do this, compress the spring clip, and then find the correct location of the fittings on the valve post.

One of the reasons for appliance leaks is the use of an inappropriate float element.

Remember, the choice of flush mechanism for the toilet should be made in accordance with the specified water pressure parameters in the system.

The following types of float valves exist:

- designed for strong water pressure;

- operating at medium pressure in the pipe;

- effective in case of weak indicators in the system.

It is worth noting that owners of private houses and apartments who live in areas with unstable pressure in the water supply network should prefer installing a stabilizing float valve.

Exhaust Valve Height Setting Table

Malfunctions of the drainage device and their elimination

Before starting repair work on sanitary equipment, you should carefully lift the lid of the toilet flush cistern and unscrew the button that regulates the drainage of water into the bowl.

The process of troubleshooting directly depends on the nature of the design fault.

The most common problem is the overflow of the flush tank with water and its subsequent leakage through the drain pipe of the structure.

The float, as a rule, begins to leak liquid for the following reasons:

- element misalignment;

- membrane wear;

- hole in the structure.

To eliminate the skew of the float, adjust the toilet flush device. However, if it was not possible to eliminate the problem using this method, it is necessary to proceed to checking the functionality of other components of the structure.

One of the most common causes of ineffective float operation is damage or wear to the diaphragm in the valve.

The seal is replaced in the following order:

- shut off the water supply to the tank;

- disassemble the valve and remove the stem;

- remove the worn membrane;

- install a new gasket into the rod.

Remember, it is quite possible to replace an old seal with a new one made of hard rubber.

If the float valve breaks down, it must be replaced.

The process for installing a new float is as follows:

- remove water from the flush tank;

- unscrew the fitting that connects the water supply to the valve;

- carefully disconnect the float lever;

- unscrew the outer and inner nuts securing the handle;

- remove the old float valve;

- install a new element;

- attach the float lever to the valve;

- fill the toilet tank with water;

- fix the float lever in the desired position;

- check the functionality of the element.

Remember, during the process of filling a ceramic container, a damaged float, as a rule, becomes heavier and sinks to the bottom.

Thus, the flushing device is an important component of the overall design of the plumbing fixture. The functioning of the mechanism is based on the principle of a water seal, which often causes various problems to appear in the descent system.

Knowledge of the structure of the toilet cistern, the operating principle of its mechanisms, as well as the main causes of malfunctions contributes to successful independent troubleshooting in the shortest possible time.

At the same time, the main criterion for effective repair of a device is compliance with the technology for performing restoration work. This approach will guarantee the long-term functioning of all elements of sanitary installations in the room.

Source: https://vodaidom.com/poplavok-dlya-unitaza-ustrojstvo-regulirovka-neispravnosti-zamena/

Common breakdowns

Often the cause of malfunctions in the toilet is the float valve; sometimes, to correct the situation, you will need to replace the float in the toilet; in some cases, it is enough to adjust it correctly.

The symptoms of these malfunctions are as follows:

- constant noise;

- the tank does not fill;

- water leaks.

Important! If the cistern is not working properly, immediate action must be taken. If difficulties with collecting water are just discomfort, then the constant operation of the overflow will ultimately cause an accident.

Water discharge does not stop

If you constantly hear the sound of water in the tank, and excess water is drained into the toilet, the inlet valve does not shut off the water. There are several reasons:

- damage to the integrity of the float (water got inside);

- incorrect adjustment of rods;

- valve clogged or damaged.

You should start by checking the float. Often, thin plastic of poor quality is used to make it. During operation, the seal may become compromised and water may seep into the hole. This will shift the alignment, causing the lever to drop below the design level, preventing the valve from operating.

A damaged float must be replaced. If the hole is small, you can seal it, but this is a temporary solution. The problem is more typical for traction models, and the cost of the part is extremely low, it’s hardly worth saving on it.

If the glass floats, you need to drain the water and carefully inspect the mechanism, try with your hand how easily the float moves. There may be threads wrapped around the slider or a foreign object that is preventing normal movement. If everything is fine, but the valve does not work, the only correct solution is to replace the entire mechanism.

No water coming in

The second most common malfunction of the float valve is blocking the water supply to the tank. It occurs either when the inlet valve is dirty (clogged) or when the float is stuck in the upper position.

Advice! Before you begin disassembling and repairing the tank mechanism, you need to make sure that there is water in the supply pipeline. Perhaps the cause of the malfunction lies in a damaged hose or a simple lack of water in the system.

The first thing to do is remove the tank cap. If the float on the rod simply hangs in the air, this is the reason. It is worth immediately inspecting the mechanism, checking what is preventing it from moving, and bending the rod if necessary. Perhaps this is not the reason, but rather the deposits that have covered the axle, it is worth trying to clean it; you may have to change the float complete with the valve.

The problem can also occur with modern glasses. It is necessary to check the ease of movement of the mechanism, clean the guides, and the valve may have to be replaced.

Another common problem with floats is misalignment of the device. The fact is that the element moves in a vertical plane, and if it is skewed, the guide slows it down. The slightest contamination is enough for it to begin to jam, as a result of which any of the listed problems is possible.

What is a float

Float is a valve responsible for water supply. It consists of a housing with a membrane and the float itself.

Water is supplied from the plumbing system by a float equipped with an adjusting screw. Rotating in different directions, the screw lowers or raises the float, that is, the water level increases or decreases. In cheap tanks, a rail is installed instead of a screw.

In some toilet models, the float inside is hollow and filled with air, while in others it is made in the form of an inverted glass . The main breakdowns are:

Hollow float. Stops working if water gets inside. It simply sinks, so it cannot be repaired. Will have to replace it.

An inverted glass . Does not perform its functions after heavy contamination, for example, limescale.