08Dec

- By: Semantics

- Uncategorized

- Comments: 0

A variety of devices are used today for processing workpieces. Let us pay attention to perhaps the most popular of them - metal cutting devices: we will consider in detail the characteristics by which they are divided, and the scope of application of each of them, design features and main operating parameters. There are so many nuances - so that you understand which one to choose and use in each specific situation.

Separately, we note that they are not only still relevant, but they also remain promising. It is mechanical technology that remains in demand, largely due to its availability. The moment of unification also plays a role: the same drills and cutters are often suitable for entire series of machines and, with all their compatibility, can provide highly accurate results.

Classification of metal-cutting tools

There are a number of key parameters - let's take a look at each.

Based on the nature of processing (action), they are divided into:

- blade - cut off excess material;

- abrasive - abrade the surface, bringing it to the desired geometry by grinding.

By design they can be:

- solid - completely made from one piece;

- composite - made of several parts, all connections of which are permanent;

- prefabricated - their elements are fastened so that they are easy to separate if necessary.

According to the mounting option, there are top-mounted and tail-mounted ones. There are also options for drives (manual, machine or combined) and shape (plate, cylindrical, disk, conical), and each of them is in demand in its niche.

Main types of metal-cutting tools

Depending on the purpose, the operations carried out with their help and the features of their execution, all devices are divided into a number of groups. Let's look at each one, paying attention to the key points.

Incisors

There is a wide range of sizes, but each of them is single-edged and designed for processing all kinds of rotating bodies. And they all have the following configuration nuances:

- made with a holder and a working part;

- made of alloys that determine a specific material, and therefore the scope of their application;

- with a specific sharpening angle depending on the use cases.

They are also divided according to purpose - into the following options:

- cutting - for separating (some portion of the workpiece from the whole) at an angle of 90 0;

- through - straight, bent, persistent - for chamfering, including perpendicular to the axis of rotation;

- threaded - for creating turns from the inside or outside of parts;

- Boring – designed to expand blind or through holes.

In terms of their design, they can be either solid or prefabricated - with replaceable plates, providing versatility (but, unfortunately, reducing overall reliability and durability).

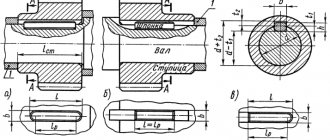

Depending on the side of fastening on the holder, cutters for lathes are divided into right and left. It’s quite easy to check which one you got. You just need to place the palm of the corresponding hand on it, with your fingers towards the top. The directions of the large and main edges should match - look at the diagram below:

Milling cutters

These are almost the most popular multi-blade cutting tools in mechanical engineering, made in the form of bodies of revolution and equipped with teeth on the working surfaces. Attention, they remove material from a fixed product. The design is more complex than the representatives of the previous group, therefore they are more expensive.

They are used to solve a wide range of problems: to give the desired geometry to the side and end planes (external), to bore holes to the required diameter, to make relatively complex shaped contours from a simple (rectangular) workpiece.

They are divided into groups according to several indicators:

- by the location of the teeth;

- according to the specifics of the edge;

- on the operations performed;

- on fastening nozzles;

- according to the material of manufacture.

The modern classification of cutting tools is very wide and varied, so we will focus on the most popular and in demand types of cutters. Using their example, one can form a correct impression of other similar devices. So, the most relevant are the following models:

End ones - needed to create contour recesses, ledges, deep grooves, smooth transitions when forming complex reliefs of body parts. They are similar in appearance to drills, but without edges at the bottom, and are often made with a conical shank, which ensures fastening rigidity.

Cylindrical - made like bushings with technological holes and grooves, due to which they are mounted on a mandrel. They have several blades at once, located along the axis, with an angle. They are used for high-precision grinding of individual sections of the workpiece; they can also be used for turning (if angular heads are installed on the spindle).

Disk - their shape is clear from the name; they are quite thin and act perpendicular to the direction of movement of the part, which allows making cuts from 1 mm. Based on the type of plates, these cutting tools for metal processing are divided into slotted, semicircular, three-sided, and modular.

Face - their edges are located at the bottom of the body, and this configuration allows you to maintain a high speed of turning the plane (the fixing table moves longitudinally); as a result, labor productivity is several times higher than with planing. They also have a cylindrical body, with a chuck, a shank and a key that transmits torque.

Worm - with shaped blades, sharpened in a reverse involute and located at a certain slope (depending on the area of application). Relevant for creating teeth on wheels, gears, and shafts. They operate on the rolling-in principle, when the workpiece is rotated with a fixed displacement step.

Corner and end - part of them is a truncated cone, and this shape allows you to quickly trim flat parts along the edge, providing a flat and smooth surface.

Saws - exclusively for cutting operations, for which their teeth are made sharp, often the same thickness as the body (in this case, they are made without transition). Attached using a groove connection. They are distinguished by economical cutting, especially in demand when processing shafts and technological profits.

Shaped - needed to give workpieces a complex and predetermined configuration (the geometry of their surface will be the opposite of the edge). Outwardly they look like files secured in cartridges by shanks.

Keyed - special, disk and finger at the same time, first acting like a drill, then with vertical working. Necessary for creating grooves.

Drills, countersinks, countersinks and reamers

The first devices of this group are well known to any person who has ever needed to make a hole in a hard surface. They are axial, they bite into the part due to the rotational movement, while the chips are removed along the helical grooves.

They differ from each other in such indicators as:

- execution material;

- shank;

- diameter (size);

- sharpening angle of the main edge.

The next popular cutting tool is a countersink, used either to widen a hole (increase the diameter) or to adjust it (increase accuracy). The conical entrance areas of the bolt seat are also machined using a special device called a countersink. Well, the roughness is reduced by a sweep - it won’t be difficult to bring the plane to the desired level of smoothness.

Broaches and firmware

The first ones have several blades at once, arranged sequentially and so that each new one protrudes above the previous one. This configuration makes it possible to remove material from the workpiece both in rotational and translational motion, and in static mode - at an angle of 90 0 to the feed direction.

They are considered professional equipment and are relatively expensive, but they have a number of advantages:

- the durability resource is high, and this is the key to low operating costs;

- During the work process, several teeth are involved at once, which allows you to increase the allowance and is a guarantee of impressive productivity;

- accuracy level – up to 6th grade inclusive;

- with their help you can effectively remove defects.

Firmware is a modern machine cutting tool that allows you to quickly make four- and hexagonal, slotted, TORX R and other holes.

If it is designed as a head, it is compatible with turning, milling, and CNC equipment, and is effective for both horizontal and vertical passes. Its supporting shaft is mounted at a given angle on ball bearings, so it successfully withstands even heavy loads. Deepening into the workpiece material occurs smoothly, so the required profile of the seat is created with high precision.

If it is aimed at creating internal holes, it is a rod with a cylindrical shank and a guide of the required cross-section. If it is used to pierce external seats, it has the opposite configuration - the desired profile is knocked out inside the disk, which is reproduced upon contact with the part.

The size range includes 7 positions, marked with the Latin letter G (from G5 to G25).

Gear cutting and grinding tools

Already from the name of the first it is clear why it is needed - to create clutch elements on splined rollers, ratchet and worm wheels and other similar parts. And its range is quite wide – it includes:

- finger and disk cutters – operate modularly;

- heads - form all the cavities simultaneously by copying (in several passes);

- combs - straight and helical, serve as planing incisors;

- cutters - wheels with edges that allow external/internal gearing.

This group also includes devices that work using the rolling method, that is, so that the edges, as a result of sliding, consistently create a surface of the required geometry.

Threading type cutting tool

It also has a “telling” name - it is needed to form helical lines of various sizes and patterns, which allow for a reliable connection. It boasts a wide range of products, including:

- heads, vortex or self-opening, made according to GOST 21760-76;

- tangential combs;

- lerks (dies);

- cutters, disk, end and others;

- taps, including nut and automatic taps, complying with interstate standards 1604-71, 3266-81, 6951-71, 8859-74.

These devices allow you to apply metric, inch, tapered, pipe cylindrical, left-handed and right-handed threads, even in through or blind holes.

Abrasive types

These are all kinds of wheels (grinding, grinding, etc.), cups, attachments used for machining parts.

The main characteristic of a cutting tool of this group is surface hardness, which must be stronger than the workpiece material in order to act on it, and not vice versa. Therefore, it is made from grains of electrocorundum, synthetic and natural diamonds, silicon carbide, randomly combined into bonds (bakelite, silicate, ceramic, magnesia, vulcanite, hyphthalic). Due to this, it acquires the ability to self-sharpen: by chipping and dulling, the upper particles make room for new layers.

All of the listed device options are rigid, but there is also a flexible category, which includes tapes and disks.

Hand-held metal-cutting tool

This is a portable alternative to machine tools - devices that facilitate human labor, and examples include:

- profile or nibblers – used to separate part of rolled sheet metal from the whole workpiece;

- panel cutters – needed for working with sandwich panels, ensuring speed and accuracy of operations;

- folding machines - allow you to automate the process of closing recumbent joints;

- molders – necessary for proper compression of rolled products;

- mobile pliers - very convenient for cold welding, they help to press the elements to be joined with great force.

Machine tool metal cutting

In the class of machine tool metal-cutting tools , depending on the technological purpose, the following groups are distinguished: cutters, cutters and broaches; thread cutting, gear cutting, abrasive, diamond and hole making. Milling cutters are multi-blade rotating tools. The cutters are designed for processing shaped and flat surfaces and for cutting workpieces. Milling cutters are usually used on milling machines. The cutters are designed for boring holes, turning, processing shaped and flat surfaces, cutting grooves. Cutters are used on lathes, turret lathes, boring, planing, and rotary machines. Broaches are a multi-bladed metal-cutting tool. Designed for processing internal and external surfaces, through holes. Used on broaching machines.

Areas of use

We looked at what cutting tools there are, but where and when are they in demand? They are virtually indispensable in all major industries, but they can only be used effectively if certain requirements are met:

- the material they are made must be harder and stronger than the metal they process;

- the workpiece must be securely fastened;

- It is necessary to strictly observe safety precautions and the parts production scheme.

If all these conditions are met, you can count on long-term and cost-effective operation.

Another important niche is small private and home workshops. They require manual devices - all kinds of machines and machines designed for piece operations, at low speeds and with low feeds.

Metal cutting tools - choose the best!

The concept of metal-cutting tools includes all the basic devices and tools for working with metal, which are used both in everyday life and in production. This tool performs many technological operations: drilling, turning, threading, milling and other types of roughing and finishing of products made from a variety of materials.

When choosing the necessary tool (be it a complete set of thread cutting tools or just a tap, drill, die, etc.), special attention should be paid to the material from which the cutting part is made. It is this that affects the reliability and wear resistance of the tool.

Choosing the type of cutting tool for metalworking

To place the correct order, you need:

- Determine what tasks it should solve - with the help of the same cutter you can perform a wide, but still limited range of work; it will not be suitable where a drill is required.

- Take into account which machine it will be installed on - it is simply necessary that it is compatible and can receive and transmit rotation force without unnecessary losses.

- Make sure that he can maintain the required cutting parameters - carry out calculations, draw up a technological map, and compare the passport data (and other indicators) of the devices he likes with it.

- Consider the efficiency of use - all other things being equal, it is better to buy the option whose wear resistance is higher, because it will last longer, this is true even for mass production, under conditions of high loads.

Hand-held metal-cutting tool

The class of hand-held metal-cutting tools includes all metal-cutting tools used without equipment. This class includes files, chisels, needle files, hacksaws and scrapers.

High-quality tools make the work of any master much easier. Naturally, the price of cheap Chinese instruments is much lower than German or Russian ones, but their quality noticeably suffers. Therefore, when choosing a tool, you need to ask yourself the question - how often and for how long will I use this tool? And if you need a tool to perform just one minor home repair, then, of course, you should save money. Otherwise, your choice should be a Russian or German instrument. It costs more, but it will also last longer.