Forged products today are used almost everywhere: railings and gratings, gates and fences, benches and tables, gazebos and barbecues often include a set of forged elements. But all these items look truly ideal only when they not only cope well with their direct responsibilities, but also serve as a worthy interior decoration.

For a long time, masters of artistic forging have tried to give their products a rich look, and some methods have survived to this day, for example, patination is often used in forging.

What is forging patination

Patination is the process of artificially aging a forged element; this effect can be achieved in several ways.

At the dawn of the development of artistic forging as an art, patination was carried out mainly by exposing the metal to various chemical and mechanical methods. These methods, in addition to their undeniable advantages (the acquisition of metal as a result of processing a stylized antique design), also had a number of significant disadvantages:

- the reagents used by craftsmen when using chemical patination methods sooner or later corroded the metal, which led to a sharp deterioration in its properties;

- As a result of mechanical influences, the metal lost its shape, as a result of which both the appearance of the product and its positive properties deteriorated.

Modern specialists in artistic forging mostly prefer other methods. We will talk about the technology of the most popular of them – applying special paint to metal – in this article.

Patination of forged products with paint

Before starting work, you need to prepare the product:

- the metal must be thoroughly cleaned of scale;

- then the product is degreased with a special primer;

- Next, the metal should be primed and painted (the primer is applied to protect the product from rust, which is the scourge of all metals, and the paint is applied to protect the primer from external influences).

The following types of paints are suitable for subsequent patination of a forged product:

Alkyd . Alkyd paints are the cheapest of the paints suitable for patination, but they also have the worst properties. Alkyd paints are recommended to be used exclusively in cases where the surface to be patinated is outdoors and has a large area (in this case, when using alkyd-based paints, you can save a lot).

Textured . Textured paints are ideal if the room designer wants to give forged materials a visual roughness and matte tint; in other cases, the best solution would be to use other types of paints.

Hammer . Hammer paints give a forged product a beaten effect, visually “breaking” the product into fragments. Hammer paints are ideal for forged products used in rooms decorated in an avant-garde style, but it is preferable to use them only indoors - they quickly lose their properties in the air.

Powder . Powder paints have an almost ideal set of properties - they are quite durable, high quality and relatively inexpensive, however, such paints have one significant limitation on their use - powder paints can only be used for painting forged products that have not previously been welded or mounted.

Electrostatic . Of all the above types of paints, it is electrostatic paints that have the best quality, but you have to pay dearly for such properties.

Having painted the forged product in the main color and waited until the paint has completely dried, you can proceed directly to patination. Patination is usually carried out in contrast:

- if the main color of the forged product is dark, then patination should be done using light paints;

- if the main color of the metal is light, then patination should be carried out using paints of dark tones.

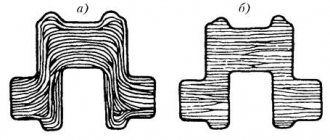

- if the metal to be patinated has a textured structure (non-uniform surface), then its entire surface can be safely patinated;

- if the product is quite smooth, then the best solution in this case would be patination of individual elements (for example, curls, flowers, ornaments, patterns and similar decorations).

How to apply patina to forging

Applying patina to forged metal is carried out in three ways, each of which has its own advantages and disadvantages and is used in a certain situation.

Applying patina using a dry brush . The master takes a brush and picks up as little paint as possible, some of which is then rubbed off on a special wooden board. This is how the master achieves the effect of invisibility of the mark left on the metal by paint. The master randomly runs the brush over the patinated surface in different directions, resulting in a pattern that leaves the impression that a layer of some noble metal is visible through the base color of the metal.

Applying patina using gloves . When using this method, the master puts two gloves on his hands (first rubber and then cotton), takes a little patina in his palms, rubs it and applies it to the surface to be patinated, not forgetting to apply the paint more intensively in the place where emphasis is required .

Metal art painting . Artistic painting of forged metal involves the use of several types of patina by the master, having different shades (quite often these shades contrast with each other). By applying different types of patina to different places on the surface, the master gives the metal visual shape and volume.

Patination is a technique for “aging” the surface of metal or wood, which is achieved by applying dyes based on various acids. As a result, the products acquire a special charm and the spirit of antiquity. Before carrying out manipulations, working surfaces are put in order, then treated with a special primer from a spray can, which allows the paint to better adhere to the surface. Patination of metal requires time and patience; we will look further at how to apply patina paint to the surface and what effect can be achieved.

Applying patina to wood with your own hands

The patination process is simple and can be done at home. For work, it is better to choose high-density wood species that are resistant to changes in humidity, or use MDF or chipboard.

Preparatory stage

First you need to carry out brushing - exposing the hard wood fibers before patina, tinting, varnishing. The method reproduces the natural aging of wood, but at an accelerated pace. The surface is treated with a wire brush or coarse sandpaper, as a result of which hard fibers are removed. Then the base is wiped with a degreasing compound. The wood is not brushed under acrylic paints or for staining, but only cleaned of all kinds of contaminants. If there is already varnish or other coating on the surface, it must be removed using sandpaper.

Chipboard and MDF boards have a homogeneous structure, unlike wood, so their preparation has its own peculiarities. To give it abrasion, the surface can be carefully treated with fine sandpaper, but the most effective is a more complex technology:

- applying a barrier primer to enhance the adhesion of the top layer of the slab to the patina,

- after drying, apply a polyurethane primer, which will become the basis for the patina,

- sanding the created coating with sandpaper to reproduce the wood structure,

- actual patination.

Applying patina using stain

Staining is ideal for furniture made in a classic style. The color of the products will become darker than it was originally. The operating procedure is as follows:

- Apply a water-based stain to the facades, covering the parts entirely. You can choose any color - walnut, mahogany, oak, beech or another.

- Use a soft sponge to wipe off part of the composition in such a way as to give an aging effect (mainly from the middle zones). The edges, threads, milling elements, and cracks should be left darker.

- Allow the composition to dry, then apply a second layer of stain of a similar shade, but not water-based, but alcohol-based.

- As the product dries, apply a layer of shellac. If you want to enhance the vintage look, you can additionally wipe off the antique wax.

Classic way

Classic patination is based on the use of acrylic, wax, bitumen, and oil. You need to choose a material of a suitable tone - wood, metal or regular. The technology resembles simple painting. First, a layer of patination material is applied to the base, then its excess is erased or shaded more thoroughly. The second layer in this case is performed using shellac.

Also, standard technology may involve the following actions:

- apply a dark patina,

- let the product dry a little, apply another layer of material of a lighter tone to highlight the dark pores,

- instead of a light tone, you can take gold or silver if we are talking about furniture in a classic style,

- as it dries, sand the base with fine sandpaper to create a scuffed effect,

- fix the result with shellac or acrylic varnish, choosing a matte composition.

Craquelure technique

This technique allows you to “draw” a network of cracks on the surface of the product, which provides an enhanced decorative effect. For craquelure, a special varnish is used with the same mark on the packaging, which can crack after drying. The procedure will be as follows:

- the surface is treated with a primer, a brush and sandpaper are not used,

- apply craquelure varnish, selecting the desired color composition (if it is transparent, you can apply acrylic paint as the first layer, and then varnish),

- apply a very thin layer of matte water-based paint, acting carefully so as not to spoil the texture.

If necessary, cracks can be rubbed with bitumen mastic to darken them, but only after the coating has completely dried (after 1–2 days). When the film cracks, the product will take on an aged appearance. To consolidate the result, it is permissible to apply a layer of shellac.

Artificial abrasions

This method is well suited for wood and MDF, and goes well with the decoupage technique:

- use dark-colored patination paint to paint the surface of the product,

- after the edges have dried, the carved elements are covered with a layer of paraffin,

- apply a second layer of patina to the object in a lighter shade or metallic tone,

- grind the surface with sandpaper,

- cover the product with stain or wax, or with a transparent matte varnish.

What you need for work

The very meaning of the word “patina” has nothing to do with the dyeing process. It is of Italian origin and refers to the film that forms on metal after prolonged interaction with oxygen.

Initially, you had to wait a long time for the metal to oxidize itself, and the result was completely unpredictable; now this technique can be reproduced at home with your own hands using the following materials:

- patina of the color you like (in powder);

- liquid solvent;

- brush (size 2-3) or sponge;

- small plastic or glass trays (do not take metal ones, they can interact with the paint);

- metal product that you want to decorate.

Pay attention to safety precautions! Means for patination involve working with chemical oxidizing agents, solvents and require special care.

It is recommended not to work in confined spaces without respiratory protection. It is better to work in the fresh air, in rooms with good ventilation (with open windows, an exhaust fan on, a draft). If acid gets on the surface of the skin, immediately rinse under running water and then apply a paste of baking soda. If rashes, burns or any skin changes occur, consult a doctor immediately!

Protect your hands! Always patina with gloves.

Overview of options

Types of patina, consistency and compositions

Depending on the idea, patination can give surfaces various effects:

- Full coverage.

- Fragmentary aging.

- Cracking.

In terms of thickness, special compositions for patina can be as follows:

Thick - will resemble a paste that is used in wood processing to paint reddish or yellowish shades, and they are also close to golden.- Liquid - made on a polymer or water base, they also help give the product shine and further improve its appearance.

- Facet varnishes - make it possible to create an aged surface due to the formation of a network of cracks.

For processing metal, wood or other materials, compositions are used on various bases, which are not the same in the stability of the finished coating and the level of adhesion to the base. The most popular are stain, acrylic paint, wax, oil, bitumen and shellac.

stain

Do-it-yourself patina for wood can be made with stain. The use of stains is the simplest way to artificially age a wooden surface, and therefore it is the cheapest. Stain will enhance wood products, and also gives them a sophisticated look, helping to “make” inexpensive types of wood into more expensive ones. Products from this group will help protect wood from rotting, mold and fungi, and enhance moisture-repellent properties.

As a rule, staining a product involves preliminary brushing - removing soft wood fibers with a strong brush, while the hard longitudinal fibers remain in place. Brushing is required to provide a more pronounced patina effect. After staining, the products are often coated with wax or shellac-type primer. The color range when using stain is limited to dark shades of wood, and it will not be possible to use silver, gold or other metallic tones.

Wax

Wax patinas in the form of a water-based paste are often used as a finishing coating. They are made by combining natural wax and metal dust. There are also colorless compositions on sale, and after application they will leave a beautiful pearlescent sheen.

The properties of wax-type patina are as follows:

- Helps to simultaneously emphasize the wood structure and tint it.

- It is easy to apply, dries slowly, is easy to rub, and therefore can be worked with in a comfortable mode for the master.

- Most often required for small areas, ideal for ash and oak.

- It has various shades - brass, silver, gold, bronze, and also iridescent tones.

- They will beautifully highlight carvings, drawings, patterns, suitable for textured and relief slabs, as well as cracks using the craquelure technique.

- They have a high degree of adhesion to plastic and wood, which will cover MDF.

- Apply with a sponge or rag, polish and dry everything within 24 hours.

Let's consider other compositions

Acrylic

Acrylic-type patina is a universal composition for plaster, wood and metal. This material is water-based, but makes it possible to create a stable coating that has excellent adhesion to surfaces. After application, the film will protect the material from rotting, as well as the proliferation of fungi and microbes.

Do-it-yourself metal patina is not difficult, and even a beginner can handle it. Acrylic patina can be used to treat the entire surface or part of it, as well as individual protruding elements. To give the base an original look, you can even combine compositions of different shades. There are also options to apply different tones of patina in several layers to obtain a unique effect, as well as a complex pattern of colors. The choice of acrylic shades is quite large - there are both classic and metallic tones. If necessary, this type of patination goes well with decoupage, alking and conventional painting.

Bitumen

The structure of such a building material helps to give the wood a special look, and also to blacken out the carvings, edges, relief recesses and protrusions. After applying bitumen to the wood, all excess should be removed with a solvent, and the absorbed composition will create an antique effect (the product will be dark in color). Bituminous patina can be made on the basis of concrete polymer, turpentine, white spirit and is not considered a finishing material. After drying, the patinated surfaces should be coated with shellac to consolidate the result, otherwise it will not last long.

Oil

This patina is suitable for metal and wood. It will not hide the natural shade of the material, and will also favorably emphasize the pattern on wooden surfaces. The properties of the oil will resemble a waxy patina - it should be easy to apply, and will also dry out slowly. You cannot use such compositions in the decoupage technique, because they dissolve the paper.

Shellac

The material itself has a yellowish or even red-brown tone, which will become darker as the number of layers increases. It can be used in isolation or in combination with decoupage, and will also become an intermediate or finishing coat. When working with shellac, use a sponge or brush.

Patination colors

On different metal surfaces, completely different color schemes can be achieved by patination. The most common patina color is greenish, which is produced by the oxidation of copper. On other metal surfaces, the resulting shade may be completely different:

- Rich yellow or ocher color on steel surfaces.

- Chocolate brown on brass and bronze items.

- Dark gray on silver items.

The choice of dry patina for metal work is quite varied. Powder is sold in almost every hardware store. Most common colors:

- aged silver;

- natural or oxidized copper;

- red gold.

Brighter radical colors are also available, for example, blue, lilac, red, allowing you to achieve an original effect on the surface of various metals.

Surface preparation

Decorative application of patina requires careful preparation of the surface being treated; the metal must be perfectly smooth. There should be no signs of corrosion on it; it will not allow the surface to be well primed; the top layers will quickly bubble and peel off.

All burrs must be removed, chips and potholes must be filled and sanded with sandpaper (first coarse, then finer).

The prepared product is coated with a special primer (most conveniently, from a spray can), and then metal patina paint is applied to it.

Tools and materials

You can artificially age furniture at home. This will require some tools and materials.

To apply paint you will need several brushes - for each composition. For preliminary sanding, use sandpaper. When it comes to restoring wooden facades or countertops, a grinding machine is used to prepare the slabs. To wipe down the decorative layer, you will need a dry rag.

To increase the adhesive properties of the surface, surface priming is needed. The basic decorative material, onto which a patina is subsequently applied, is acrylic paint or stain.

The next layer of paint is patina, of which little will remain as a result. In order to further protect the furniture, the patina is coated with varnish. For an antique effect, choose a matte varnish.

For work at home, it is better to use safe water-based acrylic compounds. They are quite durable and easy to work with.

Patina paint application technique

There are two ways to age metal: applying patina with a brush or sponge. By placing dissolved paint on the tip of a brush, you can achieve completely different textures, directional strokes and different depths of paint. Do not wet the brush before starting work; it must be dry; a wet brush will cause smudges and drops on the metal being processed.

Do not take a brush that is too large or small - the optimal bristle size is 2-3 cm. The sponge gives a “dusty” effect, but do not press it too hard, otherwise pores will be imprinted on the surface being treated.

Keep a napkin with solvent and some of the base paint with which the product is painted at the ready. Working with the patina should be virtually error-free. Repeatedly applying patina to metal in the same place gives an unsightly “flat” effect. When painting individual elements, be careful: if you accidentally “smeared” something nearby, simply paint over this area with background paint.

On video: applying patina to metal.

Patination of metal with oxidizing agents

Obtaining a patina on metal by immersing it in various chemical compounds is a labor-intensive method, which will result in the formation of a colored film (patina) on the surface of the metal. This type is much more durable, since the film does not wear off quickly under mechanical stress, like paint. If you want to feel creative and try to age metal using patination solutions, you will need special chemicals.

The surface to be treated should be prepared, as when working with paint, but not primed or painted, but degreased and bleached in an acid solution. You can carry out all the manipulations at home, create a masterpiece with your own hands or give new life to old objects.

How to do classic patination at home and get the colors you want? When patinaing brass, the most common colors sought are black or deep brown, olive, dark orange, or mouse gray. The brown color is achieved by immersing the metal in a solution of sodium thio-sulfite, popularly known as photofix.

An acid (sulfuric, hydrochloric, nitric) is first added to the prepared solution and the metal is lowered into it. Do not overexpose the product! The patina will appear very quickly. Work carefully! Use rubber gloves and take short breaks every 15-20 minutes.

Important! The coating is not very durable; it must be coated with varnish on top.

How to get other shades:

- To obtain an olive tint, brass products are immersed in a solution consisting of ammonia, water and chlorinated copper oxide (in a ratio of 4/5/2). Be very careful - the composition is toxic.

- A thick orange tint on brass will be given by a mixture of potassium sulfite, and a gray gray tint will be produced by liver of sulfur (a sintered mixture of sulfur 5 g in powder and potash).

- On copper, as on brass, the patina is very impressive. You can get a black tint on it (when immersed in sulfuric liver solution) and ancient blackness (if you mix 2-3 g of sulfuric liver, add the same amount of ordinary salt).

- Copper sulfate together with zinc chloride will give a blood-red patina.

- The luxurious blue color of steel will be given by a mixture of hyposulfite and acetic acid lead (150 g plus 50 g per 1 liter of water). The patina on steel appears both when immersed in a cold solution and when it boils (the shade will be more saturated).

- You can achieve a raven wing shade (“bluing”) by immersing the product in a chromium solution at the rate of 100 g per liter of water. The steel will acquire an amazing metallic glow with a deep, black-blue tint. After about 20 minutes, the steel will be covered with a film of an amazing blue-black hue.

- When bronze items are patinated, they acquire various shades of green and blue. To obtain a light green tint you will need 3 parts aluminum chloride, 1.5 5% vinegar and 5 copper salts. The exposure time of the desired shade on bronze is determined visually. The longer the exposure, the deeper and darker the resulting shade will be.

Patina technology

Those who have ever worked with patina know how easy it is to do. There are no difficulties when processing wood. Moreover, this process is so exciting that it brings pleasure.

But every home craftsman needs to know that when working with different types of surfaces, their own special algorithm . This is the main condition that guarantees a decorative patina.

Surface preparation . Before you begin creating a patina on your woodwork with your own hands, you should examine the surface to make sure it is suitable for the job. Products made from untreated solid wood are ideal for these purposes, since they do not require additional processing.

It’s a different matter if you have to deal with smooth varnished surfaces, coatings created using acrylic film or PVC. The paint will not stick to them. The defect can be corrected by brushing. To do this, you need to treat the surface with coarse sandpaper or a wire brush.

So, we will remove the soft wood fibers located under the film, which is unstable to such influences. Once the structure is exposed, it is ready for further processing. Now you need to use a soft brush to clean the surface from dust and degrease it.

Classic patination

Despite the fact that the technology for applying coloring compositions based on bitumen, wax or acrylic is quite simple, it must be carried out exactly according to the accepted algorithm:

- The work begins with applying a dye to the surface. We determine its quantity depending on the intensity of the result we want to get. Paint can only lie on the surface of the product or penetrate into the thickness of the relief.

- If this becomes necessary, remove excess solution with a rag.

- To create a deeper patination effect, wait for the first layer to dry. After that, apply the next one and shade it.

- When the finishing coat of paint dries, take a fine piece of sandpaper and rub the area. After completing the steps, we should get an aged, noble surface.

- At the final stage, the treated surface must be coated with alkaline varnish.

Despite all the attractiveness of modern interior items and furniture, there are still people who will especially appreciate furniture with an antique effect . But these don't have to be antiques.

A noble surface can be obtained using modern materials. But here you need to take into account that each of the painting materials has its own characteristics, so before work you need to study the technology of their application and strictly adhere to it.

Why is patina needed?

Darkening of the metal and changes in its color are a sign of the authenticity of an antique item. But artificial patination of metal is also possible, which can decorate a modern product. Not everyone likes the bright shine of fresh gold plated or polished brass. And when processed in a special way, they acquire a more sophisticated look and an elegant shade that does not interfere with the visual perception of the forged object.

In addition, the artificial patina in forging protects the material, such as bronze, from oxidation. It is weather-resistant and can protect metal for many years, both indoors and outdoors. Garden products that are artificially “aged” look especially attractive. They fit very organically into the natural landscape and become part of it.

Patination of metal in different ways

The blacksmiths of the “Fine Forging Workshop” are ready to make any products for the interior or exterior “antique”. To do this, there are several ways to artificially change the color of a metal item.

Nowadays, special acrylic paints are most often used, which in a matter of minutes can give the surface of any product an antique look. They protect the metal from corrosion and at the same time allow you to imitate different textures, for example, giving one metal the appearance of another. So there are paints that give the color of gold, bronze, copper, silver, as well as green and purple patina. In search of the required color solution, you can combine different paints.

You can change the color of a forged item using nitric acid or special chemical solutions that cover the desired surface. Acid “eats” the shine of an item’s newness, making it look “older.”

You can also age any forged product using one of the mechanical methods. For example, using a mixture of machine oil and abrasive powder. This mixture is applied to the metal and left for a short time. After this it is cleaned off. As a result, the recesses remain black, the protruding places acquire their original color, and the main background becomes a matte grayish hue. Such methods are quite labor-intensive and therefore rarely used on large products.

There is a patina in forging that is called bluing. To obtain it, the metal is rubbed with linseed oil and heated until a black film is obtained. After this, the surface is cleaned with sandpaper so that metal appears on the protruding places. This method is also very labor-intensive and is used only on small products that are located indoors.

What paint to choose for forged products and how to properly prepare the product for painting, read the article - paint for forged products.

Detailed description of the compositions

Any thing can be given a noble surface, be it kitchen furniture or an antique cabinet. The main thing is that the wooden product has texture. To treat metal and wooden surfaces, compositions on various bases are used. The difference between them lies in the degree of stability and adhesion to the base.

Mordants . If you look around the situation in the house, you will probably find patinated wood products in it. If craftsmen use stain to paint wooden surfaces, then they most likely do not aim to give it special aesthetic properties.

But, despite this, this method of painting is one of the popular methods for refining products, which at the same time protects the surface from fungi, mold, moisture penetration and rotting.

If desired, the patina effect can be made more pronounced by brushing . It preserves the longitudinal hard fibers and at the same time removes the soft ones using a special hard brush.

This is the beautification of natural solid surfaces at home. Although this finishing option allows you to get only one color of patina . After all, the stain has a dark shade, so you shouldn’t expect the appearance of a gilded surface.

Bitumen

At first glance, it is difficult to imagine that using such an inexpressive building material as bitumen you can create a masterpiece. However, it clears all doubts after the first use.

Its special structure makes the wood very pliable and simplifies the process of applying patina. If desired, the owner can get the effect of rich gilding or a subtle coating.

Using bitumen varnish, you can easily black out the recesses in the thread , highlighting the edges protruding on the surface. This material is made from concrete polymer and turpentine or white spirit. Therefore, after treating the surface, it requires applying a fixing layer with shellac varnish.

Acrylic

It is no coincidence that this water-based material is popular for creating patinas. This is explained by its versatility, because with its help you can create an aging effect on any surface - metal, wood or plaster.

The coating is very durable, has excellent adhesion to the base, protects the wood from rotting and the appearance of microorganisms. The technology for patination of wood with your own hands is also quite simple. With its help, you can process the entire surface or decorate only the protruding thread elements in the desired color.

To obtain a more expressive patina, you can use compositions of different shades . But you need to apply them in several layers. As a result, a complex color pattern is obtained.

Acrylic compositions allow you to create a patinated surface with different shades:

- gold;

- silver;

- blue, etc.