Manufacturer information

Eurobion appeared on the Russian market in 2001. The first serial production model was the station, produced under the YuBAS brand. Its operation is based on the principle of rhythmic aeration.

According to information from the official website of the manufacturer, Eurobion is part of the National Environmental Project. NEP is engaged in research work, which allows the use of innovative technologies in septic tanks.

Modern Eurobion models belong to the 4th generation septic tanks, which indicates their ease of operation - maintenance is performed once every six months and does not require the involvement of specialists.

Complete set and additional equipment of Eurobion stations

The standard septic tank package includes:

- Frame

- Technological equipment: aerator, recirculation airlift, etc.

- Compressor.

- Polypropylene elbow 110x15°.

I must say that the equipment is one of the weakest among other stations. There is no pipe for inserting the supply pipeline and there is no polypropylene rod for welding the pipe. Also, the Eurobion does not come with a hazard warning lamp.

Optional equipment. Not included in the standard package and must be purchased separately:

- Ultraviolet lamps (UV) for waste disinfection. They are installed only in elongated models with forced drainage (the drain is pumped through the lamp).

- You can also install the Bioguard system in Eurobion. This is an alarm that is triggered when there is a break in the electrical circuit and signals that the compressor has stopped working, including if it is stolen.

Construction and design of septic tanks

According to the principle of operation, Eurobion biological treatment stations are classified as aeration units. The wastewater does not accumulate in settling tanks, but is processed naturally, without the use of chemicals that can cause damage to the environment.

The heart of the station is a compressor that pumps air into the chambers, which promotes the active proliferation of aerobic bacteria that process waste.

The use of aeration units allows us to achieve a high degree of purification - up to 98%. Such an indicator is unattainable for septic tanks built by yourself.

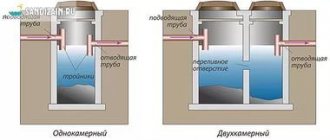

The Eurobion design is a cylindrical container made of polypropylene, divided into three chambers. Stiffening ribs strengthen the body, increasing resistance to external pressure.

The model range also includes large rectangular stations, which are designed for a capacity of 6000 l/day.

Advantages of Eurobion treatment plants

Among the large number of different models of septic tanks, the greatest demand is for easy-to-use and effective samples produced by the Yubas company. Their operating principle is based on patented solutions that allow the incubation of a large range of bacteria and microorganisms involved in wastewater treatment.

The advantages of this septic tank model include:

- No smell

- Strong and durable body material

- Possibility of self-service

- Purification level reaching 98%.

How does a septic tank model Eurobion 5 work?

Septic tank installation

Unlike other models of treatment plants, Yubas products do not have a chamber for sludge stabilization.

The processing process in it occurs as follows: wastewater enters an aeration tank or receiving chamber, which is equipped with an aerator. Here, the liquid is saturated with oxygen, as well as mechanical grinding of large fractions.

Liquid enriched with sludge from the secondary settling tank also enters here. This feature of the work made it possible to intensify the microbiological treatment of wastewater directly in the receiving chamber. Gradually, the wastewater is separated into fractions, with the heavy ones ending up in the primary settling tank, and the light ones concentrating in the upper part.

The second chamber is equipped with bottom mixers. It is flow-through, and the circulation of wastewater in it is ensured by an airlift.

Watch the video, how it works:

The third chamber is intended for settling. In it, the sediment is partially decomposed by microorganisms, and the floating sludge settles to the bottom. Structurally, it consists of a pipe to which an air drain is connected. This made it possible to ensure a constant rate of discharge of treated wastewater from the structure.

Reviews – not everything is as good as it seems

Experts who have already had the opportunity to work with the products of the Yubas company note that the manufacturer’s statement that the Eurobion septic tank has an innovative device in the environment of autonomous sewers was somewhat deceptive. In practice, many complaints arise against such treatment facilities.

Watch the video and consumer reviews:

Based on the opinions of customers, we can say that Eurobion septic tanks do not have the best reviews. These models take a long time to get into the routine, but very easily get out of it. However, it can be quite difficult to restore them again.

In addition, sediment removal must also be carried out after a certain period of operation, so there are no differences from other similar models. Another disadvantage is the lack of a sludge stabilizer, which made removing sediment and maintaining the Eurobion septic tank very inconvenient.

We compare the best models, watch the video:

As for cost, there are no advantages here compared to other products. The Eurobion septic tank has the same price as other topaz-shaped treatment systems.

Tips for cleaning a septic tank

In order for the system to work effectively, it is necessary to perform regular maintenance work. These include periodic cleaning of containers from sludge, which is performed once every six months. In addition, you need to regularly inspect the device to check the transparency of the water and the presence of an unpleasant odor, and also monitor the appearance of sediment at the drainage site. The compressor membrane must also be replaced at least once every 3 years. Only if all these requirements are met can you achieve long-term operation of the septic tank.

If you are not ready to carry out maintenance of the Eurobion septic tank, you can turn to specialists. But their services require investing a certain amount of money, which makes many people think.

Related posts:

- All the advantages and benefits of an autonomous septic tank

- Choose a septic tank or biological treatment station

- We select correctly the best products for septic tanks

- How to choose the right septic tank for a country house

- How and which one to choose a plastic septic tank

Operating principle of a biological treatment plant

Cleaning of household waste in Eurobion aeration units is divided into stages:

- The wastewater enters the receiving department, equipped with an aeration tank. Injected air bubbles mix the liquid, crush solid impurities in it, and also serve to maintain the vital activity of microflora. Here, the heavy fractions are separated from the light fractions and settle in a settling tank, and the liquid part of the wastewater is subjected to primary purification by bacteria.

- The clarified wastewater is fed into the second chamber, where aerobic treatment continues. An airlift is installed in this chamber, directing excess liquid along with activated sludge back to the receiver.

- In the third chamber, final cleaning occurs with the separation of undissolved waste and the removal of purified water to the outside.

A constant liquid level is maintained in the Eurobion septic tank. In the absence of new waste flows, the liquid circulates between the chambers. Only the excess is discarded.

Design features of the model

Design and device

The operating principle of the device is based on the biological oxidation of wastewater. This process avoided unpleasant odors, since decomposition occurs through activated sludge.

Structurally, a septic tank is a compact container. It can be installed in the ground at almost any distance from residential buildings. Under the lid of the septic tank there is a control unit, and in the tanks themselves there is an overflow system consisting of pipes.

The wastewater processing speed in some models is up to 170 liters per hour. Up to 390 liters can be drained into the container at a time. The system is equipped with a 39 W compressor designed to pump air into the containers. This is necessary for the successful development of aerobic bacteria that purify wastewater. The membranes in the compressor must be changed at least once every 4 years, in addition, every 6 months it is necessary to remove solid undecomposed waste, reduce the level of activated sludge and carry out regular maintenance of the Eurobion septic tank.

The system container is equipped with a U-shaped remover. It circulates wastewater, preventing the appearance of a film on its surface. An air drain is equipped on the opposite side of the tank. It makes the remover more effective by creating bubbles that break up the film and move it.

Advantages and disadvantages

According to owner reviews, Eurobion autonomous cleaning systems have the following advantages:

- A high degree of purification allows you to use recycled water for technical needs, for example, watering a site.

- A good indicator of the volume of salvo discharge, compared with other domestic manufacturers. Thanks to the three-stage Aerodrain system, even compact models in emergency situations can take up to 600 liters at a time, despite the fact that their nominal salvo discharge is 200 liters.

- The case material is resistant to sudden temperature changes and mechanical stress.

- Easy to operate and maintain. All work can be done independently.

- Thanks to the use of the aeration cleaning method, there are no unpleasant odors.

- Compact sizes. The cylindrical body without dead spots allows you to make the most of your workspace.

- There is a possibility of downtime after 8 months of continuous operation. If the duration of the interruption in operation does not exceed 90 days, mothballing of the station is not required;

- Possibility of remote control.

The main disadvantage of stations, inherent in all aeration installations, is the dependence on electricity, which is necessary for the operation of the compressor and pump.

Some negative reviews about Eurobion septic tanks are related to the difficulty of removing solid sediment.

The disadvantages of the designs also include the poor location of the ventilation hole in some models. It is located on the cover above the compressor, which can lead to moisture penetration with subsequent failure of the electronic components of the station.

Users note the station's sensitivity to the type of waste. The manufacturer recommends using neutral or biodegradable detergents so as not to destroy bacteria in the septic tank.

Advantages

The list of Eurobion advantages is very long

- Highly reliable drainage sections

(polypropylene reservoirs are heat resistant and durable). - Long service life

(can exceed 60 years). - Effectively cleans drains

(98% of sewage is returned to the water supply purified). - There is no need to inoculate the surfaces of sections with microbacteria

, since their reproduction is without intervention. - Automated control system

– monitoring the operation of the station using microprocessors. - Easy installation.

- You can resume work after a long break.

- No special care required.

- Periodic disinfection is necessary only with the use of special cleaning products labeled bio.

- There is no need for pumping with a vacuum cleaner.

Eurobion septic tanks are unique not only because of innovative sewage treatment technologies, but also because of their versatility of operation. It can be installed in a country house, in a country building, in a sports complex, hotel or other institution. The above advantages of this septic tank distinguishes it from treatment facilities produced by other companies. It is currently the most popular among a wide audience of consumers.

Installation and maintenance of Eurobion

Installation of an autonomous sewer system should be carried out by specialists who have been trained by the manufacturer and are familiar with the rules for installing the station. Due to the high popularity of the company, in almost every major city there are official representatives who can offer an adequate price for a Eurobion septic tank with turnkey installation.

According to the maintenance regulations, for the efficient operation of the Eurobion septic tank it is necessary:

- If there is an alarm indication, monitor it daily

; - Check purified water for transparency and presence of odor monthly

; - Visually monitor the operation of the station with the lid open (see point No. 8 in the data sheet for the Eurobion septic tank), if necessary, clean the secondary settling tank and receiving aeration tank from floating inorganic debris monthly

; - Pump out excess activated sludge once every 6-7 months

. To do this, you need to turn off the power to the compressor and wait 15-20 minutes, then use the handle to lower the false bottom in the receiving tank, then lower the drainage pump to the bottom of the secondary settling tank and pump out liquid (about 200 l) in the installation no more than 20 cm! into a compost pit or plot;

Note! Be very careful when pulling the pump back out so as not to touch the sump pipe.

- Change the membranes in the compressor once every 2-3 years

; - Perform a full service once every 5 years

: you need to check whether the intermediate bottom opens for the entire stroke using the standard mechanism. If so, then pumping the primary settling tank is not necessary. If there is an accumulation of sand, it is better to call a sewer truck; - Replace the aeration element. Done once every 10 years.

Expert opinion

Dmitry Chernov

Design engineer. Experience in designing wastewater treatment plants - 18 years.

Ask a Question

Note! Waste sludge is an excellent organic fertilizer for garden and indoor plants, which is a source of nitrogen and phosphate compounds.

The manufacturer Eurobion recommends entrusting servicing of autonomous sewer systems only to service specialists.

Turnkey installation of autonomous sewage system Eurobion

Pre-installation measurements and cost estimates

Before installation, a survey engineer is scheduled to visit the site. He arrives on the agreed day and determines:

- A place for a septic tank, taking into account the permissible distances to the road, house, trees (up to 3-5 meters) and sources of drinking water (up to 50 m).

- Soil type and groundwater level. Taking this into account, the specialist chooses a method of drainage. In sandy or sandy loam soil with low groundwater, Eurobion is installed with gravity drainage into a filter well. For clay and/or high ground, a forced modification with a drainage pump is chosen, with pumping into a ditch.

- The depth of the drain pipe from the house. This affects the selection of modifications according to the insertion depth. The pipe must be led to the septic tank with a slope of 2 cm per meter of route. The distance to home is taken into account. If the drain pipe is located deep, then choose Eurobion Midi, Long or Superlong septic tanks with an elongated body. With such models you can cut the pipe deeper.

The measurer also discusses additional work with the customer. It happens that you need to cut down bushes for a septic tank. Sometimes you can raise the outlet of the fan pipe so as not to install a more expensive extended station. This work is also performed during installation.

After measurements and discussion with the customer of all the nuances, an installation diagram is drawn and an estimate is drawn up. The Zagorod company calculates estimates directly on site, within 45 minutes after measurements. Our company includes every last detail in the estimate. The total cost of installation is immediately clear. We carry out delivery strictly according to the estimate, that is, we bring everything that is needed for installation.

Installation of housing and pipelines

The pit is dug 50-60 cm longer than the length and width of the septic tank, so that there is 25-30 cm left on each side for sprinkling with sand. A sand cushion 10 cm thick is poured at the bottom of the pit.

During installation, the septic tank is leveled. The permissible slope is up to 5 mm per 1 m. The supply pipeline is cut into the receiving chamber, in which a movable false bottom is located.

Then I sprinkle the septic tank with sand and spill it with water. All chambers communicate with each other, so water can be poured into any compartment without the risk of damaging the structure. Backfilling and filling are carried out in stages. First, pour water to a depth of 30 cm, then sprinkle the septic tank with sand and compact it, then fill it again, sprinkle it, and so on until the outlet of the aerodrain system. This water level is called working.

Sanding and watering

The height of the insert from the bottom is 1.6 m from the bottom for any model. The recommended insertion depth for a standard station is 30 cm. In this case, during volley discharges, the supply pipe will not be flooded. The insertion is made using a crown and a hot air gun. A hole is cut out using a crown, and the pipe is sealed with a polypropylene rod using a hairdryer. The input is sealed.

Correct insertion of the pipe

Installation of a compressor and pump in Eurobion forced septic tanks

The compressor is installed in the electrical compartment and plugged into a power outlet. The pump in forced modifications is installed in a chamber for purified water. The pump cable is inserted into the compressor compartment and the plug is plugged into the second socket.

Connecting the compressor and pump

If desired, the compressor can be installed outside the septic tank. This is not difficult to do, but there is no point in such a setup. It is generally not recommended to install a compressor in a living room - there is not enough oxygen in it, in winter warm air enters the pipe and condensation forms on it. Installing a compressor in a heated room is only possible with constantly running supply ventilation.

The compressor is connected through a HDPE pipe 25. Plastic cone nozzles are provided for this purpose. The remote compressor is plugged into an outlet in the room where it is installed. When placing the compressor inside the septic tank, the cable is laid in a corrugation, inserted into the compressor compartment and connected to the receiving block. Together with the compressor, an alarm is installed, a lamp and a float are hung in the receiving chamber.

In the technical data sheet, the manufacturer strongly recommends venting exhaust air through the supply pipeline. It is best if the air is removed through a vent pipe leading to the roof of the house. This will avoid the breakdown of water seals, although a septic tank can operate effectively without such ventilation. The exhaust air exits normally through the holes in the cover.

Fully installed and connected septic tank

Preservation of Eurobion septic tank

Important rule!

During conservation, it is prohibited to pump activated sludge from the station below the minimum operating point (1.4 m from the bottom to the surface of the liquid).

The mothballing of the Eurobion station is carried out in the following order:

- The supply of wastewater stops;

- The station and the compressor are de-energized (it is advisable to disconnect it and bring it into the house or a dry room);

- It is mandatory for a septic tank with forced drainage of wastewater to turn off the drainage pump and bring it into the house;

- To compensate for the internal stresses of the installation body, when ice forms, place 2-3 2-liter or 5-liter plastic bottles, partially filled with sand and closed with a lid, in the receiving aeration tank and secondary settling tank. They must float standing up, like floats;

- Insulate the lid of the septic tank with a material that does not absorb moisture and is at least 5 cm thick. Cover everything on top with film and secure it so that it does not blow away with the wind.

After conservation, no waste water should enter the installation (For example, if you come for 1-2 days and use the sewerage system). Eurobion with forced drainage of wastewater will immediately overflow and an accident will occur, and in the case of a gravity-flow septic tank, it will go into anaerobic mode, but this is only if there is no ice in the station.

The depreservation process is carried out in the reverse order as during conservation. Only after this can wastewater be supplied. As a rule, it will take 1-2 weeks for the Eurobion station to reach operating mode.

Comparison of septic tanks Round and Eurobion

In 2021, the Rusin station appeared. More recently, it was renamed Round. Today, 2 modifications are available, designed for 4 and 5 people, with gravity or forced drainage. The depth of insertion of the supply pipe from the zero ground level is up to 60 cm.

Round is an economical modification of Eurobion 5. The cost reduction is achieved by simplifying the design:

- There are no external stiffeners.

- The lid has no hinges (simply fits onto the body).

- There is no top edging (the lid protrudes 20 cm).

- Economical compressor.

At the Zagorod company you can buy a Eurobion Round septic tank from the official manufacturer.

| Productivity, l/day | Salvo discharge, l | |

| Eurobion Round-4 itself. | 800 | 250 |

| Eurobion Round-4 prin. | 800 | 200 |

| Eurobion Round-5 itself. (Standard) | 900 | 390 |

| Eurobion Round-5 prin. (Standard) | 900 | 320 |

| Eurobion Round-5 itself. (Midi) | 900 | 390 |

| Eurobion Round-5 prin. (Midi) | 900 | 320 |

The South Korean DongYang compressor is installed in Round. Eurobion Art used to be equipped only with Japanese Hiblow compressors, but today German Thomas compressors are also used. It is believed that Thomas is more reliable than Dong Yang, although the difference is not critical. Both compressors are efficient and durable. They serve, on average, 5-7 years.

The Round septic tank uses a Chinese UniPump Sub 2009 pump. The Eurobion uses a Dab Nova 180 MA pump (Italy, Hungary). In the Dub Nova pump, the float is mounted on a rigid rod (stage) and moves only in one plane. When turning the pump (when the station is turned on), the float may rest against the chamber wall and get stuck in this position. UniPump Sub 2009 is a standard design pump with a float attached to the end of the cable and moves freely.

Eurobion Round septic tank diagram. Until recently it was called Rusyn.

Warranty periods

The manufacturer Eurobion provides a guarantee for:

- Electrical equipment for a period of 1 year with proper use;

- The technological equipment of the installation is valid for a period of 3 years, subject to timely maintenance.

The warranty period begins from the date of signing the purchase and sale agreement and does not apply to damage or malfunction of spare parts and components due to improper installation, maintenance or use.

Ask the seller to fill out a warranty card!

The lineup

The characteristics of the most popular models for a private home are shown in the table.

| Eurobion 4 R ART | Eurobion 5 R ART midi (C 900) | Eurobion 8 R ART standard (C 600) | Eurobion 10 R ART standard (C 600) | Eurobion 15 R ART standard (C 600) | |

| Number of persons | 4 | 5 | 8 | 10 | 15 |

| Salvo discharge, l | 250 | 390 | 700 | 900 | 1125 |

| Productivity, m3/day | 0,8 | 0,9 | 1,6 | 2,0 | 3,0 |

| Weight, kg | 120 | 140 | 230 | 260 | 320 |

| Dimensions L*W*H, m | 1,0/1,0/2,33 | 1,08/1,08/2,64 | 1,35/1,35/2,39 | 1,75/2,0/2,39 | 1,58/1,58/2,39 |

| price, rub. | 68000,00 | 76000,00 | 95500,00 | 118700,00 | 165600,00 |

Which septic tank to choose

When choosing a suitable model, it is necessary to take into account the number of permanent residents and the average water consumption per day. Also, you should pay attention to the permissible salvo discharge. Although the manufacturer states that it is permissible to exceed it in emergency cases, you should not abuse this opportunity so as not to wash out the microflora.

If you still have questions about choosing a Eurobion septic tank, ask them in the comments below. Also, here you can share your experience of operating stations from this manufacturer.

Operating principle: aerobic cleaning

Domestic wastewater is transported through pipes to the receiving tank of the aeration tank, from it to the activation tank, then to the settling tank. Already in the first compartment, the treatment of circulating wastewater with activated sludge begins. Heavy impurities fall into the activation tank, light impurities float up and decompose here, but a little longer. The biofilm is removed using a U-shaped remover that also circulates water.

For the full development of activated sludge, two conditions are necessary: abundant saturation of the tanks with air and a regular supply of untreated domestic wastewater.

In the corner opposite from the remover there is an air drain, which makes the work more efficient: it forms bubbles that destroy the biofilm and move it towards the remover. The system is designed so that it operates continuously. If there is not enough wastewater, it stops draining water into the external environment, only processing pollution.