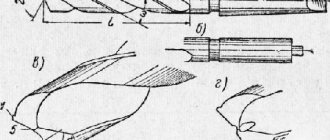

Countersinking: tools and features Countersinking is an intermediate process for processing holes, usually located

Composition of the dye Silver enamel is not the kind of paint with silver ions that should

Characteristics and features of lubricants for angle grinders When servicing any hand tool with moving parts

29Jan By: Semantics Uncategorized Comment: 0 When manufacturing metal at an enterprise, classification is used

Types of deformation Deformation is a change in the shape or size of the body. There are several types of deformation:

Why do you need a compressor receiver? In addition to air accumulation, the receiver, included in the pneumatic line with the compressor,

The surface of the finished part is not always perfectly flat, smooth and geometrically correct. She's like that

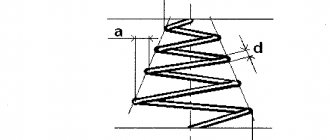

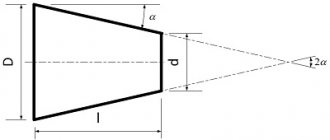

Calculator and formula for calculating the taper of a part. Taper can be defined as the ratio of the difference

Welding is always associated with various kinds of dangers: from the possibility of fire to physical injury.