Septic tanks and aeration tanks (biological treatment stations) are local structures designed for wastewater treatment using biological treatment technology. Both options involve the processing of organic waste by microorganisms. The latter oxidize and decompose complex organic matter into simple substances. Insoluble sediment and mechanical impurities are separated.

It is easier to understand the difference between a septic tank and a biological treatment station if you learn more about the design features and purpose of each system.

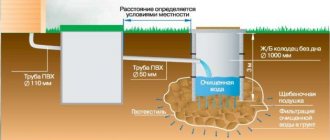

- Septic tanks are easy-to-use, simple structures in the form of tanks connected by overflow holes. The energy-independent system provides mechanical wastewater treatment. After the wastewater is clarified, it goes into the soil, where further treatment occurs - the organic matter is completely decomposed.

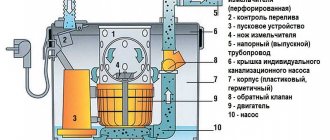

- The treatment station is a plastic container with several chambers, a compressor and automation responsible for processing wastewater. Bacteria need to create optimal conditions - regularly saturate the drains with oxygen. Energy-dependent stations are divided into full-cycle installations (Astra, Topas, Biodeka) and bioseptics (Eurolos BIO, Garda, Kolo Vesi).

- The aeration station consists of several compartments with aerators. Organics decompose in each independent compartment. Wastewater is moved by airlifts using an air compressor.

- Bioseptics provide for the settling of sludge in the receiving chamber. Pumps move the effluent through the diffuser to the bio-loading facility, where oxygenation occurs and attached bacteria purify the effluent. The next step is to return the liquid to the receiving chamber. This recirculation process through a biofilter allows wastewater to be effectively treated.

The principle of operation of septic structures

A septic tank is a structure designed to treat wastewater. The design of its device assumes the presence of a multi-chamber system. Wastewater flows into the first tank through a pipeline from the house. This is a septic tank. It undergoes bacterial decomposition of wastewater. In some devices, most often industrial ones, special structures are installed here that perform primary filtration of contaminated water. Decomposition of wastewater occurs under the influence of oxygen-free or anaerobic bacteria. They convert the liquid entering the settling tank into clarified water, gas and mineral insoluble sediment or sludge.

All anaerobic septic tanks consist of several chambers. In the first, primary wastewater treatment and partial filtration occur. In the second and subsequent stages, the purification process continues.

The gas formed as a result of the decomposition of wastewater is removed using a ventilation pipe, while the water goes through the overflow hole into the second tank. Here, anaerobic bacteria continue to clean the wastewater. From here, clarified water can flow into the next container or be supplied to the so-called filtration fields. After soil filtration, clean liquid is absorbed into the soil. Such structures are classified as energy-independent or anaerobic systems.

There is also a type of device that requires electricity to operate. These are aerobic septic tanks with a biological treatment system. Wastewater treatment in such devices is carried out by aerobic microorganisms that cannot exist without oxygen. Therefore, the compressor, which automatically turns on at certain intervals, supplies air inside the tanks. The process of wastewater decomposition in such installations occurs as quickly as possible. The degree of purification of contaminated water reaches 98%.

For an aerobic septic tank to operate, a constant flow of oxygen is required, since the bacteria contained in the activated sludge die without it, and the cleaning process stops

One of the simplest structures is a storage septic tank. This is a single-chamber sealed device designed to accumulate wastewater, which is subsequently pumped out using a sewage disposal machine. The tank is additionally equipped with a tank filling level sensor. This option is optimal for those who rarely appear in their country house, and also if, for various reasons, it is impossible to equip an effective wastewater treatment area.

Stages of biological treatment and installation of the station

The stages are as follows:

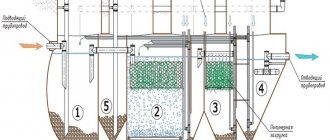

- Wastewater enters the first chamber, where heavier particles settle at the bottom and smaller particles remain at the top. The process of primary oxidation of substances occurs immediately.

- The biomass is sent to the next chamber - the aeration tent. There are beneficial microorganisms that clean the incoming mass and form activated sludge.

- The precipitate that has formed enters the stabilizer. There is also water that was purified in the previous tank, so it flows into the next section for final purification and settling.

- The resulting clean liquid enters the ground.

No special equipment is required to install the station. First you need to dig a pit. The depth is determined depending on the height of groundwater. If they are located high, then there will be a need to install a loading plate, and if the water is low, then the area needs to be compacted well.

Afterwards, the station is placed in a dug pit, covered with sand (in layers) and compacted well. They make inlets and outlets for sewer pipes, install and connect electrical cables. Everything is carefully removed, leaving only the hatch on top of the site.

Septic tanks - operating features

The modern market offers various equipment for creating an autonomous sewer system. It is represented by a variety of models of septic tanks and treatment plants. Which one should you choose? The answer to this question depends on many reasons.

Let's say you decide to go with a septic tank. First, you need to clearly understand that it is most often a plastic container divided into several sectors, each of which has its own purpose. So, the first one is used for collecting and settling wastewater. In this case, the more solid components settle to the bottom, and the liquid flows into the chamber for further purification.

Here, further decomposition of the wastewater occurs and again the more liquid part flows into the third compartment, and large fractions settle to the bottom. In the last tank, water is purified and discharged to the filtration fields. This is the operating principle of the simplest septic tank.

types of septic tanks

There are many different types of such structures. They are divided according to the following criteria:

- Material (plastic, fiberglass, metal, concrete)

- Installation method (recessed, surface)

- Processing method (with biological or mechanical treatment)

As you can see, the choice is quite wide, which allows everyone to choose a sample in accordance with certain requirements. But all types of septic tanks, even deep biological treatment, have one drawback. No matter how modern they are, you will still have to pump out the solid mass from them. Even if not as often as from a cesspool, but it is necessary.

Popular models and how to choose

Construction of the autonomous station “Eurobion”.

Unilos Astra, compared to other brands, does not require special attention during operation. You can check the installation and wash it 2-3 times a year.

Sizes may vary depending on performance. The body contains polypropylene, which is a durable and environmentally friendly material. There are “stiffening ribs” installed on the sides, which provide additional resistance to loads.

The housing itself contains 4 compartments inside: a receiver, an aerotank, a secondary settling tank (for sludge separation) and a final settling tank (for clean water separation).

“Topas” is also a compact wastewater treatment plant for a summer residence. Consists of polypropylene. Inside, the body is divided into separate compartments by partitions. The station has additional installations in the form of a pump and compressor, which provide high-quality water purification.

The stand-alone model is easy to maintain, reliable and does not require much space for installation. There are many brands that are designed for different numbers of people living in the house. As a standard, the maximum number of people that can service the equipment is written next to the name (for example, “Topas-5” for a house where 4 or 5 people permanently live).

The treatment station for a private house “Topol” was developed jointly by Germany and Russia. The body is durable, made of three-layer homogeneous polypropylene. On the sides, as in the Unilos station, there are stiffening ribs. The material insulates heat well, which is why it can be used all year round without additional insulation.

“Eurobion” is a new model for a country house, so it has practically no disadvantages. There are also stiffening ribs. Compared to other stations, the presence of electronics is kept to a minimum. All electrical appliances are located in a special separate compartment. The station itself is small and light and requires maintenance every six months.

According to user reviews, the Eurobion biorefinery station works properly. There is no unpleasant odor, the water after purification is crystal clear. Maintenance of the device is simple using a drain pump. The disadvantage is that after a break the station takes a long time to start up.

Most users respond well to all models. Each of them has both advantages and disadvantages that are easy to deal with.

What is a septic tank?

A septic tank is usually called a system of overflow wells in which wastewater settles and organic sediment is subjected to biological fermentation without access to oxygen.

Advice! Settling wells can be located separately or placed in a single housing. The second option is used more often today, as it is more compact.

The quality of water purification in septic tanks is low. In conventional settling tanks, the percentage of contaminant extraction is 50-60%. In modern anaerobic plants, the purification level can reach 75-85%.

However, even improved quality of treatment is not enough to allow water to be discharged without additional treatment. Therefore, septic tanks are always installed in conjunction with post-treatment plants, most often these are:

- filter wells;

- irrigation domes;

- filter fields, etc.

Advantages

Despite the low quality of treatment and the need for additional treatment of wastewater, septic tanks have a number of undeniable advantages. This:

- Autonomy. No power supply is required to operate the septic tank; the station operates in autonomous mode.

- Easy installation. The installation of ready-made septic tanks, as well as the construction of homemade tanks, can be done independently;

- Variety of options. Septic tanks are produced in different capacities; you can choose a mini-model, which is designed for cottages or baths, but there are also quite productive models that can serve a large house.

- Resistance to peak loads. In most cases, in residential buildings, sewage flows are formed unevenly. The peak load occurs in the evening, a large amount of wastewater is generated in the morning, and at night and during the day, wastewater may not flow for several hours. Septic tanks cope well with this mode of operation.

- Affordable price. Ready-made models have an affordable price. And if you wish, you can build a treatment facility almost free of charge, using waste material such as worn-out car tires.

Advice! Such primitive septic tanks, such as a septic tank made from tires or old barrels, can be used only with a very small amount of waste. Such primitive designs cannot provide a sufficient level of water purification.

Minuses

Such treatment plants also have disadvantages, in addition to the already mentioned insufficiently high level of purification. This:

- Long processing cycle. The main cleaning method in such installations is sedimentation. In order for the liquid to settle well, it must be inside the unit for at least 72 hours. And to ensure that this condition is met, the septic tank capacity must be large enough. Therefore, when there is a large amount of wastewater, the installation of septic tanks of impressive size is required.

- The need to build post-treatment plants. These are additional costs and additional space that the installation will occupy. In addition, under difficult geological conditions at the construction site, it is necessary to use schemes that include drainage sediments, which deprives the septic tank of one of its main advantages - autonomy.

- The need for cleaning using special equipment. Septic tanks are cleaned of accumulated sediments using a vacuum truck. This is due to the fact that the sediment must not only be pumped out, but also safely disposed of.

- Presence of odor. During the process of anaerobic fermentation, unpleasant-smelling gases (methane, hydrogen sulfide, etc.) are released, so a characteristic odor emanates from the septic tank.

Multiplast septic tanks Termit

Production technologies and range

The equipment is represented by 2 main product lines:

- settling tanks.

Produced under the Termite brand. Includes several modifications: Pro – 2- and 3-chamber septic tanks for dachas with low groundwater level; Transformer - the same as Pro, but with one neck (more rigid design); Transformer PR is a modification with a pump for forced pumping of treated wastewater at high groundwater levels. There are also storage models with a capacity of up to 5.5 cubic meters; - biological treatment stations.

Produced under the Ergobox brand. They are modifications of Transformer (PR) models in which a compressor and aerators are installed.

All these products are made using rotational molding from Korean-made HDPE. The result is a durable, seamless structure with developed stiffening ribs. The wall thickness is 20 mm.

Watch a short promotional video about production and work in general.

You will learn how and from what materials cast containers are made and what capacities the enterprise has. Characteristics of popular septic tanks from "Multplast"

| Model | Termite Pro 3.0 | Ergobox 6 S* |

| terms of Use | For a family of up to 6 people at low ground level, when the soil is sand, sandy loam, loam. | For a family of up to 6 people with a low groundwater level, because the gravity version. The type of soil does not matter. |

| Short description | 3-chamber horizontal settling tank for primary treatment under anaerobic conditions. It is necessary to install a filtration field for wastewater treatment. | 3-chamber VOC in horizontal design with a Japanese compressor and a German pump. Discharge of treated wastewater into a ditch, onto the terrain, into the ground. |

| Material | HDPE 20 mm thick | |

| Size, L×W×H or D×L, mm | 2300×1155×1905 | 2000×1000×2100 |

| Electricity consumption, W/h | — | 63 |

| Weight, kg | 165 | 137 |

| price, rub. | 52100 | 73700 |

* S – gravity flow. There is a PR modification with a pump for forced pumping out of treated wastewater. It costs 6 thousand rubles. more expensive than the gravity version.

Video demonstrating the installation process of a Termite septic tank. From a short video you will also learn about what diameter the supply pipe should be, whether it can have 90-degree turns, how and where to discharge the treated wastewater, etc.

Conclusions:

It’s easy to notice the similarity of products from “Multplast” with products like Tank. All the same pronounced stiffening ribs and simple design. Of particular interest may be versions with a compressor - a simple modification gives the design special properties. However, it must be taken into account that a small number of chambers can lead to poor quality of wastewater treatment and, as a consequence, the need to construct a filtration field or well for additional treatment.

How does a septic tank work?

A septic tank of standard design is a rectangular or cylindrical container divided into three chambers. The drain enters the container and flows from chamber to chamber by gravity, and this is probably the main advantage of a septic tank. It does not require electricity for constant operation, except in cases where a biofilter and a well with a pump for forced pumping are installed along with the septic tank.

Construction and operation of a septic tank

In a septic tank, water undergoes mechanical and biological treatment. In the first chamber, which occupies approximately half the volume of the septic tank, mainly mechanical cleaning is carried out - the deposition of sand and large impurities heavier than water. In the second and third chambers, sedimentation of the suspension continues and at the same time intensive bioremediation takes place - the decomposition of complex organic molecules into simpler ones and their absorption by anaerobic bacteria. The degree of water purification at the outlet is approximately 90% from suspended matter and 50-60% from organic substances.

Materials

A septic tank is an underground structure that must be corrosion-resistant, lightweight and at the same time very durable. Concrete, metal, plastic or fiberglass are used to make septic tanks.

Septic tanks made of fiberglass meet all the requirements listed above, so they are the most reliable. The body of such a septic tank is made by machine or manual winding, and the side semicircular parts are cast in a special mold. Some septic tanks have internal stiffeners, and the body is reinforced with fiberglass reinforcement.

The most popular septic tanks today are plastic. They are not as durable as fiberglass septic tanks, but they are less expensive and do a good job of treating wastewater. Septic tanks made of polyethylene, such as Termit and Rostok, are in great demand. In the Rostock septic tank, the second chamber is a built-in filtration system, which eliminates the need to install a separate biofilter. The body of Termit septic tanks has vertical ribs and projections that serve as lugs.

Installation of septic tanks

It is necessary to say about the features of installing septic tanks. The fact is that this is a relatively light device and can simply be squeezed out of the ground by high groundwater. To prevent the septic tank from ending up on the surface in the spring, a concrete slab is installed during its installation. It can be poured at the bottom of the pit and the septic tank is attached to it with metal cables (this is called anchoring). Another option is to pour a slab over the septic tank so that it loads it with its weight and prevents it from moving under strong pressure. A septic tank secured in this way will be firmly held in the ground. You can install a septic tank without a slab, even with high groundwater - in this case it is sprinkled on all sides with a cement-sand mixture (CSM). Dense backfill holds the septic tank well in the ground.

The degree of purification in a septic tank is low and the water coming out of it cannot be discharged directly into a ditch. Therefore, when installing a septic tank, a soil treatment system must be installed. Usually this filtration field is perforated pipes with ventilation, laid in a layer of crushed stone. Another option is to install a drainage well.

Soil purification is often replaced by a biofilter. The biofilter can be built into the septic tank or mounted as a separate unit, as, for example, in Rostock septic tanks. A biofilter is a ventilated container with expanded clay or other loading in which post-treatment occurs. From the biofilter, water can be discharged into a storage well (on clay, loamy soil) or directly into a ditch.

Advantages of septic tanks:

- Simple design, no electrical equipment and no risk of breakdowns.

- They operate autonomously and operate normally during a power outage.

- They do not freeze in winter and do not need preservation.

- They do not require special maintenance, pumping with a sewage disposal machine every 1-2 years.

- Low price.

Disadvantages of septic tanks:

- Medium degree of purification, the output water is cloudy.

- The workmanship is not always good, leaks are possible.

- Additional treatment of wastewater in the soil (filtration field, drainage well) or in a biofilter is required. Installation becomes more expensive, and the area of the entire treatment system is larger.

Topol-ECO treatment facilities Topas

The manufacturer's catalog includes both individual treatment facilities for private homes, as well as complex and specialized solutions for a group of houses, towns and enterprises. There are also other plastic products: cellars, decorative stones, contact tanks, galvanic baths, etc.

Production technologies and range

To assess the scale of production, we recommend that you first look at the “kitchen” from the inside. A 13-minute tour of the plant, from which you will learn about the assembly technologies used and methods for controlling finished products.

The company produces VOCs, which comprise 3 large groups:

- For private houses.

Topbio - non-volatile septic tanks for installation in sandy soils. Topas and Topas-S are stations with two or one compressor, respectively. Topaero - treatment facilities with protection against increased volley discharge of wastewater. - For enterprises and towns.

Topglobal is a complex of equipment with reinforced concrete tanks for cleaning household goods. and industrial wastes. Topaero-M is a set of VOCs with increased total productivity for the treatment of domestic wastewater. Topaero-M/E is an analogue of the previous version for any type of waste. - Specialized stations.

Toplos-FL – for cleaning wastewater from organic matter. Cyclone is a system for post-treatment of household wastewater. Toplos-KM – container-type VOC for household use. drains. Toppolium is a fat separator from wastewater from public catering establishments. Toprein is a stormwater treatment plant.

The presented equipment covers a wide range of performance. The youngest models are designed for 4 people, the oldest – up to 200. The use of active forced aeration guarantees the purification of household waste by 98%. Therefore, the company positions its sewage treatment facilities as treatment facilities that do not require calling a sewer truck.

In most cases, polypropylene sheets with a thickness of 8 to 20 mm are used as the main material.

The rigidity of the structure is achieved by using internal partitions and lattice structures as stiffeners. Characteristics of popular septic tanks from Topol-Eco

| Model* | Topas 4 | Topbio | Topaero 3 |

| terms of Use | For permanent use by a family of up to 4 people on a plot with any ground level and type of soil. | For permanent or seasonal use by a family of 3-6 people on a site with sandy soil and low groundwater level. | Permanent use for large families and guests – up to 15 people in total. Any ground conditions. |

| Short description | System with two compressors for wastewater aeration and deep biological treatment. Effluent can be disposed of in the ground or in a ditch. | A vertical 5-chamber non-volatile septic tank for which a filtration field is required. | Aeration system designed for volley discharge of wastewater up to 1 m3. Wastewater with up to 98% purification is odorless and can be disposed of in a ditch. |

| Material | Polypropylene 12.5 mm for external walls, internal partitions 8 mm thick. | ||

| Size, L×W×H, mm | 950×970×2500 | 1600×1200×3000 | 2400×1200×2500 |

| Electricity consumption, W/h | 42-63 | — | 208 |

| Weight, kg | 215 | 400 | 605 |

| price, rub. | 89900 | 115900 | 218700 |

* you can select a modification with a built-in pump for forced pumping of treated wastewater. Models with higher productivity come with an extended neck for in-depth installation of the station when it is located far from home, as well as reinforced versions for difficult soils.

Watch a short promotional video about Topas systems. It describes their operating principle and installation features on a real site.

Conclusion:

The main part of the products from Topol-Eco, which can be used in a private home or on a summer cottage, are energy-dependent biological treatment stations. They are made using the most advanced technology to date, which is why they are more expensive than conventional septic tanks with a filtration field. But you also need to take into account that such equipment requires qualified maintenance, does not tolerate long-term power outages and is designed for constant use.

Following these recommendations will help you make the right choice:

Number of station users

SNiP 2.04.01-85 determines water consumption per person up to 200 liters per day. The arrival of guests or family celebrations initiates a volley discharge of a large volume of wastewater, so the station must have a sufficient power reserve.

A fiberglass septic tank with a three-day processing time for wastewater with a capacity of at least 3 m3 can cope with servicing the family. Overfilling the internal volume is inevitably accompanied by a deterioration in the quality of cleaning by an average of 50%.

Wastewater disposal technologies

The most common practice is to purify process water by discharging it onto a filtration field or onto a bottom filter of a sewer well. The system has proven itself well on filtering sandy and sandy loam soils.

A sufficiently high level of groundwater or soil with a high clay content is a justified reason for moving wastewater into the central sewer, reservoir or onto the relief surface. The owner of a bioseptic tank can implement any of these options, provided the quality of wastewater treatment is not lower than 97-98%.

A decrease in this indicator by several percent can trigger large-scale penalties and, in some cases, an official ban on the operation of the station.

For temporary storage of treated wastewater, sealed intermediate wells are used: plastic, fiberglass, concrete tanks and other containers that block leakage of the contents into the ground. Wastewater disposal is carried out by removal by sewerage trucks, pumping into a reservoir or relief fold with a drainage pump.

Highly purified industrial water can be used for watering lawn grass, fruit trees and shrubs. If there are undisposed helminth eggs in the wastewater, the permit issued by the sanitary services to discharge the wastewater is revoked.

Depth of maximum soil freezing

For the Moscow region, the average is 1 m 40 cm. Laying a water pipeline above this level can provoke the formation of an ice plug and even extensive depressurization. In difficult situations, the problem is solved by installing detachable heat-insulating casings made of extruded polystyrene foam.

Soil freezing depth (in cm)

Frequency of operation of the sewer system

Light country houses are most often used for Sunday relaxation, which involves visiting the country house approximately once a week. Biological treatment aeration stations can only operate with a constant supply of wastewater.

With a prolonged absence of nutrients, the food supply of processing bacteria is depleted, which negatively affects their life activity. Septic tanks "Unilos" Astra, "Bioxi", "Topas" and their analogues are designed to serve areas with permanent residence.

To maintain the vital activity of activated sludge, it is recommended to periodically dump crushed food waste or cat or dog food into the system. Feeding costs are compensated by maintaining the efficiency of bacteria and quickly reaching the maximum productive operating mode of the station.

Suffice it to recall that after rebooting the septic tank, the functionality of activated sludge is restored over a fairly long period of time.

Station price

Stations of the same design and power are in the same price segment. The cost of the models is determined by the number of compressors, the depth of the supply pipeline, and the plastic or fiberglass material of the housing.

In particular, experts explain the increased cost of the Bioxi station model range by its more efficient performance compared to other brands.

The offered assortment includes more expensive combined septic tanks “Tver”, which combine the performance characteristics of a septic tank and an aeration unit. A design feature of such devices is the presence of an additional chamber for anaerobic wastewater treatment.

Septic tanks of this brand differ from standard biological treatment plants in that they have minimal consequences after long breaks in operation.

Biological treatment station description and operating principle

A deep biological treatment station operates using waste products of microorganisms found in wastewater. The device creates special conditions under which microbes can exist. Air is pumped there, using which bacteria decompose waste. The chambers contain anaerobic and aerobic microorganisms that absorb harmful substances entering the liquid and process them in the process of their life activity.

The device itself is a reservoir, inside of which there are several chambers. Depending on the number of sections, several degrees of cleaning are distinguished.

In the first chamber, large particles settle at the bottom, which leads to water stratification. It is divided into separate factions. Afterwards the precipitate is removed.

Chamber 2 – “activator”. Air is supplied there through a special compressor. Air is necessary for the normal functioning of microorganisms. Due to the anaerobic process, activated sludge is obtained, which is a good fertilizer. His flakes are used for cleansing.

This is what the treatment plant looks like.

The 3rd chamber receives the same sludge that is formed in the 2nd section. This compartment is another settling tank. From here, clean water flows into the last chamber. The degree of purification reaches 98%. This water can be used to water vegetables in the garden.

Harmful impurities undergo oxidation under the influence of oxygen. The process is called “aeration”, i.e. Phosphorus and other harmful substances are removed from wastewater.

CLEANING PROCESSES

More specifically, these are processes of wastewater clarification using biological treatment. All other stages are largely post-treatment stages.

Let's look at several cleaning processes:

- Nitrification

- Denitrification

During the process of nitrification, ammonia nitrogen is removed from wastewater with the help of autotrophic bacteria that use inorganic carbon for nutrition. The presence of organic substances in water can have a negative effect, i.e. slow down the development of nitrifying bacteria.

The process of nitrification is one of the stages of decomposition of high molecular weight nitrogen-containing compounds, mainly of a protein nature.

Process phases:

- Ammonium nitrogen (NH4) is oxidized to nitrites (NO2).

- Nitrites (NO2) are oxidized to nitrates (NO3)

This stage occurs in aerobic conditions (aerobic zone) - aeration tanks with the help of activated sludge, in parallel with the oxidation of organic substances. This means that the main oxidizing element is air.

The use of a stationary solid carrier (bioloading-irrigation) in them is more profitable, both from an energy and operational point of view.

The advantages of structures with attached microflora are numerous and they become more obvious in conditions where the priority task of a complex of treatment facilities is the removal of elements such as nitrogen and phosphorus, since in such structures it is possible to maintain a sufficiently high age of nitrifying microflora, and in combination with anaerobic microorganisms to implement denitrification and removal phosphorus compounds.

The second method for removing nitrogen in the form of N2 is post-treatment in an anaerobic denitrifier at the last stage of biological treatment. Our bioload (BBZ) is used there.

The aerobic conditions themselves are created thanks to the forced supply of air into the aeration zone with the help of special auxiliary devices, namely compressors and blowers, which provide the necessary injection. Air dispersion occurs using aerators of various designs, and the bacteria themselves form a biofilm on the biological loading blocks.

These processes can also occur in natural conditions, but such phases of the process occur very slowly.

During the denitrification process, water is purified from NO2 and NO3. Heterotrophic bacteria are used here.

This stage occurs under anaerobic conditions (anoxic zone). It is necessary for the reduction of oxidized forms of nitrogen to gaseous nitrogen:

NO3=NO2-NO=N2O=N2

The anoxic process is called because the breakdown of organic substances is carried out under the influence of chemically bound oxygen supplied with nitrate forms.

Important factors for the normal course of the process are control over the supply of free oxygen dissolved in water, it should be minimal, and the presence of a sufficient amount of organic substrate, determined based on the ratio C:N = 4:1. If there is a shortage of easily oxidizable substances, a special installation for recharging wastewater is required.

When constructing technological treatment schemes, anoxic zones can be implemented either before or after aerobic treatment.

Post-denitrification has proven itself in the treatment of highly concentrated organic wastewater with a low concentration of ammonium groups.

The pre-included anoxic zone allows for the most efficient use of the available easily oxidizable reserve in the event of the influx of medium-concentrated wastewater.

The use of anaerobic-aerobic treatment technology with high-performance and compact anaerobic reactors of a new generation makes it possible to remove the bulk of contaminants (up to 80-95%) from wastewater with a high content of organic substances with minimal energy consumption and heat losses. The remaining part of the contaminants decomposes under aerobic conditions at the second stage of purification.

Pros and cons of a biological treatment plant

Station advantages:

- Easy to install at home without the help of specialists.

- The installation itself is compact and does not take up much space.

- Compared to a septic tank, the degree of purification is higher.

- Since processing is carried out in a timely manner, there is no unpleasant odor.

- There are no special soil requirements during installation.

- The station operates stably even in the cold season due to its high frost resistance.

Flaws:

- The station operates using electricity, so if there is no electricity, the device is not in use.

- It is necessary to regularly check the serviceability of the equipment.

- If necessary, clean the device, always using special detergents.

- If the equipment is installed in a country house and no one lives there in winter, then the device must be mothballed and then restarted.

Facilities and methods for biological wastewater treatment

Cleaning is carried out in full, sometimes nitrogen can even be removed. The sludge is stabilized and therefore used as fertilizer.

The device is easy to use, so there is no need to hire specially trained people to operate the installed equipment. Such a station can be installed anywhere on the site. In addition, the systems are made of polypropylene, which does not deteriorate under the influence of the sun and is not subject to corrosion. Therefore, the device will last a long time.

Stability of cleaning is maintained throughout the year, since there is a foamed substance inside the body that preserves the thermal layer of biological mass.

Ozonation stations are often used to completely clean wastewater or for complete disinfection. The device has a high oxidizing capacity, which does not lead to a change in the salt composition. In addition, the environment is not polluted.

TD Engineering equipment for septic tanks Tver

Production technologies and range

- for private houses.

Biological treatment stations made of polypropylene of the Tver-P line are designed for 2-36 users, depending on the performance of the system; - for residential complexes.

Cleaning equipment in a metal or polymer housing with high capacity for 30-1500 people. - for rotation camps.

Container version Tver-S for 6-1000 people; - in block-modular design.

Modular designs Tver-BM with flexible adjustment of wastewater flow by varying the number of connected blocks; - for solid waste landfills.

Specialized Tver-MSW stations in container design for deep treatment of wastewater from solid waste landfills.

All models of Tver treatment systems are energy-dependent installations for seasonal or permanent residence.

Polypropylene with a thickness of 5 mm is used as the material for the walls of the containers. The rigidity of the structure is ensured by stiffening ribs and internal partitions. Characteristics of popular septic tanks from the Engineering Equipment Trade House

| Model | Tver 1P* |

| terms of Use | For permanent use by a family of 4-6 people. Can be installed in any soil conditions. |

| Short description | 6-chamber biological treatment station with anaerobic and aerobic reactors. Horizontal design with two service hatches. Treated wastewater can be discharged into the ground or ditch. |

| Material | Polypropylene 5 mm thick |

| Size, L×W×H or D×L, mm | 2450×1100×1670 |

| Electricity consumption, W/h | 38 |

| Weight, kg | 150 |

| price, rub. | 103800 |

* There are 7 more modifications of this station, for example, the model with the PN index has a pump compartment with a submersible pump for forced supply of treated wastewater.

The video below provides detailed information about installing a Tver-0.75 PN septic tank. A company representative at a real site explains the structure of the system and the role of each of its elements. Station maintenance is described in detail. If you are thinking about buying this model, be sure to check it out!

Conclusions:

Trade House "Engineering Equipment" does not offer a large selection of systems for country houses. The guys simply developed a model that works well and scaled it up. The result is not the most compact water purification station at an average price. The main thing is that it works, right?

Operating principle of three-section treatment plants

- The wastewater is fed into the first section, equipped with a built-in aerator. An increased oxygen content initiates the acceleration of biological oxidative processes and the destruction of the structure of organic suspension.

- At the second stage of processing, the wastewater is moved to a section with a biofilter or aeration tank. At this stage, complex organic structures are decomposed into simple chemical compounds.

- In a biofilter, wastewater is purified through the activity of anaerobic bacteria, so there is no need to use an aerator.

- Aerobic strains of bacteria require a constant flow of air, which is supplied by a compressor to the aerator. This technology makes the septic tank a volatile device. Long interruptions in power supply negatively affect the quality of cleaning.

- In the secondary settling tank, the pulp is divided into sludge sludge and process water, which is discharged into the ground for further treatment or disposed of in any convenient way.

After processing in compost heaps, sludge sludge is converted into a complete complex fertilizer.